Phone:

(+65)8319-0742

html

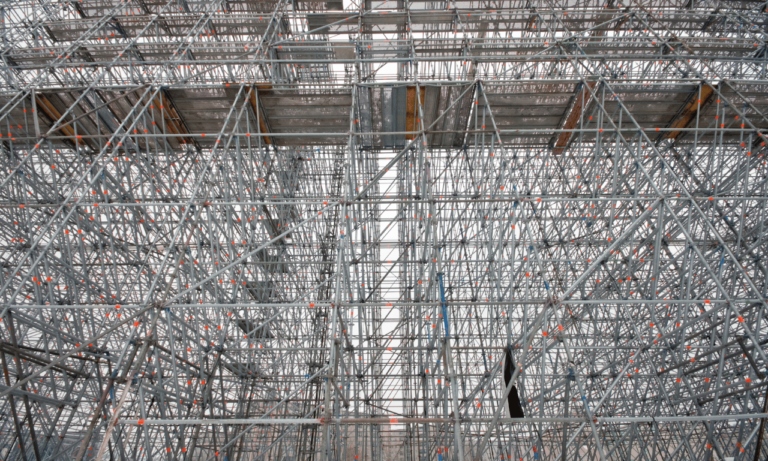

The realm of construction is underpinned by the principles of safety and efficiency, both of which are significantly reinforced through the commitment to Scaffold Safety Engineering. Recognizing its critical role, industry professionals are continually refining robust construction site safety protocols that revolve around the intuitive design and orchestrated usage of scaffolding structures.

With heightened caution and adherence to expert guidelines, the safeguarding of every individual on the construction site is elevated, minimizing risks while optimizing the execution of various high-altitude tasks. Through the meticulous development of scaffold systems, we establish a foundation for pursuing operational excellence without compromising the well-being of the workforce.

Key Takeaways

- Understanding the impact of Scaffold Safety Engineering on work site security.

- Implementing robust construction site safety measures to protect workers.

- Adhering to expert guidelines for the design and use of scaffolding.

- Advancing safety practices through regular inspections and maintenance.

- Upholding stringent safety standards to mitigate potential risks.

- Fostering a safety-centric work culture through comprehensive training.

The Critical Role of Scaffold Safety Engineering in Construction

Access scaffolding stands as the backbone of heightened efficiency and secure operations in construction sites. By allowing tasks at varying heights to transpire safely and swiftly, the presence of tailored scaffolding can be a game-changer. Emphasizing the importance of robust workplace scaffolding guidelines, scaffolding design standards, and stringent construction safety regulations could not be more vital in minimizing the risks workers face daily.

Understanding Access Scaffolding and Its Benefits

Constructing grand edifices and towering structures demands the assured safety and maneuverability that only high-grade scaffolding can provide. From industrial complexes to residential constructions, the advent of advanced scaffolding design not only safeguards those who brave the altitudes but also streamlines the workflow—a testament to the pivotal role of safety in engineering.

Assessing Risks: Fall Statistics and Construction Safety

Alarming statistics point to falls as a leading culprit in construction-related injuries and fatalities. Over 62% of construction sites are fraught with fall risks, underscoring the indispensable nature of up-to-date scaffold safety measures and the unremitting vigilance required to enforce them. The march towards fewer injuries is inexorably linked to the implementation of comprehensive safety protocols—a pursuit scaffold safety engineering champions persistently.

| Scaffold Safety Feature | Benefits | Regulatory Compliance |

|---|---|---|

| Guardrail Systems | Provides barrier against falls | Meets OSHA standards |

| Non-slip Decking | Reduces slip hazards | Aligned with safety guidelines |

| Load Capacity Signage | Prevents overloading | Complies with load guidelines |

| Regular Inspection Schedules | Identifies and addresses potential risks | Adheres to mandatory inspection requirements |

Compliance with OSHA Scaffold Requirements

Ensuring worker safety on construction sites hinges on meticulous adherence to OSHA scaffold requirements. These regulations serve as the cornerstone of scaffold safety training and overall safety compliance in scaffolding. Beyond mere guidelines, these requirements are crucial mandates that affect every aspect of scaffold use, from assembly to dismantling.

OSHA's Role in Scaffolding Safety Standards

The role of the Occupational Safety and Health Administration (OSHA) extends far beyond setting mere suggestions for the construction industry. OSHA’s rigorous scaffold requirements are designed to uphold the highest safety standards, dictating specific criteria for scaffold design, construction, and operational use.

Implementing OSHA's Scaffold Safety Regulations and Training

The implementation of OSHA’s scaffold safety regulations is a proactive step employers must take to ensure a reduction in work-related accidents. OSHA’s detailed training programs aim to arm workers with a comprehensive understanding of scaffolding hazards and the know-how to prevent them. As a critical aspect of job-site readiness, scaffold safety training includes:

- Evaluating scaffold integrity and stability

- Understanding weight capacity limits

- Mastery of fall protection systems

- Identifying and mitigating potential hazards

A partnership between employers and employees fosters safety compliance in scaffolding, where both parties are well-versed in OSHA’s scaffold requirements and obligated to maintain a safe construction environment. Below is an overview of scaffold standards as outlined by OSHA:

| Scaffold Type | Capacity Requirements | Fall Protection | Training Requirement |

|---|---|---|---|

| Suspended Scaffolds | At least 4 times the intended load | Personal fall arrest system | Competent person training |

| Supported Scaffolds | At least 4 times the intended load | Guardrail systems | Qualified person for erection/dismantling |

| Mobile Scaffolds | At least 4 times the intended load | Stabilizers or outriggers | User training for safe movement |

Ultimately, respecting OSHA requirements, embracing comprehensive scaffold safety training, and ensuring continual safety compliance are non-negotiable for a safer future in construction scaffolding operations.

Principles of Effective Scaffold Safety Training

Implementing robust scaffold safety training programs is a critical investment in accident prevention that enhances overall workplace safety. It is imperative that such training programs cover not only the mechanics of scaffold construction but also comprehensive risk management and emergency response protocols. By providing a multifaceted approach to training, employers empower their workforce with the knowledge to maintain secure working conditions and minimize the risk of accidents.

Integral to the development of such programs is the emphasis on practical, hands-on experiences where workers can apply the theoretical knowledge they have gained in real-world scenarios. It ensures not only compliance with regulatory standards but also cultivates a safety-first mindset among the workforce.

| Training Module | Objective | Skills Gained |

|---|---|---|

| Basics of Scaffold Erection | Understanding scaffold components and correct assembly techniques. | Correct identification and assembly of scaffold parts, ensuring stability. |

| Fall Protection Procedures | Implementing safety measures to prevent falls and injuries. | Usage of personal fall arrest systems, guardrails, and toe boards. |

| Risk Identification & Management | Recognizing potential hazards associated with scaffolding. | Hazard detection, risk assessment, and implementation of control measures. |

| Emergency Response Training | Preparing workers to effectively respond to accidents and emergencies. | First aid, rescue operations, and efficient communication skills. |

Adherence to established scaffold safety training programs significantly contributes to a culture of workplace safety and is a primary defense against workplace incidents. When workers are thoroughly trained, the principles of accident prevention become ingrained in daily operations, leading to a resilient and conscientious workforce.

Scaffold Safety Engineering: Best Practices and Design Standards

Developing effective scaffold safety engineering involves a harmonious blend of scaffolding design standards and best practices in scaffold safety, meticulously formulated to safeguard workers and ensure operational sturdiness. By adhering to these guidelines, construction projects can substantially mitigate risks and foster a culture of safety.

Key Elements of Scaffold Design for Maximum Safety

When considering scaffold construction, several critical factors come to the forefront to enhance worker safety and structural reliability. The hallmarks of superior scaffold design include:

- Ensuring adequate strength and rigidity to support both workers and materials

- Integrating versatility to accommodate various project types and environments

- Incorporating user-friendly features for efficient assembly and dismantling

- Employing dynamic load testing to confirm resilience under stress

Engineering Strategies to Minimize Scaffolding Hazards

Proactive scaffolding hazard prevention measures form the cornerstone of scaffold safety engineering. Implementing these strategies is essential in proactively addressing potential concerns:

- Selecting premium materials that meet or exceed regulatory standards

- Regular inspections to identify and rectify any signs of wear or damage

- Ensuring easy access to safety features like guardrails and fall arrest systems

- Adopting comprehensive safety protocols for both erection and dismantling processes

By integrating these safety-centric design principles and engineering techniques, companies can uphold the integrity of their scaffolding systems and secure the well-being of their workers.

Safety Compliance in Scaffolding: Inspection and Hazard Prevention

Adhering to structured scaffold inspection procedures is a cornerstone in reinforcing construction safety and effectively practicing hazard prevention. These measures are essential for ensuring that the working environment is secure and potential risks are mitigated. Below, the steps for conducting scaffold inspections and techniques for preventing hazards on construction sites will be detailed.

Steps for Scaffold Inspection Procedures

Regular and meticulous inspections form the basis of a strong safety protocol on construction sites. The following procedure ensures that every inspection is thorough and leaves no stone unturned:

- Verify the structural integrity and stability of the scaffold.

- Check the condition of platforms and planking to ensure they are undamaged and securely fastened.

- Examine guardrails, toe boards, and other protective measures to confirm they are in place and intact.

- Inspect all connections and fastenings for signs of wear, damage, or improper installation.

- Review the scaffolding tags that indicate the last inspection date and any issues that were noted.

This scaffold inspection checklist not only promotes safety but also compliance with regulatory standards.

Techniques for Scaffolding Hazard Prevention

Once scaffolds pass inspection, continuous efforts must be made to prevent hazards. Below are the proactive measures indispensable for maintaining a safe scaffolding system:

- Keeping the work area clean to reduce the risk of slips and falls.

- Properly securing the scaffold to the building structure to prevent shifting or collapse.

- Installing clear signage to alert workers of potential scaffold hazards.

- Enforcing adequate fall protection including personal protection equipment (PPE) such as hard hats and safety harnesses.

These efforts ensure a robust approach to construction safety and contribute to a culture of mindfulness regarding hazard prevention.

| Inspection Item | Status (Pass/Fail) | Comments |

|---|---|---|

| Structural Stability | Pass | No defects or displacements observed. |

| Guardrails and Protection | Pass | All protective barriers are properly installed. |

| Planking Condition | Fail | Replacement of the damaged planks required. |

| Connections and Fastenings | Pass | All connections secured and checked. |

| Safety Signage | Pass | Visible and adequate signage in place. |

By implementing stringent scaffold inspection procedures and prioritizing hazard prevention, construction sites can significantly enhance the safety of their operations. Vigilance in these areas demonstrates a commitment to construction safety and can lead to better protection of workers and the overall project.

Maximizing Workplace Scaffolding Guidelines for Worker Protection

Fostering a rigorous approach to workplace scaffolding guidelines is critical to establishing a safe construction environment. Compliance with these guidelines goes hand-in-hand with initiatives that ensure worker protection, as they provide a framework that safeguards against the inherent risks of working at potentially dangerous heights. Central to this framework is a firm commitment to the continuous education of construction personnel, emphasizing the essentials of scaffold safety and operability.

- Regular Training Sessions

- Comprehensive Safety Audits

- Active Enforcement of Protocols

Translating workplace scaffolding guidelines into action demands not only an understanding of what needs to be implemented but also ensuring that these guidelines are deeply integrated within the daily routines of the workforce. Consistent training and clear channels of communication are the underpinnings of a culture that values each employee’s wellbeing. To this end, it’s not enough to simply have guidelines in place; they must be adapted into common practice through engagement and accountability.

- Continual Safety Culture Reinforcement

- Clear, Accessible Communication Channels

- Empowerment Through Worker Involvement

Employers carry the significant responsibility of structuring a safe construction environment. This is accomplished by calling upon their leadership to set clear expectations about safety practices, as well as by granting workers the tools needed to identify and mitigate potential hazards. Close supervision compliments this goal, bridging the gap between static policies and dynamic, on-site application.

| Guideline | Purpose | Outcome |

|---|---|---|

| Constant Supervision | To monitor the correct application of safety practices | A reduction in workplace accidents and increased compliance with safety standards |

| Up-to-date Training | To keep workers informed on the latest safety techniques and equipment | Workers are equipped to tackle various scenarios with confidence and knowledge |

| Regular Equipment Checks | To prevent equipment malfunctions | Maintained integrity of scaffolding structures and minimized risk of collapse |

By upholding a high standard of workplace scaffolding guidelines, and truly committing to the values of worker protection, the construction industry can move toward a future where every site is a model of a safe construction environment. It is through this lens that scaffolding guidelines should not be seen merely as regulatory requirements but as the foundational elements of a proactive safety culture.

Conclusion

The intricacies of Scaffold Safety Engineering are not just technical requirements; they embody a commitment to human life and the overall success of construction endeavors. It’s clear that maintaining construction site safety is not a one-off activity but a continuous journey that involves regular updates to training, processes, and systems. To ensure an efficient construction process, it’s imperative that every stakeholder from engineers to laborers understands and respects the gravity of safe scaffolding practices.

In the constellation of construction site activities, worker safety shines as the brightest star, guiding the actions and decisions of a conscientious industry. Through the vital practice of Scaffold Safety Engineering, the likelihood of accidents is significantly reduced, supporting the overarching goal of a hazard-free workplace. Critical to this achievement are the dedicated efforts of professionals who design, inspect, and oversee the use of scaffolds – ensuring that the elevation of structures parallels the elevation in safety standards.

Ultimately, a construction firm that embeds safety as a pillar of its culture sets a precedent in the industry, one that resonates with the ethos of care and precision. A safe scaffold is the foundation upon which workers can confidently build, not just structures, but also a legacy of integrity and diligence in the pursuit of construction excellence. The scaffold, therefore, stands not just as a temporary platform, but as a testament to an enduring commitment to safety and quality in the built environment.

FAQ

What practices can enhance scaffold safety engineering on a construction site?

Enhancing Scaffold Safety Engineering involves implementing robust construction site safety measures, following expert guidelines, ensuring the professional design and engineering of scaffolding systems, providing proper installation, conducting thorough inspections, and offering comprehensive worker training.

Why is scaffold safety engineering crucial in construction?

Scaffold Safety Engineering is critical as it increases workplace safety by providing secure platforms for workers at height, reduces the risks of falls – a leading cause of construction fatalities, and ensures adherence to scaffolding design standards and construction safety regulations.

How does compliance with OSHA scaffold requirements ensure a safe construction environment?

Compliance with OSHA scaffold requirements guarantees that scaffolding systems meet federal safety standards for design, construction, and usage. This includes weight capacity, fall protection, and falling object precautions, significantly reducing workplace accidents through proper training and adherence to regulations.

What are the principles of effective scaffold safety training?

Effective scaffold safety training includes technical aspects of scaffolding use, erection, and dismantling, as well as management practices, hazard recognition, and adherence to fall protection procedures to prevent accidents and instill a culture of workplace safety.

What design standards should be considered for maximum scaffold safety?

Standard practices in scaffold design for maximum safety include ensuring load-bearing capacities, stability, and adaptability to different environmental conditions. Also, integrating safety features such as guardrails and fall arrest systems is paramount.

What steps are involved in scaffold inspection procedures?

Scaffold inspection procedures involve checking for structural stability, ensuring guardrails are secure, and identifying any damage or defects. Inspections should be conducted regularly and any issues addressed immediately to maintain safety compliance.

How can scaffold hazard prevention be implemented Effectively?

Scaffolding hazard prevention can be achieved by maintaining the cleanliness of work platforms, securely attaching scaffolds to structures, providing clear signage, preventing unauthorized access, ensuring proper use of personal protective equipment, and offering worker training to recognize and manage potential risks.

What are some workplace scaffolding guidelines that can protect construction workers?

Workplace scaffolding guidelines include strict adherence to safety regulations, thorough training in handling scaffolding, supervision to enforce safety protocols, clear communication of guidelines, proper use of equipment, and regular scaffold assessments for a safe construction environment.

Source Links

- https://www.linkedin.com/pulse/access-scaffolding-enhancing-safety-efficiency-abhishek-mishra

- https://www.linkedin.com/pulse/scaffolding-construction-enhancing-safety-productivity-araxy-v–uu2kc

- https://www.forconstructionpros.com/business/construction-safety/article/22737527/amtrust-financial-7-ways-to-improve-scaffolding-safety-in-construction