Phone:

(+65)8319-0742

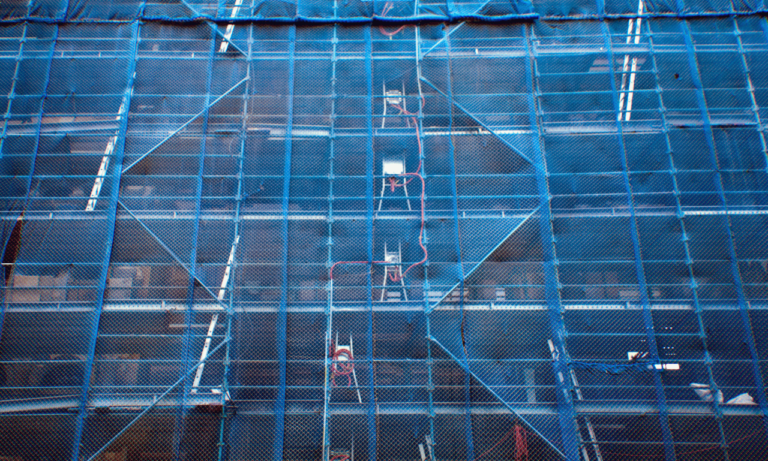

In the construction world, scaffolding systems are key for workers to safely reach high places and finish projects well. There are many scaffold types, each made for certain needs. This guide will cover 16 construction scaffolds, showing their benefits, downsides, and how to stay safe. You’ll learn about scaffold componentsscaffold assembly to pick the best scaffolding for your project.

Scaffolding is a must-have in construction, giving workers a safe way to work at heights. But with so many scaffold types, picking the right one can be hard. From basic to special types like mast climbers and trestle scaffolds, knowing each one’s details is key for good performance, scaffold safety, and following the rules. This guide will look at 16 construction scaffolds, their main parts, how to put them together, and best ways to use them. This will help you make smart choices and make your construction projects go smoother with the right scaffolding systems

Key Takeaways

Scaffolding is a critical component in construction, providing safe access to elevated work areas.

There are 16 main types of scaffolds, each with unique features and applications.

Choosing the right scaffold type depends on factors like project requirements, load capacity, and mobility.

Proper scaffold assembly and adherence to safety regulations are essential for worker protection.

Understanding the strengths and limitations of each scaffold type streamlines construction processes and enhances efficiency.

Understanding Scaffolding Basics

Scaffolding is key in the construction world. It gives temporary support and access for workers on building, maintenance, and repair projects. With 16 types of scaffolding, knowing the basics is vital for your team’s safety and efficiency.

What is Scaffolding?

Scaffolding is a temporary setup on a building or construction site. It has metal poles and walkboards that let workers reach high places. Scaffolding consists of various types, each with specific components designed for different applications. For instance, tube and coupler scaffolding consists of prefabricated pieces held together with couplers, while suspended scaffolding consists of platforms suspended from above by ropes or wires. The scaffold meaning goes beyond being a structure; it’s a vital safety system for workers and materials during construction.

Definition and Purpose

Scaffolding is a temporary elevated structure designed to support workers and materials during construction, maintenance, and repair projects. The primary purpose of scaffolding is to provide a safe and stable platform for workers to perform tasks at elevated heights. Scaffolding can be made of various materials, such as steel, aluminum, and wood, and must comply with strict safety regulations to prevent accidents and ensure worker safety.

Scaffolding serves multiple purposes, including supporting workers and their tools, as well as bearing significant loads from building materials. There are three main categories of scaffolding: support scaffolds, suspended scaffolds, and platform lifts. Support scaffolds are valued for their stability and versatility, making them ideal for a wide range of construction projects. Suspended scaffolds offer flexibility and ease of access for high-rise buildings, allowing workers to reach difficult areas with ease. Platform lifts provide mobility and can reach challenging areas, making them suitable for projects that require frequent repositioning and varying heights.

The choice of scaffolding system depends on the project requirements and local regulations. Different types of scaffolding are common in different regions due to local expertise and the availability of equipment. For example, aluminum scaffolding is becoming more common in Scandinavia and Northern Europe due to its lightweight nature and labor cost savings. In contrast, wooden poles and bamboo scaffolding are prevalent in some countries where labor is affordable and aluminum is expensive.

In conclusion, scaffolding is a crucial resource for workers in various activities, providing safe and efficient access to elevated areas during construction, maintenance, and repair projects. Understanding the different types of scaffolding and their purposes is essential for selecting the right scaffold for each project and ensuring compliance with safety regulations.

Key Components of Scaffolding

Different scaffolding types have various parts, but some common ones are:

Standards: Vertical poles that hold up the scaffold and its users

Ledgers: Horizontal poles that connect standards for stability

Braces: Diagonal poles that add strength to the scaffold

Putlogs: Short poles that support walkboards

Walkboards or Platforms: Horizontal surfaces for workers to stand on

Guardrails: Safety barriers to prevent falls

Toeboards: Boards along the platform’s edge to stop tools and materials from falling

Other parts like casters, leveling jacks, frames, and fastening pins can make scaffolds more stable and useful.

Importance of Choosing the Right Scaffold Type

Choosing the right scaffold is crucial for your project. Consider the work’s nature, height, site conditions, and budget. Steel scaffolding is preferred for its safety and durability, even if it costs more than wood.

Clamp scaffolding, known for its versatility and adaptability, is composed of steel or aluminum tubes connected by clamps. It is suitable for complex shapes like industrial plants and bridges, and its ease of assembly and disassembly makes it popular in the industry.

Supported scaffolding is great for building levels and is versatile. But, it’s hard to use on uneven ground or in tight spots. Suspended scaffolding is perfect for working on the outside of buildings or in hard-to-reach places.

Knowing about scaffolding, its parts, and the right type to choose helps construction pros keep their teams safe and efficient.

Suspended Scaffolding Systems

Suspended scaffolding systems are great for construction projects that need access to high places. They have platforms hanging from above, often from a roof or another structure, held by ropes or cables. These are perfect when projects are over 30 meters tall, offering a safe place for workers.

Catenary Scaffolding

Catenary scaffolding uses ropes or wires hanging from a building above. These ropes connect to each other with vertical wires or ropes parallel to the building. This setup creates a stable and flexible platform for workers.

Float Scaffolding

Float scaffolding uses ropes or wires that hang from a beam at a right angle to the building. It’s great for reaching specific spots on a building’s outside. This type lets workers move the platform easily to where they need it.

Interior Hung Scaffolding

Interior hung scaffolding is like float scaffolding but for inside buildings. It has ropes or wires hanging from beams parallel to the walls. This gives workers a stable and adjustable place to work on inside projects.

Two-point scaffolding, or swing stage scaffolding, is very common. It has a platform that can go up and down, held by wires or ropes at each end. This system is flexible and moves easily around a building. It’s often used for tasks like cleaning windows, painting, and fixing the outside of buildings.

Multilevel Scaffolding

Multilevel scaffolding has several platforms at different heights. It hangs from a structure with ropes or wires, with ladders and platforms between them. This is perfect for projects that need access to different levels of a tall building, like building skyscrapers.

Choosing the right suspended scaffolding depends on the project’s needs, how much weight it can hold, and its safety features. It’s important for these systems to have at least three main ways to support the weight. Also, they must have fall arrest systems to stop a worker from falling if they lose their balance.

Supported Scaffolding Types

Supported scaffolding is a versatile and widely used type of scaffolding system. It provides a stable platform for workers at various heights. These scaffolds are built from the ground up, with platforms supported by standards fixed to the ground.

Supported scaffolds come in several forms, each with unique features and benefits. They are suitable for a wide range of construction projects.

Frame Scaffolding

Frame scaffolding, also known as steel scaffolding, is the most popular type. Fabricated frame scaffolds, constructed with fabricated end frames, ensure structural integrity and versatility. They have modular components that are easy to assemble and can be configured in many ways. This type of scaffolding is constructed in one or two stages, making it quick and efficient for many projects.

Its modular nature allows for easy adaptation to the specific needs of each job site.

Ladder jack scaffolding is a simple and cost-effective option. It uses two or more ladders set at an angle against a building, with brackets to support a platform. This type is ideal for short-term projects or tasks needing access to a limited area.

Mast Climber Scaffolding

Mast climber scaffolding is designed for heavy loads and large work areas. It has a sizeable platform anchored to a tall structure that can be powered up and down by a motor. This type is commonly used in building tall structures like bridges.

The motorized platform makes accessing different levels of the structure easy. It’s an efficient choice for projects needing work at various heights.

Mobile scaffolding, also known as rolling scaffolding, is easy to move from one location to another. It has a platform roughly halfway up four standards, connected by ledgers and guardrails. The base has wheels or casters for easy movement.

This type is perfect for projects needing frequent platform movement, like painting or maintenance tasks.

Choosing the right supported scaffolding for a construction project is crucial. Factors like load-bearing capacity, height, and mobility needs must be considered. By selecting the right scaffold, contractors can ensure a safe and efficient work environment for their team.

Specialized Scaffolding Options

There are many specialized scaffolding options for different construction needs. These include pole scaffolding, trestle scaffolding, and tube and coupler scaffolding. Each has its own benefits and uses.

Pole scaffolding uses wood for all parts of the structure. It’s great for outdoor projects on uneven ground or around obstacles. Key features include:

Sturdy wooden poles for support

Adjustable ledgers and transoms for different heights and setups

Good for projects with tough terrain or limited access

Trestle Scaffolding

Trestle scaffolding is for indoor work and repairs. It has movable tripods or ladders that support a platform. This makes it easy to change the height and position. It’s perfect for:

Light work up to 5 meters high

Painting, plastering, and other finishing tasks inside

When you need to move and adjust the scaffolding

Tube and coupler scaffolding uses steel tubes and couplers for a strong and adjustable scaffold. It’s flexible and easy to set up. It’s great for many construction tasks, like:

Complex or odd-shaped structures

Heavy-duty projects needing a lot of support

When the scaffolding must fit around obstacles or unique building features

A clamp scaffolding tube is a crucial component in tube and clamp scaffolding systems, emphasizing its versatility and adaptability for constructing various complex structures.

Knowing about these specialized scaffolding options helps contractors pick the best one for their projects. This ensures a safe and efficient work area.

16 Scaffold Types for Every Construction Need

There are 16 scaffold types to pick from, making it easy for construction pros to find the right scaffolding system for their project. These construction scaffolding options ensure safety, work efficiently, and adapt to any job site.

Aerial lifts, such as those mounted on vehicles, are designed to elevate people, materials, and equipment to work at heights. These lifts emphasize construction and safety aspects, highlighting their mobility, flexibility, and the materials used for their construction. Adhering to safety regulations and guidelines is crucial for the proper maintenance and operational safety of aerial lifts.

Scaffolding comes in two main types: suspended and supported. Suspended scaffolding includes:

Catenary scaffolding

Float scaffolding

Interior hung scaffolding

Two-point (swing stage) scaffolding

Multilevel scaffolding

These scaffolding systems are great for reaching high places. They’re perfect for facade work, painting, and upkeep. These systems often consist of one or more platforms upheld by rigid load-bearing elements, providing stability and flexibility.

Supported scaffolding types give a solid base for building projects. Popular ones are:

Frame scaffolding

Ladder jack scaffolding

Mast climber scaffolding

Mobile scaffolding

Pole/wood pole scaffolding

Trestle scaffolding

Tube and coupler scaffolding

Each of the 16 scaffold types has its own benefits and uses. For example, frame and brace scaffolding is widely used in North America and Europe for building homes and businesses. Mast climbing scaffolding is great for heavy loads, like building walls with brick or blocks. These scaffolds often rely on an overhead structure to support the platforms, which is essential for multi-level and suspended scaffold applications.

There are also specialized scaffolding types like shoring, cantilever scaffolding, and trestle scaffolding. Shoring helps hold up concrete slabs while building. Cantilever scaffolding is useful when there’s no ground support or traffic near walls. Trestle scaffolding is perfect for indoor work up to 5m high. These types are often platform supported, with different scaffolds structured to hold platforms in place, allowing for easy adjustments and access to elevated work areas.

Knowing about these 16 scaffold types helps construction pros pick the best scaffolding system for their projects. This ensures safety, boosts productivity, and saves costs on every job site. Support scaffolding, known for its stability and versatility, is a robust category used primarily in the construction industry. Supported scaffolds are particularly useful for tasks performed at significant heights, involving the transport of heavy loads.

Systems scaffolding, a category of modular scaffolding, includes various pre-engineered components designed for systematic assembly. Its adaptability for different applications, such as Kwikstage and Cuplock systems, makes it a popular choice globally.

Factors to Consider When Choosing Scaffolding

Choosing the right scaffolding is key for safety, efficiency, and following the rules. Think about what you need for your project to make a smart choice. This will help your project do well.

Type of Construction Project

The type of project you’re working on affects your scaffolding choice. Think about the project’s size, the materials used, and the tasks on the scaffold. For instance, a home building project might need different scaffolding than fixing an industrial plant.

Load-Bearing Capacity and Height Requirements

Figure out how much weight the scaffolding must hold safely. Make sure it can carry workers, tools, and materials without being unstable. Also, think about how high you’ll be working. This will help pick the right scaffolding type and setup.

For construction heights of 50 meters or less, supported scaffolding is generally recommended.

For heights exceeding 50 meters, suspended scaffolding is often the preferred choice.

Some projects need scaffolding that can move easily and change size. Mobile scaffolding is great for moving around, and adjustable scaffolding fits different heights and setups. Think about your construction site and how often you’ll need to move or change the scaffolding.

Budget Constraints

Scaffolding can be a big expense, so watch your budget. Decide if renting or buying is cheaper for your project. Remember, spending on quality scaffolding can save money later by needing less maintenance.

Think about these factors and work with a trusted scaffolding supplier. The right scaffolding is key for your project’s needs and keeps your workers safe.

Scaffolding Safety Guidelines and Regulations

Keeping workers on construction sites safe is very important. Scaffolding is a key part of this. About 2.3 million construction workers, or 65% of the industry, often use scaffolding. Following safety rules is a must to prevent accidents.

Scaffolding accidents cause around 4,500 injuries and 50 deaths each year. These incidents also lead to $90 million in lost workdays. It’s clear that safety is crucial.

OSHA Standards for Scaffolding

The Occupational Safety and Health Administration (OSHA) has set strict rules for scaffolding. These rules depend on the scaffold type. But, every scaffold must hold its own weight and four times the maximum load it can carry.

OSHA also has other important rules. For example, scaffolds must be at least 10 feet away from electrical hazards. Workers should always have three points of contact with the scaffold. And, scaffolds are marked with tags to show if they are safe or not.

OSHA also suggests using Ground Fault Circuit Interrupters (GFCIs) for electrical tools on scaffolds. This helps prevent electric shocks.

Proper Scaffold Erection and Dismantling

Putting up and taking down scaffolds correctly is key to their safety. This means making sure the base is stable and using the right bracing. It also means installing guardrails and toeboards properly.

Scaffolds should be set up, used, kept up, and taken down by a skilled person. The ANSI/ASSP A10.8-2019 standard sets rules for scaffolds in construction and building work. It defines a qualified person as someone with the right skills or lots of experience.

Regular Inspections and Maintenance

Checking scaffolds regularly is vital to spot and fix safety issues. Scaffolds should be checked by a skilled person before work starts and after any event that could damage it. Scaffolding is often a top cause of OSHA violations, showing how important regular checks are.

By following OSHA rules, erecting scaffolds correctly, and doing regular checks, construction companies can lower the risk of accidents. This makes the workplace safer for their workers.

Advantages of Using the Right Scaffold Type

Choosing the right scaffold type for a construction project brings many benefits. It makes the work safer, more efficient, and productive. Workers can reach areas easily and work comfortably, lowering the chance of accidents.

The right scaffold helps speed up the construction process. For example, Walk-Thru Scaffolding Frames make it easy to move around while carrying tools. This saves time and energy by cutting down on climbing.

Using the right scaffolding also protects the building being worked on. Ladder Scaffolding Frames are great for building towers and making precise height adjustments. They fit the project’s needs, preventing damage to the structure.

Scaffolding has benefits off the construction site too. Skinny Frames are great for tight spaces and save on decking materials. They’re perfect for stucco work and other light tasks. The right scaffold type helps contractors save money and resources.

In summary, the right scaffold type offers many advantages for construction projects. It boosts safety, efficiency, and productivity, and saves costs. Choosing the right scaffold is key to a successful construction process.

Choosing the Best Scaffolding Supplier

When picking a scaffolding supplier for your project, think about a few key things. You want a supplier that offers top-notch quality, great customer support, and can tailor solutions for you. This ensures your project goes smoothly and safely.

Quality and Durability of Scaffolding Components

It’s vital to check the quality and durability of the scaffolding parts. You want them to be strong and safe for your project. Choose suppliers that use top materials like galvanized steel or aluminum and follow strict quality checks.

Components that last longer save you money by needing fewer repairs or replacements. This makes your project safer and more cost-effective.

Customer Support and Expertise

A good scaffolding supplier should have great customer support and expert advice. They should help you pick the right scaffolding for your project. They should also be there to help you during the project, solving any problems that come up.

Look for suppliers known for making customers happy and being quick to help. This shows they care about your project’s success.

Customization Options

Every project is different, and custom scaffolding can make a big difference. A great supplier should let you customize scaffolding to fit your needs. This means you can change its size, how much weight it can hold, or its layout.

Custom scaffolding helps you tackle tough projects or tricky site conditions. It saves time and money by making your work more flexible.

Keep these things in mind when choosing a scaffolding supplier. You’ll get quality parts, expert advice, and solutions made just for you. Picking a reliable supplier is a smart move for your project’s safety, efficiency, and success.

Conclusion

This guide has shown the importance of knowing the 16 types of scaffolds used in construction. It’s key for construction pros to understand the options, like suspended and supported scaffolds, and specialized ones. They need to think about the project type, how much weight it can hold, the height, if it needs to move, and the budget.

Following safety rules from OSHA is crucial for a safe work area. It’s important to set up scaffolds right, take them down safely, check them often, and keep them in good shape. This helps lower the chance of accidents and keeps workers safe.

Working with a good scaffolding supplier is also vital. They should offer quality parts, great support, and custom options. This lets construction teams get scaffolding that fits their needs. With the right supplier, projects can run smoother and better, helping both clients and workers.

To sum up, knowing about scaffold types, focusing on safety, and working with a reliable supplier are key to using scaffolding well in construction. This guide has given valuable advice for construction pros. It helps them pick the right scaffolding and make their projects successful.

frequently asked questions

What are the main types of scaffolding systems?

The main types are suspended and supported scaffolding. Suspended scaffolding includes catenary and float types. It also includes interior hung, two-point, and multilevel scaffolding. Supported scaffolding has many types like frame and ladder jack scaffolding.It also includes mast climber, mobile, pole/wood pole, trestle, and tube and coupler scaffolding.

What factors should be considered when choosing scaffolding for a construction project?

Think about the project type and how much weight it can hold. Consider the height and if you need to move the scaffolding. Also, think about how adjustable it needs to be and your budget.Look at the project’s size and the heights and levels you’ll work at. The materials used are also important.

What are the key components of scaffolding?

Key components include casters or leveling jacks and frames. Braces, toeboards, walkboards, guardrails, and fastening pins are also important. The specific components vary by scaffold type.

What are the OSHA safety standards for scaffolding?

OSHA has strict rules for scaffolding. Each scaffold must hold its own weight and four times the maximum load it will carry. It’s important to follow the right steps to put up and take down scaffolding safely.

How often should scaffolding be inspected?

Check scaffolding before work starts and after any event that could affect it. Regular checks help spot and fix safety issues or structural problems.

What are the benefits of using the right scaffold type for a construction project?

The right scaffold type boosts safety, efficiency, and productivity. It helps complete projects faster and cheaper. It also protects the structure from damage from bad access or support.

What should be considered when choosing a scaffolding supplier?

Look at the quality and durability of the scaffolding. Check the supplier’s customer support and customization options. A good supplier offers quality scaffolding, great support, and custom solutions for your project.