Phone:

(+65)8319-0742

Starting a construction, maintenance, or repair project means choosing the right scaffolding systems. This choice is key to your project’s safety and efficiency. Scaffolding is a temporary structure that supports workers and materials at heights. It provides a stable platform for tasks.

Whether you’re buying or renting scaffolding, knowing what to look for is important. This knowledge helps you find the right scaffolding for your project.

When picking scaffolding, think about the project’s type, site height, and layout. Scaffolding must be strong and safe, with guardrails and slip-resistant platforms. It should also support tools and materials, be easy to move, and simple to set up and take down.

Key Takeaways

- Scaffolding is a temporary structure that supports workers and materials at various heights during construction, maintenance, or repair projects.

- Choosing the right scaffolding is crucial for ensuring the safety of everyone involved and improving productivity.

- When purchasing scaffolding, consider factors such as the type of construction work, height and layout of the project, and specific job site requirements.

- Industry standards require scaffolding to be sturdy and secure, with features like guardrails and slip-resistant platforms for safety.

- Other important considerations include height and reach requirements, weight capacity, mobility, and ease of assembly and dismantling.

Understanding the Basics of Scaffolding

https://www.youtube.com/watch?v=SNI_WoQhbog

Scaffolding is key in construction projects that need workers at heights. It gives a safe place for workers to reach high areas. Knowing about scaffolding is important for contractors, construction owners, and DIY fans.

What is Scaffolding?

Scaffolding is a temporary setup for workers and materials in building and repair jobs. It’s made of metal parts that connect to form a strong work area. It lets workers safely do tasks at different heights, which is crucial in construction.

Types of Scaffolding

There are many scaffolding types, each for different needs. Here are a few:

- Supported Scaffolding: This is the most common. It can hold more weight and workers than others.

- Suspended Scaffolding: Good for tight spaces, it’s fast to set up but holds fewer workers.

- Mobile Scaffolding: Perfect for quick, moving projects. It’s on wheels for easy moving.

Scaffolding safety standards say each scaffold must hold its own weight and four times the maximum load. The exact rules depend on the scaffold type.

Importance of Choosing the Right Scaffolding

Picking the right scaffolding is vital for worker safety and project success. The right choice affects stability, load, and safety rules. Consider the project’s needs, height, weight, ease of use, and budget when choosing scaffolding.

By picking the best scaffolding for your project, you ensure a safe and productive work area. This follows safety standards and boosts project success.

Factors to Consider Before Buying Scaffolding

When buying scaffolding, it’s important to think about safety and efficiency. You need to look at safety features, how high and far it can reach, its weight capacity, and how easy it is to move. These factors help ensure a safe and efficient work area.

Safety Features

Safety is key when choosing scaffolding. Look for sturdy construction, slip-resistant platforms, and strong guardrails. These features help prevent accidents and keep workers safe at height. Experts say safety rules require guardrails, midrails, and other features to keep the work area safe.

Height and Reach Requirements

The scaffolding’s height and reach depend on the project’s needs. Consider the working height, weight limits, and the materials and equipment used. For very high buildings, suspended scaffolding is best. Supported scaffolding works well for large buildings or long structures.

Weight Capacity

The scaffolding must support workers, tools, and equipment. Overloading can cause failures and accidents. Always check the manufacturer’s weight limits. Remember, safety and following rules are crucial to avoid disasters.

| Scaffolding Type | Recommended Usage | Cost Comparison |

|---|---|---|

| Supported Scaffolding | Large-scale buildings, overlength structures | Budget-friendly |

| Mobile Scaffolding | Construction tasks requiring frequent changes | Budget-friendly |

| Suspended Scaffolding | Extremely high buildings (50+ meters) | More expensive |

Mobility and Ease of Assembly

Mobility and ease of assembly matter for job site efficiency. Mobile scaffolding is good for tasks that change often. Think about how easy it is to set up, take down, and move to ensure smooth work.

Scaffolding has been a vital tool for builders for over 17,000 years, enabling them to reach new heights and construct magnificent structures.

By carefully looking at safety, height, weight, and mobility, you can choose the right scaffolding. This ensures safety and helps projects run smoothly and efficiently. It makes the work environment safe and productive for everyone.

Choosing the Right Scaffolding Supplier

Choosing the right scaffolding supplier is key for your construction project. A good supplier can greatly improve your project’s safety, efficiency, and success. With many suppliers out there, it’s important to think about a few key things before you decide.

First, look at the quality of the products. You want suppliers that offer top-notch scaffolding parts that follow industry standards. High-quality scaffolding keeps your workers safe and your structure stable. Look for reputable scaffolding accessories suppliers who use strong materials like steel for their products.

Quality of Products

When checking product quality, consider these points:

- Materials used in making the products

- If they follow safety standards and regulations

- How long the products last

- If they can be customized for your project

Reputation and Experience

The reputation and experience of a supplier are also important. Think about these factors:

- How long they’ve been in the scaffolding business

- What other clients say about them

- Any big projects they’ve worked on

- If they’ve won any awards

Experienced suppliers know a lot about scaffolding systems. They can help you choose the best one for your project.

Customer Service and Support

Good customer service and support are crucial. Look at these aspects:

| Service Aspect | Description |

|---|---|

| Responsiveness | They answer quickly and are easy to talk to |

| Technical Support | They have staff ready to help with any problems |

| Training and Education | They offer training on how to safely use scaffolding |

| After-sales Support | They help with maintenance and repairs |

A supplier with great customer service can help solve any issues. This makes your project go smoothly.

By thinking about these factors and doing your research, you can find a reliable scaffolding supplier. They should meet your project’s needs and support you throughout the construction process.

Scaffolding Purchase Making the Right Choice

When looking for scaffolding to buy, think about your project’s needs. Consider the type, size, weight, height, and safety features. Making the right choice is key, as it’s a big investment.

For projects over 8 months, buying scaffolding is often cheaper. It lets you control safety, maintenance, and setup better. For short-term jobs, aluminum or steel scaffolds are best because they’re strong and easy to use.

Owning scaffolding is wise for companies that need it often. It saves money over time and makes workers more efficient.

When buying scaffolding, keep these points in mind:

- Size and load capacity of the scaffolding

- Safety standards and features

- Customization and adaptability to specific project requirements

- Potential for generating additional revenue by renting out purchased equipment

| Scaffolding Type | Benefits | Ideal Projects |

|---|---|---|

| Aluminum | Lightweight, durable, quick assembly | Short-term, commercial projects |

| Steel | High strength, durability | Long-term, heavy-duty projects |

| Demo | Reduced costs, faster deployment | Temporary, light-duty projects |

It’s important to compare prices and quality when buying scaffolding. Use tools to find the best deals. While renting might be cheaper for short projects, owning scaffolding offers more control and savings for frequent use.

Types of Scaffolding Available for Purchase

When looking for scaffolding for your project, knowing the different types is key. Each type has its own benefits and uses. We’ll look at frame scaffolding, tube and clamp scaffolding, and system scaffolding. This will help you choose the right scaffolding for your needs.

Frame Scaffolding

Frame scaffolding is popular for its versatility and cost. It has frames and cross braces for a stable structure. Sets usually include frames, cross braces, and clips for easy setup.

Look for high-quality steel, like that from Texas A & M, for safety and durability. Avoid recycled steel frames for safety reasons. Buying sets is often cheaper and more convenient than individual pieces.

Many suppliers offer matching styles for brands like Safeway and Snap-On. This ensures compatibility and easy integration with your equipment.

Tube and Clamp Scaffolding

Tube and clamp scaffolding is great for unique projects. It’s made of tubes and clamps for a customizable platform. Its adaptability allows for complex setups and working around obstacles.

Choose high-quality components and easy-to-assemble sets. Reputable suppliers, like those on https://scaffoldtype.com/16-scaffold-types/, offer top-notch sets that meet safety standards.

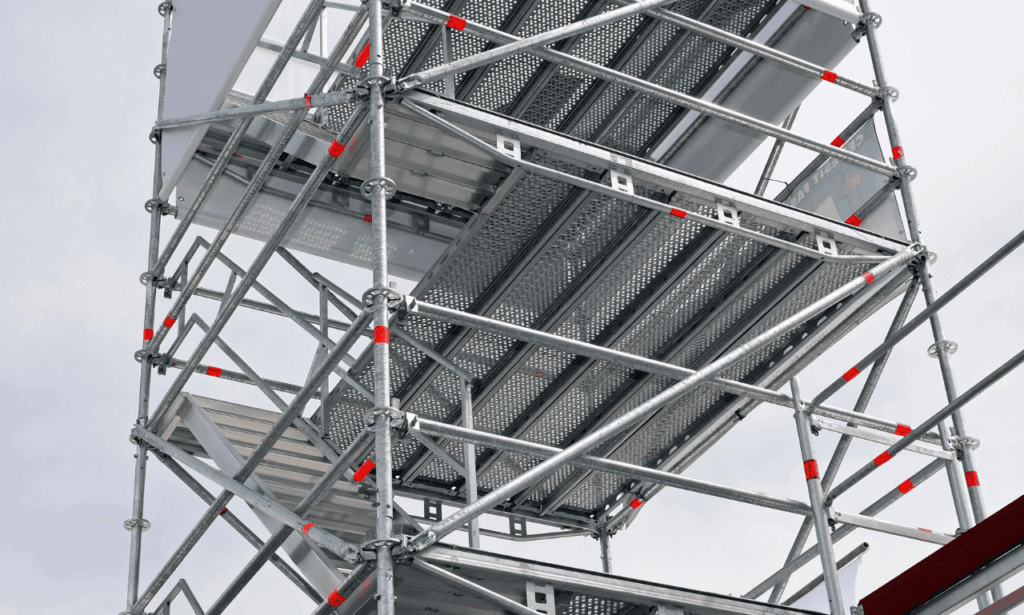

System Scaffolding

System scaffolding is modular for quick setup. It’s safe, adaptable, and efficient for construction sites. Its modular design allows for various configurations for different projects.

Consider your project’s weight, height, and reach needs when buying system scaffolding. Suppliers offer towers in heights from 5 to 20 feet. Rolling towers are mobile, while non-rolling towers are stable for fixed structures.

| Scaffolding Type | Key Features | Best Suited For |

|---|---|---|

| Frame Scaffolding | Interconnected frames and cross braces, quick assembly, cost-effective | General construction projects, residential and commercial buildings |

| Tube and Clamp Scaffolding | Highly customizable, adaptable to unique structures, versatile | Complex architectural designs, working around obstacles, industrial applications |

| System Scaffolding | Modular components, quick assembly, promotes safety, adaptable | Large-scale construction projects, high-rise buildings, industrial facilities |

When buying scaffolding, think about your project’s needs. Know the weight, height, and reach required. Understanding the different scaffolding types helps you choose the best for your project’s safety and efficiency.

Scaffolding Safety Regulations and Compliance

When buying scaffolding, it’s key to follow safety rules set by groups like the Occupational Safety and Health Administration (OSHA). These rules keep workers safe and make sure the scaffolding is strong. Knowing the latest rules is vital for a safe work area.

OSHA Standards

OSHA has detailed rules for scaffolding safety in CFR 1926.450-454. These rules cover design, building, and using scaffolding. Important points include:

- Scaffolding must hold its own weight and at least four times the maximum load, including people, tools, and equipment.

- It’s essential to do regular checks, like before starting work, and have a skilled person spot hazards and fix them.

- Workers need to learn how to use scaffolding safely, spot dangers, and know what to do in emergencies.

Weight Capacity Requirements

Ensuring scaffolding can handle the weight is crucial. OSHA says scaffolds must hold their own weight and at least four times the maximum load. This stops accidents from overloading or structural failure.

| Scaffold Type | Maximum Intended Load | Minimum Support Capacity |

|---|---|---|

| Light Duty | 25 lbs/ft² | 100 lbs/ft² |

| Medium Duty | 50 lbs/ft² | 200 lbs/ft² |

| Heavy Duty | 75 lbs/ft² | 300 lbs/ft² |

Fall Protection Measures

Fall protection is vital for scaffolding safety. OSHA says to use fall protection systems at heights of 10 feet or more. These can be:

- Guardrails: Must be on open sides and ends of platforms and meet certain height and strength needs.

- Personal Fall Arrest Systems: Includes harnesses, lanyards, and anchors that stop falls and prevent hitting lower levels.

- Safety Nets: Put below the work area to catch falling workers or objects.

By focusing on scaffolding safety and following OSHA scaffolding regulations, buyers can make sure their scaffolding is safe. This not only keeps workers safe but also avoids legal troubles and fines.

Maintenance and Care for Your Scaffolding

Keeping your scaffolding in good shape is key for safety and performance. Almost all construction workers use scaffolding. So, it’s important to check, clean, and fix it regularly to spot and fix any problems.

Make sure to clean your scaffolding after each use. This stops damage from things like stucco and paint. Metal parts can rust if exposed to heat and humidity. Use WD-40 on bolts and nuts to prevent rust and make your scaffolding last longer.

Wood parts need protection from rain to avoid warping. Always check your scaffolding for any damage. If you find something wrong, replace it right away. A detailed checklist can help you keep your scaffolding in good shape.

“Proper maintenance of scaffolding equipment leads to a safer and more productive work environment for construction workers, reducing overall construction costs.”

It’s also important to train workers on how to use and care for scaffolding. This training should cover how to assemble and dismantle it safely. It helps keep everyone safe and extends the life of the equipment.

If your scaffolding gets damaged, you have a few options:

- Replace the damaged parts

- Use it for less demanding tasks

- Scrap the damaged parts

- Fix the faulty parts

- Shorten the scaffolding to remove damaged sections

By focusing on scaffolding maintenance, construction sites can be safer and more efficient. This also helps save money by avoiding the need for costly replacements and repairs.

Common Mistakes to Avoid When Buying Scaffolding

Buying scaffolding requires careful decisions to keep your construction projects safe and efficient. Many buyers make mistakes that can be costly and dangerous. Here, we’ll cover three key errors to avoid when buying scaffolding.

Choosing the Wrong Type of Scaffolding

One big mistake is picking the wrong scaffolding for your project. There are many types, from small ones for lower walls to tall mobile towers. You need to think about the height, weight, and where it will be used. The wrong choice can be unsafe and slow down your work.

Neglecting Proper Installation and Maintenance

Another mistake is ignoring the need for proper installation and upkeep. Even the best scaffolding can be dangerous if not set up right or kept in good shape. Bad installation can weaken the scaffolding, risking accidents. Not doing regular checks and repairs can also cause damage and safety problems.

Sacrificing Quality for Lower Prices

Some try to save money by choosing cheaper scaffolding. But, this can be risky. Cheap scaffolding might not be safe or last long. It’s better to spend more on quality scaffolding from trusted suppliers to keep everyone safe and the equipment working well.

| Mistake | Consequences | Prevention |

|---|---|---|

| Choosing the wrong type of scaffolding | Safety risks, inefficiencies | Consider height, weight capacity, and ground conditions |

| Neglecting proper installation and maintenance | Compromised structural integrity, accidents, costly repairs | Ensure correct installation, perform regular maintenance checks |

| Sacrificing quality for lower prices | Subpar equipment, safety hazards, shorter lifespan | Invest in high-quality scaffolding from reputable suppliers |

To avoid these mistakes, do your homework, talk to experts, and always choose safety and quality. This way, your construction projects will be safe, efficient, and successful.

Conclusion

Choosing the right scaffolding equipment is key for safe and efficient construction projects. As a buyer, it’s vital to think about several factors before buying. This scaffolding purchase guide shows why knowing the basics is important.

Look for safety features, the right height and reach, and how much it can hold. Also, how easy it is to set up matters. It’s crucial to pick a trusted supplier for quality products and advice.

Following safety rules, like OSHA standards, is a must when buying scaffolding. Keeping your scaffolding in good shape also helps it last longer and work better.

By knowing what to avoid, like picking the wrong scaffolding or going for cheap over quality, buyers can make better choices. This leads to safer and more successful construction projects.

With the knowledge from this guide, buyers can find the right scaffolding for their needs. Investing in quality scaffolding means safer, more efficient, and successful projects.