Phone:

(+65)8319-0742

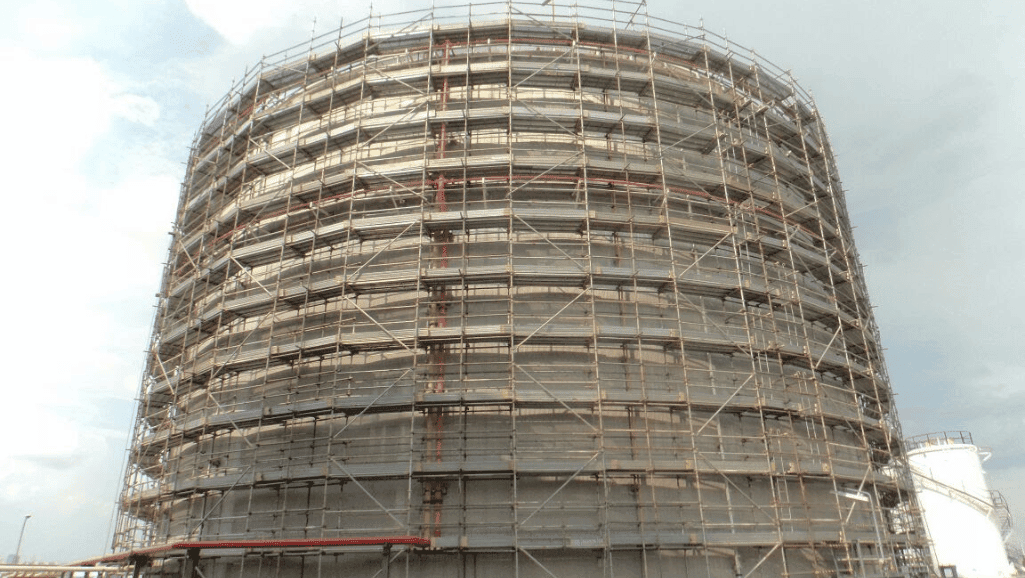

In the realm of construction scaffolding, the Tube and Coupler Scaffolding system stands out as a basic type for building projects. This robust scaffolding system is tailored to provide sturdy platforms conducive to the safe maneuvering of construction personnel and materials. Reliability is imbued into every joint, thanks to the integral scaffold tubes and coupler clamps, which accommodate the adaptability needed for complicated edifices. While its resilience is perfect for bearing heavy loads across multistory sites, every Tube and Coupler Scaffolding system must be meticulously planned to uphold stringent OSHA standards, guaranteeing the safety of the workforce and the efficiency of the construction process.

Delving into the mechanics of Tube and Coupler Systems, we discover a network of Scaffolding Components that form the backbone of construction sites across the globe. Designed to offer superior stability and versatility, these systems leverage the robustness and adaptability of Scaffold FittingsTube and Clamp Scaffolding to mitigate the challenges of complex architectural endeavors. The coupler scaffold is particularly versatile, making it suitable for various environments such as refineries and power plants, where its adaptability to complex structures is highly valued.

Key Takeaways

- Tube and Coupler Scaffolding provides versatile, durable support for construction sites.

- Scaffold tubes and coupler clamps offer customizable setups for complex structures.

- Meticulous planning is critical for ensuring the system meets safety and load capacity regulations.

- The systemâs design is particularly beneficial for heavy-duty applications and reaching multiple stories.

- Adhering to OSHA standards is paramount in the installation and usage of scaffolding systems.

- Tube and Coupler Scaffolding is adaptable, capable of conforming to irregular work surfaces and project specifications.

Understanding Tube and Coupler Scaffolding Systems

Delving into the mechanics of Tube and Coupler Systems, we discover a network of Scaffolding Components that form the backbone of construction sites across the globe. Designed to offer superior stability and versatility, these systems leverage the robustness and adaptability of Scaffold Fittings and Tube and Clamp Scaffolding to mitigate the challenges of complex architectural endeavors.

Components and Configuration

The configuration of Tube and Coupler Scaffolding hinges on its numerous crucial components, each integral to constructing a resilient and dependable structure. From the strong scaffold tubes that extend vertically and horizontally to the array of coupler clamps like swivel and sleeve couplers, every piece plays a significant role in scaffold systems.

Renowned for their formidable load-carrying capacity, Tube and Coupler Scaffolding systems are engineered to resist the intense weight of construction materials and tools, delivering a secure working environment for myriad construction scenarios. The versatility of scaffold fittings facilitates adjustments, reinforcing safety and efficiency on-site.

It is the inherent design flexibility of the Tube and Clamp Scaffolding that sets it apart, permitting the tailor-fitting of scaffolds to the most intricate and irregular building shapes. Professionals in the field rely on these adaptable components to erect scaffolds that align perfectly with the unique contours of each construction project, ensuring precision and dependability.

| Type of Coupler | Function | Application in Scaffolding |

|---|---|---|

| Right Angle Couplers | Secure tubes at 90 degrees | Creating right angles for frames and supports |

| Swivel Couplers | Connect tubes at various angles | Supporting diagonal bracing in scaffolds |

| Sleeve Couplers | Join scaffold tubes end-to-end | Extending the length of scaffold runs |

| Board Retaining Couplers | Secure scaffolding boards in place | Preventing movement of platforms |

| Base Plate Couplers | Provide a flat bearing surface | Stabilizing scaffolds at the base |

Strengths of Tube and Coupler Scaffolding

Renowned for their formidable load-carrying capacity, Tube and Coupler Scaffolding systems are engineered to resist the intense weight of construction materials and tools, delivering a secure working environment for myriad construction scenarios. The versatility of scaffold fittings facilitates adjustments, reinforcing safety and efficiency on-site.

Design Flexibility for Complex Structures

It is the inherent design flexibility of the Tube and Clamp Scaffolding that sets it apart, permitting the tailor-fitting of scaffolds to the most intricate and irregular building shapes. Professionals in the field rely on these adaptable components to erect scaffolds that align perfectly with the unique contours of each construction project, ensuring precision and dependability.

Key Features of Tube and Coupler Scaffolding

Central to the integrity of construction projects, a reliable scaffolding system is crucial for ensuring the safety and productivity of workers. Among various systems, tube and coupler scaffolding stands out due to its versatile framework, characterized by its capacity for heavy-duty scaffolding demands. This robust structure is designed to facilitate multiple platform scaffolding, which allows workers to operate at various heights simultaneously, effectively increasing the efficiency of construction efforts.

When it comes to scaffolding, nothing is more critical than adhering to scaffolding safety standards. Each component within this system is meticulously crafted to not only withstand vertical loads but also lateral pressures brought on by winds or unbalanced weights, especially when the structure is sheathed in protective mesh. Guardrails and toeboards are notable protective measures integrally designed within the scaffolding setup to safeguard against falls and dropped objects, which in tandem with strict compliance with safety standards, form a fortress of security.

| Feature | Description | Impact on Safety |

|---|---|---|

| Heavy-Duty Construction | Capable of supporting significant load capacities and multiple work platforms. | Enhances stability and ability to handle dynamic construction demands. |

| Adherence to Standards | Complies with engineered designs and rigorous safety protocols. | Ensures worker safety and mitigates risk of structural failures. |

| Protective Measures | Incorporates essential protective features such as guardrails and toeboards. | Prevents falls and injurious accidents, creating a secure working environment. |

This system’s modularity and strength make it an ideal choice for challenging construction landscapes. Critical elements like reliable scaffolding systems have the added benefit of being scalable, meaning as the project grows, so does the capability of the scaffolding to accommodate additional requirements. Overall, tube and coupler scaffolding offers a resilient, flexible solution that upholds scaffolding safety standards without sacrificing functionality.

Tube and Coupler Scaffolding in Construction Projects

Components and Benefits

Tube and coupler scaffolding is composed of steel tubes and couplers, which are essential for constructing a stable and secure structure. The couplers connect the tubes at various intervals, adhering to engineering standards and regulations. This scaffolding system offers several significant benefits:

Flexibility: Tube and coupler scaffolding can be assembled into various configurations, such as birdcage scaffolding, suspended scaffolding, and supported scaffolding, to meet the specific needs of different projects.

Adaptability: Its design allows it to be used across a wide range of industries, including construction, maintenance, and restoration, making it a versatile choice for many applications.

Strength: The system’s ability to support heavy loads makes it ideal for projects that require a strong and stable structure, ensuring the safety and efficiency of construction activities.

Safety: The use of high-quality couplers and tubes provides a secure and stable structure, significantly reducing the risk of accidents and injuries on the job site.

Safety Considerations

Safety is paramount when working with tube and coupler scaffolding. To ensure a safe working environment, several key safety considerations must be observed:

Proper Assembly: Ensuring that the scaffolding is correctly assembled and securely anchored is crucial to prevent collapse and ensure stability.

Quality Materials: Using high-quality steel construction and reliable couplers is essential to maintain the strength and stability of the structure.

Worker Training: Providing comprehensive training to workers on the safe use and assembly of the scaffolding is vital to prevent accidents and ensure proper handling.

Regular Inspections: Conducting regular inspections of the scaffolding to check for any signs of wear, damage, or instability is necessary to maintain safety standards.

Engineering Design: Ensuring that the scaffolding is properly designed and engineered to support the weight of workers and materials is critical to prevent overloading and structural failure.

By adhering to these safety considerations, construction sites can maintain a secure environment, protecting workers and ensuring the successful completion of projects.

Heavy-Duty Load Capacity

Heavy-duty Scaffolding is designed to withstand substantial loads, offering a steadfast solution for construction sites that deal with heavy materials. With a remarkable capacity to endure 75 lbs. per square foot, these structures can confidently support the demands of large-scale projects.

Adaptability to Unique Building Structures

The adaptability of Construction Scaffolding is evident in its ability to morph to the contours of unique architectural designs. Whether faced with intricate facades or irregular layouts, tube and coupler scaffolding provides tailor-made configurations that facilitate efficient construction workflows.

Evaluation of Scaffold Types: Light, Medium, and Heavy Duty

It is essential to evaluate the appropriate scaffold type to ensure project efficacy while upholding safety standards. Construction projects range from needing Light-duty Scaffolding, well-suited for less intensive tasks, to Medium-duty Scaffolding for moderate loads, and finally the robust Heavy-duty Scaffolding for the most demanding jobs.

| Type | Load Capacity (lbs./sq. ft.) | Common Uses |

|---|---|---|

| Light-duty | 25 | Light work, few workers, hand tools |

| Medium-duty | 50 | General construction, some materials |

| Heavy-duty | 75 | Storing materials, extensive construction |

Safety Measures and Hazard Prevention

Ensuring the safety of workers on construction sites, particularly when working with tube and coupler scaffolding, necessitates rigorous safety measures and the implementation of robust hazard prevention strategies. A carefully structured approach to scaffolding safety can significantly reduce the risk of onsite accidents and ensure a secure environment for construction personnel.

Hazard Assessments and Safety Protocols

Scaffolding Safety Protocols begin with a comprehensive hazard assessment, designed to identify and mitigate potential risks associated with scaffold construction and use. These protocols cover a range of safety concerns, including fall prevention, structural stability, and protection from environmental factors that may compromise the integrity of the scaffold.

Importance of Qualified Scaffold Design

A Qualified Scaffold Design is pivotal for constructing safe scaffolding structures, particularly those that rise over 125 feet. Such designs must be conceptualized by certified professionals to ensure that all safety standards are met. This involves calculating load capacities and ensuring the scaffold can bear at least four times the maximum intended load without faltering.

Guardrails, Toeboards, and Fall Protection

The integration of Guardrail Systems and Toeboards is a fundamental aspect of Fall Protection Scaffolding. These elements serve as critical barriers against falls and dropped objects, which are common hazards on construction sites. Adherence to installation standards for guardrails and toeboards is a non-negotiable safety measure.

In addition to passive fall protection, Active Fall Protection measures include the use of Personal Fall Arrest Systems that catch workers in the event of a fall, thus playing an indispensable role in preventing serious injuries. Such systems must be regularly inspected and maintained to ensure optimal performance when needed.

| Safety Feature | Function | Regulatory Standard |

|---|---|---|

| Guardrail Systems | Prevent falls from height | OSHA 1926.502(b) |

| Toeboards | Protect from falling objects | OSHA 1926.451(f)(1) |

| Personal Fall Arrest Systems | Catch workers in the event of a fall | OSHA 1926.500-503 |

By implementing these safety measures with attention to detail and compliance with regulations, employers can significantly mitigate scaffold-related hazards and safeguard the well-being of workers on construction sites.

Practical Insights: Erection, Use, and Dismantling

When it comes to constructing safe and reliable structures, the processes of scaffolding erection, use, and dismantling are fundamental components that require keen attention to detail. These stages are pivotal in ensuring the integrity and stability of scaffolding systems, ultimately leading to safe working environments for construction personnel. This section provides valuable insights on establishing a secure scaffolding set-up, maintaining its safety during use, and removing it with precision.

Level Foundations and Sturdy Footings

To begin with, it’s imperative that one considers the importance of level foundations and sturdy footings in the scaffolding erection process. A flat and solid base is necessary for scaffolding stability, acting as the bedrock upon which safety is built. Whether you’re working on soil, concrete, or any other surface, leveling and compacting the ground, as well as using proper base plates and sole boards, are essential steps that cannot be overlooked.

Bracing and Securing for Stability

To achieve scaffolding stability, bracing elements should be strategically placed to prevent any lateral movement that could undermine the structure’s integrity. The bracing follows specific patterns, often in the form of cross, diagonal, or horizontal reinforcement, making sure that each join is methodically secured to handle the stresses that accompany construction activities.

Tagging Systems for Scaffold Safety

Regular scaffolding safety inspections are a necessary discipline in the scaffolding lifecycle. Employing a tagging system is a universally accepted practice to communicate current safety status. These tags are visual indicators that inform users whether the scaffold is safe for use or if it requires any necessary repairs or adjustments. A green tag indicates full functionality and safety, whereas a red tag denotes prohibited usage until the structure is rendered safe and secure again. These disclosures are critical to a scaffold’s operative reliability.

As scaffolding dismantling commences, it’s critical to ensure the removal of components in reverse order from which they were erected, attentively checking that this process doesn’t compromise the scaffolding’s stability for others still working on site. The proficiency to safely dismantle and inspect scaffolding stability hinges on rigorous training and a solid understanding of structural principles. Achieving this level of expertise is non-negotiable for fostering a culture of uncompromised safety and preventing potential accidents throughout the deployment of a scaffolding system.

What is Tube and Coupler Scaffolding?

Tube and coupler scaffolding, also known as tube and clamp scaffolding or tube and fitting scaffolding, is a versatile and robust scaffolding system widely used in the construction industry. This system employs steel tubes and couplers to create a stable and secure structure, making it ideal for various construction, maintenance, and restoration projects. Its adaptability allows it to be used in diverse environments, including refineries, petrochemical plants, and power plants. Whether for residential, commercial, or industrial applications, tube and coupler scaffolding provides a reliable solution for building and maintenance tasks.

Scaffold Tubes and Coupler Clamps

Scaffold tubes are the primary structural element that provides the high-strength skeleton of the scaffold. Employed in combination with versatile coupler clamps, they enable the assembly of scaffolding that can withstand considerable loads and offer flexibility in design. Coupler clamps, including swivel, sleeve, and putlog varieties, ensure secure joins between tubes, allowing for custom scaffold shapes to meet complex construction requirements.

Understanding the Role of Scaffold Fittings

Scaffold fittings, which encompass a wide variety of specialized components such as girder couplers and board retaining couplers, play a pivotal role in scaffold safety and functionality. These fittings are the critical connectors that bolster the structural integrity of scaffolding by ensuring tubes and boards are firmly held in place.

Transporting and Storage of Scaffolding Pieces

Efficient scaffolding transporting and storage systems are critical for maintaining scaffolding components in top condition. Proper handling and storage practices ensure that scaffold tubes, coupler clamps, and all scaffold fittings are protected against damage, thus extending their usable life and promoting safety on the job site. It’s also essential to streamline these operations to minimize downtime between projects.

| Component | Function | Considerations for Transporting and Storage |

|---|---|---|

| Scaffold Tubes | Provide the structural framework | Stack neatly to avoid bending; protect from the elements |

| Coupler Clamps | Join scaffold tubes at various angles | Store in labeled bins for easy identification and access |

| Scaffold Fittings | Secure tubes and boards in place | Inspect regularly; lubricate as needed before storage |

Maintenance and Inspection of Tube and Coupler Systems

For the tube and coupler scaffolding systems crucial to construction, sustaining Scaffolding System Integrity demands a committed approach to Scaffolding Maintenance. The durability and safe functionality of these systems significantly rely on a regimen of continual monitoring and preservation. It is imperative that the individuals tasked with this responsibility possess thorough training to discern and respond to signs of wear, environmental damages, and structural vulnerabilities. Through vigilant maintenance, we extend not only the service life of the scaffolding components but more vitally, we ensure a Secure Scaffolding edifice.

Regular Scaffolding Inspection is another cornerstone in certifying the safety and efficiency of these structures. Inspections must be meticulous, methodically examining every joint, tube, and coupler for faults. This process is not merely about identifying current issues but about preemptive detection, foreseeing issues before they escalate into real-world risks. These thorough assessments, when performed routinely, fortify the scaffolding against potential breaches in safety, thereby reinforcing public and worker confidence in the structural integrity of the scaffolding in use.

Lastly, integrating the knowledge of hazards and load capacities inherent to differing scaffolding systems is critical. Education concerning the nuanced aspects of tube and coupler scaffolding, including routine maintenance in various environmental conditions and adherence to site safety requirements, cannot be overstated. Employers must champion these insights, embedding them deeply into their operational protocols. In sustaining these standards, the construction sector is better equipped to uphold the pillars of safety and dependability expected of professional Scaffolding System Integrity.

Frequently Asked Questions

What are the primary components of tube and coupler scaffolding systems?

Tube and coupler scaffolding systems consist of scaffold tubes as the core structural element supported and connected by various types of coupler clamps such as swivel, right-angle, and sleeve couplers. Scaffold fittings, including girder and board retaining couplers, are also integral components.

How does tube and coupler scaffolding ensure strength and safety?

The strength and safety of tube and coupler scaffolding stem from its robust construction, which enables it to support multiple platforms at significant heights. Safety is further enhanced through strict adherence to scaffolding safety standards, hazard assessments, and the use of guardrails, toeboards, and fall protection systems.

Can tube and coupler scaffolding be adapted for complex construction sites?

Yes, due to its design flexibility, tube and coupler scaffolding can be customized in multiple directions to fit complex and irregular structures, making it ideal for diverse and intricate construction environments.

What factors determine the duty rating of scaffolding and its load capacity?

The duty rating of scaffolding, which classifies it as light, medium, or heavy-duty, is determined based on the maximum intended load it can support, including workers, tools, and materials. Light-duty scaffolding supports 25 lbs. per square foot, medium-duty supports 50 lbs. per square foot, and heavy-duty scaffolding supports 75 lbs. per square foot.

What safety measures must be considered when using tube and coupler scaffolding?

When using tube and coupler scaffolding, it is essential to conduct hazard assessments, implement safety protocols, ensure scaffolds are engineered by a professional when required, and incorporate protective measures like guardrails, toeboards, and fall protection systems to comply with safety regulations.

What is the importance of stable foundations in the erection of scaffolding?

Stable foundations and sturdy footings are vital during the erection of scaffolding to prevent sway and displacement. Proper bracing also plays an essential role in ensuring the stability of the structure.

Why is tagging systems essential for scaffold safety?

Tagging systems play a crucial role in scaffold safety by providing a color-coded method to indicate the status of the scaffold following inspections. They alert users to potential safety issues and confirm the scaffold’s readiness or lack thereof for use.

How should scaffolding pieces be transported and stored?

Scaffolding pieces should be carefully transported and strategically stored to prevent damage and maintain ease of access. This ensures the longevity and reusability of the components for future construction projects.

Why are routine maintenance and inspection crucial for tube and coupler scaffolding?

Routine maintenance and detailed inspections are critical for identifying defects, damage, and safety concerns, ensuring the integrity and security of the scaffold. Regular checks by trained personnel extend the lifespan of the scaffolding components and guarantee safe usage.