Phone:

(+65)8319-0742

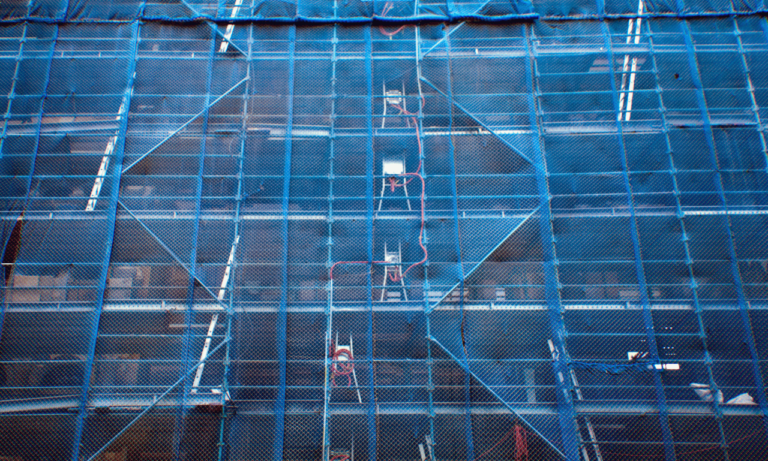

Confined spaces pose unique challenges when it comes to installing scaffolding. These areas, characterized by limited access, poor ventilation, and potential hazards, require careful planning, adherence to safety regulations, and the expertise of professionals. In this article, we will explore the significance of confined spaces, the potential dangers they present, and the necessary precautions to ensure safe scaffolding installation.

Key Takeaways:

- Confined spaces require special considerations for scaffolding installation.

- Confined spaces can have limited access, poor ventilation, and potential hazards.

- To ensure safety, it is important to assess risks and follow regulatory requirements.

- Professional expertise and proper training are crucial for confined space scaffolding.

- Choosing suitable components and implementing safety measures are essential steps in the installation process.

Understanding Confined Spaces

Confined spaces pose unique challenges in various industries due to their limited access and potential hazards. These areas, such as storage tanks, silos, crawl spaces, and tunnels, are not designed for continuous human occupancy. When it comes to scaffolding installation in confined spaces, it is crucial to understand the specific characteristics and risks associated with these environments.

One of the key features of confined spaces is their limited openings for entry and exit. This restricted access can make working within these spaces challenging and requires careful planning and coordination. Additionally, confined spaces often have poor ventilation, inadequate lighting, and can contain hazardous substances or conditions.

Proper ventilation is essential in confined spaces to prevent the buildup of hazardous gases, fumes, or dust. The lack of adequate airflow can lead to serious health risks, such as asphyxiation or exposure to toxic atmospheres. Therefore, ensuring adequate ventilation during scaffolding installation is crucial to maintaining a safe working environment.

The presence of hazardous substances or conditions further emphasizes the need for strict safety protocols. Some confined spaces may contain chemicals, flammable materials, or other potentially dangerous elements. Proper identification, assessment, and mitigation of these hazards are essential to protect workers and prevent accidents.

By understanding the characteristics of confined spaces, such as limited access, restricted ventilation, and the potential for hazardous substances, professionals can implement the necessary safety measures for scaffolding installation. These precautions include proper hazard assessment, appropriate ventilation systems, and the use of personal protective equipment. With these measures in place, the risks associated with working in confined spaces can be effectively minimized.

The Dangers of Confined Spaces

Working in confined spaces can pose significant risks and hazards that must be carefully addressed to ensure the safety of workers. These spaces, characterized by limited access and poor ventilation, can create life-threatening situations if proper precautions are not taken.

Lack of Oxygen

A lack of oxygen is a common danger in confined spaces and can lead to asphyxiation or loss of consciousness. Without adequate oxygen supply, workers may experience difficulty breathing, dizziness, and even death. It is crucial to assess oxygen levels and implement appropriate measures to mitigate this risk.

Toxic Atmospheres

Confined spaces can contain toxic gases, vapors, or substances that pose serious health risks. Exposure to toxic atmospheres can lead to respiratory problems, chemical burns, and other severe health complications. Proper ventilation, testing, and monitoring are essential to prevent the accumulation of harmful substances.

Physical Hazards

In addition to atmospheric risks, confined spaces may have physical hazards that can endanger workers. These hazards may include uneven surfaces, sharp edges, falling objects, or unstable structures. Thorough inspections and precautionary measures such as proper lighting, personal protective equipment, and guardrails are crucial to prevent accidents and injuries.

Engulfment or Entrapment

One of the most catastrophic risks in confined spaces is the potential for engulfment or entrapment. The nature of these spaces, with limited egress points, increases the danger of workers becoming trapped in hazardous substances or being engulfed by flowing liquids or bulk materials. Strict safety protocols, team communication, and the presence of an emergency rescue plan are essential to address this risk.

| Dangers | Risks |

|---|---|

| Lack of Oxygen | Asphyxiation, loss of consciousness |

| Toxic Atmospheres | Respiratory problems, chemical burns |

| Physical Hazards | Uneven surfaces, falling objects, unstable structures |

| Engulfment or Entrapment | Suffocation, injury |

Steps for Safe Scaffolding Installation in Confined Spaces

Installing scaffolding in confined spaces requires careful consideration and adherence to specific steps to ensure the safety of workers. By following these guidelines, you can mitigate the risks associated with working in these challenging environments. The key steps for safe scaffolding installation in confined spaces include:

1. Conducting a Thorough Assessment

Prior to scaffolding installation, it is crucial to conduct a comprehensive assessment of the confined space. This assessment involves identifying potential hazards such as limited access, poor ventilation, or the presence of hazardous substances. Understanding the specific risks enables you to develop a tailored plan that addresses these challenges effectively.

2. Ensuring Regulatory Compliance

Complying with regulatory requirements and safety codes is essential for safe scaffolding installation. Obtain the necessary permits and ensure adherence to guidelines set by relevant regulatory bodies. This ensures that your scaffolding installation meets the required safety standards and reduces the risk of accidents or non-compliance penalties.

3. Engaging Professional Expertise for Scaffold Design

Confined space scaffolding design requires professional expertise to develop a system that maximizes safety and efficiency. Engage the services of experienced professionals who have expertise in working with confined spaces. They can evaluate the specific requirements of your project and design a scaffold system that meets your needs while minimizing risks.

4. Choosing Suitable Scaffold Components

Selecting the right scaffold components is crucial for ensuring stability and safety. Utilize components that are specifically designed for confined spaces, considering factors such as size, weight, and maneuverability. This ensures that the scaffold system is appropriate for the space and minimizes the potential for accidents or structural failures.

5. Preparing the Space

Prior to scaffold installation, prepare the confined space by clearing any obstacles or debris that may hinder the safe erection of the scaffold system. Create a clean and organized workspace to enhance the safety and efficiency of the installation process.

6. Scaffold Erection According to Design Specifications

Follow the scaffold system’s design specifications precisely during the erection process. Ensure that all components fit securely and that the structure is stable and level. Any deviations from the design, no matter how small, can compromise the safety and integrity of the scaffolding, posing risks to workers.

7. Implementing Safety Measures

Implementing additional safety measures is critical to protect workers during scaffold installation. This includes providing appropriate access points, such as ladders or stairs, to ensure safe movement within the confined space. Installing guardrails and other fall protection systems further enhance worker safety while working at height.

By following these steps and prioritizing safety at every stage of the scaffolding installation process, you can reduce the risks associated with working in confined spaces. The combination of assessment, regulatory compliance, professional expertise, suitable scaffold components, space preparation, proper erection, and safety measures significantly contributes to a safer working environment.

Compliance with Safety Regulations

When it comes to installing scaffolding in confined spaces, ensuring compliance with safety regulations is of utmost importance. Safety regulations, such as those set by OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute), are designed to protect workers and maintain a safe working environment.

OSHA standards are specifically tailored to scaffold safety and provide detailed guidelines for the proper installation, use, and maintenance of scaffolding systems. These standards cover various aspects, including scaffold design, load capacity, fall protection measures, and access and egress requirements. By following OSHA standards, employers can ensure that their scaffolding installations meet the necessary safety standards and mitigate the risks associated with working in confined spaces.

Additionally, compliance with ANSI standards is equally crucial. ANSI standards encompass a wide range of safety practices and requirements, including those related to scaffolding. They provide industry-accepted guidelines and criteria for scaffold construction, use, and inspection. By adhering to ANSI standards, companies can demonstrate their commitment to safety and maintain a high standard of scaffold performance.

By complying with these safety regulations, companies can prioritize the well-being of their workers and reduce the likelihood of accidents or injuries in confined space scaffolding projects.

Key Safety Regulations:

- OSHA standards for scaffold safety

- ANSI standards for scaffold construction and use

| Regulation | Description |

|---|---|

| OSHA | Regulatory standards for scaffold safety, covering design, use, and maintenance. |

| ANSI | Industry-accepted guidelines for scaffold construction, use, and inspection. |

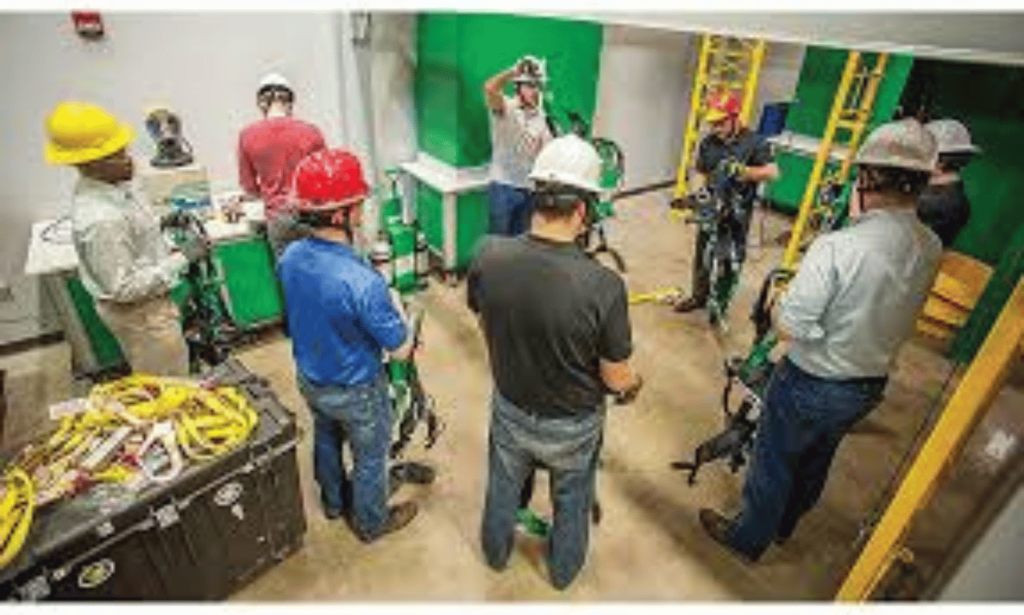

Training and Education for Confined Space Work

Proper training and education are essential for conducting confined space work safely. Individuals should undergo comprehensive confined space training to acquire the necessary knowledge and skills to mitigate hazards effectively.

An effective training program should cover various aspects, including **hazard recognition**, **safety procedures**, and the correct use of **personal protective equipment (PPE)**. This training ensures that workers are aware of the specific risks associated with confined spaces, enabling them to identify potential hazards proactively.

Key elements of confined space training:

Hazard recognition: Training should focus on teaching workers how to identify and assess potential hazards within a confined space. This includes recognizing electrical, chemical, or physical hazards that may pose risks to their safety.

Safety procedures: Workers should be trained on the proper procedures for entering, exiting, and working within confined spaces. This includes understanding lockout/tagout procedures, ventilation requirements, and maintaining effective communication.

Personal protective equipment (PPE): Proper and consistent use of PPE is crucial when working in confined spaces. Workers should be trained on the selection, inspection, and correct usage of PPE, such as respiratory protection, fall protection, and protective clothing.

Training sessions should be interactive and include practical exercises to reinforce learning and allow participants to apply their knowledge effectively.

By investing in **confined space training** and providing workers with the necessary skills, organizations can ensure a safer work environment and reduce the likelihood of accidents or injuries.

| Benefits of Confined Space Training | Effective Training Methods |

|---|---|

|

|

Equipment and Tools for Confined Space Scaffolding

In order to ensure safe scaffolding in confined spaces, it is crucial to use the right equipment and tools. This includes specialized scaffolding systems designed specifically for confined spaces, such as compact frames and platforms that can navigate tight areas without compromising safety. These systems are engineered to provide the necessary support and stability, while also being adaptable to the unique challenges posed by confined spaces.

Additionally, proper ventilation equipment is essential for maintaining a safe and breathable atmosphere within the confined space. Confined space ventilation systems help to remove any potential hazardous gases, fumes, or vapors that may be present. This ensures that the air quality remains within acceptable standards, reducing the risk of respiratory issues and other health hazards.

It is important to note that when working with confined space ventilation systems, best practices must be followed. This includes regular maintenance of the equipment to ensure its optimal functioning. Routine inspections should be conducted to identify any potential issues or defects, allowing for timely repairs or replacements. By adhering to these best practices, the effectiveness and reliability of the ventilation equipment can be maximized, ensuring the safety of workers within the confined space.

Key Equipment and Tools for Confined Space Scaffolding:

- Specialized scaffolding systems designed for confined spaces

- Compact frames and platforms

- Confined space ventilation systems

- Respiratory protection equipment

- Personal protective equipment (PPE)

| Equipment/Tool | Description |

|---|---|

| Specialized scaffolding systems | Scaffolding systems specifically designed for confined spaces, providing stability and adaptability. |

| Compact frames and platforms | Frames and platforms that can navigate tight spaces, allowing for safe access and work areas. |

| Confined space ventilation systems | Equipment designed to remove hazardous gases, fumes, or vapors from the confined space, ensuring a safe and breathable atmosphere. |

| Respiratory protection equipment | Masks, respirators, or other devices that protect workers from inhaling harmful substances or contaminants. |

| Personal protective equipment (PPE) | Safety gear and clothing, including helmets, gloves, and harnesses, to protect workers from potential hazards. |

Rescue and Emergency Preparedness

Adequate rescue and emergency preparedness are crucial when working in confined spaces. It is essential to have a comprehensive rescue plan in place to ensure the safety of workers in case of an emergency. This plan should include well-defined procedures for evacuating workers from confined spaces efficiently and swiftly.

Training plays a vital role in preparedness for confined space rescue. Workers should be provided with thorough training on rescue techniques, including how to identify and respond to different emergency situations. Additionally, they should be trained on the proper use of rescue equipment, such as harnesses, ropes, and communication devices.

Regular drills and evaluations of the rescue plan are necessary to maintain preparedness and identify any areas that may require improvement. Conducting mock rescue scenarios allows workers to practice their skills and familiarize themselves with the procedures. It also enables supervisors to assess the effectiveness of the rescue plan and make any necessary adjustments.

Collaboration and communication are vital during rescue operations in confined spaces. Well-coordinated efforts among the rescue team, supervisors, and workers are necessary to ensure successful evacuation. Establishing clear lines of communication and assigning designated roles and responsibilities to each team member is crucial for smooth execution of rescue procedures.

Evacuation Procedures

Evacuation procedures should be specific to the unique challenges posed by confined spaces. Key considerations for developing evacuation procedures include:

- Identifying primary and secondary evacuation routes: There should be clear routes established for workers to exit the confined space quickly and safely. These routes should be easily accessible and free from obstructions.

- Establishing communication protocols: Effective communication is critical during an evacuation. Establish a system for workers to communicate their status and location to the rescue team.

- Implementing buddy system: Pairing workers in confined spaces with a buddy ensures that they can look out for each other and assist in case of an emergency.

- Providing clear instructions: All workers should be familiar with the evacuation procedures and understand their roles and responsibilities during an emergency.

- Regular training and drills: Conduct periodic training sessions and evacuation drills to keep workers prepared and confident in implementing the evacuation procedures.

By prioritizing rescue and emergency preparedness and implementing robust evacuation procedures, workers in confined spaces can minimize the risks associated with emergencies and ensure their safety.

Conclusion

Ensuring confined space safety during scaffolding installation is of utmost importance. By following the necessary steps and precautions, such as conducting thorough assessments, complying with safety regulations, and implementing appropriate safety measures, workers can mitigate the risks associated with working in confined spaces.

Professional expertise, adherence to safety regulations, and careful planning are vital when working in confined spaces. It is essential to engage professionals with experience in confined space scaffolding installation to ensure the highest level of safety and hazard mitigation.

By prioritizing confined space safety and employing best practices in scaffolding installation, organizations can create a secure environment for workers and minimize the potential dangers present in confined spaces.

FAQ

What is a confined space?

A confined space is an area with limited openings for entry and exit and is not designed for continuous human occupancy. Examples include storage tanks, silos, crawl spaces, and tunnels.

What are the risks associated with working in confined spaces?

Working in confined spaces can be hazardous due to a lack of oxygen, toxic or flammable atmospheres, physical hazards, and the potential for engulfment or entrapment.

What steps should I follow for safe scaffolding installation in confined spaces?

To ensure safe scaffolding installation in confined spaces, you should conduct a thorough assessment, ensure regulatory compliance, engage professional expertise, choose suitable components, prepare the space, erect the scaffold system, and implement safety measures.

What safety regulations should I comply with when installing scaffolding in confined spaces?

When installing scaffolding in confined spaces, it is important to comply with safety regulations set by organizations such as OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute).

How important is training and education for confined space work?

Proper training and education are essential for safe confined space work. Workers should be trained on hazard recognition, emergency procedures, and the correct use of personal protective equipment for working in confined spaces.

What equipment and tools are necessary for safe confined space scaffolding?

Using the right equipment and tools, such as specialized scaffolding systems designed for confined spaces and proper ventilation equipment, is essential for safe confined space scaffolding. Following best practices for equipment maintenance and inspection is also crucial.

How important is rescue and emergency preparedness for working in confined spaces?

Adequate rescue and emergency preparedness are vital when working in confined spaces. Having a comprehensive rescue plan, proper rescue training, and the use of rescue equipment are necessary to ensure worker safety.

What are the key points to consider when installing scaffolding in confined spaces?

When installing scaffolding in confined spaces, it is crucial to conduct thorough assessments, comply with safety regulations, engage professional expertise, choose suitable components, prepare the space, erect the scaffold system, and implement safety measures to ensure a safe working environment.