Phone:

(+65)8319-0742

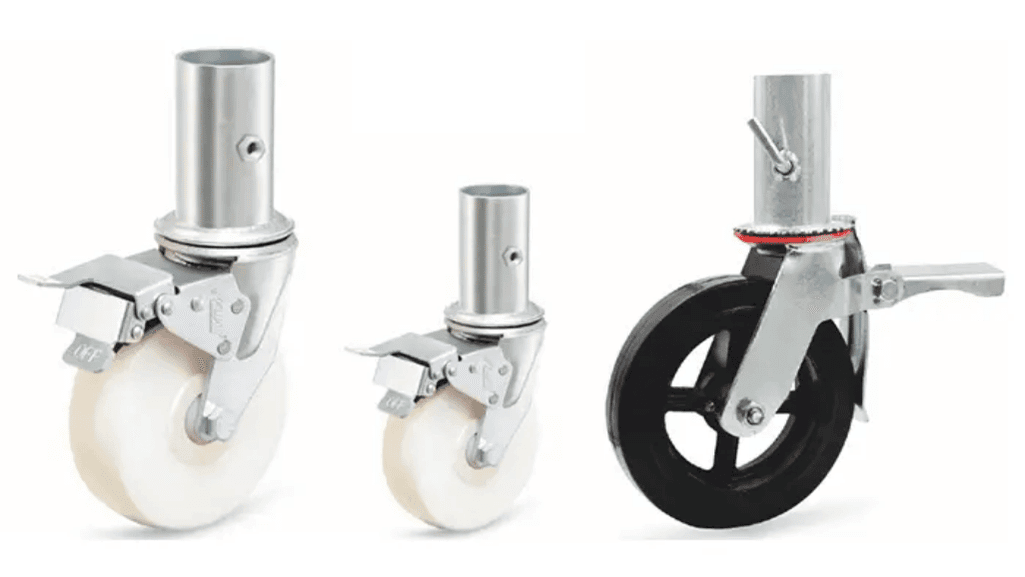

Scaffold Caster Wheel are key to easily moving your scaffolding on a construction site. Choosing the correct wheels ensures stability and efficiency. This article covers the different types of scaffolding wheels, their features, and tips for maintaining them.

Key Takeaways

Scaffolding wheels, including all-terrain and heavy-duty types, enhance mobility and stability for efficient construction operations.

Pneumatic casters excel on uneven surfaces due to their shock absorption, while cast iron casters are ideal for heavy loads and durability.

Choosing the right scaffolding wheels involves assessing load capacity, material properties, and necessary safety features for optimal performance.

Understanding Scaffolding Wheels

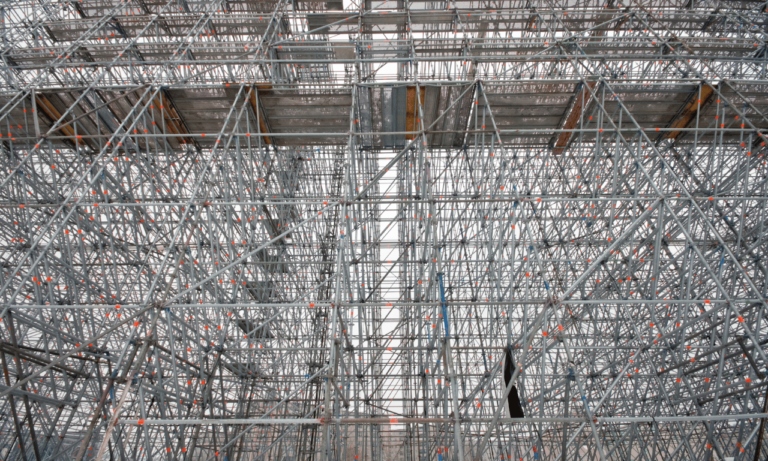

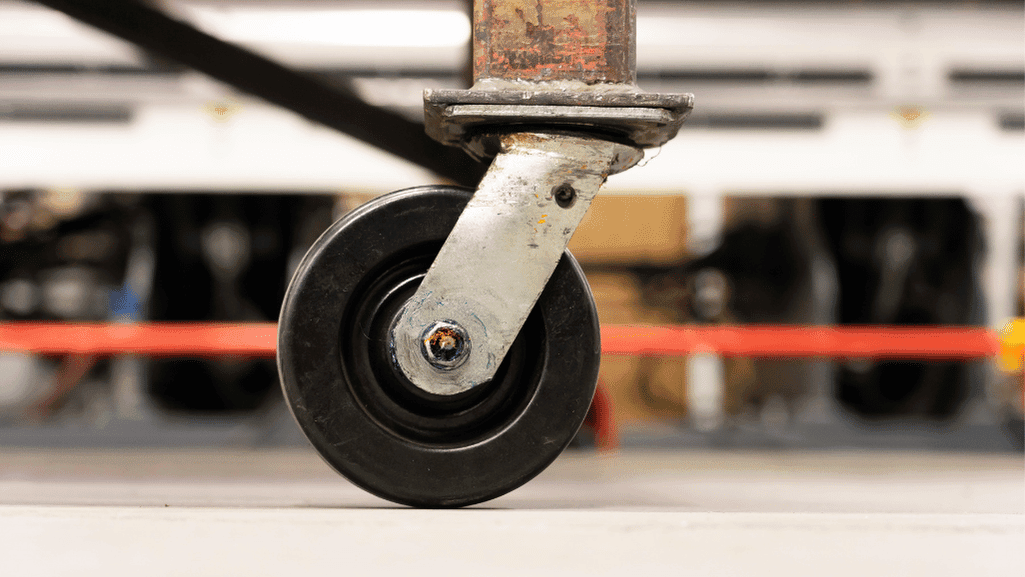

Scaffolding casters, also known as caster wheels for scaffolding systems, play a pivotal role in ensuring the portability and overall effectiveness of these structures. Designed to navigate different ground conditions, these casters allow for effortless movement of scaffolding across work sites. Such mobility is vital for projects necessitating regular adjustments. It enables workers to swiftly shift their platforms without having to take apart and rebuild the entire scaffold.

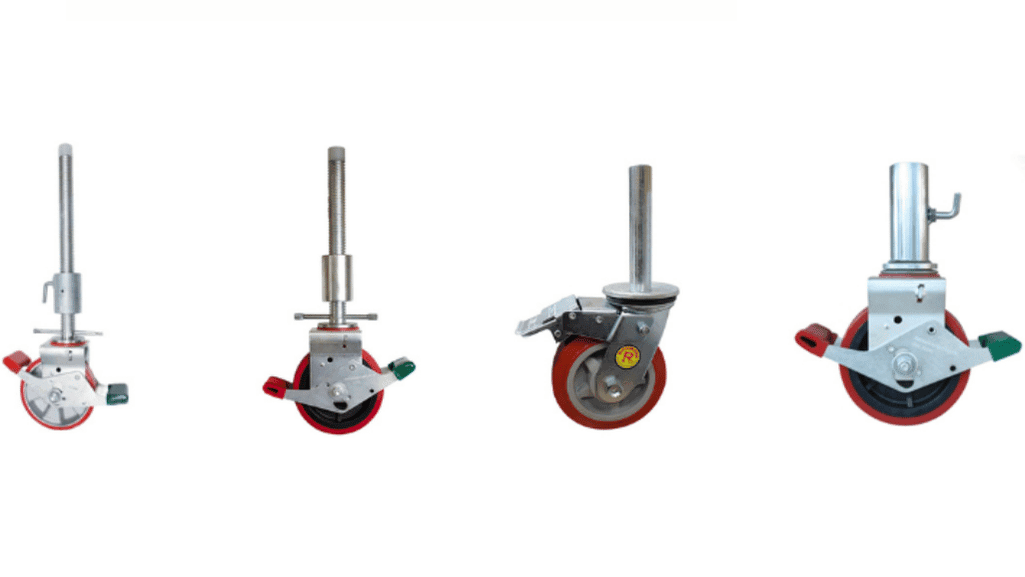

There are essentially two main types of caster wheels used in scaffolding: all-terrain and heavy-duty models. These cater specifically to varying environmental challenges and load-bearing demands, maintaining stability and functionality under diverse circumstances. All-terrain casters excel on rugged or inconsistent surfaces while heavy-duty ones can bear significant loads crucial for sustaining large-scale constructions.

Durable construction materials like rubber, polyurethane (PU), polyvinyl chloride (PVC), and nylon are utilized in crafting high-quality scaffolding casters. Selected based on their resistance against tough environments, such materials guarantee optimal wheel performance along with an extended service life. Knowing about the available materials along with understanding the specific types offers guidance when choosing suitable scaffold wheels tailored to meet particular construction requirements.

Types of Scaffolding Casters

Exploring the realm of scaffolding casters requires a grasp of the various kinds on offer and their particular uses. Casters, also referred to as scaffolding wheels, greatly improve the transportability of scaffold structures, enabling laborers to effortlessly relocate platforms across diverse terrains. Pneumatic casters and cast iron casters stand out as principal varieties in this context, each designed with distinctive attributes that cater to varying mobility requirements and load-bearing capacities.

Deciding between these types hinges on the specific demands your building project presents. The ensuing information delves into pneumatic casters versus those made from cast iron—discussing their respective characteristics and advantages they bring forth.

Pneumatic Casters

Pneumatic casters are frequently selected for construction projects where the terrain is rough or uneven. These types of caster wheels excel in absorbing shocks, allowing for smooth transit across irregular surfaces. They provide a stable platform for scaffolding to navigate over bumpy landscapes commonly encountered on such worksites.

The air-filled tires of pneumatic casters serve as an effective buffer to lessen impacts and diminish vibrations. This characteristic plays a crucial role in safeguarding both the structural integrity of scaffolding frameworks and the welfare of construction workers on site. Without appropriate wheels like these, rocky environments could cause continuous jarring that might result in structural harm and increase risks to staff members.

For tasks demanding regular relocation over diverse terrains, pneumatic casters stand out as an ideal solution due to their emphasis on seamless mobility which helps minimize damage to both scaffolds and caster longevity itself. Incorporating pneumatic casters into settings with complex surface conditions can markedly elevate efficiency while enhancing safety during operations.

Cast Iron Casters

At the opposite end of the spectrum, cast iron caster wheels are lauded for their remarkable strength and ability to bear substantial loads. Engineered for heavy lifting, these caster wheels are perfectly suited for strenuous scaffolding tasks. The solid construction of cast iron ensures that these casters can endure the rigorous demands typical in heavy-duty construction settings where consistent stability and robustness are crucial.

Suitable especially for scenarios where scaffolding must support significant weight without sacrificing stability, cast iron casters stand out as a preferred option. Their superior load-bearing capabilities paired with unwavering durability render them indispensable on expansive projects, enabling scaffolding systems not only to uphold their own structure but also manage additional burdens from materials and machinery.

Crafted to withstand some of the harshest environments imaginable, these wheel assemblies offer dependable service over long durations. Cast iron caterwheels provide essential dependability whether it’s utilized at a towering building site or within an industrial endeavor ensuring your scaffold remains securely anchored and operational.

How to Choose the Right Scaffolding Wheels

It is essential to choose the appropriate caster wheels for your scaffolding in order to maintain safety and increase productivity at your construction site. The capacity of these casters to bear weight is a fundamental aspect, with larger wheel diameters typically accommodating heavier loads, which are ideal for heavy-duty projects. Caster wheels featuring broader treads can handle more substantial weights by spreading the load out more effectively.

The composition of the caster wheels significantly affects their functionality. Hard materials such as steel or cast iron often have greater capacities for carrying loads, whereas softer options like rubber excel in providing traction and absorbing shocks. It’s crucial to select wheel materials that align with the particular conditions encountered on your worksite. Durable alternatives such as high-strength nylon or polyurethane can withstand various environmental factors.

Safety mechanisms like brakes and locks are also vital features that should be taken into account when choosing casters because they prevent any unintended movement of the scaffolding when it’s supposed to remain stationary, thus enhancing overall workplace safety. Factoring in an extra margin for safety allows you to compensate better for imbalances and unexpected forces impacting your scaffold setup.

Partnering with a dependable supplier who provides both customization services and robust after-sales support will greatly influence outcome quality. Custom solutions enable you to meet unique demands specific to each project while reliable customer service ensures efficient resolution should any issues arise concerning product availability.

Taking all these points into consideration aids in selecting optimal scaffold wheels designed specifically towards meeting project requirements comfortably while ensuring effective risk management throughout operations at your building site.

Load Capacity Considerations

To ensure that scaffolding wheels can bear the necessary weight without losing stability, it’s critical to understand their load capacity. Crafted often from materials like robust rubber and cast iron, these heavy-duty wheels are engineered to shoulder substantial burdens while retaining equilibrium. This aspect is crucial in construction settings where the scaffold must not only hold its own mass but also take on additional weights such as workers and building materials.

Scaffolding wheel capacities differ significantly, with some able to support a modest 265 pounds while others can handle hefty loads exceeding 2,200 pounds—variances that hinge on their design and material composition. To determine suitable scaffolding wheels for your needs, consider the comprehensive weight they’re expected to sustain, which encompasses the structure of the scaffold itself along with any personnel, equipment, and supplies involved in your project. This consideration ensures that chosen wheels will cope with demands placed upon them without compromising structural fortitude or security.

When picking out scaffolding wheels for safety assurance purposes, consider uneven distribution of weighty loads as well as unexpected forceful impacts. Thus accounting for a safety margin within selected load-bearing capabilities guarantees enduring stability and safeguarding during usage time frames. Scrutinizing load capacity constitutes an essential component when selecting optimal scaffolding wheels fit for purpose at hand.

Maintenance Tips for Scaffolding Wheels

It’s essential to keep up with the maintenance of scaffolding wheels to secure their durability and effectiveness. Conducting systematic checks is key for spotting any deterioration early on and verifying that they comply with safety regulations. By catching problems in their infancy, you can avoid more substantial complications later on while preserving your scaffolding’s stability and efficiency.

By regularly cleaning the wheels of the scaffold structure, one can remove accumulated debris such as dirt and grease that might hinder wheel performance. This cleanliness aids in ensuring that the movement remains unhindered and minimizes potential harm to the components. Adding a lubricant to parts where there is motion will improve how well these parts work by facilitating smoother operation.

Prompt attention to fixing any broken elements within your scaffold setup is vital for preventing Wear-and-tear. Swift action not only retains its structural integrity, but also reinforces overall safety measures when using this equipment. Storing them away from moist environments helps shield against weather-related damage. This preservation technique prolongs their use-life so they’re ready whenever needed.

Adhering strictly to these guidelines ensures that your scaffold wheels stay robustly reliable, guaranteeing both safe usage practices as well as proficient handling during operations.

Where to Find Quality Scaffolding Casters

Ensuring that you acquire high-quality scaffolding casters is crucial for the safety and productivity of your construction endeavors. Bullcaster, a leading producer in this field, creates more than 20,000 scaffolding wheels each day with options including adjustable and heavy-duty models. Opting for an esteemed provider like Bullcaster guarantees access to dependable and superior casters.

When choosing a supplier for these components, it’s vital to select those who comply with rigorous quality management systems such as ISO9001. Such certification demonstrates that the supplier upholds strict standards throughout their manufacturing processes, which translates into reliable and safe products. By investing in top-notch scaffolding wheels from trusted suppliers, there can be significant cost benefits due to decreased labor costs and enhanced project completion rates.

Procuring your scaffoldings’ casters from distinguished manufacturers ensures you receive items tailored to withstand durability challenges, meet load capacity requirements while prioritizing safety. This commitment not only boosts efficiency within your projects, but also delivers confidence by utilizing equipment of exceptional caliber.

Common Questions About Scaffolding Wheels

The stability and maneuverability of a scaffolding system are heavily dependent on its wheels, which serve as foundational elements during construction tasks. Inquiries often arise regarding the variety of scaffold casters available. For example, pneumatic casters excel in providing effortless motion over rough terrain, while those made from cast iron boast exceptional strength and an impressive capacity for bearing loads. Comprehending these distinctions is vital to making informed decisions about caster selection tailored to your particular requirements.

Questions also abound concerning how one should determine the suitable load capacity for scaffolding wheels. To ascertain this figure accurately, it’s necessary to account for the cumulative weight that will rest upon the wheels—this includes not only the framework of the scaffolding but also any personnel working on it along with all materials present thereon. The essence lies in guaranteeing that chosen wheels can sustain such burdens without jeopardizing their structural integrity or operational efficacy—a key aspect for upholding safety standards.

Upkeep tends to be a topic ripe with queries. Performing routine checks, establishing cleaning protocols regularly and executing repairs punctually are fundamental practices aimed at prolonging both functional life span and optimal functioning condition of scaffolding castors. Deliberating on these typical questions empowers you with enhanced insight into effectively picking out appropriate wheels for your scaffoldings while ensuring their diligent usage as well as maintenance strategies remain uncompromised.

Summary

In essence, the wheels on scaffolding are crucial for improving both movement and stability of these structures. Being aware of the various options available, such as pneumatic and cast iron scaffold casters, is important when choosing the appropriate ones based on your project’s specific requirements. It’s essential to take into account aspects like the load-bearing capacity, type of wheel material used, and built-in safety measures in order to select the most fitting wheels for a construction environment.

Consistent upkeep and acquiring top-tier scaffolding casters from well-regarded vendors enhance both efficacy and security within your building projects. By adhering to recommendations outlined in this article, you can ensure that your scaffolding wheels operate at their best level. Thereby providing a solid yet maneuverable platform suitable for any construction task. Make informed selections with care regarding maintenance practices—this will support success across all elements involving scaffold mobility.

Frequently Asked Questions

What are the main types of scaffolding casters?

The main types of scaffolding casters are pneumatic casters, which provide shock absorption on uneven surfaces, and cast iron casters, recognized for their durability and high load capacity.

How do I determine the load capacity required for scaffolding wheels?

To determine the load capacity required for scaffolding wheels, calculate the total weight they must support, which includes the scaffolding structure, personnel, tools, and materials.

This calculation ensures the wheels can safely bear the total load during use.

What materials are scaffolding wheels typically made from?

Scaffolding wheels are commonly made from durable materials like rubber, polyurethane, polyvinyl chloride, and nylon, tailored to meet specific environmental and load needs.

Why is regular maintenance of scaffolding wheels important?

Regular maintenance of scaffolding wheels is essential to ensure their longevity and optimal performance, which helps prevent wear and safety issues.

This proactive approach safeguards both workers and the integrity of the scaffolding system.

Where can I find high-quality scaffolding casters?

You can find high-quality scaffolding casters from reputable suppliers like Bullcaster, which follows ISO9001 quality management standards, ensuring reliable and durable products.