Phone:

(+65)8319-0742

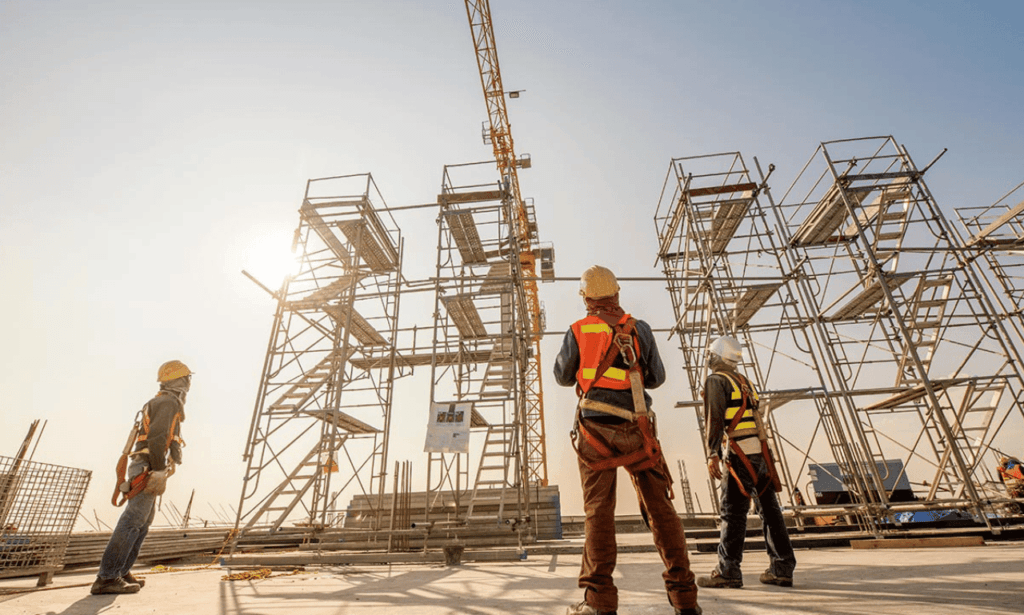

In the construction world, erected scaffolding is key. It helps workers stay safe at high places. Made from wood and steel, it’s strong and safe for people and tools.

Putting up and keeping scaffolding right is very important. It keeps workers safe and helps projects succeed.

Scaffolding Solutions showed how important good scaffolding is. They worked on a live rail shut down. Despite tough conditions, they kept everyone safe.

They had no injuries, accidents, or near misses. They reached their Goal ZERO.

Good scaffolding is vital for safe paths and work areas. It lets workers move around safely and do their jobs well. Following the rules and best practices helps make work safer and more productive.

Key Takeaways

- Erected scaffolding is a critical temporary structure that supports workers and enables safe construction at elevated heights.

- Proper installation and maintenance of scaffolding are crucial for ensuring worker safety and project success.

- Competent scaffolding solutions, such as those provided by Scaffolding Solutions, can overcome challenges and maintain a perfect safety record.

- Well-designed scaffolding provides safe access walkways and work platforms, allowing workers to navigate the construction site efficiently.

- Adhering to industry standards and best practices is essential for creating a safer and more productive work environment through scaffolding solutions.

Importance of Scaffolding Safety in Construction

Scaffolding safety is key in the construction world. It keeps workers safe and helps projects run smoothly. The importance of scaffolding safety is huge. Accidents can hurt people and cost a lot of money.

The construction world uses scaffolding a lot. It helps workers reach high places and do their jobs. But, working high up and scaffolding issues are big risks. So, safety must be top priority and rules must be followed closely.

Statistics on Scaffolding-Related Injuries and Fatalities

There are a lot of scaffolding accidents. Every year, about 4,500 people get hurt. Sadly, around 60 people die from these accidents in the U.S. Most of these deaths are from falls.

OSHA says 65% of construction workers use scaffolds. The BLS says over 62% of construction workers face heights. This shows how crucial safety is.

Financial Impact of Scaffolding Accidents

Scaffolding accidents cost a lot of money too. They make workers miss work, costing about $90 million a year. These accidents also lead to fines, legal costs, and higher insurance for companies.

The costs of scaffolding accidents go beyond the immediate. They can cause long-term disability claims and lawsuits. Companies also lose reputation, making it hard to get new projects.

To avoid these costs, companies need to focus on safety. They should provide training, check scaffolding often, and give the right PPE. This way, they protect workers and keep their business safe.

Personal Protective Equipment (PPE) for Scaffolding Work

Working on scaffolding requires the right personal protective equipment (PPE) to keep workers safe. PPE acts as a shield against hazards, reducing injury risks. Choosing the right scaffold type is key, but so is the right PPE for workers at heights.

Essential PPE Items for Working at Heights

Here are the must-have PPE items for scaffolders at heights:

- Hard hats: Protect against falling objects, even from short distances.

- Fall arrest equipment: Safety harnesses are recommended for heights over six feet.

- Non-slip footgear: Boots with steel-capped toes prevent slips and trips.

- High-visibility clothing: Luminous vests are vital in low light.

- Eye and face protection: Goggles and visors protect against particles and sparks.

Benefits of Slip-Resistant Gloves and Tool Tethering Lanyards

Slip-resistant gloves and tool tethering lanyards offer big benefits for scaffolders:

- Slip-resistant gloves: Provide extra grip on safety rails and tools.

- Tool tethering lanyards: Keep tools attached to workers, preventing falls.

Using these PPE items can greatly lower accident and injury risks at heights. Employers must provide quality PPE and training on its use.

Understanding Scaffolding Load Capacities and Regulations

Scaffolding safety is key, and knowing load limits is essential. Scaffolding is made to hold specific weights to keep workers safe. Putting too much weight on scaffolding can lead to serious injuries.

Scaffolding parts are built with a 4 to 1 safety factor. This means they can handle four times the maximum load. Still, it’s wise to know your scaffold’s exact capacity before adding heavy loads.

Rules for scaffolding vary by industry and location. Always check the specific OSHA, industry, and site standards before setting up scaffolding. Following OSHA scaffolding rules is vital to avoid accidents and keep workers safe.

OSHA standard 3150 says scaffolds must hold at least four times the intended load. Suspended scaffolding needs six times the load capacity in rigging.

Scaffolds are categorized by load capacity: light-duty, medium-duty, and heavy-duty. Light-duty scaffolds can hold at least 25 pounds per square foot. Medium-duty scaffolds can handle 50 pounds per square foot, and heavy-duty scaffolds can support 75 pounds per square foot.

| Scaffold Type | Maximum Intended Load |

|---|---|

| Supported Scaffolds (Tube and Coupler) | 25 pounds per square foot |

| Mobile Scaffolds | 25 pounds per square foot |

| Mast Climbing Work Platforms | 75 pounds per square foot |

Different scaffolding systems have their own rules and safety needs. It’s important to follow OSHA’s scaffold weight limits to avoid accidents.

OSHA also has specific rules for scaffolding safety:

- OSHA’s S 1926.451(g)(1) requires guardrails on scaffolding over 10 feet high for fall protection.

- OSHA’s S 1926.451(f)(3) says scaffolding must be checked before each shift and after any incidents.

- OSHA’s S 1926.451(a)(1) mandates scaffold designs to support their weight and at least four times the intended load to prevent overloading.

By following load-bearing capacities, load limits, OSHA regulations, and industry standards, employers can keep their workers safe. This ensures a secure work environment when using scaffolding.

Proper Inspection and Maintenance of Scaffolding Components

Keeping scaffolding safe and strong needs regular checks and upkeep. Inspections find problems like damage or parts that don’t fit right. This keeps the work area safe for everyone working high up.

Identifying Defects and Damage in Scaffolding Materials

It’s key to check all parts of the scaffold before setting it up. Look for things like:

- Cracks, bends, or dents in structural members

- Corrosion or rust on metal components

- Worn or damaged coupling pins and locking devices

- Splinters, knots, or rot in wooden planks

- Frayed or damaged safety netting or guardrails

If you find any problems, take out the bad parts and replace them. Not fixing these issues can make the scaffold unstable and dangerous.

Ensuring Compatibility of Scaffolding Components

It’s also important to make sure all parts fit together right. The wrong parts can weaken the whole thing. Check these things when making sure parts fit:

- Manufacturer specifications and instructions

- Load-bearing capacities of individual components

- Dimensions and fitting tolerances of connecting parts

- Material composition and quality standards

Always follow the maker’s rules and use parts from the same set. Mixing parts from different makers can be risky unless a pro says it’s okay.

Regular checks and following the rules for parts are key to keeping scaffolding safe and strong.

Keeping up with maintenance is also crucial. This means:

- Cleaning and lubricating moving parts

- Tightening loose bolts and connections

- Replacing worn or damaged components promptly

- Properly storing materials to prevent damage or deterioration

With a good inspection and maintenance plan, you can catch problems early. This keeps the scaffold in good shape and everyone safe while working high up.

Safe Erection and Dismantling Procedures for Scaffolding

Scaffolding safety is crucial in construction. Proper erection procedures and dismantling are key to keeping these structures stable and secure. About 65% of scaffolds don’t meet OSHA standards, showing the need for strict safety rules.

Following the manufacturer’s instructions is vital when setting up scaffolds. It’s important to use the right bracing, fasteners, and anchors. Skipping these steps can weaken the scaffold and endanger workers.

Role of the Competent Person in Scaffolding Supervision

OSHA requires a competent person to oversee scaffold setup and teardown. This person must have OSHA-approved training and the right authority. They ensure all safety rules are followed and the scaffold is set up correctly.

Studies show that following proper scaffold procedures can cut accident rates by up to 80%. This highlights the importance of having a trained supervisor on site.

Key Considerations for Stable and Secure Scaffold Structures

Creating a stable scaffold involves several key steps. First, leg braces must be installed correctly to ensure the scaffold is level and sturdy. This prevents instability and collapse.

Second, decks, planks, and other components must be securely fastened. Loose parts can lead to accidents. Around 30% of scaffolds need repairs after inspections, showing the need for careful installation.

Lastly, mud sills and base plates must be the right size and securely attached. They provide a solid base for the scaffold, preventing it from shifting or sinking. Neglecting these details can cause collapses, which are common in construction.

By following these guidelines and using man lifts when needed, construction teams can greatly reduce accident risks. This ensures a safe work environment for everyone involved.

Maintaining a Clean and Hazard-Free Scaffolding Environment

Keeping the scaffolding area clean and organized is key to avoiding accidents. Regularly removing debris and tools helps prevent tripping and falls. A clean workspace is safer and more productive.

Set up a cleaning schedule and teach workers to keep their areas tidy. Store tools and materials in their places and dispose of waste quickly. This approach helps prevent accidents and injuries.

A clean and organized scaffolding environment is the foundation of a safe and productive work site.

It’s also important to keep vehicles and heavy equipment away from the scaffolding. Use barriers to protect the scaffolding from accidents. Make sure there’s enough space around heavy equipment and that operators know about the scaffolding.

| Hazard | Prevention Measure |

|---|---|

| Tripping hazards | Regular removal of debris, excess materials, and tools |

| Cluttered work areas | Implement a routine cleaning schedule and encourage worker tidiness |

| Vehicle and equipment impacts | Establish barriers or exclusion zones around the scaffold base |

Good housekeeping and a clean scaffolding area reduce accident risks. It also helps avoid OSHA violations. Investing in cleanliness and debris removal makes the work environment safer for everyone.

Erected Scaffolding: Ensuring Safety in Adverse Weather Conditions

Scaffolding is key in construction, but safety is top priority, especially in bad weather. Wind, rain, lightning, snow, and ice raise the risks of working at heights. It’s vital for workers to be careful and follow OSHA guidelines.

Risks Associated with Wind, Rain, Lightning, Snow, and Ice

Bad weather can be dangerous for workers on scaffolding. High winds can make scaffolding unstable, leading to falls or objects falling. Rain makes surfaces slippery, making it hard to stay steady.

Lightning near scaffolding can cause electrocution. Snow and ice can weaken the scaffold’s structure.

In Derbyshire, UK, scaffolding work is especially risky because of the area’s slippery conditions all year. Even in spring, when it’s warmer and sunnier, there’s still a lot of rain. This rain can slow down and make less accurate the work of setting up scaffolding.

OSHA Guidelines for Scaffolding Use in Inclement Weather

OSHA has rules to help keep workers safe in bad weather:

- Don’t climb, use, or set up scaffolds in severe weather like strong winds, heavy rain, or lightning.

- Make sure there’s proper fall protection, like guardrails, personal fall arrest systems, and safety nets.

- Use toe boards, screens, or debris nets to protect against falling objects.

- Check scaffolding parts often for damage or weakness from harsh weather.

- Train workers well on scaffolding safety and what to do in emergencies.

Employers should also follow these best practices:

- Tell workers to wear shoes with good grip to avoid slipping on wet surfaces.

- Teach workers to climb slowly and carefully on slippery surfaces.

- Encourage teamwork and watch out for each other’s safety in bad weather.

- Turn planks if they’re wet to make working conditions safer.

| Weather Condition | Potential Hazards | Safety Measures |

|---|---|---|

| High Winds | Instability, falling objects | Avoid scaffolding use, secure materials |

| Heavy Rain | Slippery surfaces, reduced visibility | Use slip-resistant footwear, climb cautiously |

| Lightning | Electrocution | Suspend work, seek shelter |

| Snow and Ice | Structural damage, slips and falls | Remove accumulation, use de-icing agents |

By following OSHA guidelines and best practices, employers can lower the risk of accidents and injuries. Proper training, being aware of hazards, and a focus on safety are key to protecting workers in construction.

Importance of Proper Training and Licensing for Scaffolding Personnel

Keeping workers and the public safe is key in the construction world. Scaffolding training and licensing are vital for this. With good training and following rules, companies can lower accident risks.

In 2020, the Bureau of Labor Statistics reported 52 scaffolding deaths. This shows the need for strict safety and trained workers. OSHA says workers must be trained to handle scaffolding safely.

OSHA-Approved Training and Manufacturer Equipment Training

OSHA demands a competent person for scaffolding work. This person must have OSHA-approved training and know the equipment well. Companies like Beacon Scaffolding offer such training.

Workers also need training on specific equipment. This ensures they know how to use it safely.

Assigning Competent Person Roles and Authority

Choosing a competent person is crucial for safety. They oversee scaffolding work and can fix hazards quickly. They have the power to act fast to keep everyone safe.

Without a competent person, jobs can be shut down, and workers can get hurt. Companies must make sure they have the right people for the job.

| Training Program | Duration | Recertification |

|---|---|---|

| OSHA-Approved Training | Varies | Every 5 years |

| Manufacturer Equipment Training | Varies | As needed |

| Competent Person Training | 5 hours | Every 5 years |

Investing in training and licensing makes workplaces safer. It also meets OSHA rules. This effort keeps workers safe and boosts the company’s image.

Understanding Scaffolding Tags and Their Significance

Scaffolding tags are key to keeping workers safe on construction sites. They come in green, yellow, and red and tell us if a scaffold is safe. OSHA rules say a skilled person must check scaffolding before work starts and after any changes.

Green tags mean a scaffold is safe and ready for use. They are shown at every entrance after a check.

Yellow tags warn of changes or safety issues. Workers must be careful and follow special rules. These tags list hazards, how to avoid them, and who approved the changes.

Red tags mean a scaffold is not safe and needs fixing. They are used when setting up or taking down scaffolds. Red tags show what needs fixing, when it was checked, and who did the check.

Scaffolding tags should display unique identification numbers, inspection dates, load capacity, inspection results, and safety status.

It’s important to place scaffolding tags where everyone can see them. Use more than one tag for tall scaffolds. Keep them safe from the weather and easy to read.

Using scaffolding tags has many benefits:

- It makes workers more aware of safety

- It helps find safe and unsafe scaffolds quickly

- It makes sure inspections and upkeep are done right

- It helps everyone talk about safety

- It makes checking scaffolds easier and keeps records clear

By understanding scaffolding tags and following safety rules, construction workers can make their sites safer. This helps prevent accidents and keeps everyone safe while working with scaffolds.

Preventing Damage to Scaffolding Structures

Keeping scaffolding safe is crucial for the 2.3 million construction workers in the U.S. who use it. Knowing what damages scaffolding helps teams prevent harm. This keeps workers safe on the job.

Impact of Manual Labor and Motorized Equipment on Scaffolding Integrity

Scaffolding can get damaged by manual labor and heavy machines. Workers might accidentally hit the scaffolding while working. It’s also possible for vehicles or machinery to knock into it. To avoid these problems, keep scaffolding away from machines:

- Keep a minimum distance of 10 feet between scaffolding and all heavy machinery

- For larger vehicles with greater swinging or reaching range, establish an exclusion zone of at least 20 feet

- Provide comprehensive training to workers on safe practices when working near scaffolding structures

Effects of Environmental Elements on Scaffolding Strength

Weather can also weaken scaffolding. Rain and moisture can cause rust, making it unsafe. To fight this, follow these steps:

- Conduct regular inspections of scaffolding structures to identify any signs of damage or wear

- Address any instances of rust or corrosion promptly to prevent further deterioration

- Ensure that scaffolding materials are properly stored and protected from the elements when not in use

- Use high-quality, corrosion-resistant materials in the construction of scaffolding structures

By taking these steps and following OSHA rules, construction teams can lower the risk of damage. Regular checks, training, and a safe work area are vital. They help keep workers safe and healthy on construction sites.

Conclusion

Scaffolding safety is key in construction. It keeps workers safe and projects on track. By focusing on safety, companies can avoid accidents and damage.

Good design and setup of scaffolding systems are vital. They prevent collapse and make work easier. This leads to better work and faster project finishes.

Following rules, checking scaffolding often, and training workers are important. Accurate setup boosts safety and quality. It also saves time and resources.

The construction world is always changing. Keeping up with new safety rules is essential. This ensures scaffolding can be adapted and reused.

Putting safety first is a moral duty and a smart business move. It helps companies succeed and maintain a good reputation. It also keeps workers safe and healthy.