Phone:

(+65)8319-0742

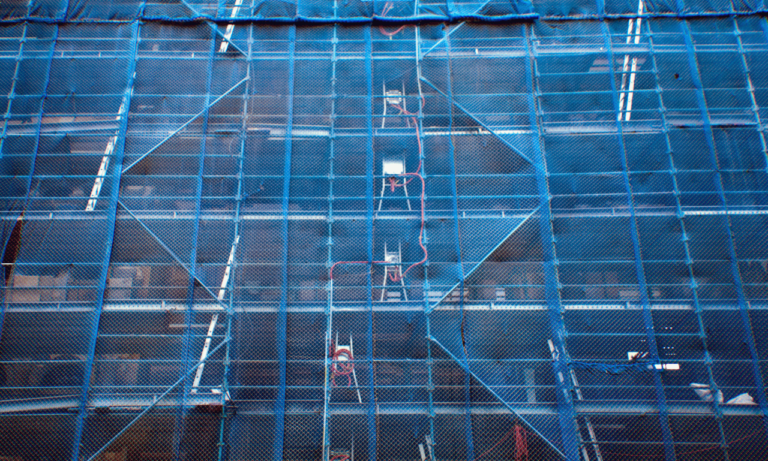

Tube and Clamp Scaffolding is a fast and versatile scaffold system that can replace or supplement traditional tubular steel scaffolding and other system scaffolds. It is easy to erect and is designed to be used in difficult or inaccessible areas. The system uses right angle and swivel clamps to join tubing members and can be built to accommodate uneven ground and complex shapes. The scaffolding is made of high-strength galvanized tubing and is available in various lengths.

Key Takeaways:

- Tube and Clamp Scaffolding is a versatile scaffold system that offers numerous advantages.

- It is easy to erect and can be used in difficult or inaccessible areas.

- The system uses right angle and swivel clamps to join tubing members.

- Tube and Clamp Scaffolding is made of high-strength galvanized tubing.

- It is available in various lengths to suit different project requirements.

Tube and Clamp Scaffolding Components and Models

Tube and Clamp Scaffolding is a versatile system that offers a variety of components and models to meet the specific needs of construction projects. These components are essential for connecting and stabilizing the scaffold structure. Additionally, the different models provide options for varying lengths, accommodating diverse project requirements. Let’s explore the key components and models of Tube and Clamp Scaffolding.

Scaffold Components

Tube and Clamp Scaffolding consists of several essential components:

- Right angle couplers: These couplers establish a right angle connection between two tubes, providing stability and structural support.

- Swivel couplers: Swivel couplers allow for the connection of tubes at various angles, facilitating flexibility in scaffold configurations.

- Base plates: Base plates form the foundation of the scaffold, ensuring stability on different types of surfaces.

- Wind clips: Wind clips enhance the safety of the scaffold by providing additional stability in windy conditions.

These components work together to create a robust and reliable scaffold system.

Scaffold Models

Tube and Clamp Scaffolding offers a range of models, each designed to accommodate specific lengths:

| Model | Length | Weight | Dimensions |

|---|---|---|---|

| VTC4 | 4 ft | 12 lbs | 48″ x 2″ x 2″ |

| VTC5 | 5 ft | 14.5 lbs | 60″ x 2″ x 2″ |

| VTC6 | 6 ft | 17 lbs | 72″ x 2″ x 2″ |

| VTC7 | 7 ft | 19.5 lbs | 84″ x 2″ x 2″ |

| VTC8 | 8 ft | 22 lbs | 96″ x 2″ x 2″ |

| VTC9 | 9 ft | 24.5 lbs | 108″ x 2″ x 2″ |

| VTC10 | 10 ft | 27 lbs | 120″ x 2″ x 2″ |

| VTC13 | 13 ft | 35.5 lbs | 156″ x 2″ x 2″ |

| VTC14 | 14 ft | 38 lbs | 168″ x 2″ x 2″ |

| VTC16 | 16 ft | 43 lbs | 192″ x 2″ x 2″ |

| VTC18 | 18 ft | 49 lbs | 216″ x 2″ x 2″ |

| VTC20 | 20 ft | 55 lbs | 240″ x 2″ x 2″ |

These models offer a range of options that can be tailored to meet the specific height requirements of construction projects.

The right combination of Tube and Clamp Scaffolding components and models provides a strong and adaptable scaffold system that can be customized to fit various construction scenarios.

Tube and Clamp Scaffold Accessories

Tube and Clamp Scaffold offers a range of accessories to enhance the functionality and safety of the scaffold system. These scaffold accessories are designed to provide additional stability, ease of assembly and disassembly, and a stable foundation for the scaffold. The following accessories are commonly used in tube and clamp scaffolding:

1. Wind Clips

Wind clips are essential accessories in tube and clamp scaffolding, especially in windy conditions. These clips attach securely to the scaffold structure, preventing movement and maintaining stability even in high winds. Wind clips ensure the safety of workers and the integrity of the scaffold system.

2. Tap'n Turn Wrenches

Tap’n Turn wrenches are indispensable tools for easy and efficient assembly and disassembly of tube and clamp scaffolding. These wrenches allow workers to quickly tighten or remove clamps, saving time and effort during scaffold construction and dismantling. The ergonomic design of the Tap’n Turn wrenches ensures comfortable handling and improved productivity.

3. Base Plates

Base plates play a crucial role in providing a stable foundation for tube and clamp scaffolding. These plates are placed at the bottom of scaffold standards or vertical posts, distributing the weight evenly and preventing sinking or tilting. The sturdy construction of base plates ensures the integrity and durability of the scaffold system.

By utilizing wind clips, Tap’n Turn wrenches, and base plates, tube and clamp scaffolding can be effectively enhanced for safety and convenience. These accessories are designed to optimize the performance and usability of the scaffold system, providing a reliable and efficient solution for construction projects.

| Accessory | Functionality |

|---|---|

| Wind Clips | Provide additional stability in windy conditions |

| Tap’n Turn Wrenches | Enable easy assembly and disassembly of the scaffold |

| Base Plates | Offer a stable foundation for the scaffold |

Benefits of Tube and Clamp Scaffolding

Tube and Clamp Scaffolding offers numerous benefits for construction and industrial projects. With its versatile nature, this scaffold system can adapt to various scenarios, making it a valuable choice as a standalone scaffold or as a supplement to other scaffolding systems.

The scaffold components of Tube and Clamp Scaffolding are constructed using high-quality steel, ensuring durability and longevity. This means that the scaffold can withstand the demands of the construction site and provide a safe working environment for workers.

One of the key advantages of Tube and Clamp Scaffolding is its ease of assembly. The system is designed for quick and straightforward setup, minimizing downtime and allowing construction projects to progress smoothly. With easy-to-understand instructions and a minimal number of components, Tube and Clamp Scaffolding can be assembled efficiently, saving both time and labor costs.

Furthermore, Tube and Clamp Scaffolding offers flexibility in terms of customization. The system can be adjusted to fit any shape, height, or width required for the project. Whether it’s working around obstacles, fitting into tight spaces, or adapting to irregular structures, Tube and Clamp Scaffolding can be tailored to meet the specific needs of the job.

Overall, Tube and Clamp Scaffolding provides a versatile, durable, and easy-to-assemble solution for construction and industrial projects. Its adaptability and customizable configuration make it a preferred choice for contractors looking for a reliable scaffold system that can be tailored to their specific requirements.

| Benefits of Tube and Clamp Scaffolding |

|---|

| Versatility in adapting to various scenarios |

| High-quality steel components for durability and longevity |

| Easy assembly, saving time and labor costs |

| Customizable to fit any shape, height, or width required |

Applications of Tube and Clamp Scaffolding

Tube and Clamp Scaffolding is a highly versatile system that finds applications in both construction and industrial projects. Its adaptability and flexibility make it a preferred choice in challenging construction areas where other scaffolding systems may not fit. This section explores the various applications of Tube and Clamp Scaffolding in different project scenarios.

Construction Projects

In construction projects, Tube and Clamp Scaffolding can be used for various purposes, including:

- Building facades: Tube and Clamp Scaffolding provides a stable and secure platform for workers to perform tasks such as painting, window installation, and repairs on building facades.

- Bridges: The versatile nature of Tube and Clamp Scaffolding allows it to adapt to the unique shapes and dimensions of bridge structures, providing safe access for maintenance and construction work.

- Staircases: Tube and Clamp Scaffolding can be utilized to support and provide safe access during the construction or renovation of staircases.

- Structural elements: Whether it’s constructing beams, columns, or any other structural element, Tube and Clamp Scaffolding offers the flexibility to meet the specific requirements of the project.

Industrial Projects

In industrial settings, Tube and Clamp Scaffolding demonstrates its versatility by serving multiple purposes:

- Maintenance work: Tube and Clamp Scaffolding allows workers to access and perform maintenance on equipment, machinery, and structures in industrial facilities.

- Plant shutdowns: During scheduled maintenance or shutdowns, Tube and Clamp Scaffolding can be used to create temporary work platforms for inspection, repair, and cleaning activities.

- Power plants: From boiler maintenance to installation of piping systems, Tube and Clamp Scaffolding offers a reliable solution in power plant construction and maintenance projects.

- Oil refineries: Tube and Clamp Scaffolding is commonly used in oil refineries for tasks such as tank maintenance, pipe installation, and equipment access.

Applications of Tube and Clamp Scaffolding

| Application | Description |

|---|---|

| Building facades | Provides stable platform for tasks like painting and repairs. |

| Bridges | Adapts to unique shapes for safe access during construction and maintenance. |

| Staircases | Supports construction and renovation work on staircases. |

| Structural elements | Offers flexibility in constructing beams, columns, and other structural elements. |

| Maintenance work | Enables safe access for maintenance tasks in industrial facilities. |

| Plant shutdowns | Creates temporary work platforms for shutdown maintenance activities. |

| Power plants | Used in construction and maintenance work in power plant facilities. |

| Oil refineries | Provides access for maintenance and installations in oil refinery projects. |

Tube and Clamp Scaffolding’s versatility and reliability make it an essential tool in construction and industrial projects. Its ability to accommodate various shapes, heights, and widths ensures it can adapt to the unique requirements of different applications. Contractors and project managers can confidently rely on Tube and Clamp Scaffolding to provide safe access and support for a wide range of tasks and structures.

Tube and Clamp Scaffolding Rentals

When it comes to scaffolding solutions, tube and clamp scaffolding offers versatility and convenience. If your project requires temporary access or scaffolding, renting tube and clamp scaffolding can be a cost-effective option. Many reputable scaffold suppliers offer rental services, providing all the necessary components and accessories to meet your construction needs.

Renting tube and clamp scaffolding offers several advantages. Firstly, it allows you to save on upfront costs associated with purchasing scaffolding equipment. By renting, you can allocate your budget more efficiently, especially if the scaffolding is only needed for a specific project or a limited period.

Rental companies typically provide comprehensive scaffolding packages, ensuring you have everything you need for setup and dismantling. This includes the required tubes, clamps, couplers, base plates, and safety accessories. You can rely on experienced scaffold suppliers to guide you through the selection process and help you create a custom configuration suitable for your project’s requirements.

Benefits of Tube and Clamp Scaffolding Rentals

- Cost-effective: Renting tube and clamp scaffolding can save you money by avoiding the need for a large upfront investment.

- Convenience: Rental companies provide all the necessary components, making setup and dismantling hassle-free.

- Flexibility: Renting allows you to adjust the quantity and size of the scaffolding as needed for different projects.

- Accessories: Scaffold suppliers often offer a wide range of accessories for rent, such as additional clamps, base plates, and guardrails.

- Professional Support: Reputable rental companies provide technical assistance and guidance for a smooth rental experience.

To ensure availability and secure the best rental terms, it’s advisable to contact scaffold suppliers in advance. Discuss your project requirements, including the duration of the rental period, the size and quantity of scaffolding needed, and any specific accessories or customization options you may require. This way, the scaffold supplier can provide you with accurate pricing and availability information.

By opting for tube and clamp scaffolding rentals, you can benefit from the flexibility, convenience, and cost-effectiveness of this versatile scaffolding system. Whether you’re working on a construction project or an industrial endeavor, renting tube and clamp scaffolding from reputable suppliers ensures you have the right scaffolding solution to support your project’s success. Contact scaffold suppliers in your area to explore the rental options available and get the scaffolding you need for your upcoming project.

Tube and Clamp Scaffolding Safety Standards

When it comes to tube and clamp scaffolding, safety should always be a top priority. To ensure the well-being of workers and the success of your project, it is crucial to adhere to industry standards and occupational safety regulations. Two key organizations, the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), have established comprehensive guidelines to promote scaffold safety.

Following these safety standards is essential as they cover various aspects of tube and clamp scaffolding, including assembly, use, and maintenance. By adhering to these guidelines, you can minimize the risk of accidents and injuries in the workplace.

- Proper Assembly: The safety standards provided by ANSI and OSHA emphasize the correct assembly of tube and clamp scaffolding. This ensures the structural integrity of the scaffold system and reduces the likelihood of collapses or accidents due to faulty construction.

- Safe Use: The guidelines also detail the proper use of tube and clamp scaffolding to prevent accidents during work. This includes weight restrictions, load capacities, and the correct placement of workers and materials on the scaffold platform.

- Maintenance: Regular maintenance is crucial to keep the scaffold system in optimum condition. The safety standards outline the necessary inspections and repairs needed to address any potential hazards or worn-out components.

Contractors and workers must familiarize themselves with these safety standards and receive proper training on scaffold safety. This includes understanding the specific requirements outlined by ANSI and OSHA, as well as participating in any additional safety programs or courses offered by reputable training providers.

By prioritizing scaffold safety and adhering to these standards, you create a safer work environment for all personnel involved. This not only protects workers from preventable accidents but also ensures compliance with legal regulations, minimizing the risk of penalties or legal complications.

Remember, safety should be at the forefront of every construction project, and tube and clamp scaffolding safety standards play a vital role in achieving this goal.

Key Elements of Tube and Clamp Scaffolding Safety Standards

| ASPECT | DETAILS |

|---|---|

| Assembly Guidelines | Proper techniques for connecting tubing and clamps to ensure a strong and stable scaffold structure. |

| Platform Safety | Guidelines for platform construction, weight limits, fall protection measures, and safe working practices. |

| Load Capacities | Specifications for the maximum load that the scaffold system can support, considering both workers and materials. |

| Maintenance Requirements | Inspection procedures, repair guidelines, and maintenance schedules to ensure the scaffold system remains in good condition. |

| Worker Training | Requirements for employee training on scaffold safety, including proper use, hazards awareness, and emergency response procedures. |

Tube and Clamp Scaffolding Maintenance

Proper maintenance is essential for ensuring the longevity and safe use of tube and clamp scaffolding. By conducting regular inspections, you can identify any damaged or worn-out components that need to be replaced, preventing potential accidents or scaffold failure. Additionally, keeping the scaffold clean and properly stored when not in use helps prevent corrosion and damage, ensuring its durability over time. The galvanized tubing used in tube and clamp scaffolding provides an added layer of protection against rust, extending the lifespan of the components and reducing maintenance requirements.

Tube and Clamp Scaffolding Maintenance Tips:

- Regularly inspect all components for signs of damage or wear.

- Replace any damaged or worn-out parts promptly.

- Clean the scaffold after each use to remove dirt and debris.

- Store the scaffold in a dry and well-ventilated area to prevent corrosion.

- Apply lubrication to moving parts to ensure smooth operation.

- Remove any rust spots using a wire brush and apply touch-up paint.

- Follow manufacturer’s guidelines for maintenance and use.

By following these maintenance tips, you can ensure the optimal performance and longevity of your tube and clamp scaffolding system. Regular inspections and proper care will help keep your scaffold in excellent condition, providing a safe working environment for your construction or industrial projects.

Tube and Clamp Scaffolding Suppliers

When it comes to purchasing Tube and Clamp Scaffolding, it is crucial to choose reliable scaffold suppliers and construction equipment providers. These suppliers offer a wide range of high-quality scaffolding products and excellent customer service to meet your project requirements.

Working with reputable scaffold suppliers ensures that you have access to durable and reliable scaffold systems. These suppliers understand the importance of providing scaffolding equipment that can withstand the demands of construction and industrial projects.

When selecting a scaffold supplier, consider factors such as their industry experience, product variety, and customer reviews. By doing thorough research, you can find suppliers who specialize in tube and clamp scaffolding and have a proven track record in delivering exceptional products and services.

Guidance in Selecting the Right Components and Accessories

One of the significant advantages of working with scaffold suppliers is their ability to provide guidance in selecting the right components and accessories for your specific project requirements. They can help you navigate through the various options available and recommend the most suitable products that align with your project’s specifications.

The expertise and knowledge of scaffold suppliers enable them to assess your needs accurately and propose scaffold systems that maximize safety and efficiency. Whether you require specific scaffold lengths, additional clamps, or specialized accessories, they can assist you in assembling a comprehensive scaffold configuration.

Comparing Prices and Checking Customer Reviews

Before making a purchase, it is essential to compare prices offered by different scaffold suppliers. While cost is a consideration, it should not be the sole determining factor. Take into account the quality of the scaffolding products and the value-added services provided.

Reading customer reviews is another valuable step in evaluating scaffold suppliers. Previous customers’ experiences and feedback can offer insights into the quality of the products, delivery process, and customer support. Pay attention to factors such as responsiveness, professionalism, and whether the suppliers meet their promises and deadlines.

Building Strong Partnerships

Establishing a strong partnership with scaffold suppliers can be beneficial for long-term projects or recurring scaffolding needs. By developing a relationship based on trust and reliability, you can streamline your scaffold procurement process and ensure a consistent supply of high-quality scaffold systems, components, and accessories.

Regular communication with scaffold suppliers allows you to stay updated on industry trends, new product releases, and innovations in scaffolding technology. This way, you can take advantage of the latest advancements to enhance the safety and efficiency of your construction or industrial projects.

Remember, selecting the right scaffold suppliers is a critical decision that impacts the success and smooth execution of your projects. Take the time to research, compare, and engage with reputable suppliers to ensure that you receive top-notch scaffold products and exceptional customer service.

Tube and Clamp Scaffolding Adaptability

One of the key advantages of Tube and Clamp Scaffolding is its adaptability. The system can be easily customized and expanded to meet the specific needs of a project. Additional clamps, base plates, and other components can be added to extend the scaffold configuration. This adaptability makes Tube and Clamp Scaffolding suitable for various construction and industrial applications, allowing for flexibility in challenging or unique project conditions.

Tube and Clamp Scaffolding: A Versatile Solution

Tube and Clamp Scaffolding is a highly versatile and flexible scaffold system that offers a wide range of applications in construction and industrial projects. Its adaptability allows it to accommodate different shapes, heights, and widths, making it an ideal choice for various challenging scenarios.

With Tube and Clamp Scaffolding, the ease of assembly and customization sets it apart from traditional scaffolding systems. It can be quickly and efficiently erected, saving time and increasing productivity on the job site. This scaffold system excels in congested construction areas where other scaffolding options may not fit or provide the desired flexibility.

Whether it’s a construction project with unique architectural features or an industrial project with complex machinery and structures, Tube and Clamp Scaffolding can adapt to the specific requirements. Its flexibility extends to uneven ground and complex shapes, allowing workers to safely access hard-to-reach areas and work at different heights.

A Versatile Solution for Various Projects

Tube and Clamp Scaffolding can be used for a wide range of applications such as:

- Building facades

- Bridges

- Staircases

- Platforms

- Towers

- And more

Its adaptability makes it suitable for both temporary and long-term projects. Whether you need a scaffold for a short-term construction project or a scaffold that can accommodate changes and modifications over an extended period, Tube and Clamp Scaffolding provides the versatility you need.

By utilizing the right components and accessories, Tube and Clamp Scaffolding offers a flexible and adaptable solution that can evolve alongside the project requirements, minimizing the need for costly reconfigurations or adjustments. This characteristic makes it a cost-effective solution for construction and industrial projects of all sizes.

When it comes to safety, Tube and Clamp Scaffolding meets industry standards and regulations. It provides a sturdy and reliable structure, ensuring that workers can perform their tasks safely at various heights and in different working conditions.

Tube and Clamp Scaffolding is a trustworthy choice for construction professionals seeking a versatile, flexible, and adaptable scaffold system. Its ability to fit various project requirements and its ease of assembly make it a preferred solution for even the most demanding construction and industrial projects.

Conclusion

Tube and Clamp Scaffolding is a versatile scaffold system that offers numerous benefits for construction and industrial projects. Its adaptability, ease of assembly, and customizable configuration make it an ideal solution for various applications. Whether used as a standalone scaffold or in conjunction with other systems, Tube and Clamp Scaffolding provides a reliable and versatile option for construction professionals.

With Tube and Clamp Scaffolding, construction teams can easily and efficiently tackle challenging areas, uneven ground, and complex shapes. The system’s high-quality galvanized tubing ensures durability and longevity, making it a valuable long-term investment. From building facades to bridges, this scaffolding system proves its versatility in a wide range of construction and industrial projects.

When considering scaffolding options, it is essential to consult reputable scaffold suppliers who offer a range of tube and clamp scaffolding equipment. These suppliers can provide expert guidance on selecting the right components and accessories, ensuring a tailored solution for your specific project requirements. Explore the possibilities of tube and clamp scaffolding to enhance your construction projects’ efficiency and safety.

FAQ

What is Tube and Clamp Scaffolding?

Tube and Clamp Scaffolding is a versatile scaffold system that can replace or supplement traditional tubular steel scaffolding and other system scaffolds. It is easy to erect and is designed to be used in difficult or inaccessible areas.

What components are included in Tube and Clamp Scaffolding?

Tube and Clamp Scaffolding consists of various components, including right angle couplers, swivel couplers, base plates, and wind clips. These components are used to connect and stabilize the scaffolding structure.

Are there different models of Tube and Clamp Scaffolding?

Yes, Tube and Clamp Scaffolding is available in different models, each corresponding to a specific length. These models include VTC4, VTC5, VTC6, VTC7, VTC8, VTC9, VTC10, VTC13, VTC14, VTC16, VTC18, and VTC20.

What accessories are available for Tube and Clamp Scaffolding?

Tube and Clamp Scaffolding offers a range of accessories including wind clips, tap’n turn wrenches, and base plates. These accessories provide additional stability, ease of assembly, and a stable foundation.

What are the benefits of Tube and Clamp Scaffolding?

Tube and Clamp Scaffolding is a versatile system that adapts to various scenarios, is easy to assemble, and can be customized to fit any shape or size required for the project. It is also made of high-quality steel for durability and longevity.

In what applications can Tube and Clamp Scaffolding be used?

Tube and Clamp Scaffolding is suitable for a wide range of applications in construction and industrial projects, including building facades, bridges, staircases, and other structural elements.

Can Tube and Clamp Scaffolding be rented?

Yes, Tube and Clamp Scaffolding is available for rent from various scaffold suppliers. Renting the scaffolding can be a cost-effective option for projects that require temporary access or scaffolding solutions.

What safety standards does Tube and Clamp Scaffolding adhere to?

Tube and Clamp Scaffolding must adhere to safety standards set by organizations such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). These standards ensure proper assembly, use, and maintenance of the scaffold system.

How should Tube and Clamp Scaffolding be maintained?

Proper maintenance is crucial to ensure the longevity and safe use of Tube and Clamp Scaffolding. Regular inspections should be conducted, damaged components should be replaced, and the scaffold should be cleaned and stored properly when not in use.

Where can Tube and Clamp Scaffolding be purchased?

Tube and Clamp Scaffolding can be purchased from various scaffold suppliers and construction equipment providers. It is important to choose reputable suppliers that offer high-quality products and excellent customer service.

Can Tube and Clamp Scaffolding be adapted for specific project needs?

Yes, one of the key advantages of Tube and Clamp Scaffolding is its adaptability. Additional clamps, base plates, and other components can be added to extend the scaffold configuration, making it suitable for various construction and industrial applications.

What makes Tube and Clamp Scaffolding a versatile solution?

Tube and Clamp Scaffolding offers a versatile solution for construction and industrial projects. Its adaptability, ease of assembly, and customizable configuration make it suitable for various applications, accommodating different shapes, heights, and widths.