Phone:

(+65)8319-0742

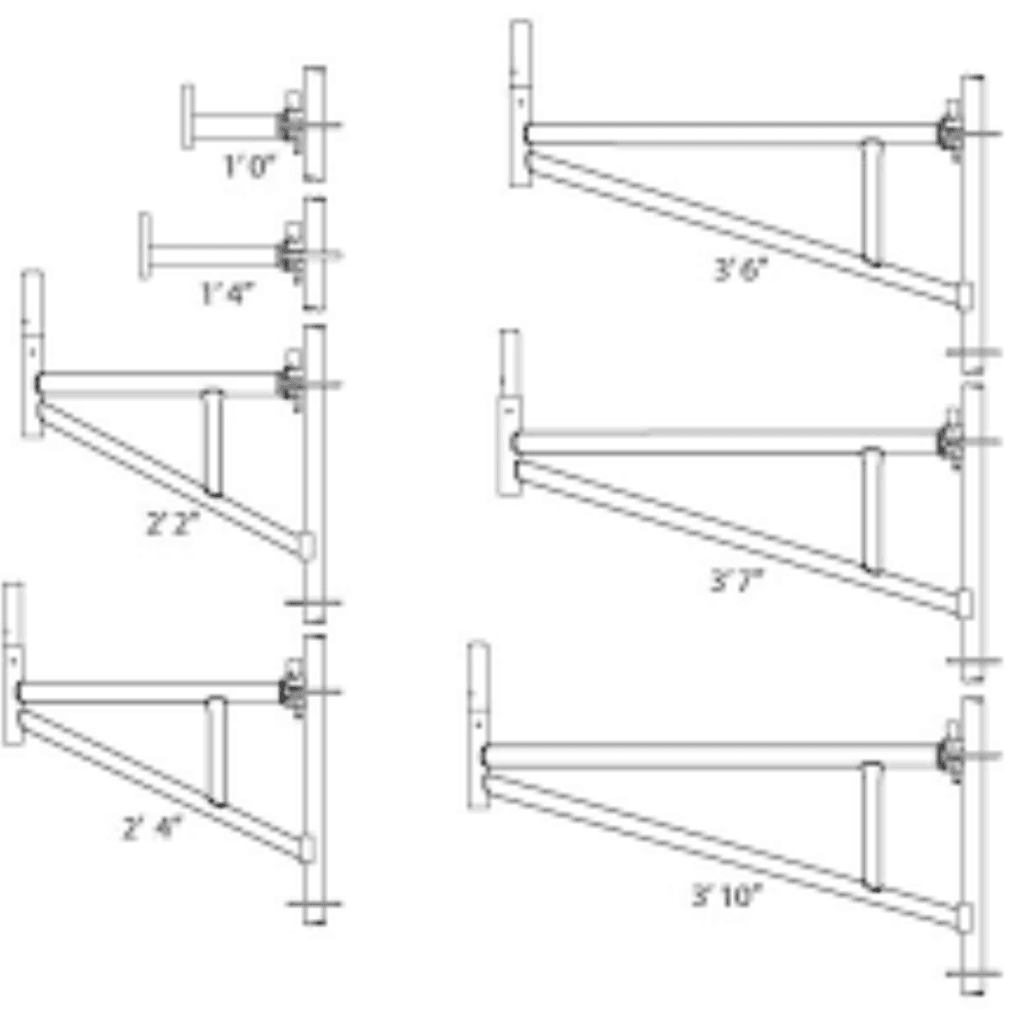

In the world of construction, professional scaffold brackets are key. They are made of tubular steel and are the core of temporary support structures. They keep worker safety platforms stable. These scaffold brackets can bolt through walls up to 8 inches thick. They use 5/8″ – 11 X 11 threaded rods. When selecting the corresponding model number, the individual product’s price is displayed prominently.

They are built to hold platforms with a maximum load of 500 pounds.

OSHA rules say carpenter’s wall bracket scaffolds must have guard rails, mid-rails, and toeboards for safety. The platform load should not exceed 500 lbs to ensure stability and safety. Also, no more than two workers can be on an 8-foot section of the scaffold at once. Following these rules helps keep workers safe while they work at heights.

Key Takeaways

Professional scaffold brackets are essential for construction safety, providing a sturdy and reliable framework for temporary support structures.

These brackets are designed to bolt through walls up to 8 inches thick, with a maximum load capacity of 500 pounds.

OSHA regulations mandate the use of guard rails, mid-rails, and toeboards on carpenter’s wall bracket scaffolds, and limit worker occupancy to no more than two per 8-foot section.

Adherence to safety guidelines is crucial in minimizing risks and ensuring a secure work environment for construction teams.

The use of professional-grade scaffold brackets is a critical component in maintaining a safe and compliant construction site.

Understanding Modern Scaffold Bracket Systems

https://www.youtube.com/watch?v=SNI_WoQhbog

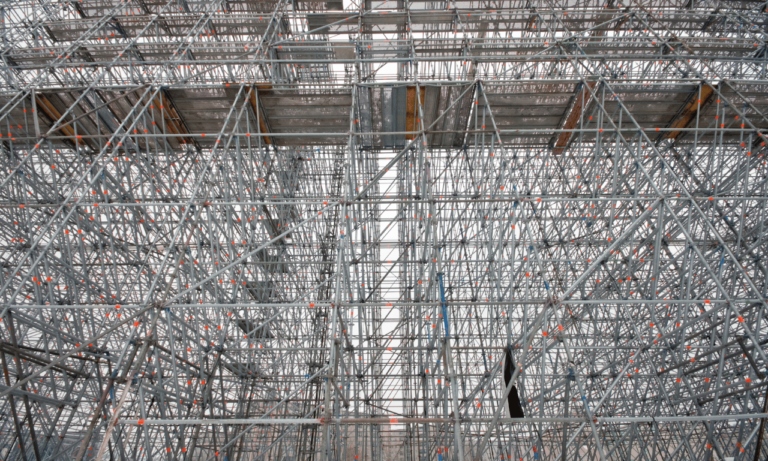

Scaffold bracket systems have changed a lot. They now offer many advanced options for construction projects. These systems use high-quality, adjustable metal frames. They are very stable and can hold a lot of weight, making them key construction site necessities.

Types of Professional-Grade Materials

Today’s scaffold bracket systems are made with strong materials like galvanized steel. This makes them last longer and resist corrosion. The adjustable metal frames are built to handle the tough conditions of construction sites. They provide a solid base for temporary structures and shoring systems.

Load-Bearing Capacities and Standards

These modular bracket systems can hold different weights, with some supporting up to 300 kg/m². To determine the correct product for your needs, refer to the table provided to select the appropriate model number. It’s important they follow OSHA and ANSI safety rules. Choosing the correct model number ensures they meet strict safety standards for workers and how loads are distributed.

Installation Requirements and Specifications

It’s vital to install these adjustable metal frames correctly for safety and effectiveness. The installation might include adjustable parts for different construction needs. This allows for easy setup and teardown for each project. Following the manufacturer’s instructions and industry best practices keeps the frames strong and safe for workers.

“The innovative design and superior quality of modern scaffold bracket systems have revolutionized the construction industry, enhancing worker safety and improving project efficiency.”

Essential Components of Scaffold Brackets

Building a safe scaffold on a construction site needs knowing the key parts. Each part, from the base to the working platforms, is vital. They all work together to keep workers safe.

The base of the scaffold is the base plate or caster. It spreads the weight and keeps the scaffold stable. These plates are at least 6mm thick and 150mm x 150mm in size. The sole plate is bigger, extending 600mm beyond the vertical pipes. It gives a solid base for the whole structure.

The vertical support is called the standard or upright. It’s made of steel or aluminum, with a diameter of 48.3mm. The horizontal bracing, or ledgers, link these standards together, making a strong frame. The working platform, made of wood or metal, is where workers stand.

Safety features like guard rails, toe boards, and safety nets are key. They protect workers from falling. Cross braces and access ladders or stairways also add to the scaffold’s strength and usability.

Choosing and installing these parts right is key for safety and following rules. Knowing each part’s role helps build scaffolds that are safe and efficient.

Safety Features and OSHA Compliance Guidelines

Keeping construction sites safe is key, and using OSHA-compliant scaffold frames is essential. OSHA rules require guard rails on platforms over 10 feet high for safety. It is important to note that scaffolds built over 10 feet in height from the ground require the inclusion of guard rails, mid-rails, and toeboards to ensure compliance with OSHA standards. These rails, along with safety harnesses and netting, prevent falls and keep workers safe.

OSHA also sets limits on how much weight platforms can hold, usually 500 lbs for certain scaffolds. It limits how many workers can be on a scaffold section, based on its length. Note that a trained person must check and maintain the scaffolding regularly to follow these safety rules and ensure compliance with OSHA requirements and recommendations.

Guard Rail Systems and Fall Protection

OSHA says guard rails are needed for platforms over 10 feet high. These rails, along with mid-rails and toe boards, stop falls and keep workers safe. Workers also need personal fall arrest systems, like harnesses, for extra protection at high heights.

Platform Weight Limitations

Scaffold platforms must hold up to four times their maximum load, as OSHA requires. For safety compliance, it is crucial not to exceed a maximum spacing of 8 feet between brackets when using 2″ X 10″ wood planks and 2″ X 4″ guard rails for carpenter wall bracket scaffolds. This “factor of safety” makes sure the equipment is strong and reduces the chance of it failing.

Worker Occupancy Guidelines

OSHA limits how many workers can be on a scaffold section. No more than two workers per 8 feet of platform length are allowed. This rule helps keep the platform stable and prevents accidents caused by too much weight.

Following these safety rules and OSHA guidelines helps construction companies keep their workers safe. It also avoids fines and penalties that can be very costly.

Advanced Scaffold Brackets for Construction Applications

Scaffolding is key in construction, and advanced brackets offer new features. These brackets meet the construction industry’s needs, focusing on safety, efficiency, and flexibility.

When selecting products, ensure you choose the corresponding model number to match your specific requirements for accurate pricing and compliance. The individual product’s price will be displayed prominently when selecting the corresponding model number.

The Layher Allround Scaffolding system is a top choice. It has adjustable brackets for uneven surfaces. These brackets make sure the platform is stable, even on tough terrain.

For heavy loads, the system has heavy duty scaffold brackets. They can hold up to 300 kg/m², meeting EN 12811-1 standards. These strong brackets are great for places needing extra support, like industrial sites or facade work.

Adjustable scaffold brackets for uneven surfaces

Heavy-duty scaffold brackets with high load capacities

Masonry brackets and facade brackets for specialized construction applications

The Layher Allround Scaffolding system also has masonry brackets and facade brackets. These are for specific tasks like masonry or facade work. They make the system even more versatile.

Advanced scaffold brackets, like those in the Layher system, are changing construction. They bring new features and high safety standards. This is making projects more productive, safe, and successful.

Installation and Maintenance Best Practices

Installing and maintaining roofing bracket scaffolding correctly is key for worker safety and equipment life. It is important to check the checkout sku for product details, including SKU number, weight, and shipping calculations before purchasing. Follow the manufacturer’s guidelines for mounting.

Regular inspections and proactive maintenance are also crucial for safety. Use the drop down menu to select the correct model number from the product table to ensure you are viewing the accurate price and specifications for your item.

Proper Mounting Techniques

Mounting construction hardware and bracing components securely is vital. Use the right bolts and rods for wall attachment. This ensures the shoring equipment is stable and safe.

Regular Inspection Protocols

Inspecting erection guides regularly is essential. Check for alignment, wear, and damage daily. Monthly, do a detailed check to ensure everything is stable.

Maintenance Requirements

Clean and lubricate moving parts to prevent rust and damage.

Replace worn or damaged parts to keep the scaffold safe and reliable.

Store scaffolding materials in a dry, covered area to protect them.

“Ensuring the safety of workers is a top priority, with proper maintenance being essential for compliance with safety regulations and standards.”

Following these best practices helps create a safer work environment. It also reduces downtime and extends the life of shoring equipment and bracing components.

Accessories and Support Components

Choosing the right accessories and support components is key for scaffold brackets. At Scaffold Type, we have a wide range of essential items. These items improve the safety and function of your scaffolding accessories, formwork accessories, reinforcement ties, and falsework materials.

Our lineup includes cross braces, hoist arms, well wheels, and side brackets. We also have access ladders, casters for easy movement, and guard rail systems. Specialized items like mortar board stands, steel stair units, and rolling tower outriggers are designed for specific tasks.

Our products ensure stability on uneven surfaces and secure attachment to buildings. Leveling jacks and tie braces with right-angle clamps are part of our range. Together, they create a strong and flexible scaffolding solution for your construction projects.

With over 30 years of experience, Scaffold Type is your top choice for scaffolding accessories, formwork accessories, reinforcement ties, and falsework materials. Our team is committed to providing top-notch products and solutions. We aim to keep your construction projects safe and efficient.

“Accessorize your scaffolding with the best to ensure safety and performance on every job site.”

Whether you’re working on a home renovation or a big commercial project, we have what you need. Our wide selection of scaffold accessories and support components will help you create a safe and reliable work area. Check out our offerings and improve your scaffolding setup today.

Conclusion

Professional scaffold brackets are key for keeping construction sites safe and efficient. They are made of strong metal and can hold a lot of weight. They also meet strict safety rules.

These brackets have special features that help in building projects. Following the right installation and care is important. This ensures workers have a safe place to work.

New technologies in scaffold brackets make work safer and more productive. As building methods change, so does the need for good brackets. This focus on safety and new ideas helps everyone on the site.

Using top-notch scaffold brackets is vital for safety and success in building projects. It’s all about following the rules, training, and using the latest in bracket design. This way, the construction world can keep improving safety and work better.

FAQ

What are the key features of professional scaffold brackets?

Professional scaffold brackets are made of strong tubular steel. The individual product’s price is displayed for each model, prominently shown in red once a model number is chosen from the dropdown menu. They can bolt through walls up to 8″ thick. This is done using 5/8″ – 11 X 11 threaded rods. These brackets can hold platforms with a maximum load of 500 lbs.

What are the OSHA requirements for carpenter’s wall bracket scaffold?

OSHA says carpenter’s wall bracket scaffolds need guard rails, mid-rails, and toeboards for safety. No more than two employees should be on any 8 feet of scaffold at once.

What materials are used in modern scaffold bracket systems?

Modern systems use high-quality materials like galvanized steel. This makes them durable and resistant to corrosion. Some systems can support up to 300 kg/m².

What are the essential components of scaffold brackets?

Key parts include base plates or casters for stability and standards or uprights for vertical support. Ledgers provide horizontal bracing. Working platforms, made of wood or metal, offer a safe place for workers.

What safety features are required for scaffold platforms?

Safety gear like guard rails, toe boards, and safety nets are vital for preventing falls. OSHA rules require guard rail systems for platforms over 10 feet high.

What are the platform weight limitations and worker occupancy guidelines?

Platforms for carpenter’s wall bracket scaffolds should not weigh more than 500 lbs. The rule is no more than two employees per 8 feet of scaffold.

What advanced features do some scaffold brackets offer?

Some brackets have adjustable parts for uneven surfaces and can handle heavier loads. They are designed for masonry or facade work. Some meet EN 12811-1 standards and can support up to 300 kg/m².

What are the best practices for installing and maintaining scaffold brackets?

Mount brackets securely to walls using the right bolts and threaded rods. Regular checks should look for structural integrity, alignment, and wear. Maintenance includes cleaning, lubricating, and replacing worn parts.

What accessories are available for scaffold bracket systems?

You can get cross braces, hoist arms, well wheels, and side brackets. Additional items include access ladders, casters, and guard rail systems. Specialized items like mortar board stands and steel stair units can enhance functionality.