Phone:

(+65)8319-0742

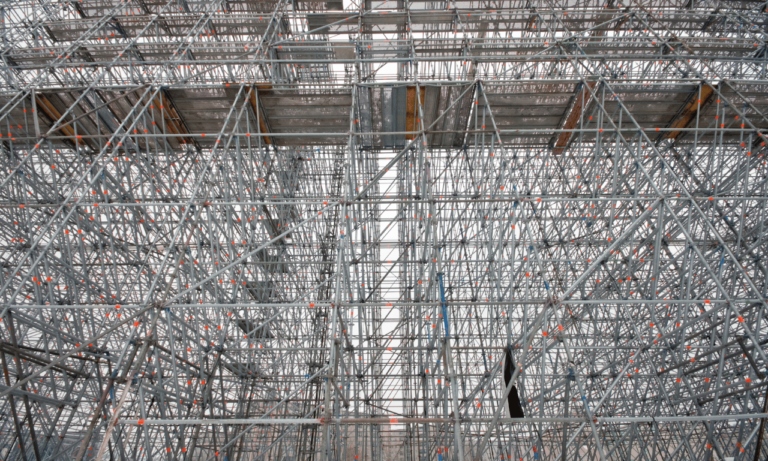

The realm of construction engineering is witnessing a revolutionary shift with the integration of Modular Scaffold Engineering. Fueled by a commitment to safety and efficiency, scaffold engineering services are advancing to meet the intricate demands of industries such as refining and petrochemical. Excel Modular Scaffold, a name synonymous with reliability, champions this transformative era with its innovative scaffolding designâa gleaming testament to their unwavering promise of zero incidents and cost efficiency.

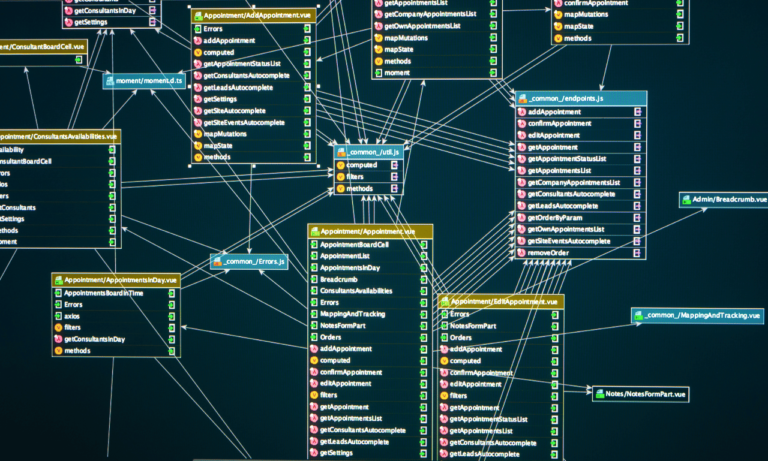

Excel’s seasoned engineering department harnesses the latest CAD technologies to craft not just scaffolding but comprehensive construction engineering solutions. Through the precise fabrication of their sister company, Deltak Manufacturing Inc, located in Walker, LA, they provide tailored components that are integral to each project’s distinct specifications, thereby offering a valuable edge in efficiency and safety.

Key Takeaways

- Excel Modular Scaffold’s proven track record of exceptional scaffold engineering services.

- Enhanced operational safety and efficiency through advanced modular scaffold engineering.

- Customized innovative scaffolding design to meet specific industry needs.

- The critical role of CAD technology in modern construction engineering.

- Commitment to safety and cost-efficient solutions within the scaffolding industry.

- Precise component fabrication enhancing project-specific scaffold applications.

Evolution of Modular Scaffolding Systems

The landscape of construction and industrial maintenance has been revolutionized by the introduction and advancement of modular scaffolding systems. As industries strive for better safety and efficiency, the modular scaffold engineering domain has risen to the forefront, offering innovative solutions tailored for today’s complex structures and high standards.

The Rise of Modular Scaffold Engineering in Industry

Within the competitive spheres of oil, gas, and construction, the adoption of sophisticated scaffold design principles is imperative. Modular scaffold engineering has emerged as a critical component in setups requiring adaptable and robust exterior building work. This shift toward modular constructs is not just a trend but a response to the growing need for safer, more efficient means of accessing challenging environments.

Key Innovations in Scaffold Platform Design

When exploring milestones in the evolution of scaffold design, one cannot ignore the seismic effect of increased structural integrity in modular scaffolding systems. Unlike previous iterations that heavily relied on fixed support, the innovative scaffolding design now supports free-standing possibilities. This capability has initiated a wave of ingenuity, crafting scaffolds fit for diverse applications while padding budgets against excess cost and time expenditure, particularly in specialized tasks like coating and insulation.

Benefits of Modular Scaffold Engineering Over Traditional Methods

The shift to modular systems is not just driven by versatility in application but also by an array of tangible benefits over traditional scaffolding. By prioritizing interlocking components, modular scaffolding systems significantly enhance on-site safety and reduce the likelihood of accidents. These systems, known for their customization versatility, serve a gamut of structural configurations, thereby minimizing the need for multiple, varied setups. Furthermore, the straightforward nature of assembly and disassembly of these innovative systems not only saves precious time but also cuts down labor costs, reinforcing modular scaffold engineering as a transformative development in the field.

In summarizing the current state of modular scaffolding, one thing is clear: its ascent within industry circles marks a departure from old constraints, steering the scaffold platform design towards a future where safety and efficiency enjoy equal priority. With modular scaffold engineering at its core, the construction, oil, and gas sectors are witnessing a new era for erecting and dismantling structuresâa paradigm propelled by innovation and a keen understanding of the demands of modern industry.

Engineering Solutions for Complex Construction Challenges

The field of construction engineering continues to overcome obstacles through the integration of modular scaffold engineering and robust engineering solutions. Professionals in this domain are leveraging their expertise to conceive, develop, and implement applications that meet the dynamic needs of construction projects. Noteworthy advancements are predominantly seen in the production of custom modular platforms and guardrail systems, which are instrumental in enhancing site safety and accessibility.

One of the pillars of these engineering advancements lies in the use of domestically-sourced steel and premium materials. The components used in these systems are not only durable but are precisely laser-cut and robotically welded for optimal integrity and performance. With a focus on safety, these custom fabricated access solutions cater to an array of construction demands, fitting projects of varying scales perfectly.

To better understand the scope and benefits of these engineering efforts, consider the following table, which outlines the key features of modern scaffold systems:

| Feature | Advantage | Impact on Construction Engineering |

|---|---|---|

| Custom Modular Platforms | Enhanced safety and versatility | Allows for safe, custom solutions for complex structures |

| Guardrail Systems | Preventative fall protection | Improves worker safety and meets regulatory standards |

| Automated Welding | Precision and strength in joints | Ensures the highest level of structural integrity |

| Laser-cut Components | Tailored fittings and connections | Enables complex designs with reliable assembly |

| Domestic Steel Usage | Quality assurance and durability | Supports the longevity and sustainability of construction projects |

By closely examining these features and benefits, it’s clear that modular scaffold engineering not only supports but elevates the capabilities of construction engineering. The result is an industry that is better equipped to deal with the intricate and often unpredictable challenges that arise within the realm of modern construction.

- Improved safety protocols

- Greater adaptability to project needs

- Cost-effectiveness through customizable designs

Ultimately, the seamless fusion of ingenuity, safety, and adaptability is what defines today’s engineering solutions, with modular scaffold engineering at the vanguard of this transformative movement in construction engineering.

Modular Scaffold Engineering: Combining Safety with Efficiency

At the heart of every construction project is the dual priority of safety and efficiency, which is where modular scaffold engineering and scaffold engineering services play a pivotal role. The objective is clear: to engineer structures that will not only speed up construction but ensure that each worker returns home safely every day.

The meticulous integration of CAD technology into the process of scaffold design enhances both the structural integrity and the safety features of the scaffold systems. As engineering solutions continue to evolve, the emphasis remains steadfast on scaffold safety and the delivery of reliable service.

Engineering a Zero-Incident Safety Culture in Scaffolding

Developing a safety culture that aims for zero incidents is at the forefront of scaffold engineering services. The approach encompasses a comprehensive review of potential hazards, rigorous training in safety protocols, and the design of scaffolds that surpass standard safety regulations. This commitment ensures that modular scaffold engineering contributes significantly to the overall safety of construction sites.

The Role of CAD Technology in Scaffold Safety and Design

CAD technology serves as the backbone of precision in modular scaffold engineering. The detailed nature of CAD allows for intricate planning and virtual testing of scaffolds before physical construction. These simulations ensure that the final structure adheres to all safety and design standards, mitigating risks long before scaffolding is erected.

| Feature | Benefit | Technology Used |

|---|---|---|

| Preventative Hazard Analysis | Minimizes on-site injuries | Risk Assessment Software |

| Virtual Load Testing | Ensures structural integrity under stress | 3D Modeling Programs |

| Automated Component Analysis | Maximizes efficiency and compatibility of scaffold parts | AutoCAD® |

| Environmental Simulation | Assesses performance under various weather and load conditions | Finite Element Analysis |

| Real-time Revision Capability | Enables swift responsiveness to design changes | Inventor® |

The pursuit of excellence in modular scaffold engineering is never-ending. With each project, scaffold safety is enhanced through the innovative use of CAD technology and insightful engineering services that protect the well-being of every individual on-site.

Material and Manufacturing Advancements in Scaffolding Technology

In the realm of scaffolding technology, recent progress in materials and fabrication techniques has been pivotal in enhancing scaffold performance and reliability. A particular spotlight has been cast on domestic manufacturing and its contribution to higher scaffold quality. By focusing on local production, manufacturers maintain more rigorous oversight, guaranteeing that the custom fabrication processes meet or exceed expected standards.

The Impact of Domestic Manufacturing on Scaffold Quality

When it comes to domestic manufacturing, the proximity to the end-use markets plays a significant role in ensuring quality. Companies leveraging domestic resources can more readily enforce quality control protocols against the backdrop of established industrial norms, leading to scaffolding systems that are robust and compliant with rigorous safety criteria.

Custom Fabrication and Stringent Quality Control Protocols

Custom fabrication is at the core of creating bespoke scaffold solutions tailored to unique project requirements. Coupled with stringent quality control protocols, manufacturers can deliver products that are not only innovative but also adhere to the highest standards of safety and efficiency. These protocols span multiple checkpoints throughout the production process, ensuring consistency and precision at every step from inception to completion.

For a more granular understanding of how these processes interlink, consider the following comparison of attributes between traditional and technologically advanced scaffolding systems:

| Attribute | Traditional Scaffolding Systems | Advanced Scaffolding Systems with Domestic Manufacturing |

|---|---|---|

| Material Quality | Variable, often import-dependent | High-grade, domestically sourced |

| Customization | Limited by design standardization | Highly adaptable through custom fabrication |

| Quality Assurance | Standard protocols with potential for oversight gaps | Detailed quality control at each manufacturing stage |

| Regulatory Compliance | May not meet local codes fully | Designed to comply with domestic safety regulations |

| Production Oversight | Diffuse, often complicated by distance | Centralized and streamlined for efficiency |

With these insights, it becomes apparent how domestic manufacturing, underpinned by custom fabrication and strict quality control protocols, significantly bolsters the integrity and functionality of today’s scaffolding technology. Construction professionals rely on these advancements for safe, reliable, and efficient structures that rise to the modern challenges of their industry.

Innovative Scaffolding Design: Enhancing Project Turnaround Time

The intricacies of innovative scaffolding design are pivotal in reducing the project turnaround time. By emphasizing customization, modular scaffold engineering allows for an unrivalled degree of flexibility in construction and maintenance projects. Dynamic systems streamline the erection and dismantling process, directly contributing to a faster completion timeline.

With execution efficiency as a prime focus, the adoption of modular scaffold engineering practices is seen as a cornerstone for productivity improvements. The design and engineering of modular scaffolds serve not only as a safety-enhancing measure but also as a critical tool for on-site agility and responsiveness to project needs.

- Customization accommodates complex architectures

- Enhanced safety features reduce work-related disruptions

- Intuitive assembly and disassembly shorten labor hours

| Innovative Feature | Benefit | Impact on Project Turnaround Time |

|---|---|---|

| Pre-engineered modular systems | Standardization resulting in ease of use | Expedited set-up and dismantling procedures |

| Intelligent design customization | Tailored to meet project-specific requirements | Reduced need for on-site adjustments |

| Real-time tracking software | Efficient management and oversight | Swift response to logistical demands |

As innovative scaffolding design evolves, the symbiosis between advanced engineering and construction demands becomes more evident. Dedication to refining these techniques is a testament to the industry’s commitment to propelling project turnaround time forward effectively. The end result is a framework that not only supports the physical structure but also the timeline of project completion.

Conclusion

The arena of modular scaffold engineering has undeniably transformed the landscape of construction and maintenance projects. Through the iteration of scaffolding technology, professionals in the field have succeeded in creating a nexus between the uncompromising safety protocols required in high-stakes environments and the drive for operational efficiency in an ever-competitive market. The advancements in innovative scaffolding design have not just met industry demands; they continue to push the boundaries of what is possible, ensuring that projects can be completed faster, more safely, and with greater cost-effectiveness.

As industries evolve and undertake more complex and ambitious projects, the flexible and dynamic nature of engineering solutions provided by modular scaffolding is critical. The modular approach has proven its mettle, allowing for rapid assembly and disassembly, providing unsurpassed versatility and ensuring that each structure best meets the needs of its application. This adaptability is a hallmark of the modular scaffolding system, ensuring it remains integral to a myriad of sectors looking to streamline operations without compromising on safety.

Looking ahead, the impact of modular scaffold engineering is poised to continue its ascent, shaping the future of construction engineering with every steel interlock and safety check enforced. The promise of this technology is evidentâis streamlined operations augmented by rigorous safety measures and actionable insights into cost management. We can expect the modular scaffolding sector to maintain its essential role, innovating and refining the harmonious balance between speed, safety, and structural integrity.

FAQ

What distinguishes modular scaffold engineering from other construction engineering methods?

Modular scaffold engineering is characterized by its versatility, safety, and efficiency. It uses interlocking components that can be quickly assembled and disassembled, providing customizable solutions to complex construction challenges. This method outperforms traditional scaffolding with easier logistics, greater stability, and a better fit for varying worksite conditions.

How has modular scaffolding evolved and why is it favored in industries?

Modular scaffolding systems have evolved to become highly efficient and extremely stable, which is why they are preferred in industries like oil, gas, and construction. Innovations in design allow for free-standing configurations that do not always require structural fixation, leading to significant cost and time savings for projects that involve coating and insulation applications.

What are the primary benefits of using modular scaffolding over traditional methods?

The key benefits include enhanced safetydue to the locking mechanisms of scaffold components, greater customization versatility, and ease of assembly and disassembly. These features enable a quicker project turnaround, reduce the potential for accidents, and provide flexibility to adapt to various project requirements.

How does modular scaffold engineering address complex construction challenges?

Engineering solutions in modular scaffold engineering address the intricacies of modern construction projects by offering customized platforms, guardrails, and other access solutions. This improves site safety and accessibility, irrespective of project scale, thanks to the use of high-quality materials and state-of-the-art CAD technology for precision in design.

How does modular scaffold engineering contribute to workplace safety?

Modular scaffold engineering places a strong emphasis on safety culture with a goal of achieving zero incidents. Through the use of advanced CAD technology, engineers can create scaffold designs that meet and exceed safety standards, while also providing tools for real-time data monitoring to manage scaffold-related costs and ensure operational safety.

Why is domestic manufacturing important for scaffold quality?

Domestic manufacturing of scaffolding materials is pivotal because it allows for close supervision of the production process, ensuring the integrity and quality of the scaffold components. This domestic proximity aids in maintaining consistent standards and facilitates rapid response to custom fabrication needs, ultimately resulting in a superior product.

What roles do custom fabrication and quality control play in scaffold engineering?

Custom fabrication allows for scaffold components to be made to spec for particular project requirements, while stringent quality control protocols ensure these components comply with industry standards and engineering practices. Together, they guarantee that the scaffolding materials are safe, reliable, and fit for the intended purpose.

How does innovative scaffolding design enhance construction project efficiency?

Innovative scaffolding design leverages adaptability and custom solutions to enhance efficiency in construction projects. By tailoring scaffolding parts to specific project needs and employing software for real-time tracking of scaffold usage and costs, projects can be managed more effectively with adaptations made quickly as needs evolve.

Optimal Temporary Shoring and Bracing Design Tips

In the realm of construction, the stability of temporary structures is as crucial as the permanence of…

Enhancing Scaffold Safety Engineering Practices

html

The realm of construction is underpinned by the principles of safety and efficiency, both of which…

Understanding Scaffold Fluid Dynamics Essentials

The realm of tissue engineering is evolving with advancements in Scaffold Fluid Dynamics (SFD), which…

Understanding Scaffolding Psychology Essentials

In the dynamic intersections of educational psychology and developmental psychology, the concept of Scaffolding…

Top Educational Support Strategies for Teachers

As educators, maximizing academic success hinges on implementing effective educational support strategies…

No posts found