Phone:

(+65)8319-0742

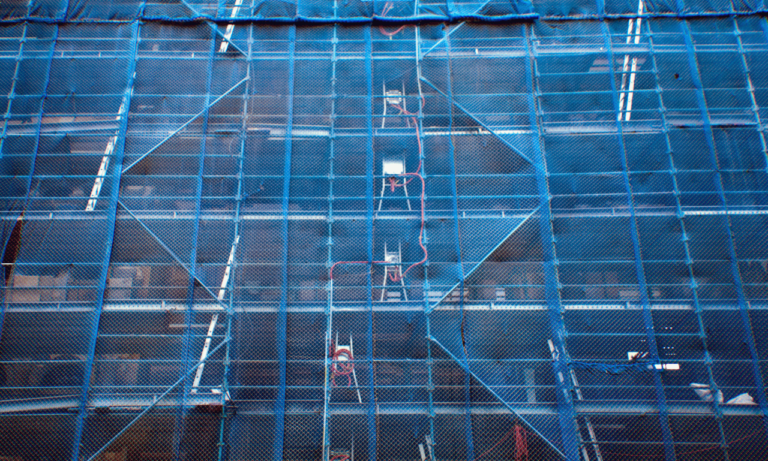

When it comes to construction projects or industrial applications that require working at heights, using the right scaffolding system is crucial for ensuring safety and efficiency. That’s where Hoist Towers Scaffolding comes in. As a trusted supplier of scaffolding solutions, Hoist Towers provides reliable tower scaffolding and construction hoist services to meet your specific needs.

Whether you require scaffolding rental for a short-term project or need a trusted partner for long-term scaffolding services, Hoist Towers is here to provide you with the highest quality industrial scaffolding. With their expertise and commitment to safety, you can rest assured that your scaffolding needs will be met with the utmost professionalism and adherence to industry standards.

Key Takeaways:

- Hoist Towers Scaffolding offers reliable tower scaffolding and construction hoist services.

- They provide scaffolding solutions for both short-term rentals and long-term projects.

- Hoist Towers prioritizes safety and adheres to industry standards.

- Their industrial scaffolding is of the highest quality and reliability.

- Count on Hoist Towers for all your scaffolding needs.

Importance of Scaffolding Safety

Scaffolding safety is a critical aspect of any construction or industrial project to prevent preventable accidents and ensure the well-being of workers. According to industry statistics, incidents related to scaffolding account for numerous injuries each year, leading to financial burdens and potential fines for companies.

One of the fundamental safety measures in scaffold work is the use of personal protective equipment (PPE). Workers should wear hard hats and utilize fall arrest equipment to mitigate the risk of falls or head injuries when working at heights.

To maintain the integrity of scaffolding structures and avoid overloading, it is essential to adhere to specified load-bearing capacities. Complying with scaffolding regulations provides clear guidelines to prevent structural failures and accidents.

Prior to scaffold setup, conducting a thorough equipment inspection is vital to ensure the materials’ quality and integrity. Inspecting each component and following the manufacturer’s instructions during assembly enhances safety during scaffold operations.

Creating a safe work environment is crucial for scaffolding safety. This includes maintaining work area safety by ensuring a clutter-free space, providing adequate lighting, and implementing proper housekeeping practices.

Effective training programs play a pivotal role in promoting scaffolding safety. Workers should receive comprehensive training on scaffold usage, including safe climbing practices and adherence to proper tagging systems for scaffold identification.

By prioritizing scaffolding safety through the use of appropriate personal protective equipment, adhering to load-bearing capacities and regulations, conducting thorough inspections, following manufacturer’s instructions, ensuring work area safety, and providing comprehensive training, companies can prevent avoidable accidents and create a safer working environment for their employees.

Scaffold Types and Scaffolding Safety

When it comes to scaffolding, there are three main types that are commonly used in construction: supported scaffolds, suspended scaffolds, and machinery scaffolds. Each type requires specific safety considerations and precautions to ensure the well-being of workers and the structural integrity of the scaffold.

Supported Scaffolds

Supported scaffolds, also known as frame or system scaffolds, are commonly used in construction projects. They consist of a series of platforms supported by rigid tubular frames. Supported scaffolds are typically erected from the ground up and rely on a solid foundation to provide stability.

Suspended Scaffolds

Suspended scaffolds, on the other hand, are suspended from the top of a building or structure using ropes, cables, or other suspension devices. These types of scaffolds are often used for tasks that require workers to access upper levels of a building, such as painting or window cleaning. It is crucial to ensure that the suspension devices are properly installed and maintained to prevent accidents.

Machinery Scaffolds

Machinery scaffolds, also known as rolling or mobile scaffolds, are designed with casters or wheels that allow for easy movement. These scaffolds are often used for tasks that require frequent repositioning, such as electrical or plumbing work. It is important to ensure that the scaffold is stable and secure before allowing workers to use it.

Regardless of the scaffold type, it is important to have a competent person overseeing the construction and usage of the scaffold. A competent person is trained to identify potential hazards and take corrective measures to ensure worker safety. Additionally, a qualified person with relevant expertise should provide training on safe scaffold usage to all workers involved.

Regular inspections by competent individuals are crucial to identify and resolve any issues that may compromise scaffold safety. Compliance with standards and regulations, such as those set by the Occupational Safety and Health Administration (OSHA), is vital to ensure scaffold safety and prevent accidents or injuries.

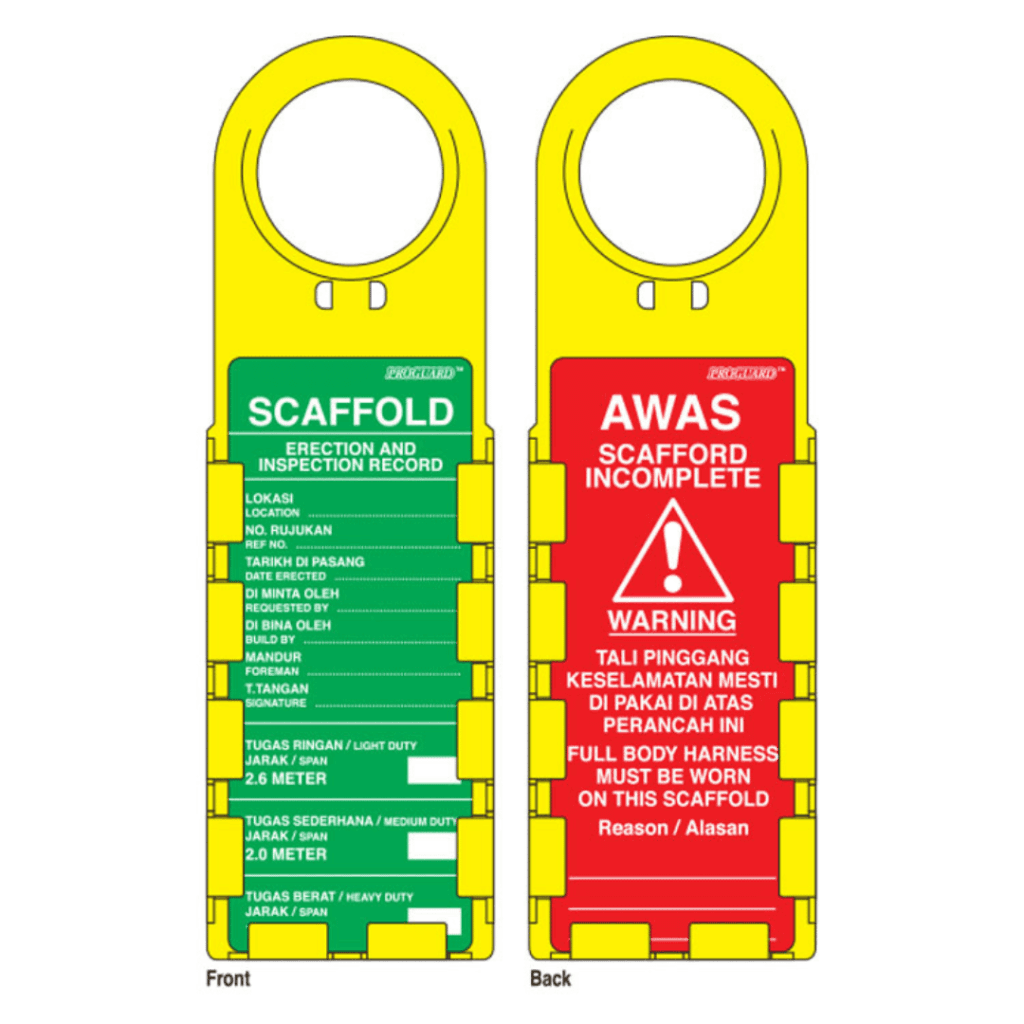

One important aspect of scaffold safety is the use of scaffold identification tags. These tags are used to indicate whether a scaffold is safe or unsafe for use. Green tags indicate that the scaffold has been inspected and is safe to use. Yellow tags highlight modifications or special precautions that need to be taken. Red tags signify that the scaffold is unsafe and should not be used until the necessary repairs or adjustments have been made.

| Scaffold Identification Tag | Meaning |

|---|---|

| Green | Safe to use, inspected |

| Yellow | Modifications or special precautions |

| Red | Unsafe, repairs needed |

By understanding the different scaffold types and implementing proper safety measures, workers can carry out their tasks with confidence, minimizing the risk of accidents and ensuring a safe working environment.

Scaffolding Safety Dos

To ensure the safety of scaffold operations, it is crucial to adhere to several important practices:

1. Conduct Regular Scaffold Inspection

Before starting each work shift, thoroughly inspect the scaffold to ensure its structural integrity. Check for any signs of damage, loose components, or missing parts. This inspection will help identify potential hazards and prevent accidents during scaffold usage.

2. Provide Proper Training and Toolbox Talks

Train all workers involved in scaffold operations on safety protocols and best practices. Conduct regular toolbox talks to reinforce safety procedures and address any concerns or questions. Proper training and communication are key to promoting a culture of safety and preventing accidents.

3. Use Appropriate Personal Protective Equipment (PPE)

Equip all workers with the necessary personal protective equipment. This includes helmets, safety harnesses, safety belts, and slip-resistant footwear. The use of PPE minimizes the risk of injury in case of falls or accidents and provides additional protection on the scaffold.

4. Check Inspection Tags

Always verify the inspection tags on the scaffold before use. These tags indicate the scaffold’s safety status and whether it has undergone necessary inspections. Ensuring that the scaffold is properly inspected and deemed safe by a competent person is crucial for worker safety.

5. Be Mindful of Load Capacity

Adhere to the recommended load capacity of the scaffold at all times. Overloading the scaffold can compromise its stability and increase the risk of collapse. Ensure that workers and materials do not exceed the specified weight limits to maintain a safe working environment.

6. Provide Handholds for Stability

Ensure that there is a secure handhold above the scaffold platform to provide stability and support for workers. Handholds should be easily accessible and strategically placed to assist workers in maintaining balance and preventing falls.

7. Level the Scaffold

After each move, ensure that the scaffold is leveled and properly positioned. Uneven or unstable scaffolds can lead to accidents and injuries. Use proper leveling techniques to ensure a stable working platform.

8. Use Safety Belts and Ladders

When working at heights on the scaffold, always use safety belts and lanyards to prevent falls. Ladders should be used to access and exit the scaffold safely. Ramps or stair towers can also provide safe access to elevated platforms.

9. Maintain Cleanliness on the Scaffold

Keep the scaffold clear of debris, materials, and tools to prevent tripping hazards. Regularly clean the scaffold to maintain a safe and organized working environment. A clean scaffold promotes better visibility and reduces the risk of accidents.

10. Monitor Weather Conditions

Avoid working on scaffolds during adverse weather conditions such as strong winds, heavy rain, or snowfall. Unfavorable weather can increase the risk of accidents and compromise scaffold stability. Always prioritize worker safety and postpone scaffold operations if necessary.

11. Work with Licensed Staff

Ensure that all personnel involved in scaffold operations are properly trained, licensed, and authorized. Working with licensed and experienced staff helps ensure compliance with safety standards and regulations. Their knowledge and expertise contribute to maintaining a safe working environment.

12. Maintain Three Points of Contact

When climbing or descending the scaffold, always maintain three points of contact for added stability. This means using both hands and one foot or both feet and one hand while maneuvering on the scaffold. Three-point contact reduces the risk of slipping or losing balance.

By following these scaffolding safety dos, employers can create a safer work environment and protect workers from potential accidents or injuries.

Scaffolding Safety Don'ts

To ensure the safety of workers and prevent accidents, it is important to be aware of the scaffolding safety don’ts. By avoiding these common mistakes and following proper safety guidelines, you can minimize the risks associated with scaffolding work.

1. Scaffold Overload

Avoid overloading scaffolds beyond their load capacity to prevent structural failure and potential accidents. Adhere to the weight limits specified by the scaffold manufacturer and ensure that the load is distributed evenly.

2. Red Tag Scaffolding

Do not use scaffolds with red tags, as they indicate unsafe conditions. Red tags are typically placed on scaffolds that have not been properly inspected or have known safety issues. Always use scaffolds with green tags indicating that they are safe for use.

3. Moving Scaffold While Occupied

Never move a scaffold while workers or materials are still on the platform. Ensure that the scaffold is securely positioned and stable before any movement is attempted. This will prevent accidents and injuries that can occur due to unexpected platform shifts.

4. Unstable Scaffold Bases

Before using a scaffold, ensure that the bases are stable and level. Unstable bases can lead to scaffold tipping or collapse, posing serious risks to workers. Use proper leveling techniques and ensure that the scaffold is securely anchored to prevent any movement.

5. Makeshift Components

Avoid using makeshift components or making unauthorized modifications to the scaffold. Only use components that are specifically designed and approved for use with the scaffold system. Making unauthorized modifications can compromise the integrity and stability of the scaffold, increasing the risk of accidents.

6. Unattended Scaffold

Do not leave scaffolds unattended for extended periods. Unattended scaffolds may be accessed by unauthorized personnel or be subjected to adverse weather conditions, increasing the risk of accidents. Properly secure and lock the scaffold when not in use.

7. Adverse Weather Conditions

Avoid using scaffolds during adverse weather conditions, such as high winds or heavy rain. These conditions can make the scaffold unstable and increase the risk of falls and accidents. Monitor weather forecasts closely and plan scaffold work accordingly.

8. Climbing Scaffold Frames

Refrain from climbing on scaffold frames or other components that are not intended for climbing. Scaffold frames may not be designed to support the weight or movement of workers, posing risks of falls and structural damage.

9. Throwing Objects from Scaffold

Never throw objects from the scaffold without proper precautions. Falling objects can cause injuries to workers below or disrupt work in progress. Use tool lanyards and secure all tools and equipment to prevent accidental drops.

10. Moving Mobile Scaffold with People Onboard

Avoid moving mobile scaffolds if anyone is onboard. Moving a scaffold with people still on the platform can lead to accidents and injuries. Ensure that all workers have safely disembarked before any movement of the scaffold takes place.

By following these scaffolding safety don’ts, you can create a safer work environment and minimize the risks associated with scaffolding operations.

Tips for Using Scaffolding Properly

When it comes to using scaffolding, following proper procedures is crucial for safety and efficiency. By incorporating these tips into your workflow, you can ensure a smooth and secure scaffold setup:

Barricading the Scaffold Area

Prior to starting any scaffolding work, it’s important to barricade the area to prevent unauthorized access and ensure the safety of workers and bystanders.

Validating Parts

Before assembly, carefully inspect and validate all scaffold parts to ensure they are in good condition and meet safety regulations.

Aligning the Scaffold

Proper alignment of the scaffold with the building is essential for stability and load distribution. Take the time to align the scaffold correctly before proceeding.

Proper Assembly

Follow the manufacturer’s instructions for proper assembly, ensuring that all components are securely connected and in the correct position.

Adjusting Baseplates

Adjust the baseplates to ensure a level and secure foundation for the scaffold. This will help prevent instability and ensure worker safety.

Erecting the First Bay

Erect the first bay of the scaffold by attaching vertical and horizontal components, making sure they are correctly aligned and securely fastened.

Leveling the Scaffold

After each bay is erected, carefully level the scaffold to maintain stability and prevent tilting or leaning.

Measuring Diagonal Dimensions

Take accurate measurements of the scaffold’s diagonal dimensions to ensure squareness, which is crucial for a stable and secure structure.

Creating Working Platforms

Create working platforms by arranging planks and adding upper ledgers and transoms. Ensure that they are securely fastened and can support the intended load.

Setting Up Access Bays

Establish access points to the scaffold by setting up stairs or ladders at strategic locations. This will allow workers to enter and exit the scaffold safely.

Adding Braces and Returns

Provide additional support and stability to the scaffold by adding braces and returns at appropriate intervals. These components help distribute loads and prevent sagging or swaying.

Longitudinal Braces

Install longitudinal braces to counteract horizontal forces and enhance the overall strength and stability of the scaffold.

Toeboards

Attach toeboards along the edges of the working platforms to prevent tools, materials, or debris from falling off the scaffold, ensuring a safer work environment.

Stairs

Install stairs at suitable locations to provide efficient access to different levels of the scaffold. Ensure that the stairs are securely anchored and meet safety standards.

Working Platform Between Scaffold and Building

Set up a secure working platform between the scaffold and the building, ensuring a safe and stable surface for workers to perform their tasks.

Scaffold Inspection

Before using the scaffold, perform a thorough inspection to verify its safety and structural integrity. Pay attention to all components, connections, and overall stability.

By following these tips, you can ensure the proper use of scaffolding and create a safe and secure working environment for all involved.

Scaffolding Safety Training

Scaffolding safety training is crucial for equipping workers with the necessary skills and knowledge to ensure their safety when working with scaffolds. This training provides practical lessons that enable workers to understand the potential hazards and risks involved in scaffold work, and how to mitigate them effectively.

By undergoing scaffold safety training, workers gain essential knowledge on how to protect themselves and others from injuries. They learn about the proper use of personal protective equipment (PPE), such as helmets, harnesses, and safety shoes, which provide vital protection against potential hazards.

Moreover, scaffold safety training emphasizes compliance with standards and regulations to ensure a safe working environment. Workers learn about the importance of adhering to local regulatory standards and guidelines, which play a significant role in preventing accidents and ensuring the overall safety of scaffold operations.

Competent person inspections are another crucial aspect covered in scaffolding safety training. Workers are educated on the significance of regular inspections carried out by qualified individuals. These inspections help identify any potential hazards or issues related to the scaffolding structure, ensuring its integrity and the safety of workers.

Proper and adequate scaffold safety training provides workers with the necessary knowledge and skills to recognize and control scaffolding hazards. It empowers them to create a safe and secure work environment, reducing the likelihood of accidents and injuries.

In conclusion, scaffolding safety training is essential for protecting workers and preventing accidents. It equips them with the necessary practical knowledge to identify potential hazards, comply with safety standards, and perform competent person inspections. By providing adequate scaffold safety training, companies can ensure the well-being of their workers and maintain a safe work environment.

Scaffolding Tagging

Scaffold tags play a crucial role in ensuring the safety of scaffolds and the workers who use them. Competent persons perform regular inspections and tag the scaffolds accordingly, providing a clear indication of their safety status.

When inspecting scaffolds, the competent person assigns each scaffold an identification tag number, which is recorded for future reference. This helps track the history of the scaffold and ensures that it undergoes the necessary inspections.

The tags themselves come in different colors, with each color representing a specific safety status. Green scaffold tags indicate that the scaffold has undergone a competent person inspection and is safe to use. These tags provide assurance to workers that they can proceed with their work without any immediate safety concerns.

Yellow scaffold tags are used when modifications or special precautions have been made to the scaffold. This could include temporary alterations or additional safety measures that need to be observed by workers. It is essential for workers to be aware of these modifications and take the necessary precautions while using the scaffold.

Red scaffold tags are placed on scaffolds that are deemed unsafe for use. This could be due to structural damage, missing components, or other identified risks. It is crucial for workers to recognize and respect red scaffold tags, as these clearly indicate that the scaffold must not be used until necessary repairs or modifications have been made.

In addition to tagging, several other safety measures enhance scaffold safety. Ground fault circuit interrupters (GFCIs) should be installed to protect workers from electrical hazards. Personal protective equipment, such as slip-resistant gloves and tool lanyards, should also be used to minimize the risk of accidents.

To maintain scaffold safety, regular inspections should be conducted to identify any potential damage or defects. Inspecting scaffolds for damage, including signs of wear and tear, is essential to ensure their structural integrity and prevent accidents.

It is also important to maintain a safe distance from heavy equipment while working on scaffolds. Heavy equipment can cause unintended damage or collapse if it comes into contact with the scaffold. By maintaining a safe distance, workers can minimize the risk of accidents and injuries.

| Scaffold Tag Colors | Meaning |

|---|---|

| Green | The scaffold has undergone a competent person inspection and is safe to use. |

| Yellow | Modifications or special precautions have been made to the scaffold. |

| Red | The scaffold is unsafe for use and must not be used until necessary repairs or modifications have been made. |

Maintaining Scaffolding Integrity

Ensuring the integrity of scaffolding structures is crucial for the safety of workers. Various factors can compromise the stability of scaffolds, including **scaffold damage**, **excessive weight**, and **forceful impacts**. Overloading scaffolds beyond their **weight limits** can lead to structural failure and potential accidents. Therefore, it is essential to adhere to the recommended load capacities of scaffolds.

Environmental elements can also weaken scaffolding structures over time. Rust caused by exposure to moisture and other corrosive elements can erode the scaffolding’s strength. Regular **inspections** are necessary to identify and address issues such as rust and **wear and tear**. By promptly addressing scaffolding damage, you can ensure the ongoing safety and stability of the structure.

In addition to avoiding damage and environmental effects, maintaining a **safe distance from heavy equipment** is critical for scaffolding integrity. Forceful impacts from nearby machinery can shake or dislodge scaffolding components, increasing the risk of collapse. By keeping a sufficient distance between scaffolding and heavy equipment, you minimize the chance of accidents caused by inadvertent contact or collision.

Regular inspections, adherence to weight limits, protection against **scaffold damage**, and maintaining a safe distance from heavy equipment are essential practices for preserving scaffolding integrity and ensuring the safety of workers.

Factors Affecting Scaffolding Integrity

| Factors | Impact on Scaffolding Integrity |

|---|---|

| **Scaffold damage** | Compromises the structural stability of scaffolds |

| **Excessive weight** | Can cause structural failure and collapse |

| **Forceful impacts** | Shakes or dislodges scaffolding components, increasing the risk of collapse |

| **Environmental elements** | Rust and other corrosive effects can weaken the structure over time |

| **Regular inspections** | Identify and address scaffolding damage and wear and tear |

| **Weight limits** | Adherence to recommended capacities ensures structural stability |

| **Safe distance from heavy equipment** | Prevents forceful impacts and accidental damage to the scaffold |

Setting Up Safe Distances

When working with scaffolding around heavy equipment, it is crucial to establish safe distances to ensure the safety of workers and prevent accidents. By maintaining proper distances and implementing appropriate safety measures, the risk of scaffolding collapse and other potential dangers can be minimized.

A minimum safe distance of at least 10 feet is recommended between scaffolding and heavy equipment. However, for larger vehicles with a greater swinging or reaching range, it is advisable to establish an exclusion zone of 20 feet. This larger zone provides a buffer to protect against inadvertent contact or collisions between the equipment and the scaffold.

To further enhance safety, the use of barriers should be considered. Barriers can act as a physical barrier between the scaffolding and nearby heavy equipment, reducing the risk of accidental contact and potential scaffold collapse. By effectively isolating the scaffold area, barriers help to create a safer working environment for all personnel involved.

It is important to note that the establishment of safe distances and the use of barriers should be based on a thorough assessment of the specific worksite conditions and the nature of the heavy equipment involved. Consultation with safety experts and adherence to safety guidelines and regulations are essential in determining the appropriate measures to ensure the well-being of workers and the integrity of the scaffolding structure.

By setting up safe distances, utilizing barriers, and implementing appropriate safety protocols, workers can carry out their tasks with confidence and reduce the risk of accidents caused by the proximity of heavy equipment to scaffolding structures.

| Benefits of Setting Safe Distances | Precautions for Heavy Equipment |

|---|---|

| ⢠Minimizes the risk of scaffolding collapse | ⢠Ensure heavy equipment operators are trained and experienced |

| ⢠Protects workers from potential accidents and injuries | ⢠Maintain regular equipment maintenance and inspections |

| ⢠Reduces the likelihood of accidental contact between scaffolding and heavy equipment | ⢠Follow proper signaling and communication protocols |

| ⢠Creates a safer work environment | ⢠Adhere to established safe distances and exclusion zones |

Conclusion

Ensuring scaffolding safety is vital for maintaining workplace safety and preventing accidents. By following the recommended dos and don’ts of scaffolding and implementing proper safety measures, such as using personal protective equipment and adhering to load capacity limits, accidents can be effectively prevented. Additionally, compliance with regulations, regular inspections, and providing proper training to workers are essential components of scaffolding safety.

By prioritizing safety in scaffolding operations, companies can create a safe working environment for all employees. Regular inspections help identify potential hazards and ensure compliance with safety regulations. Proper training equips workers with the knowledge and skills to mitigate risks associated with scaffolding work. This commitment to scaffolding safety not only protects workers from accidents but also helps companies avoid fines and legal repercussions.

In conclusion, incorporating scaffolding safety into daily work practices is crucial for accident prevention and compliance with regulations. By consistently implementing safety measures and providing ongoing training, companies can enhance workplace safety and protect the well-being of all employees involved in scaffolding operations.

FAQ

What are the key safety measures for scaffolding?

The key safety measures for scaffolding include using personal protective equipment, adhering to load-bearing capacities, following scaffolding regulations, conducting material inspections, ensuring a safe work area, and providing proper training for workers.

What are the different types of scaffolds?

The different types of scaffolds are supported scaffolds, suspended scaffolds, and machinery scaffolds. Each type requires specific safety considerations and precautions.

Why is scaffolding safety important in the workplace?

Scaffolding safety is important in the workplace to prevent accidents and injuries, comply with regulations, avoid financial burdens and potential fines, and ensure a safe working environment for all.

How can scaffolding integrity be compromised?

Scaffolding integrity can be compromised by factors such as excessive weight, forceful impacts, environmental elements like rust, and wear and tear over time.

What should be avoided when working with scaffolding?

When working with scaffolding, it is important to avoid overloading the scaffold, using scaffolds with red tags, moving the scaffold while occupied, working on unstable scaffold bases, using makeshift components, leaving scaffolds unattended, working in adverse weather conditions, climbing on scaffold frames not meant for climbing, throwing objects from the scaffold, and moving mobile scaffolds with people onboard.

How should scaffolding be set up properly?

To set up scaffolding properly, start by barricading the area, validating the parts, aligning the scaffold, assembling the first lift, erecting the bays, creating working platforms, setting up access bays and supports, installing guardrails, and conducting a thorough inspection before use.

Why is scaffolding safety training important?

Scaffolding safety training is important to equip workers with the necessary skills and knowledge to work safely with scaffolds, prevent accidents, comply with safety standards, and maintain a safe working environment.

How can scaffolding integrity be maintained?

Scaffolding integrity can be maintained by conducting regular inspections, adhering to weight limits, avoiding damage from heavy equipment, and addressing any wear and tear or damage promptly.

What should be the safe distance between scaffolding and heavy equipment?

A minimum distance of at least 10 feet is recommended between scaffolding and heavy equipment, with an exclusion zone of 20 feet for larger vehicles with a greater swinging or reaching range. The use of barriers is also advisable to prevent scaffolding collapse caused by nearby heavy equipment.

What are the key takeaways for scaffolding safety?

The key takeaways for scaffolding safety are to comply with safety regulations, conduct regular inspections, provide proper training, use personal protective equipment, adhere to load-bearing capacities, and maintain a safe work area.