Phone:

(+65)8319-0742

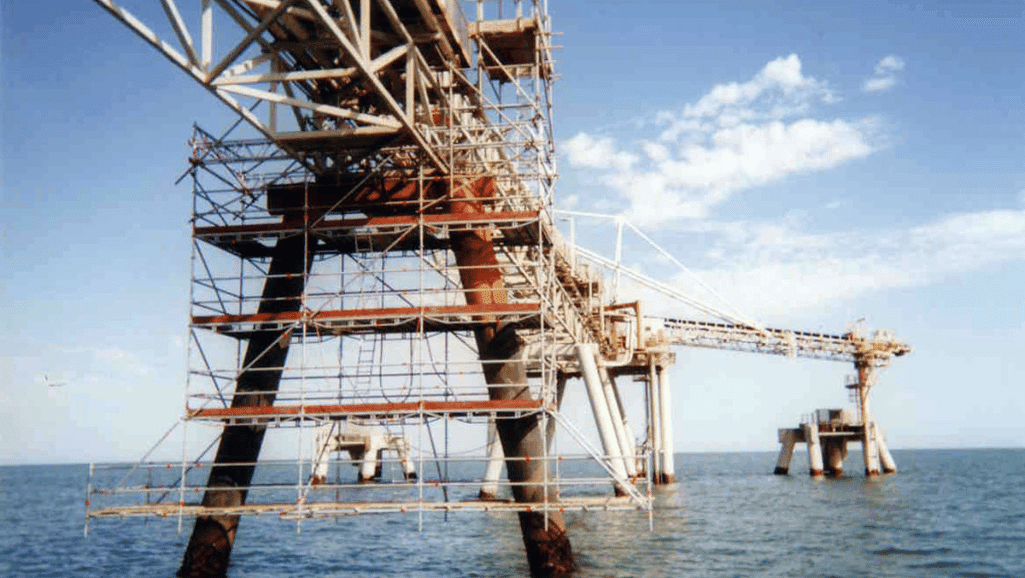

Suspended scaffolding is an essential piece of construction safety equipment used to access hard-to-reach areas. When properly installed and utilized, scaffold systems provide a secure platform for workers to carry out their tasks at elevated heights, while ensuring fall protection solutions are in place.

When working with suspended scaffolding, it is crucial to adhere to Occupational Safety and Health Administration (OSHA) regulations as well as the manufacturer’s operating procedures to ensure worker safety. From the anchorage system to the outrigger beams, every component must be carefully considered to ensure stability and prevent accidents.

It is important to note that suspended scaffolds must be properly tied or secured to prevent swaying, and workers should never work on a scaffold during storms or high winds. Any damaged or weakened components should be promptly taken out of service, and regular inspections of suspension ropes and hoists are imperative. Moreover, makeshift devices should never be used on top of scaffold platforms, and counterweights must be properly secured to prevent tipping.

By following proper setup protocols and safety guidelines, construction professionals can ensure that suspended scaffolding operates safely and efficiently.

Key Takeaways:

- Suspended scaffolding is crucial for accessing hard-to-reach areas in construction activities.

- Adhering to OSHA regulations and manufacturer’s operating procedures is essential for worker safety.

- Components such as anchorage systems, outrigger beams, and platform capacity must be carefully considered.

- Regular inspections of suspension ropes and hoists are necessary for safe scaffold operation.

- Proper setup protocols and safety guidelines ensure secure aerial work practices.

Types of Suspended Scaffolding

When it comes to suspended scaffolding, there are different types that cater to various construction needs. Understanding the differences between single-point, two-point, and multi-point suspension scaffolding is crucial for selecting the appropriate system for your project. Let’s take a closer look at each type:

1. Single-Point Suspension Scaffolding

Single-point suspension scaffolding is a versatile option that offers access to both vertical and overhead work areas. It consists of a single suspension point, typically located at the center of the platform. This type of scaffolding is ideal for tasks that require mobility and flexibility.

2. Two-Point Suspension Scaffolding

Two-point suspension scaffolding, also known as swing stage scaffolding, provides a balanced system with increased load capacity. It typically features two suspension points at both ends of the platform, allowing for stability and enhanced maneuverability. This type of scaffolding is commonly used for larger projects that require efficient and safe access to elevated work areas.

3. Multi-Point Suspension Scaffolding

Multi-point suspension scaffolding offers stability and wide coverage, making it suitable for large-scale construction projects. It features multiple suspension points along the platform, ensuring secure and balanced support. This type of scaffolding is commonly used for tasks that require extended reach and extensive work areas.

By understanding the characteristics and advantages of each type of suspended scaffolding, construction professionals can make informed decisions based on project requirements, accessibility needs, and safety considerations.

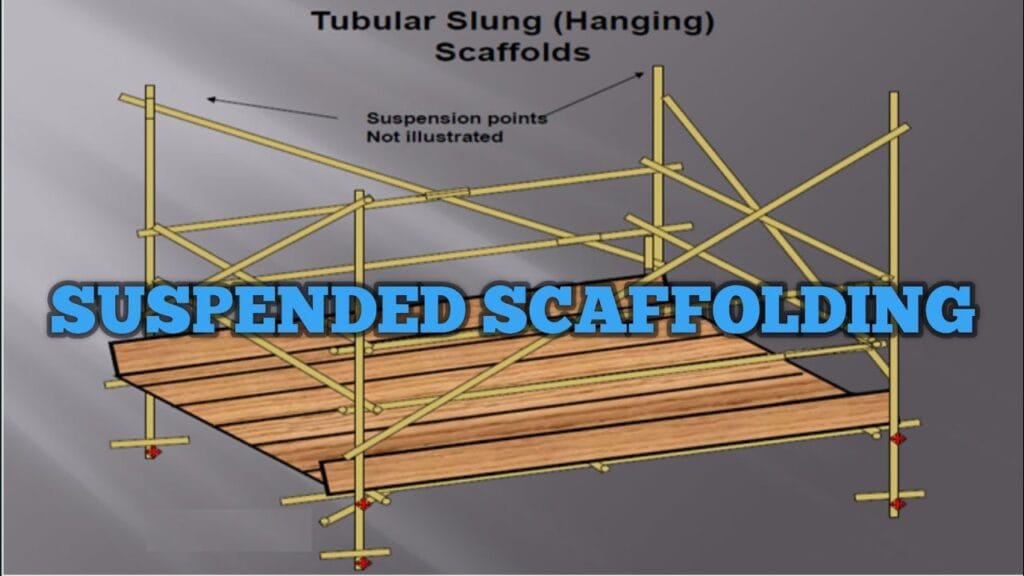

Components of a Suspended Scaffold

In order to ensure the safe operation of a suspended scaffold, it is important to understand its various components. A suspended scaffold consists of the following key elements:

Scaffold Platform

The scaffold platform serves as the working surface for workers and should be wide enough to accommodate both workers and their equipment. It is essential that the platform is sturdy and secure to prevent any accidents or injuries.

Suspension Ropes

The suspension ropes are the primary support system for the scaffold and play a critical role in maintaining stability. Regular inspection of the suspension ropes is crucial to identify any defects or signs of wear and tear that may compromise their integrity. Ensuring the reliability of suspension ropes is vital to prevent accidents and protect the safety of workers.

Counterweights

Counterweights are used to balance the weight of the scaffold and ensure its stability. Proper positioning and secure attachment of counterweights are essential to prevent tipping and maintain the scaffold’s equilibrium. This measure significantly contributes to the overall safety of the suspended scaffold.

Safety Devices

Various safety devices are employed to enhance worker safety while using a suspended scaffold. These devices include guardrails, midrails, toeboards, and personal fall arrest systems. Guardrails and midrails provide a physical barrier to prevent falls, while toeboards help to prevent objects from falling off the platform. Personal fall arrest systems are designed to stop a worker’s fall should they accidentally slip or lose balance. The proper use of these safety devices is crucial to minimize the risk of accidents and ensure the well-being of workers.

Regular maintenance and inspection of all the components mentioned above are essential to identify any potential issues and prevent accidents. By ensuring the integrity and functionality of these components, workers can safely perform their tasks on a suspended scaffold.

OSHA Standards for Suspended Scaffolding

When it comes to scaffold safety, OSHA standards play a crucial role in ensuring worker well-being and avoiding potential penalties. One of the key standards to adhere to is the 29 CFR 1926.451 standard, which outlines specific requirements for suspended scaffolding.

General Requirements

- Sound construction: The scaffold must be constructed in a way that provides stability and prevents collapse.

- Load capacities: The scaffold must be capable of supporting its own weight, along with any additional loads imposed on it.

- Guardrails: A guardrail system must be in place to protect workers from falling off the scaffold.

- Competent personnel: Only qualified and trained individuals should be involved in the erection, dismantling, or alteration of scaffolds.

By following these OSHA standards, employers can create a safe working environment and reduce the risk of accidents or injuries related to suspended scaffolding.

Ensuring Compliance

- Regular inspections: Scaffolds should be inspected by competent personnel before each work shift and after any incidents that could affect their structural integrity.

- Training programs: Employers must provide proper training to workers on scaffold safety, including the potential hazards associated with suspended scaffolding and the correct use of fall protection systems.

- Documentation: Records of scaffold inspections, training sessions, and competent personnel qualifications should be maintained to demonstrate compliance with OSHA standards.

Complying with OSHA standards not only protects workers but also helps companies avoid costly penalties and citations that can result from non-compliance.

ANSI/ASSP A10.8-2019 Standard

The ANSI/ASSP A10.8-2019 standard, developed by ANSI and ASSP, provides comprehensive guidelines for scaffold safety. This standard is an essential resource for construction companies and workers involved in suspended scaffolding operations. It covers various aspects of scaffold safety, including design, construction, qualification of scaffold erectors, and more.

Familiarizing yourself with the ANSI/ASSP A10.8-2019 standard is crucial to ensure compliance with industry safety requirements. By adhering to these guidelines, construction professionals can effectively mitigate risks and maintain a safe worksite environment.

Some of the key areas covered by the ANSI/ASSP A10.8-2019 standard include:

- Scaffold Design: The standard provides specifications and requirements for the design and engineering of suspended scaffolding systems. It ensures that scaffolds are structurally sound and capable of supporting the intended loads.

- Construction and Installation: It outlines proper procedures for erecting and dismantling suspended scaffolds. This includes guidelines for the use of anchorage systems, platform installation, and stability requirements.

- Qualification of Scaffold Erectors: The standard addresses the qualifications and training requirements for scaffold erectors. It emphasizes the importance of competent personnel who are knowledgeable about scaffold safety and best practices.

- Maintenance and Inspection: The ANSI/ASSP A10.8-2019 standard emphasizes the regular inspection and maintenance of suspended scaffolding systems. This includes checking suspension ropes, counterweights, and other components for defects or wear.

- Safety Protocols: It provides guidance on implementing safety protocols, including the use of personal protective equipment (PPE), fall protection systems, and hazard identification measures.

By following the ANSI/ASSP A10.8-2019 standard, construction companies can ensure that their scaffold systems meet industry safety requirements. This promotes a culture of safety and helps to protect workers from potential hazards and accidents.

Manufacturer Guidelines for Suspended Scaffolding

When it comes to ensuring the safety of workers and maintaining equipment reliability, following the manufacturer’s guidelines for suspended scaffolding is paramount. These guidelines provide specific instructions for the proper installation, operation, and maintenance of the equipment, ensuring that it is used safely and effectively.

The manufacturer’s product manuals are an invaluable resource that contains detailed information tailored to the equipment’s specifications. These manuals provide step-by-step instructions on how to assemble and disassemble the scaffolding, operate the control systems, and conduct routine inspections.

By familiarizing yourself with the manufacturer’s guidelines and product manuals, you will gain access to valuable knowledge that can help prevent accidents and ensure the well-being of workers. These guidelines outline best practices for equipment safety, including proper usage, load capacities, and recommended maintenance procedures.

Key Points to Remember:

- Thoroughly read and understand the manufacturer’s product manuals before operating the suspended scaffolding.

- Adhere to the recommended usage guidelines and always follow the specified safety measures to prevent accidents and injuries.

- Strictly follow the manufacturer’s instructions for safety inspections and routine maintenance to ensure the equipment’s optimal performance and longevity.

- In case of any doubts or questions, consult the manufacturer’s customer support or a qualified professional for clarification and guidance.

By adhering to the manufacturer’s guidelines, you demonstrate a commitment to equipment safety and provide a secure environment for workers. Remember that the manufacturer’s expertise and experience play a crucial role in the reliability and safety of the suspended scaffolding, and their guidelines should not be overlooked.

Safety Guidelines for Using Suspended Scaffolding

When it comes to using suspended scaffolding, following safety guidelines is crucial to ensure the well-being of workers and prevent accidents. By implementing proper planning, training, maintenance, and use, construction teams can create a safe work environment. Let’s explore these essential safety measures in detail:

1. Proper Planning

Start by designing and installing scaffolds with the help of qualified professionals. Adequate planning ensures that scaffolding meets safety standards and is suitable for the specific project requirements. Regular inspections should be conducted to identify any signs of damage or deterioration that may compromise the scaffold’s integrity.

2. Proper Training

Workers must receive proper training on scaffold use and safety guidelines. Training programs should cover topics such as scaffold assembly and disassembly, fall protection, and equipment inspection. By equipping workers with the necessary knowledge and skills, you can minimize the risk of accidents and promote a culture of safety on the worksite.

3. Proper Maintenance

Regular maintenance is essential to ensure the ongoing safety and functionality of suspended scaffolding. All components should be inspected regularly for signs of wear, damage, or deterioration. Defective parts should be repaired or replaced promptly to prevent accidents. Document all maintenance activities to keep track of the scaffold’s condition over time.

4. Proper Use

Adhering to proper use guidelines is vital for the safe operation of suspended scaffolding. Workers should always wear appropriate personal protective equipment (PPE), including helmets, harnesses, and non-slip footwear. It is essential to avoid overloading the scaffold beyond its recommended capacity and refrain from making unauthorized modifications that may compromise its stability.

By following these safety guidelines for using suspended scaffolding, construction teams can ensure the well-being of their workers and maintain a secure work environment. Implementing proper planning, providing adequate training, conducting regular maintenance, and promoting safe use practices are key to preventing accidents and achieving successful project outcomes.

Importance of Safety in Suspended Scaffolding

Safety is of utmost importance when working with suspended scaffolding. Adhering to safety standards and regulations not only ensures the productivity of construction projects but also prioritizes the well-being of workers and protects the surrounding community.

By following strict safety guidelines, contractors and dealers can create a safe and compliant worksite, minimizing the risk of accidents and promoting a positive work environment.

Benefits of Prioritizing Safety in Suspended Scaffolding:

- Worker Well-Being: Emphasizing safety standards guarantees the physical and mental well-being of workers, reducing the likelihood of workplace injuries and accidents.

- Enhanced Productivity: A safe working environment fosters increased productivity as workers can focus on their tasks without the fear of potential hazards or unsafe conditions.

- Compliance with Regulations: Adhering to safety standards ensures regulatory compliance, protecting businesses from costly fines and penalties.

- Community Protection: By implementing safety measures, construction projects contribute to the overall protection of the surrounding community, minimizing the risk of accidents or incidents that could impact nearby residents.

Ultimately, prioritizing safety in suspended scaffolding demonstrates a commitment to upholding industry best practices and establishing a culture of responsibility and care for both workers and those living in the nearby community.

| Key points | Benefits |

|---|---|

| Worker Well-Being | Promotes a safe working environment, reduces injuries and accidents |

| Enhanced Productivity | Allows workers to focus on tasks without distractions or safety concerns |

| Compliance with Regulations | Avoids fines, penalties, and legal consequences |

| Community Protection | Ensures the safety and well-being of nearby residents |

Conclusion

In conclusion, suspended scaffolding is an essential tool for accessing hard-to-reach areas in construction activities. However, ensuring the safety of workers is paramount. By following safety protocols and setup instructions, workers can ensure secure aerial work practices. This includes proper planning, installation, and maintenance of suspended scaffolding.

Compliance with OSHA standards, ANSI/ASSP guidelines, and manufacturer’s guidelines is vital for maintaining a safe and compliant worksite. These protocols provide crucial safety measures and best practices to minimize accidents and protect worker well-being.

By prioritizing safety in suspended scaffolding, companies can promote productivity and create a positive work environment. Implementing secure aerial work practices not only benefits workers but also safeguards the surrounding communities. With proper planning, adherence to safety protocols, and ongoing maintenance, suspended scaffolding can be safely utilized to enhance construction efficiency and worker safety.

Frequently Asked Questions

What is suspended scaffolding?

Suspended scaffolding is a crucial piece of equipment used in construction activities to access hard-to-reach areas. It is a temporary platform that is suspended from an overhead support system, allowing workers to perform tasks at elevated heights.

Why is suspended scaffolding important?

Suspended scaffolding is important because it provides a safe and efficient way for workers to access areas that are otherwise difficult to reach. It allows construction activities to be carried out at heights while ensuring worker safety and productivity.

What are the key considerations for suspended scaffolding safety?

The key considerations for suspended scaffolding safety include following OSHA regulations and manufacturer’s operating procedures, ensuring proper anchorage and stability, regular inspections and maintenance, and the use of necessary fall protection devices.

What are the different types of suspended scaffolding?

There are different types of suspended scaffolding, including single-point suspension scaffolding, two-point suspension scaffolding, and multi-point suspension scaffolding. Each type has its own advantages and is suitable for specific project requirements.

What are the components of a suspended scaffold?

The components of a suspended scaffold include the platform, suspension ropes, counterweights, and safety devices. These components work together to ensure the stability and safety of the scaffold.

What are the standards for suspended scaffolding safety?

The Occupational Safety and Health Administration (OSHA) has specific standards for scaffold safety, outlined in the 29 CFR 1926.451 standard. This standard addresses the general requirements for scaffolding safety, including construction, design, load capacities, and competent personnel.

What is the ANSI/ASSP A10.8-2019 standard for suspended scaffolding?

The ANSI/ASSP A10.8-2019 standard is a comprehensive set of guidelines developed by ANSI and ASSP for scaffold safety. It covers design, construction, qualification of scaffold erectors, and more. Familiarizing yourself with this standard is important for maintaining a safe and compliant worksite.

How important are manufacturer guidelines for suspended scaffolding?

Manufacturer guidelines provide specific instructions for the safe installation, operation, and maintenance of their suspended scaffolding equipment. It is crucial to familiarize yourself with these guidelines to ensure equipment safety and worker well-being.

What are the safety guidelines for using suspended scaffolding?

Safety guidelines for using suspended scaffolding include proper planning and design, proper training, regular maintenance and inspections, and proper use of personal protective equipment. These guidelines are essential for ensuring worker safety and preventing accidents.

Why is safety important in suspended scaffolding?

Safety is of utmost importance in suspended scaffolding as it ensures worker well-being, enhances productivity, and protects communities. By prioritizing safety, contractors and dealers can create a safe and compliant worksite, reducing the risk of accidents.