Phone:

(+65)8319-0742

Safety is a top concern when working at heights, with approximately 4,500 scaffolding-related injuries occurring annually. Personal protective equipment (PPE) such as hard hats, non-slip footgear, and fall arrest equipment are crucial for protecting workers. Scaffolding equipment must be designed with specific load-bearing capacities in mind to avoid accidents caused by overloading. It is important to be familiar with industry-specific regulations and standards and to inspect all scaffolding materials before use. Following manufacturer instructions, ensuring a safe work area, and practicing good housekeeping are also key factors in ensuring scaffold safety. Monitoring weather conditions and working with licensed staff and contractors are additional measures that help prevent accidents on scaffolds.

Key Takeaways:

- Personal Protective Equipment (PPE) is essential for scaffold safety.

- Familiarize yourself with industry regulations and standards.

- Inspect scaffolding materials before use.

- Follow manufacturer instructions and maintain a safe work area.

- Monitor weather conditions and work with licensed professionals.

Ensuring the safety of workers on scaffolds is crucial for maintaining a hazard-free construction site. By implementing the right safety measures and adhering to regulations, the risk of scaffold accidents can be greatly reduced. In the following sections, we will explore personal protective equipment for scaffolding safety, the importance of understanding load-bearing capacities, scaffolding regulations and standards, pre-installation inspections, scaffolding safety during inclement weather conditions, proper training and supervision, fall protection, and material handling on scaffolds. Stay tuned to learn how to create a safe work environment for all construction site workers.

Personal Protective Equipment for Scaffolding Safety

When it comes to scaffolding safety, personal protective equipment (PPE) plays a vital role in ensuring the well-being of workers. PPE is designed to safeguard against specific hazards commonly encountered on construction sites. Here are some essential types of PPE that should be utilized:

Hard Hats

Hard hats are a crucial piece of PPE on any construction site, including scaffolding projects. They protect workers from potential head injuries caused by falling objects. By wearing a hard hat, workers can minimize the risk of serious injury.

Non-Slip Footgear

Wearing non-slip footgear is vital when working on scaffolding platforms. Slip-resistant shoes or boots provide enhanced traction and help prevent slips and falls, especially in potentially wet or slippery conditions.

Fall Arrest Equipment

Falls from scaffolding can have severe consequences. To mitigate this risk, fall arrest equipment, such as harnesses and lanyards, must be used. These devices are designed to arrest falls and protect workers from potentially life-threatening accidents.

Tool-Protecting Gloves and Tool-Tether Lanyards

Gloves with slip-resistant features improve workers’ grip and provide hand protection on scaffolding. Tool-tether lanyards are used to secure tools, preventing them from falling and causing accidents. By using these PPE items, workers can maintain a safer work environment.

| PPE | Usage |

|---|---|

| Hard Hats | Protects against falling objects |

| Non-Slip Footgear | Prevents slips and falls |

| Fall Arrest Equipment | Protects against falls from scaffolding |

| Tool-Protecting Gloves | Improves grip and hand protection |

| Tool-Tether Lanyards | Prevents tools from falling |

Using appropriate PPE significantly reduces the risk of injuries on scaffolds. It is essential for all workers to recognize the importance of PPE and follow proper usage guidelines to maintain a safe working environment. By prioritizing safety and utilizing the appropriate PPE, workers can minimize the likelihood of accidents on scaffolding projects.

Load-Bearing Capacities and Safety Factors of Scaffolding

Scaffolding structures are designed with specific load-bearing capacities and safety factors in mind to ensure the safety of workers. It is crucial to understand these factors when working with scaffolds to prevent accidents and injuries.

The load-bearing capacity of a scaffold refers to the maximum weight that the structure can support without compromising its stability. Exceeding this limit can lead to scaffold failure, causing serious harm to workers and those nearby. Therefore, it is essential to adhere to the load-bearing capacities specified by the manufacturer and relevant scaffold safety regulations.

In addition to load-bearing capacities, scaffolding structures are designed with safety factors that provide a margin of safety. Safety factors account for uncertainties and variations in loads and are typically expressed as a ratio. A common safety factor for scaffolding structures is 4 to 1, meaning that the structure is designed to withstand four times the expected load. This ensures that even if the load exceeds the intended capacity, the scaffold maintains its integrity and provides a significant safety cushion.

When working with scaffold platforms, it is important to consider their load-bearing capacities as well. Scaffold platforms should be able to support the weight of workers, tools, and materials without bending, breaking, or collapsing. Regular inspections should be conducted to ensure that the platforms are in good condition and meet the safety requirements.

Adhering to scaffold safety regulations is crucial for maintaining load-bearing capacities and safety factors. These regulations outline the necessary guidelines and standards that scaffold structures and platforms must meet to protect workers and ensure their safety. By following these regulations and conducting regular inspections, the risk of accidents and injuries on scaffolds can be significantly reduced.

| Load-Bearing Capacities | Safety Factors | Scaffolding Structures | Scaffold Platforms | Scaffold Safety Regulations |

|---|---|---|---|---|

| Specifies the maximum weight a scaffold can support without compromising stability | Provides a significant safety cushion with a 4 to 1 safety factor | Designed to withstand expected loads and uncertainties | Should support workers, tools, and materials without bending or breaking | Guidelines and standards that ensure scaffold safety and integrity |

Understanding Scaffolding Regulations and Standards

When it comes to scaffolding safety, it is crucial to understand the regulations and standards that govern the industry. Different industries have specific requirements for scaffold construction and usage. These regulations are put in place to ensure the safety of workers and minimize the risk of accidents and injuries.

One of the primary authorities in scaffolding regulations is the Occupational Safety and Health Administration (OSHA) in the United States. OSHA has established comprehensive guidelines and regulations to protect workers on construction sites. These regulations cover various aspects of scaffolding safety, including design, construction, and usage.

In addition to OSHA regulations, there are industry-specific standards that must be followed. These standards are developed by industry associations and organizations to address the unique challenges and risks associated with different sectors. Compliance with these industry-specific standards is essential to ensure the safety and well-being of workers.

Competent Person Inspection Requirement

One important aspect of scaffolding safety is the Competent Person inspection requirement. According to OSHA regulations, a Competent Person must inspect the scaffold before it is used. The Competent Person is someone who has the knowledge, training, and experience to identify hazards and ensure that the scaffold meets all safety requirements.

The Competent Person inspection involves a comprehensive assessment of the scaffold’s structure, components, and load-bearing capacities. Any defects, damage, or issues that could compromise safety are identified and addressed before workers are allowed to use the scaffold. This inspection is crucial for ensuring that the scaffold is in a safe and reliable condition.

Furthermore, specific customer sites may have additional requirements and standards that must be followed. These requirements could include project-specific safety measures, additional training, or additional inspections. It is important to research and understand these customer site requirements to ensure full compliance and to maintain a safe working environment.

Complying with Scaffolding Safety Regulations

Building and using scaffold structures according to the applicable regulations and standards is crucial for ensuring the safety of workers and minimizing the risk of accidents. By complying with these regulations, construction companies can create a safe and healthy work environment.

Failure to comply with scaffolding safety regulations can have severe consequences. Accidents and injuries not only harm workers but also expose companies to legal liabilities and financial losses. Therefore, it is in the best interest of all stakeholders to prioritize scaffolding safety and adhere to the relevant regulations.

Training and Hazard Recognition

Proper training plays a vital role in ensuring scaffolding safety. Workers should receive comprehensive training on scaffold construction, usage, and safety protocols. This training equips them with the knowledge and skills to recognize and minimize scaffold-related hazards.

Workers should be aware of the specific regulations and standards that apply to their industry and customer sites. They should also understand the importance of following safety protocols and using personal protective equipment (PPE) correctly. This knowledge and awareness empower workers to be proactive in maintaining a safe work environment.

By understanding and complying with scaffolding regulations and standards, construction companies can ensure the safety of their workers and create a culture of safety on their construction sites.

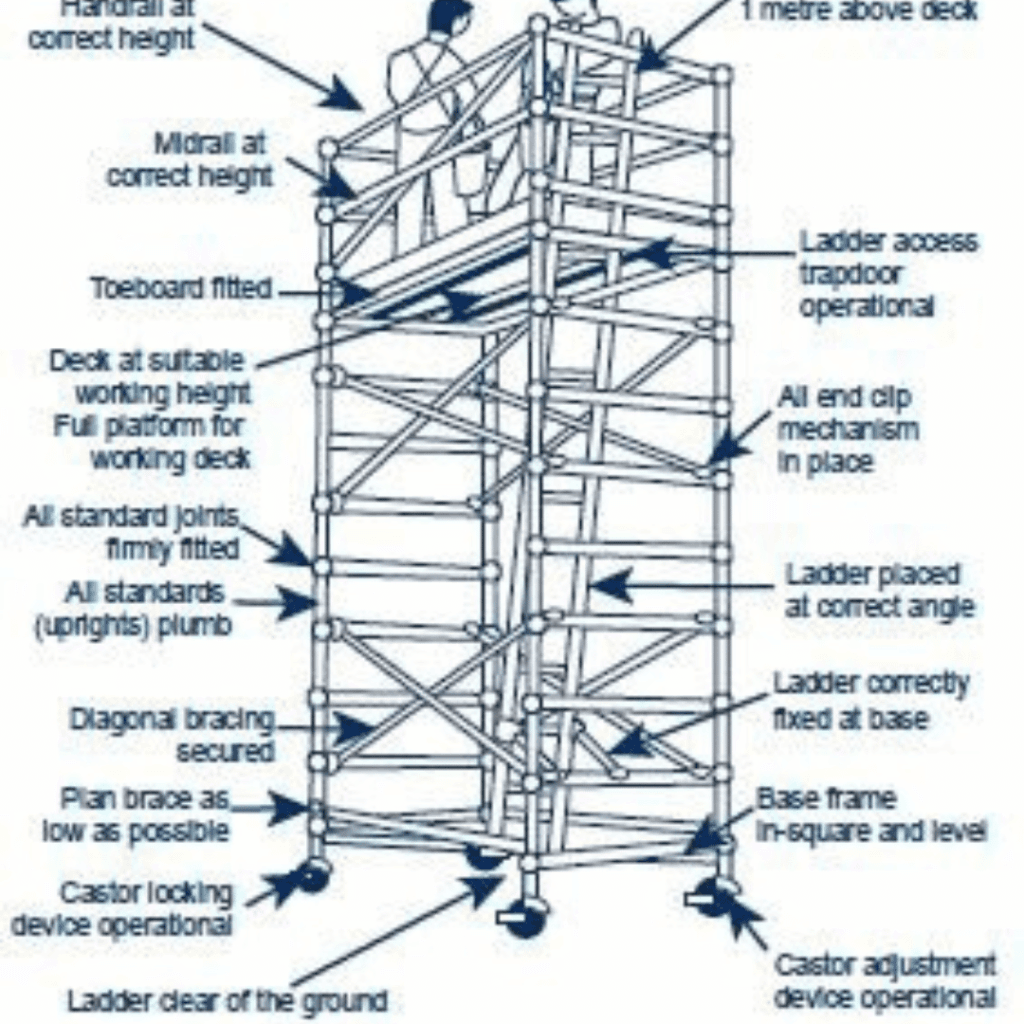

Pre-Installation Inspections and Scaffold Integrity

Before installing scaffolding, conducting thorough inspections is crucial to ensure the safety and structural integrity of the scaffold. These inspections include:

- Scaffold materials inspection: Inspect all scaffold materials for any defects or damage that could compromise the structural integrity. This includes checking for cracks, bends, rust, or any other signs of wear and tear.

- Scaffold structure inspection: Examine the scaffold structure for any potential issues such as misalignment, instability, or weak points. Ensure that all components are properly connected and securely fastened.

- Matching components: Verify that all scaffold components, including braces, connectors, and platforms, are compatible and properly matched. Mismatched components can lead to structural hazards and increase the risk of scaffold failure.

- Scaffold hazards: Identify and address any potential scaffold hazards during the inspection process. Common hazards include inadequate bracing, insufficient anchoring, or missing safety features.

It is essential to follow manufacturer instructions during scaffold erection, including specific requirements for bracing, fasteners, and anchor points. Regular inspections are also necessary to identify any hazards, defects, or debris that could compromise the safety of the scaffold.

Sample Scaffold Inspection Checklist:

| Inspection Item | Condition | Action Required |

|---|---|---|

| Scaffold materials | Check for defects or damage | Repair or replace damaged components |

| Scaffold structure | Ensure stability and structural integrity | Address any misalignment or weak points |

| Matching components | Verify compatibility and proper connections | Replace mismatched or incompatible components |

| Scaffold hazards | Identify potential safety hazards | Implement necessary safety measures |

Regular inspections, both before installation and throughout the use of scaffolding, are critical to maintaining a safe working environment. By identifying and addressing potential hazards, ensuring structural integrity, and following proper installation procedures, the risk of scaffold-related accidents can be significantly reduced.

Scaffold Safety During Inclement Weather Conditions

Working on scaffolds during harsh weather conditions poses significant risks to scaffold safety. High winds, rain, lightning, snow, and ice can all increase the likelihood of accidents and endanger workers on the scaffold. It is crucial to prioritize weather safety and follow OSHA guidelines to maintain a hazard-free workplace.

High Wind Safety

Strong winds can cause instability and compromise the integrity of scaffolding structures. To ensure high wind safety:

- Monitor weather forecasts regularly and postpone work on scaffolds during high wind events.

- Secure loose materials and inspect the scaffold for any loose or unstable components.

- Use wind-resistant barriers or shielding to minimize the impact of strong winds.

Rain Safety

Rain can create slippery surfaces on scaffolds, increasing the risk of falls and accidents. To ensure rain safety:

- Cover scaffolds with weatherproof materials to prevent rainwater accumulation.

- Use non-slip footgear and implement appropriate fall protection measures.

- Inspect the scaffold for any signs of water damage or structural weaknesses.

Lightning Safety

During thunderstorms, the risk of lightning strikes poses a severe threat to scaffold safety. To ensure lightning safety:

- Follow OSHA guidelines and immediately evacuate scaffolds when lightning is present.

- Provide workers with a safe indoor location to seek shelter during storms.

- Implement a clear lightning safety protocol and communicate it effectively to all workers.

Snow and Ice Safety

Snow and ice accumulation on scaffolds can create slippery surfaces and add additional weight that exceeds the scaffold’s load-bearing capacity. To ensure snow and ice safety:

- Clean snow and ice from scaffolds before allowing workers to resume work.

- Inspect the scaffold for any damage or weaknesses caused by the weight of snow and ice.

- Apply anti-slip coatings or other measures to improve traction on scaffold platforms.

Monitoring Weather and Enforcing Safety Rules

To maintain scaffold safety during inclement weather conditions:

- Regularly monitor weather forecasts to stay informed about upcoming weather events.

- Enforce strict adherence to weather safety rules and guidelines.

- Provide workers with proper training on identifying weather hazards and taking appropriate safety precautions.

By prioritizing scaffold safety during inclement weather conditions and following OSHA guidelines, construction sites can mitigate the risks associated with adverse weather and protect the well-being of workers.

Proper Training and Scaffold Supervision

Proper training and supervision are paramount to ensuring the safety of scaffolding operations. By providing comprehensive scaffolding training, workers can develop the necessary skills and knowledge to safely erect, use, and dismantle scaffolds. This training should cover various aspects such as understanding scaffold components, load-bearing capacities, and specific safety practices.

When it comes to the implementation of scaffolding, it is crucial to involve licensed staff and contractors who possess the expertise and experience to handle scaffolding safely and efficiently. Their familiarity with industry-specific regulations and standards ensures compliance and reduces the risk of accidents.

Adhering to appropriate scaffold safety training is essential for safeguarding workers’ well-being. Training programs should focus on teaching recommended climbing practices, including maintaining three points of contact and utilizing ladders or stairs to ascend and descend scaffolds. This ensures that workers are equipped with the necessary skills to navigate scaffolding structures safely.

The use of scaffold tags is an effective visual indicator of scaffold safety. These tags provide important information about the inspection status, load capacity, and usage guidelines of the scaffold. A competent person should regularly inspect these tags to ensure that the scaffolding remains safe for use.

Additionally, scaffold supervisors play a crucial role in maintaining scaffold safety. They are responsible for monitoring scaffold activities, conducting competent person inspections, and enforcing safety protocols on-site. Their active involvement and oversight contribute to the overall safety and compliance of scaffold operations.

Roles and Responsibilities for Scaffold Safety

| Role | Responsibilities |

|---|---|

| Scaffold Trainees | – Attend and actively participate in scaffold training programs – Apply trained scaffold erection, usage, and dismantling techniques – Follow climbing practices for safe scaffold access |

| Licensed Staff and Contractors | – Apply industry-specific regulations and standards – Ensure proper scaffold design, construction, and usage – Supervise scaffold activities – Create and enforce safety protocols |

| Scaffold Tags Inspectors | – Regularly inspect scaffold tags for accuracy and legibility – Verify load capacity and other safety-related information |

| Scaffold Supervisors | – Monitor scaffold activities to ensure compliance with safety protocols – Conduct competent person inspections – Enforce safety regulations and address non-compliance issues |

By prioritizing proper training, licensed staff and contractors, and effective supervision, scaffold safety can be significantly enhanced, reducing the risk of accidents and promoting a secure work environment for all.

Fall Protection and Material Handling on Scaffolds

When it comes to working on scaffolds, fall protection is of utmost importance. The use of appropriate fall protection equipment is crucial in preventing accidents and ensuring the safety of workers. Harnesses, lanyards, and anchor points should always be utilized when working at heights of 10 feet or more. These fall protection systems are designed to secure workers and minimize the risk of falls, providing peace of mind and a safer working environment.

Regular inspections of fall protection equipment are essential to identify and address any potential issues or defects. This ensures that the equipment is in proper working order and can effectively protect workers in the event of a fall. By conducting regular maintenance and inspections, you can proactively identify and rectify any problems, minimizing the risk of accidents on the scaffold.

In addition to fall protection, proper material handling procedures play a crucial role in scaffold safety. Storing materials safely, using appropriate lifting equipment and rigging gear, and maintaining clear communication between workers during material handling tasks are all essential steps in preventing scaffold accidents.

Proper material handling procedures involve ensuring that materials are securely stored and organized on the scaffold to avoid potential hazards. Using the appropriate lifting equipment, such as cranes or hoists, reduces the risk of injuries caused by improper manual lifting. Rigging gear, such as slings and hooks, should be properly inspected and used according to manufacturer guidelines to ensure they can handle the loads being lifted safely.

Clear communication between workers during material handling tasks is vital to prevent accidents and ensure everyone understands the proper procedures. This includes effective signaling, using hand signals or radios, and providing clear instructions to colleagues.

By prioritizing fall protection on scaffolds and following proper material handling procedures, you can significantly reduce the risk of accidents and create a safer working environment for all. Implementing these measures demonstrates a commitment to worker safety and aligns with industry best practices.

Essential Fall Protection Equipment for Scaffold Safety

| Equipment | Function |

|---|---|

| Harness | Secures the worker to prevent falls |

| Lanyard | Connects the harness to an anchor point for fall arrest |

| Anchor Points | Designated secure points for connecting the lanyard and harness |

Conclusion

Scaffold accidents can be effectively prevented by prioritizing safety precautions and adhering to regulations. The implementation of personal protective equipment, regular pre-installation inspections, and adherence to load-bearing capacities are crucial for scaffold safety. Furthermore, a comprehensive understanding of scaffolding regulations and continuous maintenance, training, and supervision are essential in ensuring a safe working environment on construction sites.

Fall protection equipment, including harnesses and anchor points, should be utilized at all times to minimize the risk of accidents. Additionally, following proper material handling procedures and maintaining clear communication among workers when handling materials on scaffolds significantly enhances scaffold safety.

By integrating these vital safety measures into daily practices, construction site workers can effectively prevent scaffold accidents and create a secure workplace. Prioritizing protection scaffolding, scaffold safety precautions, and construction site safety not only safeguards workers but also improves productivity and overall project success.

FAQ

How does personal protective equipment contribute to scaffolding safety?

Personal protective equipment (PPE), such as hard hats, non-slip footgear, and fall arrest equipment, play a vital role in protecting workers from hazards on scaffolds. Hard hats protect against falling objects, non-slip footgear prevents slips and falls, and fall arrest equipment safeguards against falls when working on platforms.

What is the significance of load-bearing capacities and safety factors in scaffolding?

Scaffolding components are designed with specific load-bearing capacities and safety factors in mind. Placing excessive loads on scaffolds beyond their intended design capacity can lead to accidents and injuries. Scaffold platforms may break or collapse, endangering workers. Adhering to load-bearing capacities ensures worker safety and prevents structural failures.

What regulations and standards should be followed for scaffold safety?

Different industries have specific regulations and standards for scaffold safety. Federal OSHA governs scaffolding regulations, and specific customer sites may have additional project standards. It is important to research and comply with OSHA, industry, and customer site requirements to ensure safe scaffold construction and usage.

Why are pre-installation inspections and scaffold integrity important?

Conducting thorough inspections before installing a scaffold is crucial for ensuring safety. All scaffold materials should be inspected for defects or damage that could compromise structural integrity. Mismatched components and missing parts pose significant hazards and can lead to scaffold failure. Regular inspections help identify and address potential hazards and ensure scaffold integrity.

What precautions should be taken for scaffold safety during inclement weather conditions?

Working on scaffolds during harsh weather conditions increases the risk of accidents. High winds can cause instability, and rain, lightning, snow, and ice can create hazardous conditions. OSHA advises against working on scaffolds during severe weather events and emphasizes monitoring forecasts and enforcing weather safety rules to maintain a hazard-free workplace.

What role does proper training and supervision play in scaffold safety?

Proper training and supervision are crucial for scaffold safety. Workers should receive training on scaffold erection, usage, and dismantling, and licensed staff and contractors should handle scaffolding. Following climbing practices, conducting scaffold inspections, and enforcing safety protocols are important. Scaffold supervisors play a vital role in monitoring activities and ensuring safety.

Why is fall protection important on scaffolds?

Fall protection is essential when working on scaffolds. Fall protection equipment, including harnesses, lanyards, and anchor points, should be used when working at heights of 10 feet or more. Regular inspections of fall protection equipment ensure it is in good working order. Proper material handling procedures must also be followed to prevent scaffold accidents.

How can scaffold accidents be prevented?

Scaffold accidents can be prevented by following safety precautions and regulations. Utilizing personal protective equipment, conducting pre-installation inspections, adhering to load-bearing capacities, and understanding scaffolding regulations are crucial for scaffold safety. Regular maintenance, proper training, and supervision enhance scaffold safety. Fall protection equipment should be used at all times, and proper material handling procedures must be followed to prevent accidents.