Phone:

(+65)8319-0742

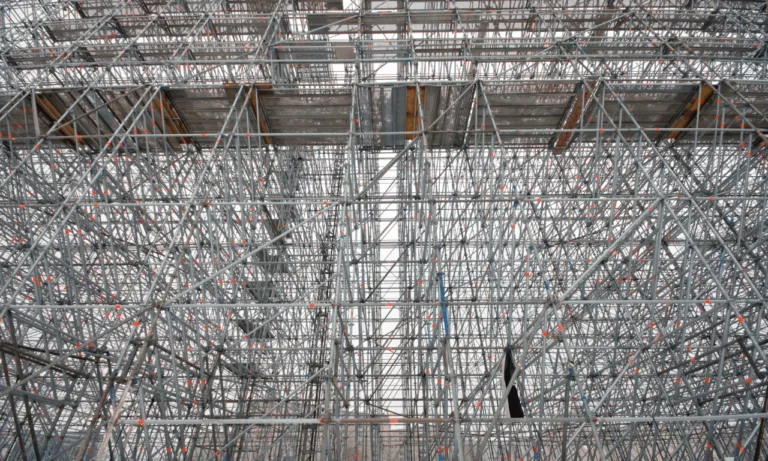

Within the technical precision of construction and engineering, the role of Load Analysis in Scaffold Design cannot be overstated. Essential for ensuring the safety and structural integrity of scaffolding, a thorough scaffold load calculation is paramount for any project, big or small. This process involves an in-depth examination of how weight and forces impact the temporary structure, ensuring it can withstand the demands of its intended use.

Moreover, a rigorous structural load assessment in scaffolding is not just about stability and safety; it’s a legal necessity to meet industry standards such as TG20. Understanding the source and magnitude of loads is vital to prevent potential failures and maintain effective and secure scaffolding systems.

Key Takeaways

- Complete load analysis ensures the safety and integrity of the scaffold structure.

- Calculations must take into account various loading conditions for accuracy.

- Abiding by construction industry regulations like TG20 is legally required.

- Understanding the origin of loads is crucial to design an efficient scaffold.

- Safety factors are instrumental in guaranteeing the structure’s stability under load.

Understanding Scaffold Load Calculation for Construction Safety

In the intricate world of construction, determining the scaffold weight capacity is not just a technical requirement but a vigorous safety measure. A scaffold’s stability and structural integrity are paramount to the safety of the workers and the public alike. The meticulous process of scaffold load calculation ensures that all involved in a construction project can operate in a secure environment.

Defining Scaffold Load Capacities and Weight Distributions

The process of scaffold weight capacity determination calls for a deep understanding of the loads that scaffolding will carry. It encompasses the sum of dead loads, the weight of the structure itself, and live loads such as construction materials, tools, and personnel. Weight distribution is also crucially analyzed to ensure that the scaffold design is optimally balanced and each component is within its capacity.

Legal Requirements for Scaffold Design Calculations

Adhering to legal requirements is non-negotiable when it comes to scaffolding design. Under the rigorous Work at Height Regulations, proper documentation or conformity to known configurations must be evident. These laws mandate that structural load assessment in scaffolding must be thorough and compliant with industry standards such as BS 1139 and EN 12810-1.

The Role of Structural Load Assessment in Scaffolding Safety

Structural load assessment is a safety cornerstone, ensuring that every scaffolding component can uphold the intended load with an appropriate safety factor in scaffolding design. The assessment meticulously identifies and calculates various loads including environmental factors like wind and snow which are imperative in crafting a design that is not only robust but also compliant with the best practices outlined in standards such as BS EN 12811-1.

The Importance of Load Analysis in Scaffold Planning

Understanding the importance of load analysis in scaffold planning is paramount to ensuring the safety and functionality of construction projects. A scaffoldâs load-bearing capacity dictates the efficiency of the workflow and the safety of construction personnel. Therefore, meticulous attention to load analysis can prevent accidents and structural oversights, making it an indispensable part of the construction planning process.

Load analysis is not just about ensuring that scaffold structures won’t fail; it’s about anticipating every imaginable scenario where the load could impact scaffolding structures. Be it the added weight of construction materials, the dynamic forces of workers in motion, or the unpredictable forces of nature such as wind and snow – all these factors must be thoroughly accounted for within the planning phase.

Another critical factor is the incorporation of safety load margins. Professional engineers often employ a safety factor of four to underwrite the load-bearing capacity of scaffolding structures. This safety factor takes into account not only the weight of the scaffold materials themselves but the maximum expected loadsâhuman traffic, equipment, suppliesâand additional environmental factors that could impact stability and integrity.

| Load Type | Description | Considerations in Load Analysis |

|---|---|---|

| Dead Load | Weight of the scaffold itself | Inherent structural capacity, material strength |

| Live Load | Workers, equipment, and materials | Variable weight distribution, dynamic forces |

| Environmental Load | Wind, snow, and other weather conditions | Environmental patterns, local climate considerations |

Ultimately, the importance of load analysis in scaffold planning cannot be overstated. It’s a comprehensive approach that considers every influence and force that a scaffold may encounter. Proper analysis ensures that projects not only start on a foundation of safety but maintain that reliability throughout the construction lifecycle, preserving structural integrity and protecting human lives.

Load Analysis in Scaffold Design: From Theory to Practice

Translating the theoretical aspects of scaffold design into actionable steps involves meticulous planning and nuanced calculations. Ensuring the safety and efficiency of scaffolding systems, especially when dealing with heavy loads, forms the cornerstone of this process. Critical to bridging this gap are the evaluation of load conditions and careful incorporation of safety margins.

Practical Steps for Conducting Scaffold Design Calculations

To initiate the practical phase of scaffold design, professionals engage in a range of calculations grounded in real-world conditions. This ensures that the final structure is not only compliant with regulations but also tailored to the specific demands of the project at hand. By optimizing scaffold design for maximum load efficiency, the risk of overloading and potential structural failure is substantially reduced.

Incorporating Safety Factors in Scaffolding Design

Including adequate safety factors is non-negotiable in scaffold design, serving as a buffer against unforeseen load variations and environmental factors. These safety considerations are critical for upholding the integrity of the structure under the weight of heavy loads. When scaffolding design considerations for heavy loads are accounted for, the chances of accidents are minimized, ensuring a safer construction environment.

Scaffold Design Considerations for Heavy Loads

Addressing the demands of heavy loads requires attention to specific design elements that bolster a scaffold’s load-bearing capacity. Through optimizing scaffold design for maximum load efficiency, designers plan for a balanced distribution of weight, minimizing point loads and stress concentrations. Advanced software aids in simulating these conditions, thereby refining the structural design for peak performance.

| Design Element | Importance in Heavy Load Support | Considerations for Optimization |

|---|---|---|

| Materials | Critical for determining strength and weight limits | Choose high-quality materials compliant with safety standards |

| Base Structure | Foundation of the scaffold’s stability under heavy loads | Ensure a solid and even base, capable of distributing loads |

| Load Distribution | Prevents localized stress and structural compromise | Design for an even dispersion of loads across the scaffold |

| Bracing | Provides lateral support and increased rigidity | Use ample bracing at calculated intervals to handle dynamic forces |

Scaffolding Design Considerations for Heavy Loads

When constructing robust scaffold structures for heavy-duty applications, scaffolding design considerations for heavy loads are pivotal. The intricate process of analyzing scaffold weight capacity determination is stepped up to ensure structural integrity. While assessing the load-bearing capacity of scaffolding structures, engineers must account for several critical aspects including material strength, geometric configuration, and compliance with safety guidelines.

Analyzing Scaffold Weight Capacity Determination

Effective analyzing scaffold weight capacity determination is crucial to accommodate the anticipated loads. Precision calculations are required to assure each component’s ability to withstand the pressure exerted by various forces. These forces include dead load, which represents the weight of the scaffold structure itself, and live loads, which encompass the construction materials, workers, and equipment. Additionally, environmental loads resulting from weather conditions further influence weight considerations.

Optimizing Scaffold Design for Maximum Load Efficiency

Engineering teams must be diligent in optimizing scaffold design for maximum load efficiency. This involves arranging scaffold elements to balance the load across all supports. Optimizing the spatial layout of cross-bracing and choosing the correct grade of materials are integral steps in achieving an efficient scaffold design.

- Materials selection for strength and durability

- Strategic placement of braces and joints

- Utilization of modern design software for precision

Assessing the Load-Bearing Capacity of Scaffolding Structures

In addition to capacity considerations, assessing the load-bearing capacity of scaffolding structures is central to ensure public and workplace safety. This analysis aims to verify the scaffold’s potential to sustain weight without risks of structural failure. It encompasses a comprehensive review of the scaffolding components, examining the quality and integrity of connections, tubes, and platforms.

| Component | Capacity (lbs) | Material Type | Safety Factor |

|---|---|---|---|

| Platforms | 2,500 | Aluminum | 4 |

| Vertical Tubes | 4,000 | Steel | 4 |

| Diagonal Braces | 3,500 | Galvanized Iron | 4 |

Conclusion

In the realm of construction where safety cannot be compromised, understanding the nuances of optimizing scaffold design for maximum load efficiency is non-negotiable. Drawing the curtain on our discussion, it’s discernible that comprehensive load analysis is not just beneficial but critical for the integrity and safety of scaffolding structures. Throughout the scaffold design process, from the drawing board to the on-site assembly, the mainstay remains a meticulous adherence to the calculations and safety protocols that govern these temporary yet vital edifices.

By imbibing scaffolding design considerations for heavy loads into the core framework of construction planning, professionals effectively lay a foundation for preventing hazardous occurrences. This detailed orchestration of calculations melds together theoretical knowledge and practical implementation, assuring that structures stand resilient under weighty demands. It’s this combination of analytical precision and practical wisdom that equips engineers and project managers with the capability to elevate standards of safety and compliance to new heights.

As the industry continually seeks to refine its approaches toward structural safety, the practice of integrating load analysis into every phase of scaffold design remains a pivotal element of successful project completion. It is the rigorous process of charting out load capacities and accounting for every pressure point that transforms a scaffold from a mere arrangement of poles and platforms into a secure and steadfast beacon of construction efficiency. Thus, in conclusion, it is through persistent vigilance in design that we fortify the bastions of urban development, protecting the lives of those who build the skylines of tomorrow.

FAQ

How is load analysis integral to scaffold design?

Load analysis is crucial in scaffold design as it ensures the structure can safely support the loads it is meant to bear. This involves evaluating loading conditions, component capacities, rigidity, and stability, along with incorporating appropriate safety factors.

What are key factors in scaffold load calculation?

Key factors in scaffold load calculation include determining the load capacities and weight distribution across the scaffold structure while considering dead loads, live loads, environmental loads such as wind and snow, and complying with safety regulations.

Why are safety factors included in scaffolding design?

Safety factors are included in scaffolding design to account for uncertainties, such as unknown loads, misuse, or potential weaknesses in materials. They provide a buffer to ensure the structure remains safe even if actual loads exceed calculations.

What legal requirements must be met in scaffold design calculations?

Scaffold design calculations must comply with legal mandates, such as providing documented proof of structural calculations or adhering to recognized standards like TG20, BS 1139, BS EN 12810-1, and BS EN 12811-1.

How do engineers ensure the stability of scaffolding structures?

Engineers ensure the stability of scaffolding structures by conducting thorough load analysis, considering design criteria, height, load types, and stability requirements, with a safety factor of four or more, to withstand expected loads and environmental pressures.

What are practical steps for conducting scaffold design calculations?

Practical steps include rigorously calculating various load conditions, stability, and rigidity assessments, and using technologies like scaffolding management software and 3D structural analysis to project load distribution effectively.

What design considerations are made for scaffolding meant to bear heavy loads?

For heavy loads, meticulous design considerations focus on analyzing weight capacity, optimizing placement of components for even weight distribution, and ensuring load transmission to supporting structures is safely managed, while also accounting for environmental factors.

How is the load-bearing capacity of scaffolding structures assessed?

The load-bearing capacity is assessed by analyzing the ability of each component to handle designated weights combined with the overall design’s efficiency in distributing these loads, keeping in mind the maximum expected loads, and environmental influences.

Modular Scaffold Engineering Solutions Expertise

The realm of construction engineering is witnessing a revolutionary shift with the integration of Modular…

Optimal Temporary Shoring and Bracing Design Tips

In the realm of construction, the stability of temporary structures is as crucial as the permanence of…

Enhancing Scaffold Safety Engineering Practices

html

The realm of construction is underpinned by the principles of safety and efficiency, both of which…

Understanding Scaffold Fluid Dynamics Essentials

The realm of tissue engineering is evolving with advancements in Scaffold Fluid Dynamics (SFD), which…

Understanding Scaffolding Psychology Essentials

In the dynamic intersections of educational psychology and developmental psychology, the concept of Scaffolding…

No posts found