Phone:

(+65)8319-0742

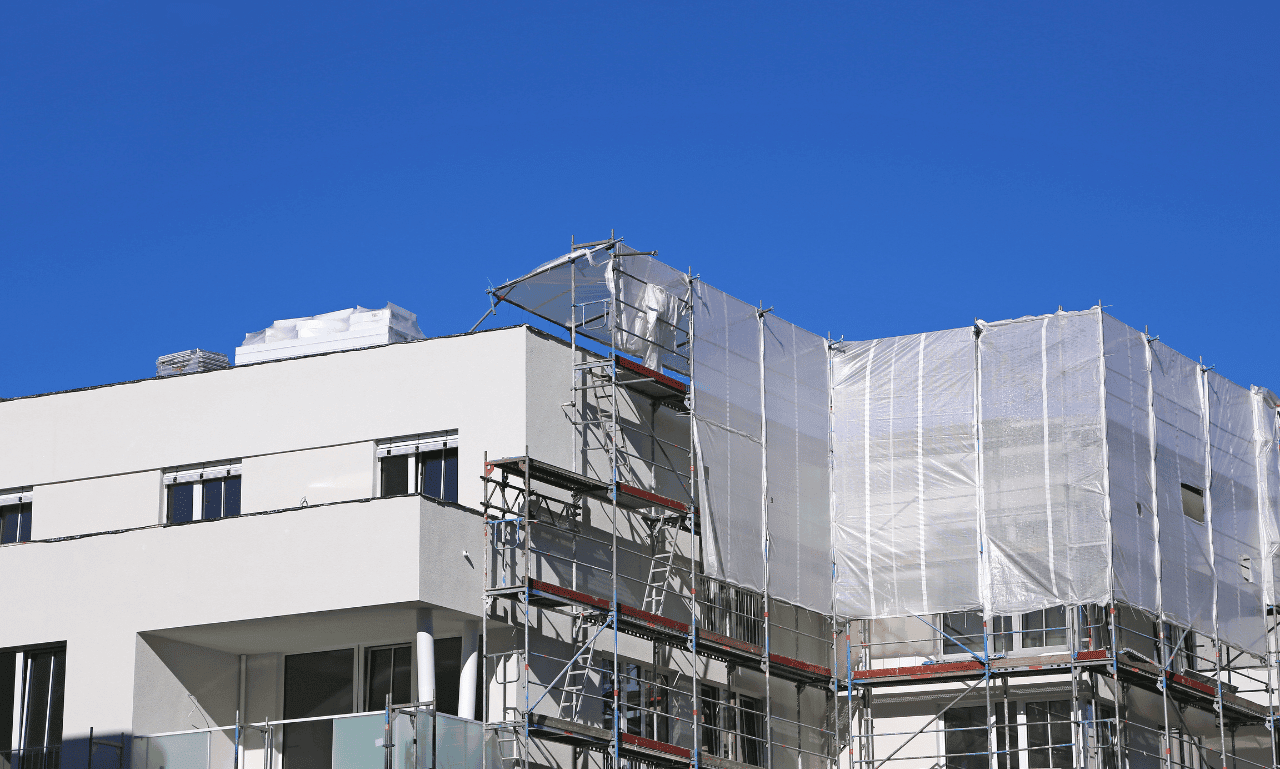

Addressing the pressing need for construction site safety, Roof Edge Protection Scaffolding emerges as a vital component in safeguarding workers during their ascent to new heights. The implementation of fall protection systems is more than a cautious stride; it is an OSHA-mandated step towards creating a fail-safe environment. With falls accounting for a significant number of on-the-job injuries in the construction industry, incorporating OSHA compliant guardrails and reliable rooftop safety measures is indispensable.

Incidents of falls from even modest elevations can be fatal or cause serious injury. Therefore, the integration of Roof Edge Protection Scaffolding not only mitigates these risks but stands as a statutory requirement for an array of roofing endeavorsâranging from solar panel setups to the fitting of climate control units. Embracing these safeguards translates to a significant downturn in roofing-related dangers.

Key Takeaways

- Ensuring construction site safety is paramount with the use of Roof Edge Protection Scaffolding.

- Installation of fall protection systems is required to prevent occupational injuries from heights.

- OSHA compliant guardrails provide a standardized barrier against rooftop incidents.

- Statutory regulations mandate the application of edge protection for various roofing tasks.

- A physical barrier is essential for reducing risk in rooftop work scenarios.

- The strategic placement of guardrails significantly enhances rooftop safety.

Understanding Roof Edge Protection Scaffolding

When it comes to maintaining construction site safety, the presence of reliable fall protection systems is non-negotiable. The critical role these systems play cannot be merely an afterthought in project planning and execution. Prevailing regulations underscore the gravity of incorporating roof edge protection barriers to mitigate the risks inherent to construction environments.

Importance of Edge Protection in Construction

Whether scaling the heights of a new edifice or refurbishing a historical landmark, construction professionals need a steadfast bulwark against the perils of high-altitude work. The implementation of stringent building protection equipment serves this vital purpose, safeguarding lives and fortifying the ethos of safety-first workplaces.

Legal Implications and OSHA Compliant Guardrails

The legal landscape governing the use of OSHA compliant guardrails is intricate. With oversight agencies mandating the implementation of customized solutions that cater to the unique aspects of each edifice, conformity with statutory provisions is as much a matter of legal obligation as it is of ethical responsibility.

Key Components of a Roof Edge Protection System

The architecture of a robust roof edge protection system is composed of several indispensable elements:

- Guardrails: Serving as the primary barrier against falls.

- Scaffold Netting: Offering additional protection from debris.

- Toe Boards: Preventing tools and materials from tipping over.

| Component | Description | Function |

|---|---|---|

| Guardrails | Metal or polymer barriers installed along the roof’s edge. | Block accidental falls and provide handhold for balance. |

| Scaffold Netting | Flexible mesh fitted beneath the guardrails. | Catch falling objects and reduce wind force. |

| Toe Boards | Solid barriers along the scaffold’s edge. | Keep materials and tools from sliding off the scaffold. |

Collectively, building protection equipment constitutes a formidable line of defense, fortifying edifices against worksite mishaps and ushering in a new era of elevated construction site safety.

Roof Edge Protection Scaffolding: Selection and Installation

Ensuring rooftop safety is paramount when it comes to the well-being of those working at heights. The selection and installation of Roof Edge Protection Scaffolding are influenced by multiple factors, all of which are critical to the effectiveness of the fall protection systems implemented. A comprehensive approach to this involves evaluating not only the physical dimensions of the roof but also the specific tasks that workers will undertake.

Determining the appropriate edge protection solutions starts with a deep dive into the roof’s pitch, height, and shape. Assessing these factors ensures that the roof edge guardrails selected will be optimally aligned with the contours and size of the building, thus providing robust protective measures without compromising on function or accessibility. In particular, the nature of the work being performedâisolated repairs versus comprehensive renovationsâinforms the scale and complexity of the scaffolding required.

- Roof Pitch: Different pitches may require specialist solutions to ensure guardrails are securely and safely installed.

- Roof Height: Height dictates the necessity for increased safety measures, as risks are amplified with elevation.

- Rooftop Activities: The more complex the task, the more intricate the scaffolding structure needed to provide a stable working platform.

It is not just about selecting the right equipment; proper installation is equally critical for maintaining rooftop safety. Professional installation by certified experts is non-negotiable to meet strict OSHA compliance and to ensure that scaffolding is both secure and efficient for use. Whether it’s a smaller cage assembly for quick interventions or full-fledged roof edge guardrails for extensive projects, each installation demands meticulous attention to legal requirements and safety standards.Only when appropriately installed, do these fall protection systems perform their role effectively, minimising the risk of accidents and enhancing the overall safety regimen on construction sites.

Roof Edge Protection Scaffolding and its correct installation are at the heart of safeguarding lives in the construction industry. The collaboration between careful selection, based on thorough risk assessments, and precise installation by seasoned professionals creates a dependable barrier against falls. Ultimately, it is this holistic approach that sustains a culture of safety and compliance in some of the most hazardous work environments.

Roof Edge Protection Scaffolding Types and Their Efficacy

When it comes to construction safety, the diversity of roof edge guardrails plays a key role in preventing accidents. From towering skyscrapers to residential homes, each construction project demands specific types of scaffolding, incorporating OSHA compliant guardrails to ensure worker protection. As we look into the various systems, it’s important to remember that while the form may vary, the functionâto safeguard livesâremains paramount.

Guardrail Systems for Enhanced Safety

To achieve the highest level of safety, construction sites employ a range of guardrail systems designed for durability and ease of use. These include fixed guardrails, which are permanently installed for long-term projects, and collapsible or freestanding versions that offer flexibility for short-term use or projects with changing protective needs.

Tailoring Scaffolding to Different Roofing Materials

The complexity of adapting building protection equipment is evident when confronting the varying surfaces and materials of roofs. Unique fixtures are required for sloped roofing compared to flat commercial edifices, understanding that the interface between scaffold and surface is critical for a secure and reliable installation.

Innovations in Building Protection Equipment

Innovation has ushered in a new era for innovative fall protection systems, including the advent of lightweight yet robust materials that contribute to easier assembly and disassembly. Additionally, cutting-edge modular edge protection systems provide versatility and adaptability, facilitating safer and more efficient working conditions.

Advancements such as wireless sensor-embedded guardrails offer real-time monitoring of stability and stress loads, highlighting the industry’s shift towards intelligent safety solutions.

| Type of Guardrail | Features | Best Uses |

|---|---|---|

| Fixed Roof Edge Guardrails | Permanent installation, high durability | Long-term projects, industrial/commercial roofs |

| Collapsible Guardrails | Portable, easy to install and dismantle | Short-term projects, varying protection needs |

| Freestanding Guardrails | No drilling required, versatile placement | Temporary setups, heritage buildings |

| Modular Edge Protection | Customizable configurations, lightweight | Complex roof shapes, adaptable scenarios |

Risk Management and Compliance in Roofing Projects

The construction industry constantly evolves, bringing to the fore the critical need for stringent risk management and compliance measures. Ensuring construction site safety, particularly in roofing projects, hinges on a solid understanding of the necessity for rigorous adherence to industry standards for edge protection and the implementation of reliable safety practices. These measures are fundamental in maintaining the safety and welfare of all personnel on site.

Meeting Industry Standards for Edge Protection Solutions

Integral to the safety protocols are OSHA compliant guardrails and roof edge protection barriers, which must align with the established industry standards for edge protection. These guidelines are meticulously designed to mitigate risks and are rigorously enforced to ensure that all construction activities, especially those conducted at substantial heights, meet the necessary safety criteria.

Minimizing Hazards with Roof Edge Guardrails

Customary construction site practices necessitate the use of roof edge protection barriers to effectively minimize hazards. These barriers serve as the primary line of defense against falls, providing essential protection for workers during the myriad of activities that characterize roofing projects. The proper installation and use of guardrails are pivotal in creating a secure workplace environment.

Ensuring Safety through Regular Inspection and Maintenance

Essential to maintaining ongoing construction site safety is the regular maintenance and inspection of installed safety systems. This proactive approach ensures that any potential issues with edge protection equipment are identified and rectified promptly, thus maintaining the integrity of the safety measures in place.

To further underscore the importance of maintenance and inspection, here is a detailed table highlighting the key aspects that need to be regularly reviewed:

| Component | Inspection Frequency | Primary Concerns | Regulatory Standards |

|---|---|---|---|

| Guardrails | Before each use | Stability, Damage, Corrosion | OSHA 1926.502(b) |

| Netting | Weekly | Integrity, Wear and Tear | AS/NZS 4994.1 |

| Edge Protection Barriers | Monthly and after adverse weather | Secure attachment, Missing components | AS/NZS 4994.2 |

| Toe Boards | Per project requirement | Proper Installation, Movement | OSHA 1926.502(j) |

Adherence to these protocols, paired with comprehensive worker training and robust communication channels, significantly diminishes risks and enshrines a culture of safety within the construction industry.

Conclusion

As this comprehensive guide has highlighted, Roof Edge Protection Scaffolding forms an integral part of maintaining rooftop safety and a commitment to accident prevention in the construction industry. The installation of OSHA compliant guardrails and a variety of fall protection systems is not just a best practice but a regulatory necessity. With the overarching goal of protecting lives, these systems are a testament to the industry’s ongoing dedication to safeguarding its workforce.

The imperative to integrate building protection equipment that adheres to stringent safety standards ensures that roofing projects do not become statistical anecdotes in reports on construction-related accidents. What becomes clear through the use of well-designed scaffolding systems is that the interplay between expert installation, application, and innovative design is paramount in creating a secure work environment. From the smallest repair project to immense construction underakings, the focus remains on preemptive risk management and establishing proactive barriers against potential falls.

In conclusion, embracing the latest trends and regulations in Roof Edge Protection Scaffolding is an investment in the well-being of construction personnel and the overall success of construction endeavors. As the scaffolding market burgeons, reflecting on the pivotal role of safety infrastructure such as OSHA compliant guardrails is essential for anyone involved in the act of constructing and maintaining edifices. It is through stringent adherence to these protective measures that construction sites can truly ensure a high level of safety and operational excellence.

FAQ

What is Roof Edge Protection Scaffolding?

Roof Edge Protection Scaffolding is a system of barriers designed to provide safety for workers operating at heights on construction sites. It includes guardrails, toe boards, and other components that prevent falls from roofs and elevated work platforms. These systems are essential for rooftop safety and construction site safety and must be OSHA compliant.

Why is edge protection essential in construction?

Edge protection is essential in construction to safeguard workers against fall-related injuries or fatalities, which are all too common in the industry. The presence of roof edge protection barriers like guardrails provides a physical barrier against falls, making it a critical aspect of construction site safety.

What are the legal requirements for OSHA compliant guardrails?

OSHA compliant guardrails must adhere to specific height and strength requirements to ensure they can effectively prevent workers from falling. They need to have a top rail, mid-rail, and toe board, and be able to withstand a minimum force without failure. The requirements for guardrails can vary depending on the height of the work area and the type of construction.

What are the key components of a Roof Edge Protection System?

The key components of a Roof Edge Protection System typically include guardrails, toe boards, safety netting, and sometimes scaffold netting. These components work together to create a barrier that prevents falls from the edges of roofs and elevated work surfaces.

How should Roof Edge Protection Scaffolding be selected and installed?

Selection and installation of Roof Edge Protection Scaffolding should be based on factors such as the pitch, height, and shape of the roof, as well as the nature of the work being performed. It’s vital to ensure the system is suitable for the specific situation and that professionals install it correctly to provide reliable fall protection.

What types of guardrail systems are available, and how do they differ in efficacy?

There are several types of guardrail systems available including fixed, collapsible, and freestanding guardrails. Each type offers different benefits and is designed to meet different requirements related to project scale and complexity. The efficacy of a guardrail system largely depends on correct selection and installation, tailored to the project’s specific needs.

How can scaffolding be tailored to different roofing materials?

Scaffolding can be tailored to different roofing materials by adjusting the scaffold design to accommodate various pitches, load capacities, and surfaces. For example, metal roofs may require different scaffolding solutions compared to shingle roofs, to ensure stability and worker safety.

What innovations are being made in Building Protection Equipment?

Innovations in Building Protection Equipment include the development of lightweight materials for easier handling and installation, the integration of technology for real-time monitoring of scaffolding stability, and design improvements for better safety and efficiency on construction sites.

How are industry standards for edge protection solutions met?

Industry standards for edge protection solutions are met by adhering to guidelines and regulations such as AS/NZS 4994.1 and AS/NZS 4994.2 in Australia, ensuring systems are appropriate for the height and type of work being conducted, and by using certified equipment installed by trained professionals.

Why is regular maintenance and inspection of roof edge protection barriers important?

Regular maintenance and inspection of roof edge protection barriers are crucial for ensuring ongoing safety. These practices help identify potential issues before they lead to failures, ensuring that the guardrails and other components remain in compliance with safety standards and are capable of preventing accidents.