Phone:

(+65)8319-0742

In construction, scaffold tube couplers are key for safety and stability. They connect scaffolding tubes, making a strong framework. This framework supports workers, tools, and materials at heights. These fittings, also known as tube clamps or coupler joints, are crucial for creating reliable scaffolding setups.

Beam couplers are essential components that connect scaffolding tubes to steel beams, enhancing stability and support for scaffolding systems. They provide reliable connections for scaffolding setups that require strong anchoring to load-bearing structures.

Scaffold tube couplers are made from strong materials like steel or aluminum. Steel couplers are best for heavy-duty jobs because they are very strong. Aluminum couplers are lighter, making them easier to move without losing strength.

Scaffold tube couplers are very versatile. They fit scaffolding poles from 1.5 inches to 4 inches in diameter. They can handle poles up to 4.0mm thick for heavy loads. This means scaffolding can be made to fit each project’s needs, ensuring safety and efficiency.

Key Takeaways:

Scaffold tube couplers are essential for connecting scaffolding tubes securely.

Steel and aluminum are common materials used in coupler manufacturing.

Couplers accommodate various pole diameters and thicknesses for customization.

Regular inspections and proper storage extend the lifespan of scaffold couplers.

Quality couplers contribute to the safety and stability of scaffolding structures.

Importance of Scaffold Tube Couplers in Construction

Scaffolding couplers are essential components used in construction to connect scaffolding tubes securely, ensuring a strong framework that supports workers, tools, and materials at different heights during building and maintenance tasks. These couplers play a crucial role in keeping construction sites safe and efficient by providing the necessary stability and support for scaffolding structures. By securely connecting scaffolding tubes, they help create a reliable and robust scaffolding system that can withstand various loads and stresses encountered on construction sites.

Importance of Scaffold Tube Couplers in Construction

Scaffold tube couplers are key construction safety accessories. They ensure scaffolding is safe and stable. These temporary structure fasteners connect tubes securely, forming a strong framework. Tube and Coupler Scaffolding systems can hold up to 75 lbs. per square foot, perfect for big construction jobs. A double coupler plays a crucial role in securely joining scaffold tubes at right angles, highlighting its load capacity and compliance with standards like EN74 and AS/NZ 1576.

Choosing and installing the right tube and fitting connectors is critical for safety. Following strict safety rules helps prevent accidents and keeps workers safe. Doing thorough hazard checks is also important to avoid risks and keep the site secure. The importance of a fixed coupler in ensuring the strength and reliability of scaffolding structures cannot be overstated.

Ensuring Safety and Stability

Using tube and coupler scaffolding needs careful safety steps:

Guardrail Systems

Toeboards

It’s essential to follow OSHA safety rules (OSHA 1926.502(b), 1926.451(f)(1), 1926.500-503) to keep the work area safe. Always check scaffolding couplers before use, during the project, and after any damage.

Enhancing Structural Integrity

Scaffold tube couplers make scaffolding stronger, able to handle various forces and loads. There are different couplers for different needs, like swivel and right-angle couplers. They add flexibility and stability to complex setups.

Qualified Scaffold Designs are mandatory for structures over 125 feet, requiring certified professionals to calculate load capacities that can withstand at least four times the intended load.

Using top-notch construction safety accessories like scaffold tube couplers is crucial. It ensures scaffolding is safe and stable, helping projects succeed and run smoothly.

Types of Scaffold Tube Couplers Available

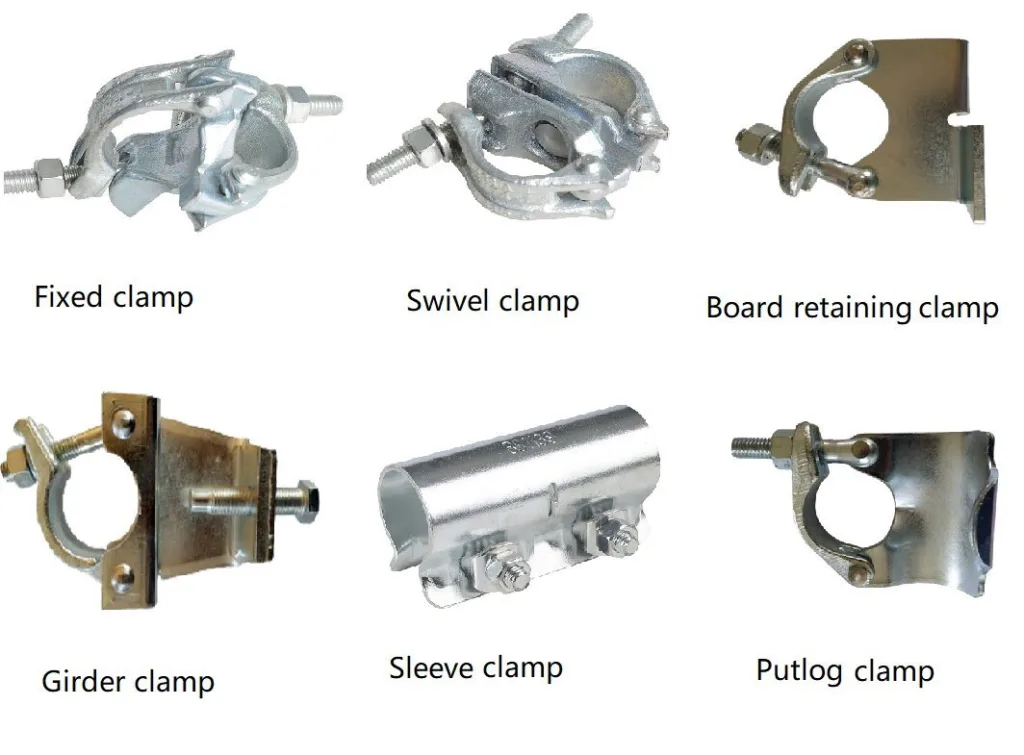

Building safe scaffolding needs the right couplers. There are many types of couplers, each for a specific use. Knowing which coupler to use is key for a strong and safe scaffolding setup. A board retaining coupler, also known as the BRC coupler, is essential for securing scaffold boards to the scaffolding structure, ensuring compatibility with standard board sizes of 38-50mm.

Fixed couplers, like right-angle couplers, make tubes connect at a 90-degree angle. They are great for the basic scaffolding structure. Tube and coupler scaffolding uses these couplers for a solid setup. Girder couplers are crucial for connecting tubes to beams, enhancing stability by securely gripping structural flanges and preventing slipping.

Swivel couplers are for more complex scaffolding. They let tubes connect at different angles. This makes scaffolding fit around obstacles and meet job site needs. Hot dip galvanized couplers offer superior anti-corrosion properties and durability, lasting 10 to 20 years, making them ideal for harsh environments.

Sleeve Couplers for Extended Spans

Sleeve couplers are used to connect scaffold tubes for longer spans or end-to-end tube connections. They ensure a strong and stable connection. They’re key in tube and clamp scaffolding systems for customizing scaffolding to project sizes.

Putlog and Board Retaining Couplers for Platform Support

Putlog couplers support horizontal members and platforms. They attach transoms or putlogs to vertical standards. This is crucial for stable platforms, like in brickwork projects.

Choosing the right couplers is vital for safety and efficiency. Knowing the types and their uses helps build scaffolding that meets quality standards.

Swivel Couplers for Flexible Connections

Swivel couplers are versatile connectors that allow scaffolding tubes to join at different angles, providing flexibility in creating complex scaffolding configurations. These couplers are adjustable, enabling users to create various scaffolding arrangements, making them ideal for situations where a flexible scaffolding structure is required. Swivel couplers are particularly useful in navigating around obstacles and adapting to the unique demands of different construction projects, ensuring that the scaffolding system can be tailored to fit the specific needs of the site.

Right-Angle Couplers for Perpendicular Joints

Right-angle couplers, also known as 90-degree couplers, connect tubes at a right angle (90 degrees), creating strong, sturdy joints. These couplers are commonly used in the construction of scaffolding frameworks, providing stability to the scaffolding structure. By forming perpendicular joints, right-angle couplers help distribute loads evenly and enhance the overall integrity of the scaffolding system, making them a fundamental component in building safe and reliable scaffolding setups.

Benefits of Using Quality Scaffold Tube Couplers

High-quality industrial safety equipment like scaffold tube couplers are key for construction projects. They ensure the safety, stability, and efficiency of temporary structures. Scaffold fittings are essential components for connecting scaffolding tubes and ensuring structural integrity, achieving safety, stability, and adaptability in different scaffolding configurations. These are vital parts of pipe scaffolding hardware

Increased Durability

Quality scaffold tube couplers are made from durable materials like galvanized steel and aluminum. This makes them last longer and resist wear and tear. They also resist corrosion, lasting through harsh weather.

This durability helps keep the scaffolding safe. It lowers the risk of collapse or failure.

Cost-Effectiveness

High-quality couplers are cost-effective for construction projects. They can be used over and over, saving on material costs. They also make setting up and taking down scaffolding faster, saving on labor costs.

The Tube-Lock® system reduces the amount of parts needed by 50% compared to the traditional tube and coupler system, and connecting two Tube-Lock® tubes is around 15 times faster than connecting two tubes in the traditional way.

Ease of Installation

Well-designed couplers make installation and dismantling easy. This saves time and money on construction sites. The standard design of steel pipe scaffolding makes ordering and assembly simpler.

This ease improves efficiency and safety. It reduces the chance of mistakes during assembly.

Investing in quality couplers from suppliers like AAIT ensures safety and cost-effectiveness. These couplers, made from high-quality steel and aluminum, provide a stable platform. They reduce the risk of accidents due to unstable platforms.

Selecting the Right Scaffold Tube Couplers

Choosing the right scaffold tube couplers is key for a safe and efficient construction project. It’s important to know your project’s needs and follow safety standards. Scaffold boards play a crucial role in maintaining safety and stability on construction sites by preventing slipping and creating a safe working platform for workers.

Think about the scaffolding type, scaffold load capacity, and structure complexity when picking couplers. Talking to qualified scaffold design experts and engineers is a good idea. The scaffold structure supports scaffolding applications, and components like ladder and plank clamps are essential for securing elements safely and effectively.

Understanding Your Project Needs

Each project needs different couplers. The coupler diameter is usually ø 48.3, but other sizes like ø 42 and ø 60 might be needed. The steel tube thickness also varies, depending on where you are.

The length of steel tubes in scaffold systems ranges between 50-6000mm, with thickness varying from 1.2-4.0mm, depending on individual project requirements.

Pressed couplers can’t hold as much weight as forged ones. The tube wall thickness affects the scaffold load capacity. Tube and coupler scaffolding is cost-effective and reliable, making it a favorite among builders.

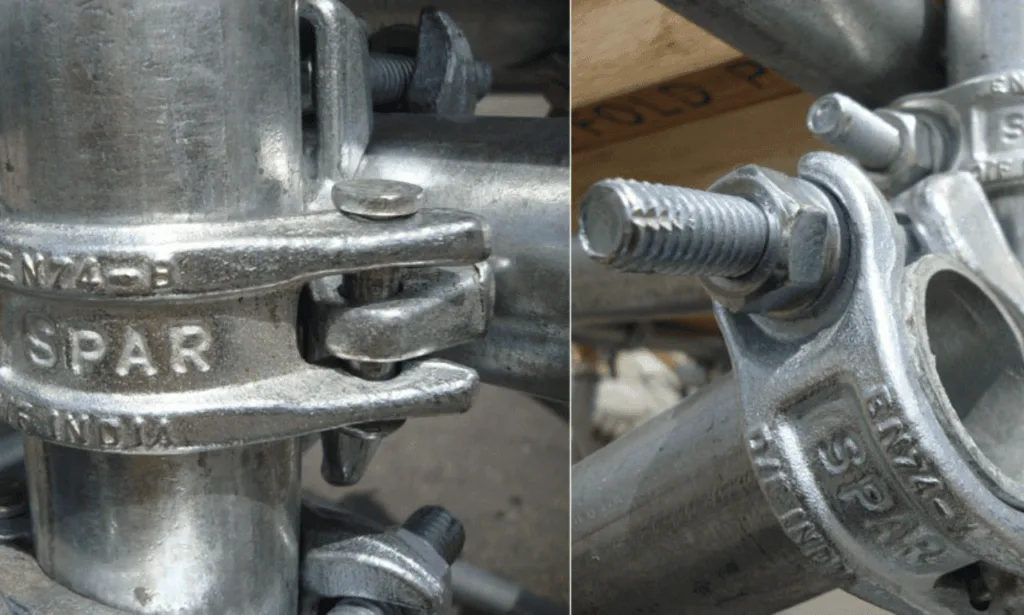

Compliance with Safety Standards

It’s important to follow safety standards like EN74 / BS1139 for scaffolding couplers. This ensures the scaffold is stable and safe. Make sure the couplers meet the required specs and are certified.

The usual working load limit of couplers is 6.25 kN at 54 Nm tightening torque. External Sleeve Couplers can handle the full tube capacity under compression. Putlog Couplers have a limit of 0.62 kN against slip at 54 Nm tightening torque.

Materials and Durability

Scaffolding couplers are usually made from strong materials like steel or aluminum. Steel couplers are tough and ideal for heavy-duty work, offering exceptional strength and durability. On the other hand, aluminum couplers are lighter and easier to handle, yet still robust enough for most construction tasks. Choosing the right coupler material is crucial for ensuring the safety and stability of the scaffolding system. Proper installation is equally important; couplers must be tightened securely to prevent slipping or coming loose, which could lead to accidents. Each type of coupler has a specific weight limit it can safely hold, and adhering to these limits is essential to maintain the stability and safety of the scaffolding structure. Regular inspections and maintenance are also vital to ensure that the couplers remain in good condition and continue to perform effectively throughout the construction project.

Innovations in Scaffold Tube Coupler Technology

The scaffolding industry is always changing. New advanced scaffolding components and technologies are coming out. They make sites safer, more efficient, and productive.

Girder couplers play a crucial role in ensuring stability and adherence to safety standards in construction settings by connecting tubes to beams.

Innovative materials and designs lead this change. They’re changing how scaffold tube couplers are made and used.

New Materials and Designs

New materials like high-strength alloys and composites are being used. They make lightweight coupling systems that are strong and don’t rust. These materials make scaffolding lighter, stronger, and last longer.

New coupler designs, like quick-release and self-locking, make setting up and taking down scaffolding easier. For example, a new coupler design makes installing and removing scaffolding 100% faster than old designs.

Impact on Productivity and Safety

These new coupler technologies greatly improve productivity and safety. They allow for faster and more secure connections. This means projects can be finished quicker.

Smart scaffolding technologies, like sensors and connectivity, are coming soon. They will make sites even safer by 2024. Advanced couplers also have better safety features and can hold more weight. This reduces the chance of accidents and keeps workers safe.

As the industry keeps adopting these new technologies, we’ll see big improvements. Setup times, labor needs, and accident rates will all go down. This will change how scaffolding systems are made and used.

The future of scaffolding looks bright. Adjustable scaffolding and new coupler technologies will make construction safer, more efficient, and green. By 2024 and beyond, we’ll see more advanced materials, smart tech, and eco-friendly practices in scaffolding. This will ensure projects are done with precision, safety, and care for the environment.