Phone:

(+65)8319-0742

In the construction industry, safety and efficiency are paramount. Multi point scaffold systems have emerged as a professional solution to meet these demands. These systems provide secure access to elevated work areas, ensuring workers can perform tasks safely and effectively.

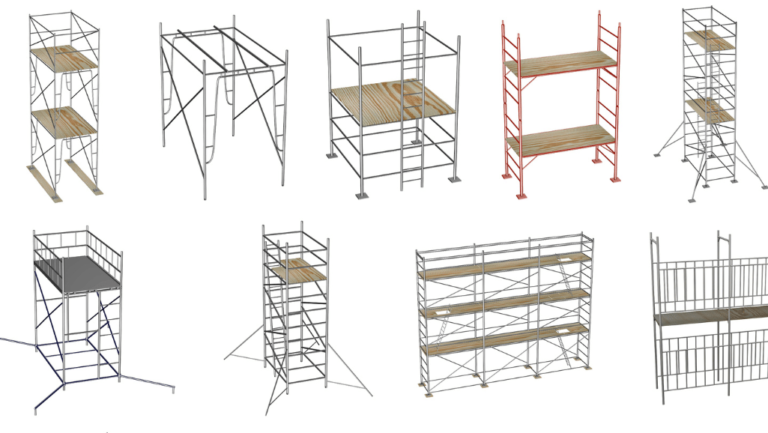

Scaffolding is essential for various projects, from building maintenance to large-scale construction. Multi point scaffold systems stand out due to their adaptability and stability. They are designed to handle heavy loads and offer flexibility for unique structures.

Safety is a top priority in scaffolding. These systems comply with strict regulations, ensuring worker protection. Proper installation and dismantling are crucial to maintaining safety standards. Components like beams and platforms are engineered for stability and load management.

Whether for a small project or a complex structure, multi point scaffold systems are versatile. They enhance productivity and safety, making them a preferred choice in the industry. For more specialized solutions, consider exploring suspended scaffolding options.

Key Takeaways

- Multi point scaffold systems improve access and safety on construction sites.

- They are adaptable for various tasks and unique structures.

- Compliance with safety regulations is essential for scaffold use.

- Components like beams and platforms ensure stability and load management.

- These systems enhance efficiency and worker safety in construction projects.

Introduction to Advanced Scaffolding Systems

Modern construction projects demand innovative solutions to meet safety and efficiency standards. Advanced scaffolding systems have become a cornerstone in achieving these goals. These systems provide secure access to elevated work areas, ensuring workers can perform tasks safely and effectively.

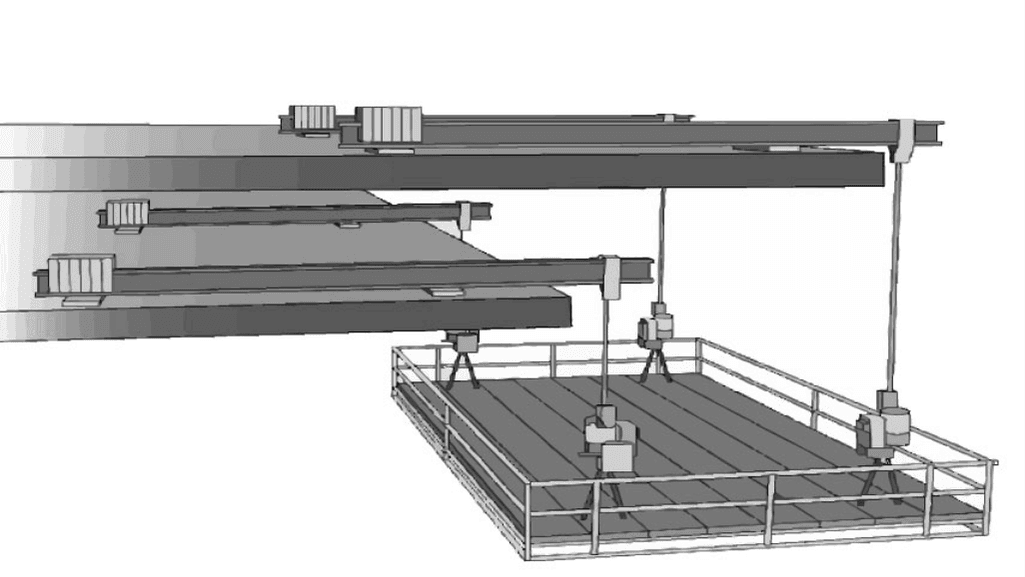

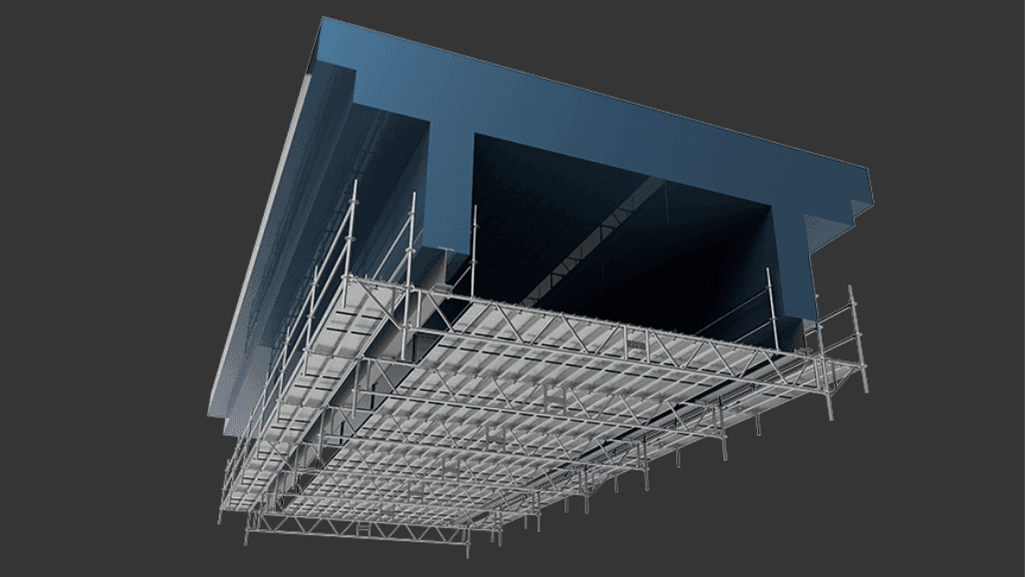

Scaffolding systems come in various types, each designed for specific tasks. From support scaffolds to suspended setups, each type plays a vital role in construction. Suspended systems, for example, rely on overhead structures and cables to provide access to hard-to-reach areas.

The evolution of scaffold design has focused on improving safety and efficiency. Modern systems incorporate components like beams and platforms engineered for stability. These advancements ensure compliance with strict regulations, protecting workers at height.

Scaffolding facilitates worker access to elevated areas, enhancing productivity. Proper use of components and adherence to safety standards are crucial. This ensures projects are completed on time and within budget.

Choosing the right scaffolding system offers numerous benefits. It improves safety, reduces project time, and adapts to unique building structures. For specialized needs, consider exploring slung scaffolding, which provides flexibility and cost-effectiveness.

Exploring the Advantages of Multi Point Scaffold

Construction sites require reliable solutions to ensure both safety and productivity. Scaffolding systems are essential for providing secure access to elevated areas, enabling workers to perform tasks efficiently. Among these systems, multi-point designs stand out for their adaptability and stability.

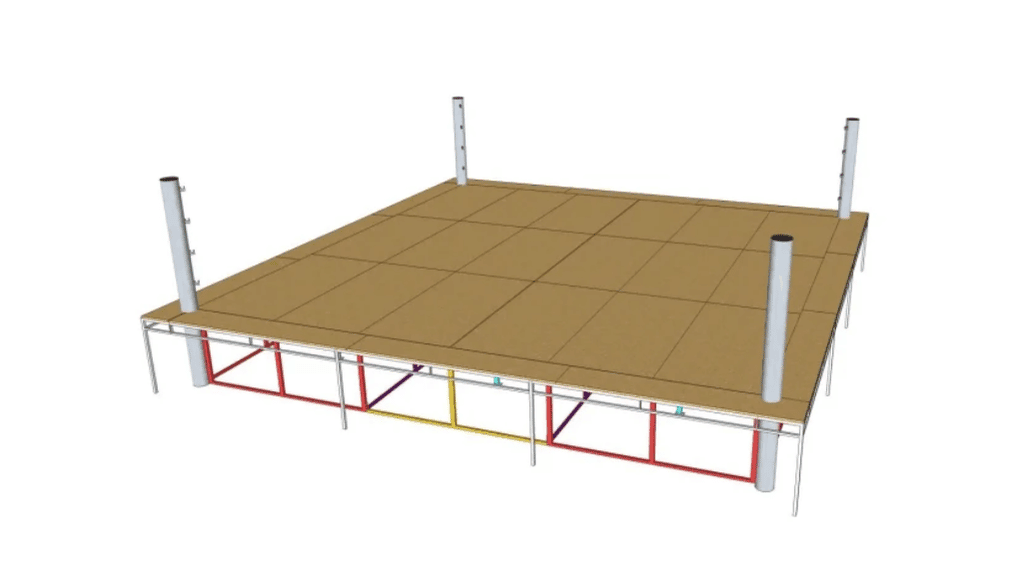

Design and Functionality Insights

Multi-point scaffolding systems are engineered for versatility. Their design includes adjustable anchoring points, which distribute load evenly across the structure. This ensures stability, even on irregular surfaces. Components like beams and platforms are crafted for durability, meeting strict safety standards.

One of the key features is the ease of assembly. These systems can be quickly set up, reducing downtime on job sites. The use of advanced materials enhances their strength-to-weight ratio, making them ideal for various construction tasks. Whether it’s a small repair or a large-scale project, multi-point scaffolding adapts seamlessly.

Application Scenarios in Construction

These systems excel in complex environments. For example, they are often used in building maintenance, where access to hard-to-reach areas is crucial. Their adjustable design allows them to fit unique structures, ensuring worker safety and efficiency.

In large projects, multi-point scaffolding provides a stable platform for both workers and materials. Its ability to handle heavy loads makes it a preferred choice for industrial applications. Additionally, systems like suspended scaffolding offer specialized solutions for tasks requiring overhead access.

By integrating thoughtful design features, these systems enhance overall project success. They not only improve safety but also reduce project timelines, making them a valuable asset in the construction industry.

Understanding Suspended Scaffold and Other Systems

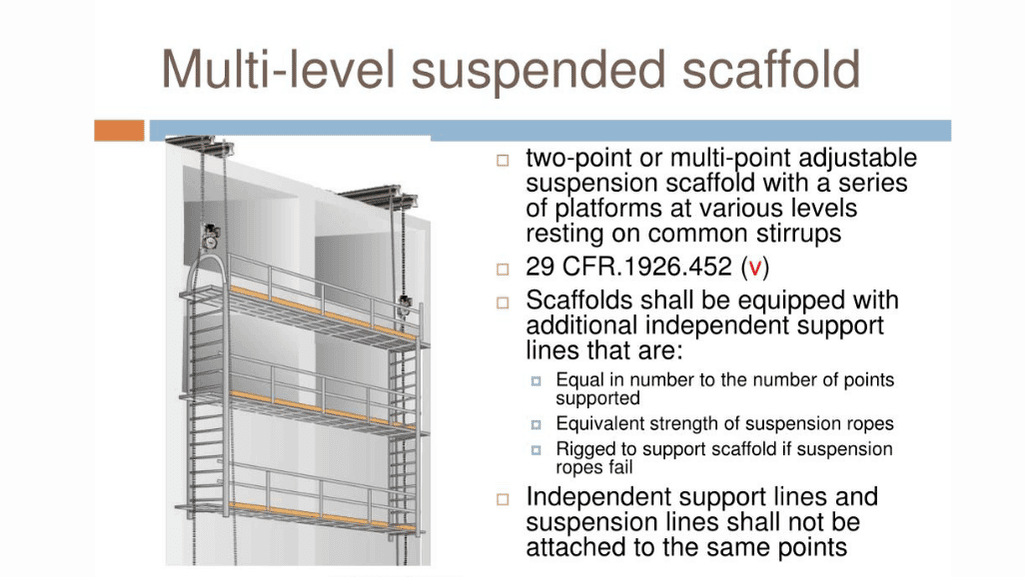

Suspended scaffolding systems have revolutionized access to high-rise structures. These systems use ropes, cables, and stirrups to provide flexibility and movement, making them ideal for tasks like window cleaning, painting, and maintenance on tall buildings. Unlike traditional support scaffolds, suspended systems save ground space and adapt to unique structures.

Comparing Suspended, Support, and Elevating Platforms

Each type of scaffolding serves a specific purpose. Suspended systems excel in high-rise projects, offering unmatched flexibility. Support scaffolds, on the other hand, provide stability for ground-level tasks. Elevating platforms are commonly used for tasks like painting and window cleaning, combining mobility with ease of use.

Suspended scaffolding relies on cables and ropes to adjust height and position. This makes it perfect for tasks requiring frequent movement. Support scaffolds, built from sturdy components, are ideal for heavy loads and static projects. Elevating platforms bridge the gap, offering mobility and stability for mid-height tasks.

Real World Examples and Industry Usage

Suspended scaffolding is widely used in skyscraper maintenance, bridge repairs, and exterior painting. For instance, the two-point swing stage scaffold is a popular choice for its simplicity and cost-effectiveness. It allows multiple workers to perform tasks simultaneously, improving efficiency.

In high-rise construction, suspended systems like the swing stage scaffold are essential. They provide access to hard-to-reach areas while ensuring safety through integrated fall arrest systems. According to OSHA guidelines, these systems must undergo regular maintenance to ensure compliance with regulations.

Choosing the right system depends on the project scope and task requirements. For example, elevating platforms are ideal for painting tasks, while suspended systems are better suited for high-rise maintenance. Understanding these differences ensures optimal safety and efficiency on the job site.

Installation, Regulation, and Maintenance Best Practices

Ensuring safety and compliance in scaffold installation is a cornerstone of construction success. Proper setup and adherence to OSHA guidelines are critical for minimizing risks on job sites. This section outlines best practices for installation, maintenance, and regulatory compliance to keep workers safe and projects on track.

Adhering to OSHA Guidelines and Local Regulations

Compliance with safety regulations is non-negotiable in scaffold installation. OSHA mandates that platforms must support at least four times their intended load. Guardrails or fall arrest systems are required for work at heights over 10 feet. Regular inspections by a competent person are essential to ensure stability and compliance.

Local regulations may also impose additional requirements. For example, in Virginia, scaffolding must maintain a minimum clearance of 10 feet from power lines. Employers must stay informed about these rules to avoid violations and ensure worker safety.

Step-by-Step Installation Process

Installing a scaffold begins with selecting the right materials and components. The foundation must be solid and level to support the structure. Beams and platforms should be inspected for damage before assembly.

Follow these steps for secure installation:

- Assemble the base on a stable surface.

- Erect vertical supports and secure them with braces.

- Install platforms and guardrails, ensuring they meet OSHA height requirements.

- Conduct a final inspection to confirm stability and compliance.

Maintenance and Inspection Procedures

Regular maintenance is crucial for scaffold longevity and safety. Inspect components weekly for wear or damage. Clean surfaces monthly to prevent corrosion. Replace any damaged parts immediately to maintain structural integrity.

According to OSHA, scaffolds must be inspected before each work shift, after severe weather, or after any incident. These checks help identify potential hazards and ensure the system remains safe for use.

Load Management and Material Selection

Proper load management is essential for scaffold safety. Platforms must support their intended load without deflection exceeding 1/60 of their length. For high-rise projects, select materials with high strength-to-weight ratios to ensure stability at greater heights.

For example, heavy-duty scaffolding can handle up to 75 lbs./sq. ft., making it ideal for industrial applications. Always verify load capacities to prevent overloading, which can compromise safety.

Training and Worker Responsibilities

Training is a cornerstone of scaffold safety. Workers must understand proper installation, inspection, and maintenance procedures. Employers should provide site-specific training to address unique hazards.

OSHA requires retraining if workers lack proficiency or if site conditions change. Proper training ensures that workers can identify risks and respond effectively, reducing the likelihood of accidents.

For more detailed guidance on scaffold safety, explore our scaffold access and egress guide.

Safety Protocols and Training for Scaffold Operations

Safety is the foundation of every successful scaffold operation. Ensuring worker protection requires a combination of proper equipment, rigorous training, and adherence to regulations. This section explores essential safety measures and training programs to enhance scaffold operations.

Essential Safety Equipment and Fall Arrest Systems

Personal protective equipment (PPE) is a must for scaffold workers. Helmets, harnesses, and non-slip boots are critical for preventing accidents. Fall arrest systems, including guardrails and safety nets, provide additional protection at height.

OSHA mandates that fall arrest systems must support at least 5,000 pounds per worker. These systems include harnesses, lanyards, and anchors designed to minimize fall risks. Regular inspections ensure these components remain functional and compliant.

Hands-On Training and Certification Programs

Effective training programs are vital for scaffold safety. Hands-on sessions teach workers how to assemble, inspect, and use scaffold systems correctly. Certification courses, led by industry experts, ensure workers understand OSHA regulations and best practices.

Key training topics include:

- Proper use of PPE and fall arrest systems.

- Safe assembly and dismantling of scaffold structures.

- Identifying and mitigating potential hazards.

For specialized projects like bridge construction, consider exploring bridge scaffolding solutions for tailored safety measures.

Regular safety inspections and maintenance are equally important. Workers should inspect scaffolds before each shift and after any incident. This ensures the system remains safe and functional throughout the project.

Selecting the Ideal Scaffold for Your Construction Project

Choosing the right scaffolding system is critical for the success of any construction project. The ideal scaffold ensures safety, efficiency, and adaptability to meet specific project demands. Evaluating factors like load capacity, access needs, and environmental conditions is essential for making the best choice.

Assessing Project Requirements and Environmental Factors

Start by analyzing the project scope. Consider the height, load requirements, and the complexity of the structure. For high-rise projects, suspended scaffolds offer flexibility and access to hard-to-reach areas. For ground-level tasks, support scaffolds provide stability and durability.

Environmental factors also play a key role. Assess the terrain, weather conditions, and space limitations. Adjustable systems are ideal for irregular surfaces, ensuring stability and safety in challenging environments.

Key Considerations for Scaffold Selection

- Load Capacity: Ensure the scaffold can handle the weight of workers, tools, and materials.

- Access Needs: Choose a system that provides secure and efficient access to all work areas.

- Material Durability: Opt for rust-resistant materials like aluminum or steel for long-term use.

- Training: Ensure workers are trained in assembly, inspection, and safe operation.

For specialized tasks, consider advanced systems like suspended scaffolding. These systems are designed for high-rise projects, offering unmatched flexibility and safety.

By carefully evaluating these factors, you can select the ideal scaffold for your project. This ensures both worker safety and project efficiency, leading to successful outcomes.

Conclusion

Advanced scaffolding systems have transformed the way construction projects are executed, ensuring both safety and efficiency. From suspended scaffold setups to supported platforms, each type offers unique benefits tailored to specific tasks. These systems provide secure access to elevated work areas, enhancing productivity while minimizing risks.

Proper installation, routine maintenance, and adherence to regulations are crucial for maintaining safety standards. Regular inspections and the use of equipment like fall arrest systems further protect workers at height. Training programs ensure that operators are well-prepared to handle these systems effectively.

When selecting a scaffolding system, consider factors like project scope, structure complexity, and environmental conditions. For specialized needs, explore reinforced scaffolding solutions that offer enhanced stability and durability.

Staying informed about evolving industry standards and technological advancements is essential. By prioritizing safety and investing in proper training, construction teams can achieve successful outcomes while protecting their workforce.