Phone:

(+65)8319-0742

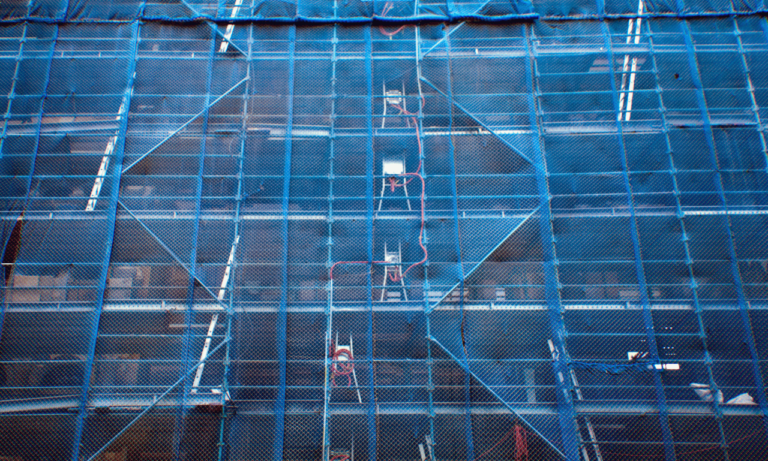

Safety is a top concern when working at height, and scaffolding-related incidents lead to approximately 4,500 injuries annually. To protect employees on construction sites, it is essential to implement proper protection scaffolding measures. This includes using safety equipment such as guardrails, fall protection systems, and edge protection barriers. Adhering to scaffolding safety regulations and standards is crucial for ensuring site safety and preventing accidents.

Key Takeaways:

- Proper protection scaffolding measures are necessary to ensure site safety on construction sites.

- Using safety equipment such as guardrails, fall protection systems, and edge protection barriers is crucial.

- Adhering to scaffolding safety regulations and standards is essential for preventing accidents.

- Scaffolding-related incidents lead to approximately 4,500 injuries annually.

- Implementing protection scaffolding measures can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment for Scaffolding Safety

When it comes to scaffolding safety, personal protective equipment (PPE) plays a critical role. Providing the right PPE to workers is essential for their protection and preventing accidents on construction sites. Adhering to scaffolding safety regulations and standards regarding PPE usage is crucial for protecting employees and ensuring overall site safety.

One of the primary risks when working at heights is the possibility of falling objects. To mitigate this risk, workers should always wear hard hats, which provide head protection against potential hazards. Hard hats are an important piece of scaffolding safety equipment that can help prevent severe injuries. By wearing a properly fitted hard hat, workers protect themselves from falling debris or tools that could cause head injuries.

In addition to head protection, non-slip footgear is crucial for preventing falls from scaffolds. Workers need to have reliable and sturdy footwear that provides excellent traction, especially when working in challenging conditions or on uneven surfaces. Proper non-slip footgear reduces the risk of slips and trips, enhancing overall safety on scaffolding structures.

When it comes to fall protection, having the right equipment, such as a fall arrest system, is imperative. A fall arrest system consists of a full-body harness, lanyard, and anchor points. The harness distributes the fall forces throughout the body, reducing the risk of injury. The lanyard attaches the worker to a secure anchor point, preventing falls from scaffolds. Fall arrest systems provide workers with the confidence and protection they need when working at heights.

Hand-protecting gloves are another essential piece of PPE for scaffolding safety. These gloves help improve grip and dexterity, reducing the risk of accidents caused by slippery tools or materials. Additionally, using tool-tether lanyards is crucial for preventing tools from falling off the scaffold, protecting workers below from potential hazards.

Implementing and enforcing the use of personal protective equipment is not only a legal requirement but also a crucial step in safeguarding workers’ well-being when working on scaffolding structures. By providing the necessary PPE and ensuring its proper usage, employers demonstrate their commitment to employee safety and compliance with scaffolding safety regulations.

Benefits of Personal Protective Equipment for Scaffolding Safety

- Reduces the risk of head injuries by wearing hard hats

- Prevents slips and trips with non-slip footgear

- Safeguards against falls with fall arrest systems

- Improves grip and prevents tool accidents with hand-protecting gloves

- Protects workers below from falling tools with tool-tether lanyards

By following these safety measures and providing the necessary personal protective equipment, employers can create a safer work environment and prioritize the well-being of their employees.

Load-Bearing Capacity and Design Considerations for Scaffolding

Scaffolding structures are carefully designed with specific load-bearing capacities and load limits to ensure the safety of workers and prevent accidents. It is crucial to understand and adhere to these capacity guidelines to maintain a secure working environment.

Load-bearing capacity: Scaffolding components are engineered to withstand certain weights and forces. Exceeding the prescribed load limits can compromise the structural integrity of the scaffold and put workers at risk. By respecting these weight restrictions, employers can prioritize the safety of their employees and prevent avoidable accidents.

Design considerations: Properly designing scaffolding structures is essential for their overall stability and safety. Factors such as platform width, height, and bracing play a significant role in ensuring the scaffold’s strength and durability. Adhering to scaffolding safety regulations enables builders to make informed design choices that align with industry standards and best practices.

Scaffolding components typically have a safety factor of 4 to 1, meaning they can handle four times the intended load before reaching their maximum capacity. This safety factor provides a significant cushion to account for unexpected or additional loads on the scaffold.

Integrating scaffold protection systems, such as guardrails and edge protection barriers, further enhances the safety of scaffolding structures. These systems provide additional layers of protection and prevent workers from falling or being exposed to potential hazards.

To ensure optimal protection scaffolding, it is crucial for construction professionals to familiarize themselves with scaffolding safety regulations and follow the recommended guidelines for load-bearing capacity and design considerations.

Benefits of Proper Load-Bearing Capacity and Design

- Enhanced safety: Designing scaffolds according to capacity guidelines reduces the risk of accidents and injuries caused by structural failures.

- Compliance with regulations: Adhering to scaffolding safety regulations ensures that construction sites meet industry standards and legal requirements.

- Long-term cost savings: Properly designed and load-rated scaffolding systems require less maintenance and are more durable, leading to potential savings in repair and replacement costs.

- Peace of mind: Workers can carry out their tasks with confidence, knowing that the scaffolding structure they are working on has been designed and tested for safety and stability.

By prioritizing load-bearing capacity and design considerations, construction professionals can create a secure working environment and mitigate the risks associated with scaffold-related accidents.

Scaffolding Safety Regulations and Compliance

Ensuring compliance with scaffolding safety regulations is paramount to maintaining a safe construction site and preventing accidents. The regulations, governed by Federal OSHA (Occupational Safety and Health Administration), establish minimum requirements that must be followed to protect workers. Additionally, industry and customer sites may have their own specific requirements that must be adhered to.

By adhering to these regulations, employers not only minimize the risk of accidents but also avoid potential liability issues. It is essential to familiarize yourself with the specific regulations applicable to your industry and job site.

One critical aspect of compliance is having a Competent Person on-site who is trained to recognize and mitigate scaffolding risks. The Competent Person is responsible for conducting regular inspections, identifying potential hazards, and ensuring that safety measures are in place.

Training workers on scaffolding safety regulations and procedures is vital to ensure compliance. They should be knowledgeable about the specific regulations set forth by OSHA, as well as any additional requirements from industry or customer sites. Regular refresher training sessions should be conducted to update workers on any changes or new safety protocols.

By creating a culture of safety and emphasizing compliance with scaffolding safety regulations, employers can establish a safe work environment and protect their workers from accidents and injuries.

Key Points:

- Compliance with scaffolding safety regulations is crucial for preventing accidents and minimizing risks.

- Familiarize yourself with the specific regulations applicable to your industry and job site.

- Have a Competent Person on-site who is trained to recognize and mitigate scaffolding risks.

- Train workers on scaffolding safety regulations and procedures, including any specific requirements from industry or customer sites.

- Regularly update workers on changes or new safety protocols through refresher training sessions.

| Types of Safety Regulations | Key Requirements |

|---|---|

| OSHA Safety Regulations | – Falls prevention measures – Proper scaffolding construction and maintenance – Required safety equipment – Competent Person inspection |

| Industry-Specific Regulations | – Additional safety measures based on industry practices – Specialized training requirements – Equipment-specific regulations |

| Customer Site Regulations | – Site-specific safety protocols – Additional safety measures mandated by the customer – Compliance with customer guidelines |

Scaffold Inspection and Maintenance

Before setting up scaffolds, it is crucial to conduct a thorough inspection of all materials to ensure their structural integrity. This step is vital for protecting workers and preventing accidents on construction sites.

Mismatched components should be avoided, as they can pose a significant hazard. Each scaffold component must be compatible and properly fitted to ensure stability and safety. Following the manufacturer’s instructions for scaffold assembly is essential to guarantee that the scaffold is set up correctly.

Regular inspections should be conducted to identify any hazards, defects, or debris that could compromise scaffold safety. Competent users should inspect scaffolds at the start of each workday, ensuring that all safety elements are in place and functioning correctly. Checklists can be used to systematically confirm the integrity of the scaffold and its components.

Proper maintenance and cleanliness are also essential for preventing tripping hazards and maintaining scaffold stability. Regular cleaning and removal of debris ensure that the scaffold remains safe and fully functional throughout its use.

Scaffold Inspection and Maintenance Checklist

| Checklist Item | Completed (Yes/No) |

|---|---|

| Inspect all scaffold components for any signs of damage or wear. | |

| Ensure that all components are properly connected and securely fastened. | |

| Check for any loose or missing guardrails, toe boards, or other safety elements. | |

| Confirm that the scaffold platform is level and free from any debris or obstructions. | |

| Inspect all access points, ladders, and stairways for stability and proper functioning. | |

| Verify that all necessary fall protection equipment, such as harnesses and lifelines, is present and in good condition. | |

| Check for proper anchoring and tie-off points for fall protection systems. | |

| Ensure that the scaffold is properly labeled with the appropriate safety tags. | |

| Inspect scaffolding before and after any modifications or repairs. | |

| Remove any debris or clutter from the scaffold platform and surrounding areas. |

By following thorough inspection and maintenance protocols, construction site managers can ensure the ongoing safety and reliability of scaffolding systems. Regular checks and proactive maintenance measures contribute to a safe working environment and help prevent accidents.

Weather and Environmental Considerations for Scaffold Safety

When it comes to scaffold safety, it’s important to consider the impact of weather and environmental conditions. Working in harsh weather or hazardous environments can significantly increase the risk of scaffold accidents, jeopardizing the safety of workers on construction sites.

Factors such as high winds, heavy rain, lightning, snow, and ice can pose serious risks to scaffold stability and compromise the safety of workers. For this reason, monitoring weather forecasts and enforcing safety rules are crucial to ensure a hazard-free workplace.

According to the Occupational Safety and Health Administration (OSHA) guidelines, it is recommended to avoid working on scaffolds during inclement weather. This proactive approach helps protect workers from potential accidents and injuries caused by adverse weather conditions.

To promote scaffold safety in challenging weather and environmental conditions, it is essential to implement specific measures and protocols. These measures could include:

- Regularly inspecting scaffolds to identify any vulnerabilities and reinforcing their stability

- Implementing robust anchoring systems to secure scaffolding in high wind areas

- Utilizing weather-resistant materials for scaffold components

- Providing adequate protection from precipitation, such as waterproof covers

By incorporating these safety measures and protocols, construction site managers can minimize the risks associated with adverse weather and environmental conditions, safeguarding the well-being of workers and ensuring scaffold safety.

Weather and Environmental Hazards and Corresponding Safety Measures

| Weather/Environmental Hazard | Safety Measures |

|---|---|

| High Winds | Secure scaffolds with robust anchoring systems and inspect for any potential vulnerabilities. |

| Heavy Rain | Utilize waterproof covers and ensure proper drainage to prevent slippery surfaces. |

| Lightning | Implement evacuation procedures when lightning is prevalent and suspend scaffold work temporarily. |

| Snow/Ice | Remove snow and ice from scaffolds, create safe walking surfaces, and ensure stability. |

By proactively addressing the challenges posed by weather and environmental conditions, construction site managers can uphold scaffolding safety standards and promote a secure work environment for all workers involved.

Training and Supervision for Scaffold Safety

Proper training and supervision are crucial elements of ensuring scaffold safety on construction sites. By providing comprehensive training to workers and implementing effective supervision, employers can significantly reduce the risk of accidents and promote a safe work environment.

Comprehensive Training Programs

Workers should undergo thorough training on scaffold safety practices to familiarize themselves with the correct procedures and guidelines. This training should include:

- Safely erecting, using, and dismantling scaffolding

- Proper usage of fall protection equipment and harnesses

- Identifying potential hazards and risks

- Understanding scaffolding safety regulations and compliance

Training programs should be periodically renewed to keep workers updated on the latest safety protocols and industry standards. Ongoing education and reinforcement of proper practices contribute to a culture of safety and minimize the likelihood of scaffold-related incidents.

Qualified Supervision

Effective supervision plays a vital role in scaffold safety. Qualified individuals should oversee scaffold operations and ensure compliance with safety procedures. Their responsibilities include:

- Identifying and addressing potential hazards

- Monitoring workers’ adherence to safety protocols

- Providing guidance and support to workers

- Conducting regular inspections to maintain safety standards

The Role of Competent Persons

Competent persons, as defined by scaffolding safety regulations, are individuals who possess the necessary knowledge and experience to evaluate scaffolds for potential risks and ensure compliance. They play a critical role in maintaining scaffold safety and should be appointed to oversee the scaffold operations.

| Benefits of Training and Supervision | Protection Scaffolding | Scaffolding Safety Regulations | Construction Site Safety |

|---|---|---|---|

| Promotes a safe work environment | â | â | â |

| Reduces the risk of scaffold accidents | â | â | â |

| Ensures compliance with safety regulations | â | â | â |

| Identifies and mitigates potential hazards | â | â | â |

By investing in comprehensive training programs and maintaining effective supervision, employers demonstrate their commitment to scaffold safety and protect workers from potential harm. These measures contribute to a productive and secure construction site, creating an environment where workers can focus on their tasks with confidence.

Scaffold Tags and Fall Protection Equipment

Scaffold tags and fall protection equipment are crucial components of ensuring the safety of workers on scaffolding. Green tags, when attached to a scaffold, indicate that it has been inspected and deemed safe for use. Yellow tags, on the other hand, indicate that modifications have been made to the scaffold and special precautions should be taken. When a scaffold is marked with a red tag, it signifies that it is unsafe and must not be used until the necessary repairs or adjustments have been made. These color-coded tags serve as visual indicators to protect workers from potential hazards.

Additionally, fall protection equipment is essential for safeguarding workers while working at heights. This equipment includes harnesses, lanyards, and anchors that are designed to prevent falls and protect against serious injuries. Regular inspection of fall protection equipment is essential to ensure that it is in good working condition and can effectively protect workers in the event of a fall. By adhering to scaffolding safety regulations and proper tagging procedures, employers can significantly reduce the risk of scaffold accidents and protect their workers.

| Scaffold Tag Color | Meaning |

|---|---|

| Green | The scaffold has been inspected and is safe for use. |

| Yellow | Modifications have been made to the scaffold, and special precautions are required. |

| Red | The scaffold is unsafe and must not be used until repairs or adjustments are made. |

Conclusion

Scaffolding accidents can have devastating consequences, resulting in severe injuries and even fatalities. To prevent these incidents, it is crucial for employers and construction site supervisors to prioritize site safety and implement the necessary precautions.

By utilizing proper scaffolding safety equipment, such as guardrails, fall protection systems, and edge protection barriers, workers can minimize the risk of falls and other accidents. Adhering to scaffolding safety regulations and standards ensures that construction sites operate in compliance with industry best practices, creating a safe work environment for everyone involved.

Regular inspections and maintenance play a vital role in identifying potential hazards and maintaining the structural integrity of scaffolds. This includes conducting thorough inspections before scaffold setup, checking for defects or mismatched components, and promptly addressing any issues that arise.

Furthermore, comprehensive training and supervision are essential in empowering workers to understand and practice scaffold safety protocols. By equipping employees with the knowledge and skills necessary to erect, use, and dismantle scaffolding correctly, employers can ensure that workers are aware of their responsibilities and can identify and mitigate potential risks.

By taking these measures and following industry best practices, employers can protect their employees from scaffold-related injuries, fostering a culture of safety and well-being on construction sites.

FAQ

What is protection scaffolding?

Protection scaffolding refers to safety measures and equipment used to ensure the safety of workers on construction sites. It includes guardrails, fall protection systems, and edge protection barriers.

Why is scaffolding safety important?

Scaffolding safety is crucial to prevent accidents and injuries. Approximately 4,500 injuries are reported annually from scaffolding-related incidents. Adhering to safety regulations and implementing proper precautions protects employees and ensures site safety.

What personal protective equipment (PPE) should be used for scaffolding?

Workers should wear hard hats, non-slip footwear, and use proper fall arrest equipment when working at heights. Hand-protecting gloves and tool-tether lanyards are also recommended for enhanced safety.

What are the load-bearing capacity and design considerations for scaffolding?

Scaffolding components have specific load limits and capacity. Overloading scaffolding structures can lead to serious injuries. It is essential to understand the load capacity and not exceed the design limits when using scaffolds.

What are the scaffolding safety regulations and compliance requirements?

Scaffolding safety regulations are governed by Federal OSHA and may have additional requirements based on industry and customer sites. Compliance with these regulations is necessary to prevent accidents and ensure site safety.

How should scaffolds be inspected and maintained?

Thorough inspections of scaffold materials should be conducted to ensure their structural integrity. Regular inspections should identify any hazards or defects. Competent users should inspect scaffolds daily, and proper maintenance and cleanliness should be maintained.

What are the weather and environmental considerations for scaffold safety?

Working on scaffolds during inclement weather, such as high winds, heavy rain, or snow, should be avoided. Safety measures should be implemented to account for these conditions and protect workers from scaffold accidents.

What training and supervision is necessary for scaffold safety?

Comprehensive training should be provided to workers on scaffold safety practices and the correct use of fall protection equipment. Supervision by qualified individuals is necessary to identify potential hazards and ensure compliance with safety procedures.

How do scaffold tags and fall protection equipment contribute to safety?

Scaffold tags indicate the safety status of a scaffold, and fall protection equipment, such as harnesses and anchors, are essential for worker safety. Regular inspections and proper tagging are vital to preventing scaffold accidents.