Phone:

(+65)8319-0742

Welcome to our comprehensive guide on wooden scaffolding! Whether you are a construction professional or a DIY enthusiast, this guide will provide you with all the essential information you need to know about wooden scaffolding, including its safety considerations and how to make the right purchase decisions. So, let’s dive in and explore the world of wooden scaffolding together.

Key Takeaways:

- Wooden scaffolding is a temporary structure used in construction, maintenance, and repair work.

- It provides stability, durability, and cost-effectiveness.

- There are various types of wooden scaffolding to suit different project requirements.

- Safety is paramount, and proper inspection, training, and attention to weight capacity are vital.

- Considerations for purchasing wooden scaffolding include project type, specifications, and budget.

What is Wooden Scaffolding?

Wooden scaffolding is a temporary structure made of metal pipes/tubes and planks, used to support workers and materials during construction, maintenance, or repair work. It serves as a stable and secure platform that allows workers to access higher areas and carry out their tasks efficiently.

This type of scaffolding is commonly used in various construction projects, such as building construction, painting, renovation, and maintenance work. It provides a reliable solution for working at heights, ensuring the safety of workers while allowing them to perform their duties effectively.

Wooden scaffolding is designed to withstand the demands of construction sites, providing a sturdy and stable framework for workers to move around and transport materials. The planks used in wooden scaffolding are typically made of high-quality wood, known for its strength and durability.

Construction projects often require workers to access elevated areas for various tasks, such as installing windows, repairing roofs, or painting walls. Wooden scaffolding offers a practical solution, allowing workers to reach these areas safely and securely.

Additionally, wooden scaffolding can be easily assembled, disassembled, and adjusted to accommodate different project requirements. Its versatile design makes it suitable for a wide range of construction and maintenance tasks, providing flexibility and convenience on the job site.

Benefits of Wooden Scaffolding

Wooden scaffolding offers a range of advantages that make it a popular choice for construction projects. From its stability and durability to its cost-effectiveness, wooden scaffolding provides numerous benefits for both contractors and workers.

Stability: One of the key benefits of wooden scaffolding is its stability. The sturdy construction of wooden planks ensures a secure work area for workers at various heights. This stability is crucial for maintaining worker safety and preventing accidents on construction sites.

Durability: Wooden scaffolding is known for its durability, allowing it to withstand heavy loads and harsh weather conditions. The natural strength of wood makes it a reliable choice that can endure the demands of construction projects, providing a long-lasting scaffolding solution.

Cost-effectiveness: Cost plays a significant role in any construction project. Wooden scaffolding offers a cost-effective option compared to other materials, making it an attractive choice for contractors. Its affordability, combined with its durability, makes wooden scaffolding a practical investment.

Versatility: Wooden scaffolding can be used in a variety of construction projects, thanks to its versatility. Whether it’s for small-scale repairs or large-scale construction, wooden scaffolding can adapt to different project requirements and provide a safe and efficient working platform.

Furthermore, wooden scaffolding is easy to assemble and disassemble, allowing for efficient setup and dismantling processes. This saves time and effort on the construction site.

Key benefits of wooden scaffolding:

Stability: Wooden scaffolding provides a stable platform for workers, ensuring a secure work area even at considerable heights.

Durability: Despite its relatively lightweight nature, wooden scaffolding is capable of withstanding heavy loads and harsh weather conditions, making it suitable for long-term use on construction sites.

Cost-effectiveness: Wooden scaffolding is often more affordable compared to other materials like metal or aluminum, making it a practical option for construction projects where budget constraints are a concern.

Versatility: Wooden scaffolding can be easily customized and adapted to meet various project requirements, allowing for flexibility in design and construction.

Sustainability Aspect

Wooden scaffolding also has a sustainable aspect to consider. Wood is a renewable resource, and when sourced responsibly, it can be an environmentally friendly choice for scaffolding. Additionally, using wooden scaffolding reduces reliance on non-renewable materials and contributes to sustainable construction practices.

Overall, the benefits of wooden scaffolding, including its stability, durability, cost-effectiveness, and versatility, make it an excellent choice for construction projects. By leveraging these advantages, contractors can ensure a safe and efficient work environment while optimizing their budget and resources.

Types of Wooden Scaffolding

Wooden scaffolding offers a variety of options to suit different project requirements. Here are some of the common types of wooden scaffolding:

1. Tube and Coupler Scaffolding

Tube and coupler scaffolding is a versatile system that uses tubes and couplers to create a stable structure. It offers flexibility and can be easily adjusted to fit various heights and configurations. This type of scaffolding is commonly used in large construction projects.

2. Frame Scaffolding

Frame scaffolding, also known as traditional scaffolding, consists of pre-fabricated frames and cross braces. It is easy to assemble and disassemble, making it ideal for both small and large construction projects. Frame scaffolding is commonly used in buildings, bridges, and industrial facilities.

3. System Scaffolding

System scaffolding utilizes pre-fabricated components, such as vertical standards and horizontal ledgers, to form a modular structure. It provides stability and versatility, allowing for quick assembly and adaptability to various project requirements. System scaffolding is often used in construction, maintenance, and industrial settings.

4. Suspended Scaffolding

Suspended scaffolding is a type of scaffolding that is suspended from the top of a building or structure. It is commonly used for maintenance, inspection, and repair work on tall structures, such as skyscrapers or bridges. Suspended scaffolding offers flexibility and easy access to hard-to-reach areas.

5. Multi-Function Scaffolding

Multi-function scaffolding, also known as multi-purpose scaffolding, is a versatile option that can be easily customized to suit different project requirements. It combines the features of various scaffolding systems and can be used as a single or multi-level structure. Multi-function scaffolding is commonly used in both construction and maintenance projects.

6. Mobile Scaffolding

Mobile scaffolding, also known as rolling scaffolding, is designed with built-in wheels or casters for easy mobility. It offers flexibility and convenience, allowing workers to move the scaffolding to different locations within a worksite. Mobile scaffolding is commonly used in construction, painting, and maintenance projects.

Tube and Coupler Scaffolding

- Key Features: Versatile, adjustable, stable

- Common Applications: Large construction projects

Frame Scaffolding

- Key Features: Easy assembly, disassembly

- Common Applications: Buildings, bridges, industrial facilities

System Scaffolding

- Key Features: Modular, quick assembly

- Common Applications: Construction, maintenance, industrial settings

Suspended Scaffolding

- Key Features: Easy access, flexibility

- Common Applications: Tall structures, maintenance, inspection, repair work

Multi-Function Scaffolding

- Key Features: Customizable, versatile

- Common Applications: Construction, maintenance projects

Mobile Scaffolding

- Key Features: Mobile, convenient

- Common Applications: Construction, painting, maintenance projects

Each type of wooden scaffolding has its own advantages and is suitable for different project requirements. Consider the specific needs and constraints of your project to ensure you choose the right type of scaffolding.

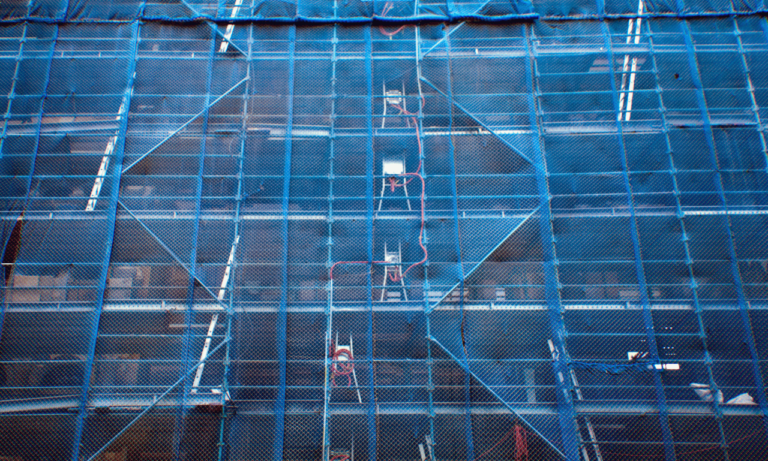

Image: Wooden Scaffolding

Wooden Scaffolding Safety Tips

Ensuring the safety of workers is paramount when using wooden scaffolding. By following these essential safety tips, you can maintain a secure work environment:

1. Inspection before Use

Before starting any work, it is crucial to inspect the wooden scaffolding for any defects, damage, or signs of instability. Look for loose planks, missing bolts or connectors, and weakened supports. Address any issues before proceeding to ensure stable and safe scaffolding.

2. Proper Training for Workers

It is vital to provide comprehensive training to all workers operating on wooden scaffolding. They should be educated on safe scaffold assembly, how to properly use safety equipment, and recognize potential hazards. Regular refresher training sessions should also be conducted to keep safety protocols at the forefront.

3. Know the Weight Capacity

Understanding the weight capacity of wooden scaffolding is essential to prevent overloading. Ensure that workers are aware of the maximum load the scaffolding can bear and strictly adhere to these guidelines. Exceeding the weight limits can compromise its stability and pose severe risks.

4. Stabilization and Securement

Proper stabilization and securement of wooden scaffolding are crucial elements in preventing accidents. Ensure that the scaffolding is properly secured to the structure it is attached to and use appropriate bracing techniques to maintain stability. Constantly monitor and reinforce the scaffolding as needed.

5. Consider Weather Conditions

Weather conditions can significantly impact the safety of wooden scaffolding. Strong winds, rain, or snow can destabilize the scaffolding, making it unsafe for use. Monitor the weather forecast regularly and take the necessary precautions, such as installing wind braces and covering the scaffolding when not in use.

By following these safety tips, you can create a secure work environment, minimize risks, and ensure the well-being of everyone on the construction site.

Safety tips for using wooden scaffolding:

Inspection before Use: Before using wooden scaffolding, thoroughly inspect it for any defects, damage, or signs of instability. Address any issues promptly to ensure a safe working environment.

Proper Training for Workers: Provide comprehensive training to workers on the safe assembly, usage of safety equipment, and hazard recognition when working with wooden scaffolding. Proper training reduces the risk of accidents and injuries.

Know the Weight Capacity: Understand and adhere to the maximum weight capacity of the wooden scaffolding. Overloading the scaffolding can compromise its integrity and lead to accidents. Ensure workers are aware of weight limits and avoid exceeding them.

Stabilization and Securement: Properly stabilize and secure the wooden scaffolding to maintain stability and prevent accidents. Use bracing, tie-ins, and base plates as necessary to ensure the scaffolding remains secure during use.

Consider Weather Conditions: Monitor weather conditions and take necessary precautions to protect the wooden scaffolding from adverse effects such as high winds, rain, or snow. Cover the scaffolding or dismantle it if severe weather is expected to prevent accidents and damage.

Purchasing Wooden Scaffolding

When it comes to purchasing wooden scaffolding, there are several important considerations to keep in mind. Whether you are a contractor, builder, or homeowner, making the right choice is crucial for the success and safety of your project. Here are some key factors to consider before making your purchase:

Type of Project

First and foremost, determine the specific requirements of your project. Consider the scale of the construction or maintenance work you will be undertaking. Different projects may require different types and sizes of wooden scaffolding. For larger projects, investing in a more robust and heavy-duty scaffolding system may be necessary. Smaller projects, on the other hand, may only require a simple and lightweight scaffolding setup.

Required Specifications

Ensure that you have a clear understanding of the specifications and features you need in your wooden scaffolding. This includes the height, width, and weight capacity of the scaffolding system. Take into account the maximum load that the scaffolding will need to support. Also, consider the number of workers who will be using the scaffolding at the same time. These specifications will help you select the most suitable scaffolding system for your project.

Budget

Establishing a budget is essential when purchasing wooden scaffolding. Consider how much you are willing to invest in your project and allocate a portion of that budget for scaffolding. It is important to strike a balance between quality and cost-effectiveness. While it may be tempting to opt for cheaper options, keep in mind that durability and safety should never be compromised. Look for reliable suppliers who offer competitive prices without compromising on the quality of their products.

Product Options and Accessories

Choosing a supplier that offers a wide range of product options and accessories is crucial. This ensures that you have plenty of choices when it comes to selecting the right wooden scaffolding for your project. Additionally, having access to compatible accessories such as guardrails, ladders, and stabilizers can enhance the safety and functionality of your scaffolding system. Consider the availability of these accessories and ensure they meet your specific requirements.

Supplier Reputation and Support

Lastly, do thorough research on the reputation and reliability of potential suppliers. Read reviews and testimonials to gauge the quality of their products and customer service. Consider established brands and suppliers that have a proven track record in the industry. A reputable supplier should provide excellent customer support and assistance, helping you make an informed decision and addressing any concerns or issues that may arise during the purchasing process.

Comparison of Wooden Scaffolding Suppliers

Supplier A

- Product Options: Tube and coupler scaffolding, system scaffolding

- Accessories: Guardrails, stabilizers

- Price Range: $$$ (High)

- Customer Reviews: Positive

Supplier B

- Product Options: Frame scaffolding, mobile scaffolding

- Accessories: Ladders, platforms

- Price Range: $$ (Moderate)

- Customer Reviews: Mixed

Supplier C

- Product Options: Multi-function scaffolding, suspended scaffolding

- Accessories: Outriggers, swivel casters

- Price Range: $$$ (High)

- Customer Reviews: Positive

Compare different suppliers based on their product options, accessories, price range, and customer reviews. This table can help you make an informed decision and select the right supplier for your wooden scaffolding needs.

Maintenance and Storage of Wooden Scaffolding

Proper maintenance and storage of wooden scaffolding are essential for ensuring its longevity and safety. By following these guidelines, you can extend the lifespan of your scaffolding and maintain a safe work environment.

Cleaning

Regular cleaning of wooden scaffolding is important to remove dirt, debris, and other contaminants that can compromise its structural integrity. Use a soft-bristle brush or a damp cloth to gently clean the surfaces of the scaffolding. Avoid using harsh cleaning solutions that may damage the wood. It’s also crucial to pay attention to hard-to-reach areas and corners where dirt tends to accumulate.

Protective Coatings

To enhance the durability of wooden scaffolding, consider applying protective coatings or treatments to the wood. These coatings can help prevent moisture absorption, wood rot, and other forms of damage. Choose a coating that is specifically designed for outdoor use and suitable for wooden surfaces. Regularly inspect and reapply the coatings as necessary.

Storing

When not in use, store the wooden scaffolding in a dry and secure location, such as a covered storage area or a shed. Protect it from exposure to excessive moisture or direct sunlight, as these elements can degrade the wood over time. Ensure that the scaffolding is stored on a level surface to maintain its stability. Avoid placing heavy objects on top of the scaffolding during storage.

Inspection

Regularly inspect the wooden scaffolding for any signs of damage, including cracks, splinters, or loose components. Replace or repair any damaged sections promptly to prevent accidents or injuries. It’s recommended to conduct thorough inspections before and after each use, as well as during periodic maintenance checks.

Training and Documentation

Provide proper training to workers on the safe use, maintenance, and storage of wooden scaffolding. Emphasize the importance of following safety guidelines and conducting regular inspections. Keep detailed documentation of maintenance activities, including cleaning schedules, coating applications, and repairs.

By implementing these maintenance and storage practices, you can ensure the longevity and safety of your wooden scaffolding. Remember to prioritize regular cleaning, apply protective coatings, store it properly when not in use, conduct inspections, and provide training to workers. Taking these steps will help you maximize the lifespan of your scaffolding investment and maintain a secure work environment.

Alternative Materials for Scaffolding Planks

While wood is a popular choice for scaffolding planks, there are alternative materials available that offer unique advantages for different construction projects. By considering these options, you can choose the material that best suits your specific requirements.

Aluminum

Aluminum is a lightweight and corrosion-resistant material, making it ideal for scaffolding planks. It offers ease of handling and transport, reducing the risk of worker fatigue and improving productivity. Aluminum planks are also durable and can withstand heavy loads, ensuring a safe and stable work platform.

Plastic

Plastic scaffolding planks are lightweight, strong, and resistant to weather conditions. They are easy to clean and maintain, making them suitable for projects that require frequent movement and assembly. Plastic planks also provide excellent insulation properties, reducing the risk of electric shock on construction sites.

Steel

Steel scaffolding planks are known for their strength and durability. They can withstand heavy loads and ensure a stable work platform, even in challenging construction environments. Steel planks are often used in projects that require long spans and high load capacities, providing reliable support for workers and materials.

Laminated Veneer Lumber (LVL)

Laminated Veneer Lumber (LVL) is a composite material made from multiple layers of wood veneers bonded together. LVL planks offer enhanced strength, stability, and resistance to warping or splitting. They are often used in construction projects that require a higher load-bearing capacity and long-term durability.

The advantages of each scaffold plank material:

Wood:

- Advantages: Traditional material with a long history of use in scaffolding. It’s cost-effective, readily available, and offers decent strength for typical construction needs.

Aluminum:

- Advantages: Lightweight material that is easy to handle, transport, and install. It’s also corrosion-resistant, making it suitable for outdoor use and in environments where moisture is a concern.

Plastic:

- Advantages: Lightweight and weather-resistant, plastic scaffold planks are suitable for outdoor use and can withstand various weather conditions. They are also easy to clean and maintain.

Steel:

- Advantages: Steel scaffold planks are strong, durable, and suitable for heavy loads. They provide excellent support and stability, making them ideal for projects requiring robust scaffolding solutions.

Laminated Veneer Lumber (LVL):

- Advantages: LVL scaffold planks offer enhanced strength, stability, and durability compared to traditional wood planks. They are engineered for superior load-bearing capacity and resistance to warping, making them suitable for demanding construction applications.

When choosing an alternative material for scaffolding planks, consider factors such as project requirements, load-bearing capacity, durability, and budget. Consulting with a scaffolding expert can help you make an informed decision based on the specific needs of your construction project.

Proper Use of Scaffold Planks

When working with scaffold planks, it is crucial to prioritize safety. By following proper procedures and guidelines, you can ensure a secure and efficient work environment. Here are some essential considerations for the appropriate use of scaffold planks:

1. Material Selection

The choice of scaffold plank material plays a significant role in ensuring the safety and durability of the scaffolding system. Consider factors such as weight capacity, weather resistance, and load-bearing capabilities when selecting scaffold planks. Common materials include wood, aluminum, steel, and laminated veneer lumber (LVL).

2. Avoid Misuse and Overloading

Misusing scaffold planks can compromise their structural integrity and pose a safety hazard. Avoid using scaffold planks for purposes other than intended, such as makeshift bridges or supports for heavy machinery. Additionally, be mindful of the weight capacity limits specified by the manufacturer and ensure that load-bearing standards are not exceeded.

3. Regular Cleaning

To maintain the longevity of scaffold planks, regular cleaning is essential. Remove any dirt, debris, or other contaminants that may accumulate on the planks, as they can affect both the stability and grip. Use appropriate cleaning solutions and techniques recommended by the manufacturer to preserve the quality of the planks.

4. Proper Storage

Proper storage of scaffold planks is crucial to prevent damage and ensure their usability over time. Store the planks in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Consider using storage racks or brackets to keep the planks organized and protected from potential hazards.

| Proper Use of Scaffold Planks | |

|---|---|

| Adjust the planks securely to make sure they are level and stable. | |

| Inspect scaffold planks for any signs of damage or wear before each use. | |

| Ensure that scaffold planks are properly secured in place using appropriate clamps or hooks. | |

| Refrain from placing heavy or concentrated loads on unsupported areas of scaffold planks. |

By adhering to these practices, you can maximize the safety and longevity of scaffold planks, creating a secure and efficient work environment. Remember to refer to the manufacturer’s guidelines and consult with industry professionals when in doubt.

Pump-Jack Scaffolding Considerations

When using pump-jack scaffolding, prioritizing safety is crucial. Proper material selection, pole spacing, bracing, and plank securing are essential considerations to ensure the stability and integrity of the scaffolding.

Material Selection

Selecting the right materials is key to maintaining the safety and durability of pump-jack scaffolding. Opt for high-quality materials that can withstand the working conditions and load requirements of your project. Consider factors such as strength, corrosion resistance, and weight when choosing materials.

Pole Spacing

Proper pole spacing is vital for maintaining stability and weight distribution on pump-jack scaffolding. Follow the manufacturer’s recommendations for the optimal distance between poles. Be mindful of the weight capacity and ensure that the poles are evenly spaced to prevent uneven stress on the scaffolding.

Bracing

Bracing plays a crucial role in the stability of pump-jack scaffolding. Ensure that the scaffolding is properly braced to prevent swaying or tilting. Follow the manufacturer’s guidelines for bracing techniques and make adjustments based on the specific requirements of your project.

Plank Securing

Securing the planks on pump-jack scaffolding is essential for the safety of workers. Regularly inspect the planks and ensure they are securely fastened to prevent any movement or dislodging during use. Use appropriate fasteners and techniques recommended by the manufacturer or experienced professionals.

To summarize, pump-jack scaffolding demands careful consideration for safety. Proper material selection, pole spacing, bracing, and plank securing are vital components to ensure the stability and integrity of the scaffolding. By following these guidelines, you can maintain a secure and productive work environment.

Conclusion

Wooden scaffolding is an excellent choice for construction projects, providing versatility, cost-effectiveness, and a safe working environment. By prioritizing safety measures, performing proper maintenance, and selecting the right type of scaffolding, you can ensure the success and well-being of your construction team.

This comprehensive purchase guide has covered all the essential information you need to make informed decisions when buying and using wooden scaffolding. Whether you are a contractor, project manager, or construction professional, following the guidelines in this guide will help you create a secure and efficient workspace.

Remember to prioritize safety by regularly inspecting your scaffolding, providing necessary training, and adhering to weight capacity and stabilization guidelines. Additionally, consider the specific requirements of your project and budget when purchasing wooden scaffolding, ensuring you choose a reputable supplier that offers the right product options and accessories.

With proper care and adherence to safety protocols, wooden scaffolding can be a reliable and durable tool in your construction arsenal, facilitating the completion of projects with efficiency and precision.

FAQ

What is wooden scaffolding?

Wooden scaffolding is a temporary structure made of metal pipes/tubes and planks, used to support workers and materials during construction, maintenance, or repair work.

What are the benefits of wooden scaffolding?

Wooden scaffolding offers benefits such as stability, durability, and cost-effectiveness. It provides a stable and secure work area, is easy to assemble and disassemble, and can be used in various types of construction projects.

What are the types of wooden scaffolding available?

The types of wooden scaffolding available include tube and coupler scaffolding, frame scaffolding, system scaffolding, suspended scaffolding, multi-function scaffolding, and mobile scaffolding.

What are some safety tips for using wooden scaffolding?

Safety tips for using wooden scaffolding include inspecting the scaffolding before use, providing proper training to workers, knowing the weight capacity, stabilizing the scaffolding, and paying attention to weather conditions.

What should I consider when purchasing wooden scaffolding?

When purchasing wooden scaffolding, consider the type of project, required specifications, and budget. Choose a reliable supplier that offers a variety of product options and accessories.

How should I maintain and store wooden scaffolding?

Proper maintenance and storage of wooden scaffolding involve regular cleaning, applying protective coatings or treatments, and storing the scaffolding in a dry and secure location.

What are some alternative materials for scaffolding planks?

Alternative materials for scaffolding planks include aluminum, plastic, steel, and laminated veneer lumber (LVL). The choice depends on the specific requirements of the project.

How should scaffold planks be used correctly?

Proper use of scaffold planks involves selecting the right material, avoiding misuse and overloading, and following cleaning and storage guidelines.

What considerations should be taken for pump-jack scaffolding?

Pump-jack scaffolding requires considerations such as proper material selection, spacing of poles, bracing, and securing of planks to ensure safety and stability.