Phone:

(+65)8319-0742

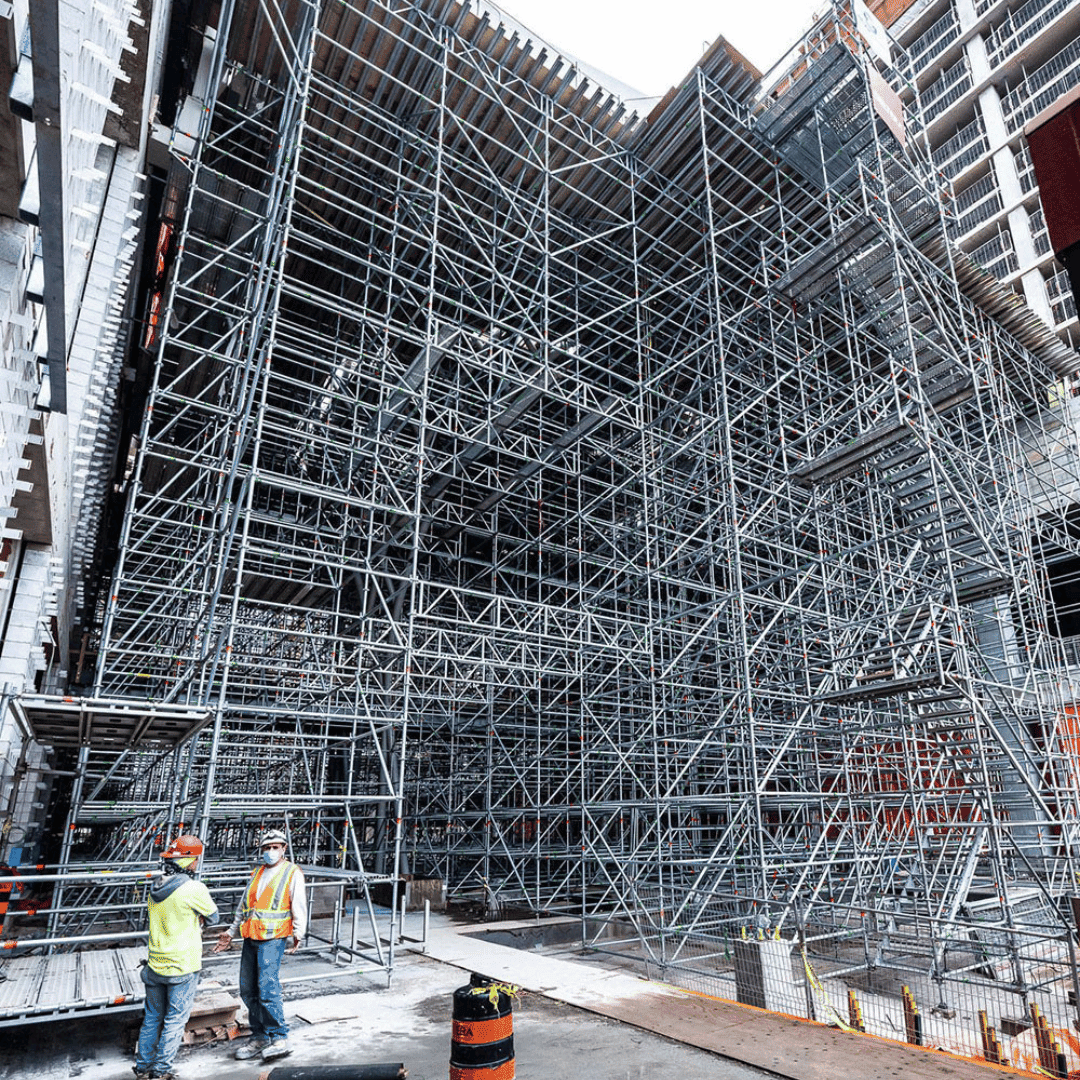

Scaffold towers play a crucial role in providing safe and versatile access solutions for construction and industrial projects. These towers, also known as construction scaffolding, aluminum scaffolding, mobile scaffold towers, and adjustable scaffolding, offer reliable support and enable workers to perform tasks at various heights. Designed to withstand heavy-duty use, scaffold towers are an integral part of scaffolding systems, ensuring the safety and efficiency of workers in different work environments.

Key Takeaways:

- Scaffold towers are essential for safe and effective access in construction and industrial projects.

- They come in various types such as construction scaffolding, aluminum scaffolding, mobile scaffold towers, and adjustable scaffolding.

- Scaffold towers are designed to withstand heavy-duty use and provide reliable support for workers.

- These towers are an integral part of scaffolding systems and ensure worker safety at different heights.

- Choosing the right scaffold tower is crucial for optimal results and efficient work at height.

A Wide Selection of Scaffold Towers for Sale

When it comes to purchasing scaffold towers, there is no shortage of options available. Reputable suppliers like TheScaffoldWarehouse.com and ScaffoldExpress.com offer a wide selection of scaffold towers for sale, ensuring that customers can find the perfect solution for their needs. Whether you are a professional contractor or a DIY enthusiast, these websites have got you covered.

At TheScaffoldWarehouse.com and ScaffoldExpress.com, you can explore a diverse range of scaffold towers, designed to meet different requirements. From non-rolling towers to specialized designs for specific applications, you’ll find everything you need in one place.

One of the major advantages of shopping for scaffold towers online is the ability to choose from different sizes, configurations, and features. The wide selection allows you to find the scaffold tower that perfectly suits your project. Whether you need a compact tower for small-scale tasks or a heavy-duty tower for more demanding projects, these suppliers have the options to meet your needs.

Competitive prices and reliable shipping options are additional benefits of purchasing from these reputable suppliers. You can find high-quality scaffold towers at affordable prices, without compromising on safety or performance. With fast and efficient shipping, your scaffold tower will be at your doorstep in no time, ready to support your work at height.

So, whether you are in the market for a construction scaffolding tower, an aluminum scaffold tower, a mobile scaffold tower, or an adjustable scaffolding tower, look no further than TheScaffoldWarehouse.com and ScaffoldExpress.com. With their wide selection, competitive prices, and reliable shipping, you can be sure that you’re making a smart choice for your access needs.

Features and Benefits of Scaffold Towers

Scaffold towers are an essential tool in construction and industrial projects, offering a wide range of features and benefits that contribute to their popularity. These towers are designed with the utmost consideration for safety guidelines, ensuring a secure work environment and minimizing accidents. Let’s explore some key features and benefits that make scaffold towers a preferred choice:

1. Lightweight and Portable

Scaffold towers are constructed using lightweight materials, such as aluminum, which make them easy to transport and assemble. Their lightweight nature allows workers to move them around the worksite effortlessly, improving productivity and efficiency. Additionally, the portability feature enables quick set-up and dismantling, saving valuable time on project timelines.

2. Durable and Sturdy

Safety is paramount when working at heights, which is why scaffold towers are engineered to be highly durable and sturdy. They are built to withstand heavy loads, ensuring a stable and secure platform for workers. The robust construction of scaffold towers not only enhances safety but also provides long-lasting reliability, eliminating the need for frequent replacements.

3. Versatile and Adjustable

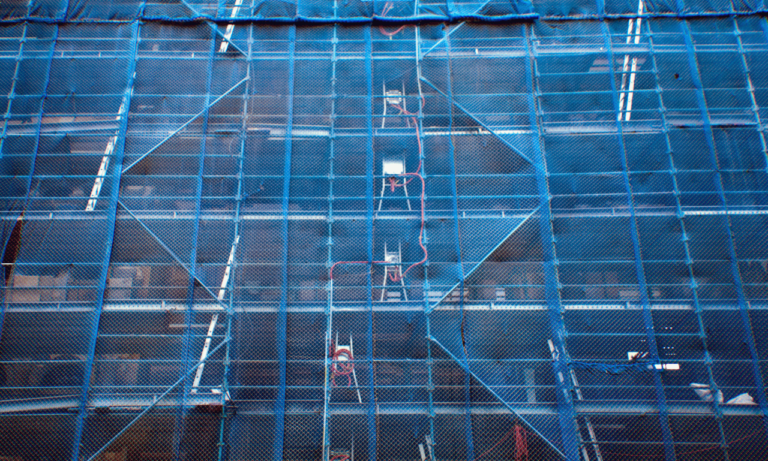

Scaffold towers offer great versatility, allowing for customization based on project requirements. They come with adjustable heights, enabling workers to access different levels and work comfortably at various elevations. To further enhance functionality, scaffold towers accommodate various accessories such as guardrails, toe boards, and platform extensions, ensuring maximum safety and convenience.

4. Compliance with Safety Guidelines

Scaffold towers are designed and manufactured in compliance with stringent safety guidelines provided by industry authorities and manufacturers. These guidelines outline crucial safety measures, such as weight limits, load distribution, and proper assembly procedures. Adhering to safety guidelines is vital to ensure the effective and safe use of scaffold towers.

5. Increased Productivity

By utilizing scaffold towers, workers can gain efficient and convenient access to different areas of the worksite. With a stable platform at various heights, tasks can be performed with greater ease, resulting in increased productivity. Scaffold towers enable workers to work comfortably and securely, reducing downtime and minimizing project delays.

Overall, scaffold towers offer an array of features and benefits that contribute to their valuable role in construction and industrial projects. From their lightweight design and durability to their versatility and compliance with safety guidelines, scaffold towers are a safe and effective solution for accessing heights. Integrating scaffold towers into worksites promotes a heightened level of efficiency, productivity, and, most importantly, worker safety.

Different Materials Used in Scaffold Towers

Scaffold towers are constructed using different materials, including aluminum, fiberglass, and steel. Each material has its own advantages and considerations when choosing a scaffold tower for a specific project.

Aluminum Scaffold Towers

Aluminum scaffold towers are popular in the industry due to their lightweight yet strong properties. They offer the perfect balance between portability and durability. These towers are resistant to rust and corrosion, making them ideal for outdoor use. The lightweight design enables easy transportation and assembly, making them a practical choice for projects that require frequent tower repositioning.

Fiberglass Scaffold Towers

Fiberglass scaffold towers are an excellent choice when it comes to electrical safety. They are non-conductive, providing protection against accidental electrocution. This makes fiberglass scaffold towers ideal for projects involving electricity or where there is a risk of exposure to electrical currents. Although slightly heavier than aluminum towers, their high visibility and excellent electrical safety features make them a preferred choice for specialized projects.

Steel Scaffold Towers

Steel scaffold towers are known for their strength and durability. They are specifically designed to withstand demanding environments and heavy loads. Steel towers provide exceptional stability and a robust platform for workers to perform tasks at heights. While steel scaffold towers may be heavier and require extra care to prevent rust, they are often the most suitable option for industrial and heavy-duty applications.

Material Comparison

| Material | Advantages | Considerations |

|---|---|---|

| Aluminum | – Lightweight and portable – Resistant to rust and corrosion | – May not be suitable for extremely heavy loads |

| Fiberglass | – Non-conductive and electrically safe – High visibility | – Heavier compared to aluminum towers |

| Steel | – Strong and durable – Suitable for demanding environments | – Requires extra care to prevent rust – Heavier than aluminum and fiberglass towers |

Considering the advantages and considerations of each material will help determine the most appropriate scaffold tower for a specific project, ensuring both safety and efficiency.

Scaffold Tower Safety Importance and Risks

Safety is paramount when it comes to working with scaffold towers. Inappropriate assembly and misuse can lead to avoidable accidents and injuries. That’s why conducting a thorough risk assessment before assembling and using a scaffold tower is crucial. By identifying potential hazards and taking necessary precautions, workers can mitigate risks and ensure a safe working environment.

There are several risks associated with working at height using scaffold towers. Falling from a height is the most obvious and serious risk, but it’s not the only one. Workers can also be injured during the assembly or disassembly process, putting them at risk of slips, trips, and falls. Additionally, there is a risk of injury from falling objects, which can cause severe harm if proper precautions are not taken. Manual handling injuries are also a potential risk, especially when lifting heavy materials or equipment onto the scaffold tower.

Proper planning, comprehensive training, and adherence to safety guidelines are essential for preventing accidents and ensuring the safety of workers. Before using a scaffold tower, it is crucial to develop a detailed plan that includes risk assessments, identifying potential hazards, and implementing appropriate control measures. Workers should undergo thorough training on scaffold tower assembly, usage, and safety protocols to familiarize themselves with best practices.

Implementing safety guidelines is crucial during the entire process of working with scaffold towers. This includes following weight limits and load distribution guidelines, inspecting the tower before each use, and using personal protective equipment (PPE) such as helmets, safety harnesses, and non-slip footwear. Regular maintenance and inspections of the scaffold tower are also necessary to ensure its integrity and safe operation.

| Common risks of working at height with scaffold towers | Precautions to mitigate risks |

|---|---|

| Falling from a height | Ensure proper assembly and secure anchoring of the scaffold tower. Use guardrails, toe boards, and safety harnesses to prevent falls. |

| Injury during assembly or disassembly | Train workers on proper assembly and disassembly techniques. Follow manufacturer’s instructions carefully and use appropriate tools and equipment. |

| Injury from falling objects | Implement safety measures such as debris nets, tool lanyards, and barricades to prevent objects from falling off the scaffold tower. |

| Manual handling injuries | Provide training on safe lifting techniques and use mechanical aids when handling heavy materials on the scaffold tower. |

By prioritizing scaffold tower safety and taking proactive measures to mitigate risks, workers can carry out their tasks efficiently and confidently. A safe working environment not only protects workers from harm but also contributes to increased productivity and successful project outcomes.

Types and Sizes of Scaffold Towers

Scaffold towers are available in a wide variety of types and sizes to accommodate different project requirements. The specific task at hand, such as plastering, roofing, or guttering, determines the type of scaffold tower needed. Additionally, scaffold towers are available in various sizes to suit the scale of the project.

For smaller projects, single-story scaffold towers are suitable. These towers provide a safe and stable platform for workers to access heights. On the other hand, larger projects require multi-story scaffold towers, which offer the necessary height and stability for taller buildings.

The standard width for a single scaffold tower is 1.8m, ensuring ample space for workers to move and perform their tasks. Heights of scaffold towers typically range from 2.2m to 11.7m, with adjustable options available to meet specific project needs.

In addition, double-width platforms and bespoke options are available for projects that require a larger working area or custom configurations. These options provide the flexibility required to optimize productivity and ensure safe work practices.

Choosing the right type and size of scaffold tower is crucial to ensure safe and efficient work at height. By selecting the appropriate scaffold tower based on project requirements, workers can enhance productivity and carry out their tasks with utmost safety.

Material Considerations for Scaffold Towers

When selecting a scaffold tower, it is important to consider the material used. Different materials offer unique features and considerations that can impact the suitability of the tower for your specific project needs.

1. Aluminum Scaffold Towers

Aluminum scaffold towers are a popular choice due to their affordability, lightweight nature, and versatility. They offer excellent strength-to-weight ratio, making them suitable for various projects. Additionally, aluminum towers are resistant to rust and corrosion, making them ideal for outdoor use. However, it is important to note that aluminum scaffold towers may take longer to assemble and disassemble compared to other materials. Furthermore, they are electrically conductive, which poses certain safety considerations when working around electrical equipment or in electrical environments.

2. Fiberglass Scaffold Towers

Fiberglass scaffold towers are known for their electrical safety properties and high visibility. They are non-conductive, providing added protection when working in close proximity to electrical installations. Additionally, the bright color of fiberglass towers enhances visibility on worksites, improving overall safety. However, it is important to consider that fiberglass towers tend to be heavier and more expensive compared to other materials. The additional weight can impact the ease of transportation and assembly, especially for larger towers.

3. Steel Scaffold Towers

Steel scaffold towers offer exceptional strength and durability, making them suitable for demanding environments. They can handle heavy loads and withstand rigorous use, providing a stable and secure platform for workers. Steel towers are also the most cost-effective option, offering excellent value for money. However, it is important to note that steel scaffold towers require regular maintenance to prevent rust and corrosion. Adequate care and protective measures must be implemented to ensure the longevity and safety of steel towers.

Evaluating the specific requirements of your project and considering factors such as material weight, cost, and electrical safety will help determine the appropriate material for your scaffold tower. By making an informed decision, you can ensure the safety and efficiency of your work at height.

Importance of Proper Planning and Training

When it comes to working with scaffold towers, proper planning and training are essential. Taking the time to plan and organize tasks involving work at height can greatly enhance safety and productivity on the worksite. Here are some key considerations to keep in mind:

Planning for Success

- Ensure that the ground where the scaffold tower will be erected is suitable and stable.

- Identify competent personnel who will be responsible for assembling, disassembling, and using the scaffold tower.

- Create a detailed plan that includes the necessary safety measures and precautions for the specific project.

- Adhere to the manufacturer’s instructions and guidelines for the scaffold tower to ensure proper usage.

Training for Safety

Proper training is essential for all workers involved in working with scaffold towers. This training should cover the following:

- Assembly and disassembly of the scaffold tower to ensure it is done correctly and safely.

- Usage of the scaffold tower, including best practices for working at height and the proper use of safety equipment.

- Pre-use inspections to identify any potential issues or hazards before starting work.

- Adherence to safety guidelines, such as weight limits and load distribution, to prevent overloading and instability.

By prioritizing proper planning and training, workers can significantly minimize the risk of accidents and ensure the safe and efficient use of scaffold towers. It is important to empower workers with the knowledge and skills needed to work at height safely and responsibly.

| Benefits of Proper Planning and Training | Examples |

|---|---|

| Enhanced Safety | Reduced risk of accidents and injuries |

| Optimized Efficiency | Streamlined processes and workflows |

| Compliance with Regulations | Meeting legal requirements and industry standards |

| Increased Productivity | Minimizing downtime and maximizing output |

| Cost Savings | Avoiding unnecessary repairs and replacements |

Reliable Suppliers of Scaffold Towers

When it comes to purchasing scaffold towers, it’s crucial to choose reliable suppliers who offer high-quality products and excellent customer service. This ensures that you have access to top-notch scaffold towers that meet your project requirements. Two reputable suppliers in the industry are TheScaffoldWarehouse.com and ScaffoldExpress.com.

TheScaffoldWarehouse.com provides a wide range of scaffold towers for sale, offering a variety of options to suit different project needs. Their scaffold towers are manufactured with precision and adhere to the highest safety standards, ensuring reliability and durability. With competitive prices and a user-friendly website, TheScaffoldWarehouse.com makes it convenient to find and purchase the scaffold towers you require.

ScaffoldExpress.com is another trusted supplier that specializes in scaffold towers. They offer an extensive selection of high-quality towers designed for various applications. ScaffoldExpress.com prides itself on delivering reliable shipping options, ensuring that your scaffold towers reach you promptly and in excellent condition. Their team of experts can assist you in selecting the right tower for your specific project, providing personalized recommendations based on your requirements.

Benefits of Choosing Reliable Suppliers

Opting for reliable suppliers like TheScaffoldWarehouse.com and ScaffoldExpress.com comes with several advantages. Firstly, you can have peace of mind knowing that you are purchasing scaffold towers from reputable sources. These suppliers prioritize quality, ensuring that their products meet industry standards and regulations.

In addition to high-quality products, reliable suppliers also provide comprehensive safety guidelines. These guidelines help you understand how to assemble, use, and maintain scaffold towers safely, minimizing the risk of accidents. They prioritize your safety and provide the necessary resources to ensure that you and your team can work confidently and securely at height.

Customer service is another crucial aspect of working with reliable suppliers. TheScaffoldWarehouse.com and ScaffoldExpress.com have a dedicated support team who can assist you throughout your purchasing journey. From addressing your inquiries and concerns to offering after-sales support, they are committed to ensuring customer satisfaction.

Why Choose TheScaffoldWarehouse.com and ScaffoldExpress.com

There are several reasons why TheScaffoldWarehouse.com and ScaffoldExpress.com stand out as reliable suppliers of scaffold towers. Firstly, their wide selection of scaffold towers allows you to choose the perfect tower for your project, whether you’re working in construction, maintenance, or any other industry that requires safe access solutions.

Competitive prices are another advantage of choosing these suppliers. They strive to offer affordable scaffold towers without compromising on quality. This makes it easier for you to obtain the scaffold towers you need within your budget.

Reliable shipping options ensure that you can receive your scaffold towers in a timely manner. Whether you’re working on a tight project deadline or planning a long-term construction project, TheScaffoldWarehouse.com and ScaffoldExpress.com take pride in delivering on time, ensuring that your project progresses smoothly.

Affordable Scaffold Tower Solutions

The table below showcases a comparison of scaffold tower prices from TheScaffoldWarehouse.com and ScaffoldExpress.com for a standard 1.8m width tower.

| Supplier | Price |

|---|---|

| TheScaffoldWarehouse.com | $500 |

| ScaffoldExpress.com | $550 |

As shown in the table, both suppliers offer affordable scaffold tower solutions, with TheScaffoldWarehouse.com providing a slightly lower price. However, it’s important to consider factors beyond price, such as product quality, customer service, and shipping options, when making your purchasing decision.

Conclusion

Scaffold towers play a crucial role in providing safe and versatile access solutions for construction and industrial projects. These towers are essential for enabling workers to perform tasks at various heights, ensuring efficient and secure work at height. To maximize the benefits of scaffold towers, it is important to choose the right tower by considering factors such as material, type, size, and safety guidelines.

Prioritizing safety is paramount when working with scaffold towers. Proper planning, training, and adherence to manufacturer’s instructions are key to preventing accidents and ensuring the well-being of workers. By investing in high-quality scaffold towers from reliable suppliers, project managers can create a safe and optimized worksite.

In summary, scaffold towers are indispensable tools for safe access solutions. By selecting the appropriate tower, following safety guidelines, and partnering with reputable suppliers, construction and industrial projects can be executed efficiently and successfully. The investment in scaffold towers goes beyond providing access; it ultimately contributes to the overall safety and productivity of the worksite.

FAQ

Why are scaffold towers essential for construction and industrial projects?

Scaffold towers provide safe and versatile access solutions for workers to perform tasks at various heights.

Where can I find scaffold towers for sale?

Reputable suppliers like TheScaffoldWarehouse.com and ScaffoldExpress.com offer a wide selection of scaffold towers for sale.

What are the features and benefits of scaffold towers?

Scaffold towers are lightweight, durable, and versatile, offering adjustable heights and various accessories for enhanced functionality and safety.

What materials are used in scaffold towers?

Scaffold towers can be constructed using aluminum, fiberglass, or steel, each with its own advantages and considerations.

Why is safety important when using scaffold towers?

Inappropriate assembly and misuse of scaffold towers can lead to accidents and injuries. Safety guidelines should be followed to ensure safe and effective use.

What types and sizes of scaffold towers are available?

Scaffold towers come in various types, suitable for different tasks such as plastering, roofing, or guttering. Different sizes are also available, from single-story to multi-story towers.

What should I consider when choosing the material for a scaffold tower?

The material used in scaffold towers, such as aluminum, fiberglass, or steel, should be chosen based on factors like weight, cost, and electrical safety.

Why is proper planning and training important when working with scaffold towers?

Proper planning and training ensure safe assembly, usage, and adherence to safety guidelines, minimizing the risk of accidents.

Where can I find reliable suppliers of scaffold towers?

Reputable suppliers like TheScaffoldWarehouse.com and ScaffoldExpress.com offer high-quality scaffold towers and excellent customer service.

Why are scaffold towers essential for safe access solutions?

Scaffold towers provide a safe and reliable platform for workers to perform tasks at various heights, enhancing productivity and project outcomes.