Phone:

(+65)8319-0742

In the construction world, keeping workers safe is key. Using the right scaffold connectors is crucial. These parts link tubes, boards, and more, making a strong structure for building projects.

There are many types of scaffold connectors, each for a different use. From couplers and clamps to brackets and base plates, they make scaffolding safer and more reliable. Choosing the right ones helps ensure scaffolding systems are safe and meet standards.

Choosing the right connectors is vital for a safe scaffolding structure. Contractors need to know the project’s load needs and design. This way, they pick connectors that support and stabilize well. This focus on detail boosts safety and makes building work more efficient.

Key Takeaways

- Scaffold connectors are vital components in ensuring the safety and stability of construction scaffolding.

- Different types of connectors serve specific purposes and contribute to the adaptability of modular scaffold systems.

- Proper selection and use of connectors based on load capacity, design, and configuration are essential for scaffold safety.

- Scaffold connectors play a critical role in creating reliable platforms for construction activities and enhancing worker safety.

- Understanding and utilizing the right connectors streamlines the construction process and ensures compliance with safety standards.

The Importance of Scaffold Connectors in Construction Safety

Scaffold connectors are key to construction safety. They link scaffolding parts together, making the whole structure stable and safe. These parts are crucial for preventing accidents and keeping workers safe. They also help projects run smoothly.

The role of scaffold connectors is huge. They make sure scaffolding is strong, even when it’s full of people, tools, and materials. This is vital for avoiding collapses and falls that can hurt or kill workers.

Connectors also help meet safety rules from groups like OSHA. Using the right connectors means following the law and keeping workers safe. It’s a must for any construction company.

| Scaffold Connector Type | Usage Percentage | Key Benefits |

|---|---|---|

| Swivel Couplers | 30% | Flexibility in scaffold design for dynamic construction needs |

| Board Clamps | 65% | Securing scaffold planks and ensuring a safe work platform |

| Base Plates | 40% reduction in ground pressure | Improved stability and load distribution compared to traditional setups |

| Joint Pins | 80% | Seamless end-to-end tube connections for efficient scaffold expansion |

| Guardrails | 90% | Essential safety barriers for worker protection at elevated levels |

The table shows how important scaffold connectors are. They help make scaffolding safe and efficient. By using the right connectors, workers can stay safe and projects can go smoothly.

Scaffold connectors are the unsung heroes of construction safety, serving as the critical link between scaffolding components and ensuring the stability and integrity of the entire structure.

In short, scaffold connectors are vital for construction safety. They provide the support and stability needed for scaffolding. By using top-notch connectors and following best practices, companies can keep workers safe and projects on track.

Types of Scaffold Connectors

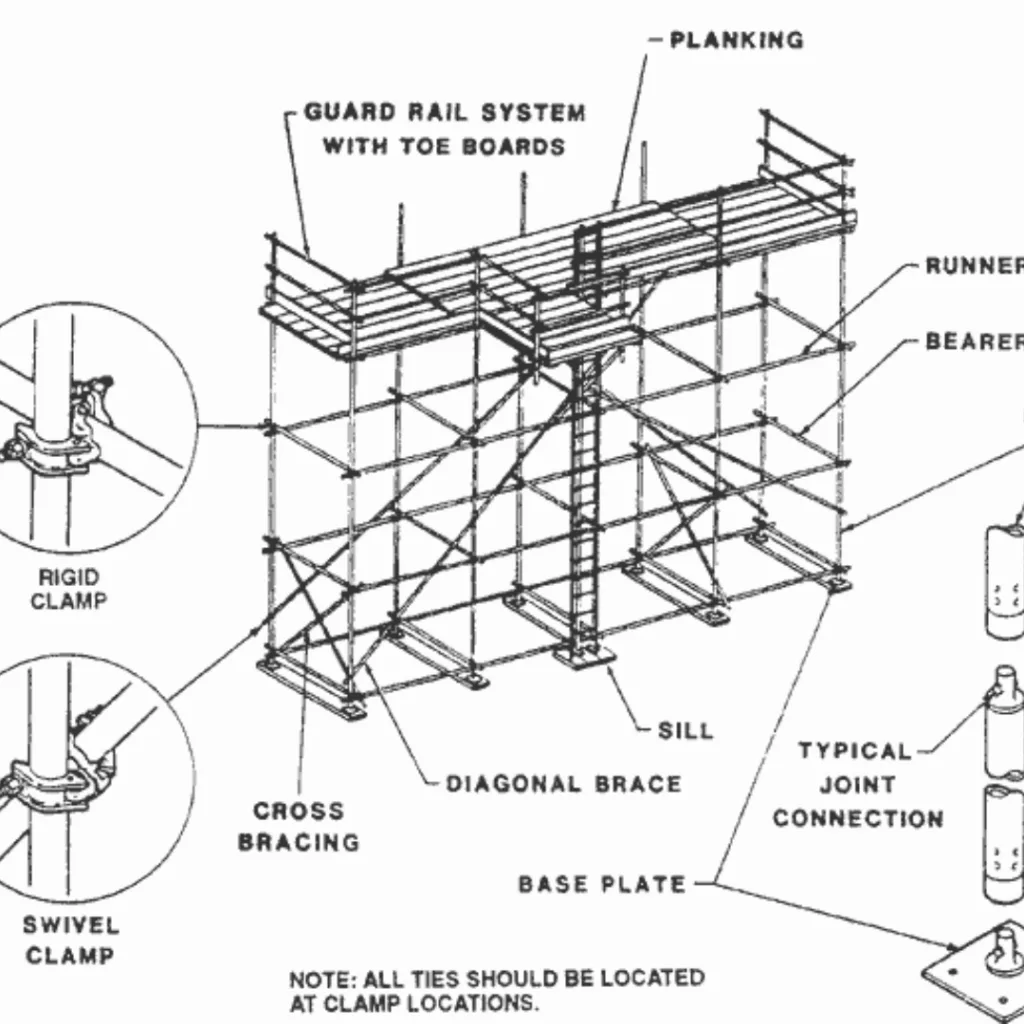

Scaffold connectors are key for keeping scaffolding safe and stable. They come in many types, each with its own role. Let’s look at the main types and how they help in construction safety.

Couplers

Couplers are the main parts that link scaffold tubes together. Swivel couplers let tubes connect at any angle, perfect for complex setups. Right-angle couplers, however, make strong 90-degree connections for stability. Putlog couplers hold transoms or putlogs to ledger tubes, often used for one-sided scaffold platforms.

Clamps

Clamps are vital for keeping scaffold boards in place. Board clamps, or board retaining couplers, prevent boards from moving. This keeps the work area safe and stable.

Brackets

Scaffold brackets add support and flexibility to scaffolding. Adjustable brackets fit tubes at various angles and heights. Fixed brackets create a solid work area. These brackets are crucial for adapting scaffolds to different needs.

Base Plates

Base plates are essential for a scaffold’s foundation. They spread the load evenly, preventing sinking. Base plate couplers secure the standards to the plates, ensuring a stable base.

Joint Pins

Joint pins connect scaffold tubes end-to-end. They allow scaffolding to grow longer. These pins ensure a strong and seamless connection, keeping the structure stable.

| Connector Type | Purpose |

|---|---|

| Swivel Couplers | Allow scaffold tubes to connect at any angle within a 360-degree range |

| Right-Angle Couplers | Form rigid connections at 90-degree angles for structural stability |

| Putlog Couplers | Secure transoms or putlogs to ledger tubes for platform construction |

| Board Clamps | Secure scaffold boards or toe-boards to prevent accidental displacement |

| Scaffold Brackets | Provide additional support and adaptability to the scaffold structure |

| Base Plates | Distribute the load evenly and provide a stable foundation for the scaffold |

| Joint Pins | Join scaffold tubes end-to-end for extending the scaffold structure |

Knowing about scaffold connectors is key for safety and stability. Choosing the right connectors and installing them correctly helps create safe scaffolds. This ensures workers are protected on various projects.

Choosing the Right Scaffold Connectors for Your Project

Choosing the right scaffold connectors is key for safety and efficiency in construction. It’s important to think about scaffold load capacity, design, and configuration. This ensures your project meets its specific needs.

Assessing Load Capacity Requirements

When picking scaffold connectors, load capacity is a top factor. Different scaffolding systems can handle different weights. It’s vital to pick connectors that can support workers, tools, and materials well.

Heavy-duty scaffolding connectors are great for heavy machinery or tough construction tasks. To figure out your project’s load needs, consider a few things:

- Type of construction work being done

- How many workers will be on the scaffolding

- The weight of tools and materials

- Environmental factors like wind, snow, or seismic activity

Considering Scaffold Design and Configuration

The design and setup of your scaffold are also key. Different scaffolding types need specific connectors for safety and stability. Think about these when evaluating your scaffold:

- The type of scaffolding system (e.g., tube and coupler, frame, or system scaffolding)

- The height and size of the scaffolding

- The surface conditions and anchoring needs

- How well it fits unique building structures or multiple platforms

Getting advice from professional scaffolding companies is crucial. They can help pick the right scaffolding for your project, keeping safety and load needs in mind.

Choosing the right connectors for your scaffold’s design and setup is vital. It ensures your scaffolding can handle construction loads safely and efficiently.

| Scaffold Type | Load Capacity | Suitable Connectors |

|---|---|---|

| Light Duty | Up to 25 lbs/ft² | Lightweight couplers, clamps, and brackets |

| Medium Duty | 25-50 lbs/ft² | Medium-duty couplers, clamps, and brackets |

| Heavy Duty | 50-75 lbs/ft² | Heavy-duty couplers, clamps, and brackets |

By looking at load capacity and scaffold design, you can pick the right connectors. This ensures your scaffolding system is safe and stable throughout your project.

Proper Installation and Use of Scaffold Connectors

Installing scaffold connectors safely and securely is key for any scaffolding structure’s stability. Following the manufacturer’s guidelines and industry standards is vital. This ensures the scaffolding is safe and prevents accidents.

Knowing how to assemble scaffolding properly is essential. It involves understanding the different parts and their roles. Also, knowing the right way to install scaffold connectors is crucial.

Training workers on scaffolding setup is a must for a safe work environment. This training should cover both the technical and safety aspects. It helps reduce the risk of accidents and injuries.

When installing scaffold connectors, remember their load limits. For example, girder couplers can handle 30 kN per pair when loaded evenly. But, their capacity drops to 15 kN if loaded unevenly. Always consider these limits during scaffold installation to keep the structure stable.

Regular checks and maintenance of scaffold connectors are also vital. Look for wear, damage, or corrosion. Make sure all connectors are tight. Replace any damaged or worn-out connectors to keep the scaffolding safe.

| Scaffold Component | Key Considerations |

|---|---|

| Scaffold Frames | Choose the right type and size for your project |

| Cross Braces | Install them correctly for stability and to prevent movement |

| Base Plates and Casters | Pick them based on mobility needs and ensure they’re level |

| Scaffold Boards | Use high-quality boards for safety and a solid platform |

| Guard Rails and Toe Boards | Install them right to prevent falls and protect against falling objects |

Staying updated with new scaffolding technology is also important. Modern scaffolding techniques can improve safety, efficiency, and sustainability. Using these advancements helps ensure scaffolding systems meet safety standards and work well.

Proper scaffold connector installation is the foundation of a safe and efficient scaffolding system. By prioritizing training, following best practices, and regular maintenance, construction companies can create a secure working environment for their employees and minimize the risk of accidents on the job site.

Maintenance and Inspection of Scaffold Connectors

Keeping scaffold connectors in good shape is key to safety and longevity. If we ignore maintenance and inspections, we risk damage and safety issues. A good maintenance and inspection plan helps avoid downtime, cuts repair costs, and keeps workers safe.

Regular Visual Inspections

Regular checks are the first step in spotting problems with scaffold connectors. These should be done by people who know the parts and how they work. Daily checks look for obvious damage like bent parts or corrosion.

Weekly, we do a deeper check to make sure everything is tight and in place. Monthly, we focus on the scaffolding’s structure and how it stands up to the weather.

Identifying Signs of Wear and Damage

When we inspect, we need to watch for signs of wear and damage. Look out for:

- Corrosion or rust on metal parts

- Cracks or bends in connectors or tubes

- Missing or loose fasteners, like bolts or pins

- Worn or damaged threads on couplers

- Bent or misaligned brackets or clamps

If we find any of these, we need to take the connectors out of service and replace them. This keeps the scaffolding safe and sound.

Replacement and Repair Procedures

When we find damaged connectors, we need to follow the right steps to fix or replace them. Sometimes, we can just tighten things up or fix small bends. But often, we need to replace them to be sure they’re safe and working right.

When we replace connectors, we must use the right parts for our system. Mixing parts from different makers can cause problems. We follow the manufacturer’s instructions to make sure the new parts fit and work well.

| Inspection Frequency | Key Areas of Focus |

|---|---|

| Daily | Visible damage, missing parts |

| Weekly | Proper alignment, tightness, overall integrity |

| Monthly | Structural soundness, foundation stability, environmental impact |

By sticking to a solid maintenance and inspection plan, we can lower accident risks, cut downtime, and follow safety rules. Training workers on how to inspect and maintain properly is key to a safe work environment.

Scaffold Connectors and OSHA Compliance

Keeping workers safe on construction sites is a top priority. Following OSHA rules is key to this goal. Scaffold connectors are crucial for keeping scaffolding systems safe and preventing accidents. OSHA has set clear guidelines for scaffold connectors to ensure a safe work environment.

Understanding OSHA Regulations for Scaffolding

OSHA has detailed rules for scaffolding in 29 CFR 1926.450-454. These cover platform safety, fall protection, access points, and more. For example, platforms must be at least 18 inches wide and hold 75 lbs. per square foot.

Fall protection is needed when working at heights of 10 feet or more. This helps prevent falls.

Knowing and following these OSHA scaffolding regulations is vital. It helps avoid penalties and keeps the workplace safe. Employers must train workers on scaffold use and safety.

Ensuring Compliance through Proper Connector Selection and Use

Choosing the right scaffold connectors is essential. They must support the scaffolding system’s weight and hold at least four times the maximum load. This ensures the scaffolding is safe.

It’s also important to install, use, and maintain connectors correctly. Regular checks are needed to spot any damage. Workers must know how to handle and use connectors properly.

| OSHA Regulation | Key Requirements |

|---|---|

| Platform Construction | Boards should support 75 lbs. per square foot over the entire span. Platforms must be at least 18 inches wide to prevent falls. |

| Fall Protection | Fall protection is required when employees are 10 feet or more above ground level. Options include guardrails or fall arrest systems, depending on the type of scaffold. |

| Access Points | Cross braces are not acceptable access points to scaffolding platforms. Acceptable accesses include ladders, stairs, stair towers, and ramps. |

| Support Scaffold Safety | Personnel must be trained on support scaffold usage. Supported scaffold should have jack legs on baseplates or a firm foundation. |

By following OSHA rules and using scaffold connectors correctly, construction sites can be safer. This protects employees and reduces accident risks.

Innovative Scaffold Connector Solutions

New scaffold connectors have improved safety, efficiency, and versatility in construction. Systems like the OCTO® system scaffolding offer great stability and flexibility. They are perfect for many projects, including industrial, aviation, and marine construction.

The OCTO® system scaffolding can hold up to eight metric tons, making it very stable. It has been tested for over a century, proving its reliability. It also needs 50% fewer parts than others, making it faster to set up and take down.

These connectors also focus on worker safety. The OCTO® system has a GuardAid® feature that makes it safe to assemble without harnesses. It also has a safety lock that gets tighter with use, making it safer.

Other systems, like Ringlock and Cuplock scaffolding, have their own benefits. Ringlock is rigid and versatile, while Cuplock is light and easy to set up. Kwikstage scaffolding is fast to assemble and can be customized for complex projects.

The OCTO® system’s design makes it easy to move and store. This is great for companies that want to save on storage and transportation costs.

Using lightweight yet strong materials, like aluminum and composites, has improved these connectors. This makes them easier to move and more reliable for construction projects.

Adding smart technologies, like sensors and monitoring systems, to scaffolding is a game-changer. These technologies can spot problems early and provide real-time data. This helps prevent accidents and keeps construction sites safe.

As construction evolves, using innovative scaffold connectors and advanced systems will be key. They ensure safety, efficiency, and flexibility in various projects. By using these solutions, construction pros can deliver top-notch results while keeping workers safe.

Training and Education on Scaffold Connector Safety

Keeping workers safe on construction sites is key. Proper training and education are crucial. Scaffold safety training is vital for those working with scaffolding. It helps reduce accidents and injuries.

Importance of Worker Training

Training workers in scaffold safety is a must for employers. It’s not just the law; it’s a moral duty. Workers need to know how to stay safe and protect others.

According to OSHA, workers on scaffolds more than 10 feet above a lower level must be protected from falling to that lower level. This includes workers on ladder jack scaffolds, walkways within scaffolds, overhand bricklaying operations, and general scaffolds with personal fall arrest systems or guardrail systems.

Good scaffold safety training covers many areas. It includes:

- Types of scaffolds and their components

- Proper assembly and disassembly procedures

- Safe use of scaffold connectors

- Fall protection systems and their importance

- Inspection and maintenance of scaffolding equipment

- Emergency response and reporting protocols

Best Practices for Safe Connector Handling

Handling connectors safely is vital. Workers need to know how to avoid accidents. Some key practices include:

- Inspecting connectors before use for any signs of damage or wear

- Using the right connectors for the scaffolding system

- Following manufacturer guidelines for installation and tightening

- Ensuring proper alignment and secure attachment of connectors

- Avoiding overloading of scaffolds and connectors beyond their rated capacity

| Scaffold Type | OSHA Requirements |

|---|---|

| Supported Scaffolds | Top edge height of toprails or equivalent member must be between 38 to 45 inches above the platform surface for scaffolds manufactured or placed in service after January 1, 2000 |

| Guardrail Systems | Must be capable of withstanding a 200-pound force applied in any downward or horizontal direction at any point along its top edge |

| Personal Fall Arrest Systems | Must be attached by a lanyard to a vertical lifeline, horizontal lifeline, or scaffold structural member |

By focusing on scaffold safety training, construction companies can create a safer work environment. Regular training and demonstrations are key. They help workers understand the importance of safe scaffold use and maintenance.

Case Studies: Successful Implementation of Scaffold Connectors

Real-world scaffold connector case studies show how these components are crucial in construction. The Burj Khalifa in Dubai is a great example. High-quality connectors ensured the scaffolding’s safety and stability, even in harsh weather conditions.

The renovation of the Sydney Opera House also highlights the importance of scaffold connectors. The project needed complex scaffolding to reach hard spots safely. Advanced connectors, like adjustable couplers, made the scaffolding adaptable and secure.

In the U.S., the San Francisco-Oakland Bay Bridge’s construction is another success story. Ensuring worker safety was key. High-quality connectors, regular checks, and maintenance helped complete the bridge safely.

These examples offer valuable lessons for the scaffolding industry. They show how choosing the right connectors and following safety guidelines can lead to success. By learning from these projects, professionals can improve safety and efficiency on their sites.