Phone:

(+65)8319-0742

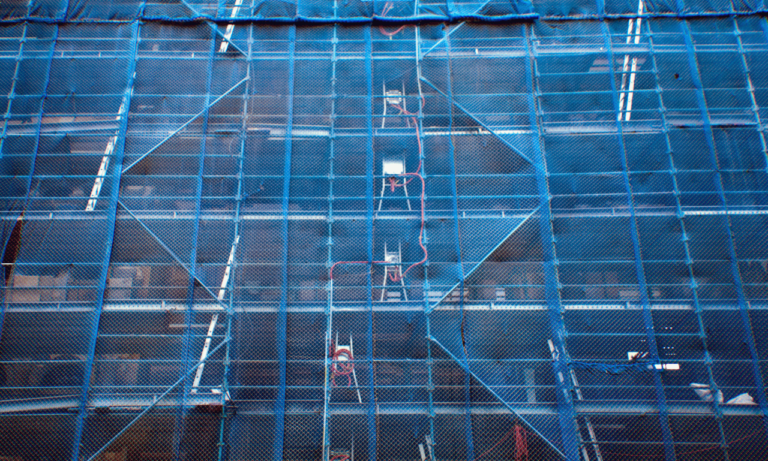

The construction world is changing fast, thanks to new lightweight scaffold systems. These new units are easy to assemble and make work safer and faster. They bring a new level of efficiency to construction sites.

Layher uses high-tensile automotive steel to make these lightweight structures. This has made setting up and taking down scaffolding much quicker. The result is a big boost in productivity and more space on trucks.

Key Takeaways

- Assembling and dismantling Layher Lightweight structures can be up to 10% faster, making birdcage scaffolding more efficient.

- Portability is enhanced as trucks can carry about 12% more lightweight scaffold volume, offering savings on fuel and manpower.

- Studies point out that a staggering 80% of scaffolding costs come from assembly, dismantling, and transportation services.

- Through intelligent design, Layher maintains load capacities while reducing the weight of scaffolding components.

- Bil-Jax Scaffold excels by providing a versatile range of scaffolding solutions suitable for both heavy-duty industrial and lighter construction needs.

- With safety as a paramount consideration, Bil-Jax Scaffold designs products that meet rigorous safety standards.

- The balance between product purchase and rental offerings from Bil-Jax Scaffold keeps options flexible for contractors, enhancing overall project efficiency.

The Cutting-Edge Advancements in Lightweight Scaffolding Technology

The construction world is always looking for ways to work smarter and safer. This has led to big steps forward in making scaffolding lighter. Now, we see the use of strong high-tensile steel and the best parts of traditional Layher scaffolding. This mix makes scaffolding stronger, easier to use, and better for different building sites.

Innovative Use of High-Tensile Automotive Steel

Using high-tensile steel, a material from the car industry, in scaffolding is a big change. Layher Lightweight uses this steel to make scaffolding much lighter. It’s now easier to move and set up, and it’s safer and lasts longer against the elements.

Compatibility with Traditional Layher Scaffolding Components

Modern scaffolding works well with the old Layher parts. This means new, lighter pieces like Layher Allround Scaffolding can easily join with what’s already there. This makes it easier to change setups and helps use what you already have longer, saving money and resources.

These new scaffolding types are making a big difference on building sites. They let workers do more and carry more stuff, thanks to the use of high-tensile steel. This has led to a 12% increase in what can be carried on trucks and a 10% boost in getting work done on site.

Benefits of Using Lightweight Scaffold in Modern Construction

The construction world is changing fast, thanks to new technologies like lightweight scaffolding. The benefits of lightweight scaffold are big, making construction safer and more efficient.

| Feature | Benefit | Impact on Construction |

|---|---|---|

| Weight | Lighter than traditional materials | Increases ease of transport and setup |

| Durability | Resistant to corrosion and deterioration | Extends the lifespan and reduces maintenance costs |

| Strength | Supports heavy loads | Enhances safety and allows for heavier construction materials |

| Flexibility | Adaptable to different heights and angles | Improves adaptation to project-specific needs, boosting efficiency |

| Assembly | Easy to assemble and disassemble | Reduces labor costs and accelerates project timelines |

| Safety | Minimizes risk of accidents | Promotes a safer work environment |

Using durable scaffolding makes workers safer and helps construction go smoother. For example, aluminum planks are easy to move around, which means quicker changes and better fits for different projects. This flexibility shows how modern scaffolding is useful for many things, not just building new structures.

Lightweight scaffolding is also good for the planet. It uses less material and creates less waste, which is good for the environment. This helps companies follow green building rules and save money on materials.

The ability to quickly set up and take down lightweight scaffolding saves time and changes how projects are done. It makes construction more efficient overall.

In the end, adding lightweight, strong scaffolding to building projects brings big benefits for safety and efficiency. As building needs grow, these systems will likely become the norm. They make construction better and help projects succeed.

Ease of Transport: A Key Advantage of Portable Scaffolding Solutions

The modern construction world needs scaffolding that’s strong, flexible, and easy to move. Ease of transport is key, thanks to portable scaffolding solutions. Companies like Alufase lead the way with their aluminum towers. These towers are strong yet easy to move.

These systems are easy to move and set up fast, which is vital for projects at many locations. They reduce the usual hassle of moving scaffolding. This makes work flow better in fast-paced construction sites.

Maximizing Efficiency with Compact Scaffold Systems

Compact scaffold systems make work more efficient, whether it’s a tall building or a big residential project. Units from Alufase, known for their lightweight yet stable frames, are quick to put together and take apart. This cuts down on downtime and increases work speed. They also fit into small spaces easily.

Reducing Costs with Easy-to-Assemble Scaffolding

Choosing the right scaffolding can save money on construction projects. Cost-effective scaffolding like Alufase’s is easy to set up and take down. This means less work for workers and lower costs for the project.

| Feature | Benefit |

|---|---|

| Lightweight Aluminum Design | Increases mobility and reduces transportation overhead |

| Easy Assembly | Decreases setup and dismantling time, reducing labor costs |

| Compact Storage | Enhances logistical efficiency, allowing for more equipment per transport |

| Versatility in Application | Adaptable to various sites and requirements without additional investment |

The evolution of scaffolding into more modular and transport-friendly formats is changing construction sites worldwide. Portable scaffolding solutions are making things easier and more efficient.

Emphasizing Safety in Scaffold Design and Material Selection

Ensuring scaffold safety is crucial for construction and maintenance work. Choosing the right material selection and design helps with safe work access. It also makes work more efficient. Companies like Bil-Jax and Layher lead the way with features like auto-lock functions and redesigned parts in their scaffolding. These features improve safety and last longer.

Recent stats show how important safety is in scaffolding. For example, in 2021, 52 people died from falls on scaffolding, according to the Bureau of Labor Statistics. OSHA also found scaffolding was a big safety issue in 2022. This shows the dangers of not using scaffolding safely.

Creating a safe ergonomic scaffold means following strict safety rules. This includes making sure platforms can hold four times the weight they’re meant for. Also, ropes must handle six times the weight. It’s also key to have someone check the scaffolding before work starts.

Companies like Bil-Jax and Layher make durable scaffold systems. Training workers well helps reduce risks like falls and collapses. Workers who know how to set up and take down scaffolding safely are a big help.

| Safety Feature | Requirement | Benefit |

|---|---|---|

| Fall Protection | Required on scaffolds over 10 feet high | Prevents major injuries and fatalities from falls |

| Load Capacity | Supports four times the intended load | Enhances structural integrity and worker safety |

| Suspension Ropes | Support at least six times the intended load | Prevents structural failures during use |

| Regular Inspections | Conducted before every shift and post-incident | Ensures ongoing compliance with safety standards |

Using strict safety rules, choosing better material selection, and training workers well are key to high scaffold safety. This approach keeps workers safe and makes construction projects more reliable and efficient worldwide.

Streamlining Construction Project Timelines with Quick-Setup Scaffolding

Using quick-setup scaffolding in construction projects helps speed up work. New technology has made efficient scaffolding systems that are fast, safe, and fit many places.

These systems can be set up up to three times faster than old methods. This means projects finish quicker. It also means using less labor and saving money, making quick-setup scaffolding a smart choice for builders.

Old scaffolding took more time and was more expensive. But, modern scaffolding is lighter and stronger. It helps workers do more on site.

| Scaffolding Type | Time Efficiency | Safety | Cost Efficiency |

|---|---|---|---|

| Traditional Scaffolding | Lower | Standard | Higher Costs |

| Frame Scaffolding | High | Enhanced | Reduced Costs |

| Low-Rise Scaffolding | Highest | Improved | Most Cost-Effective |

In crowded areas or small sites, low-rise scaffolding is perfect. It’s easy to move and safe, thanks to its design. This makes work safer and easier.

In summary, quick-setup scaffolding makes projects faster and cheaper. It also makes them safer and more flexible. This makes it key for modern building work.

Customizable Scaffolding Solutions for Diverse Building Projects

In the world of construction, the need for customizable scaffolding is growing fast. It must fit different architectural styles and project needs. Tube and clamp scaffolding show how flexible scaffolding solutions can change to fit any building shape or size. This supports a wide range of construction projects.

With new tech like 3D printing for custom parts, versatile scaffolding systems are getting better. This tech makes making scaffolding faster and ensures parts fit project needs perfectly. It shows why adjustable scaffolding is important in building today.

Also, smart scaffolding systems with sensors and IoT devices are changing how we think about safety. These systems check stability and load to keep everyone safe and maintain the scaffolding well. This is key for worker safety and the scaffolding’s life.

- Customization and Adaptability: These scaffolding options can change to meet any construction site’s needs, no matter how complex.

- Safety and Compliance: They follow strict safety rules, like OSHA’s, to keep everyone on the site safe.

- Eco-friendly Practices: The newest scaffolding uses green materials and methods. It even has solar panels for better energy use during work.

| Feature | Benefit |

|---|---|

| 3D Printing Technology | Improves customization, cuts waste |

| IoT Sensor Integration | Makes things safer by checking if the structure is stable |

| Eco-friendly Materials | Helps the planet, lowers environmental harm |

| Modular Components | Allows quick changes and setup for different uses |

| Compliance with OSHA Standards | Keeps things safe, supports loads four times heavier than expected |

The move to flexible scaffolding solutions that are precise and green shows how building is changing. These smart, adjustable scaffolding systems are key to making big construction projects more efficient. They offer both safety and usefulness.

Professional Grade Scaffoldings: Commitment to Quality and Durability

For over 20 years, companies like Bil-Jax and Layher have focused on making professional grade scaffold systems. They have shown their dedication to making durable scaffolding solutions. These solutions have won praise from many in the industry.

These companies don’t just focus on how strong their scaffold platform is. They also work on making it easy to use and safe. For example, Layher’s designs are light and innovative. This means workers put in less effort and can set up faster, saving money and boosting productivity on construction sites.

One of Bil-Jax’s satisfied customers said, “Their high-quality scaffold systems are top-notch. They offer great customer service and quickly solve problems, helping us work more efficiently.”

Bil-Jax’s quality is shown by the 27 scaffold patents they have or are waiting for. This shows their dedication to making things better and new. Their products last a long time, as seen in many positive reviews. This shows they meet the needs of their customers, even in tough situations.

Looking into the innovative Phonak hearing aids can also show how modern tools improve satisfaction. It gives a good idea of how different products can make a big difference in various areas.

| Scaffold Type | Features | Customer Feedback |

|---|---|---|

| OCTO® System Scaffolding | Fewer components, faster assembly | “Reduces setup and dismantling time, trimming down operational costs significantly.” |

| Layher STAR Frame | 37% weight reduction, 24% faster assembly | “Handling and assembling have never been easier, enhancing our project timelines dramatically.” |

| Kwikstage | Modular, customizable | “Versatile for complex structures, very stable and easy to configure.” |

Every high-quality scaffold system, like Kwikstage’s flexibility or OCTO®’s new locking system, makes a big difference. It leads Scaffolding Solutions to suggest these as the best for those who value safety and getting results in construction and other fields.

Exploring Versatile Scaffolding Systems for Commercial and DIY Use

The scaffolding industry has become a key part of the construction world. It offers many designs for both big commercial projects and small DIY tasks. Safety is a top priority, following the latest standards. These standards help reduce injuries and deaths from scaffolding each year.

Adjustable Height Scaffold for Varied Operational Needs

Adjustable scaffolds meet the different needs of work sites, from 1.0m to 3.6m tall. They are used for everything from small home fixes to big commercial builds. These systems are safe and efficient, making them easy to set up and take down.

Scaffold Rental Services: Flexible Options for Contractors

Renting scaffolding is a smart choice for contractors who don’t need to buy it. Prices range from $88 to $240 a week, making it affordable for various projects. Upgrades like wheels and platforms make the scaffolding safer and more useful.

Synergy Scaffolding & Access Equipment offers customizable solutions. They have everything from foldable scaffolds to big cup lock systems. These are perfect for big tasks in different places.

| Feature | Details | Upgrade Options | Price Range |

|---|---|---|---|

| Height Adjustability | 1.0m, 1.8m, 3.6m | N/A | $869 – $2889 |

| Rental Pricing/Week | N/A | 6-Inch, 8-Inch Wheels, Ladders | $88 – $240 |

| Wheel Upgrades | Adjustable Castor Wheels | 6-Inch or 8-Inch | $200 – $250 |

In conclusion, whether for big commercial scaffolding projects or small DIY scaffold projects, there are many options. These include scaffold rental services and systems that follow strict safety rules. The adjustable height scaffold and rental options make sure every project gets the right tools.

Conclusion

Aluminum scaffolding is changing how we build things. It’s clear that being strong, easy to move, and flexible is key in building today. Aluminum scaffolding is a top choice for building and fixing things, beating out wood and steel in many ways.

Companies like Layher and Bil-Jax lead in making scaffolding that meets many needs. These scaffolds are light, don’t rust, and make building easier. They show how aluminum scaffolding is better than wood in many ways.

Choosing the right scaffolding means knowing what you need. You should think about how strong it is, how much it can hold, and the cost. Companies like AAIT Scaffold offer great support and follow safety rules. They help customers use their products well.

Aluminum scaffolding shows how building is changing for the better. It’s a big step in making building safer and more efficient.