Phone:

(+65)8319-0742

Welcome to our essential guide on cantilever scaffolding! In construction projects where access to difficult-to-reach areas is required, cantilever scaffolding proves to be a valuable solution. This unique type of scaffold is anchored to a building at one end and supported by needles or struts, making it ideal for working on building facades, bridges, and windows.

In this guide, we will explore the advantages of cantilever scaffolding, its applications in scaffold construction, and the different types of scaffolding systems available. Additionally, we will delve into the crucial safety measures and best practices that should be followed while constructing and working with cantilever scaffolding.

Key Takeaways:

Cantilever scaffolding provides access to hard-to-reach areas during construction projects

- It is anchored to the building at one end and supported by needles or struts

- Common applications include façade maintenance, bridge construction, and window installation

- Proscaf offers unique capabilities for cantilevered scaffolding, such as load bearing cross-braces

- A well-designed cantilevered scaffold should consider load capacity, environmental conditions, and safety features

Common Applications of Cantilever Scaffolding

Cantilever scaffolding is a versatile and valuable tool in various construction scenarios. Its unique design and functionality make it well-suited for a range of applications, including:

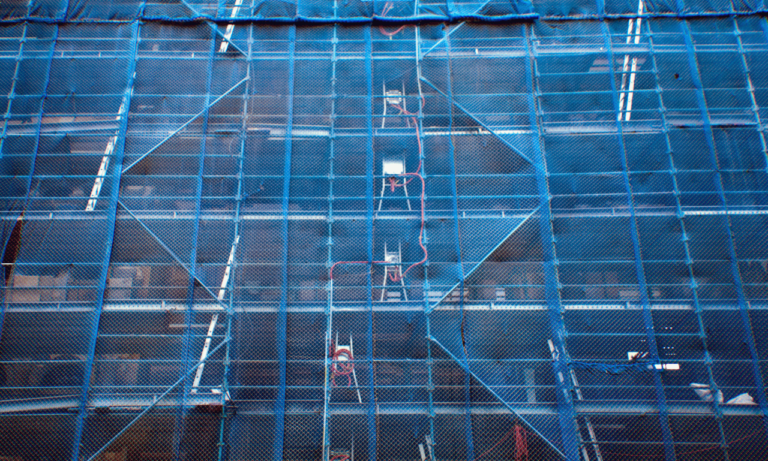

Façade Maintenance

One common use of cantilever scaffolding is in building maintenance and cleaning projects where access to the façade is required. It allows workers to safely reach and work on the exterior of high-rise buildings, ensuring the upkeep and appearance of the structure. Whether it’s washing windows, painting, or performing repairs, cantilever scaffolding provides a stable platform for workers to carry out these tasks efficiently.

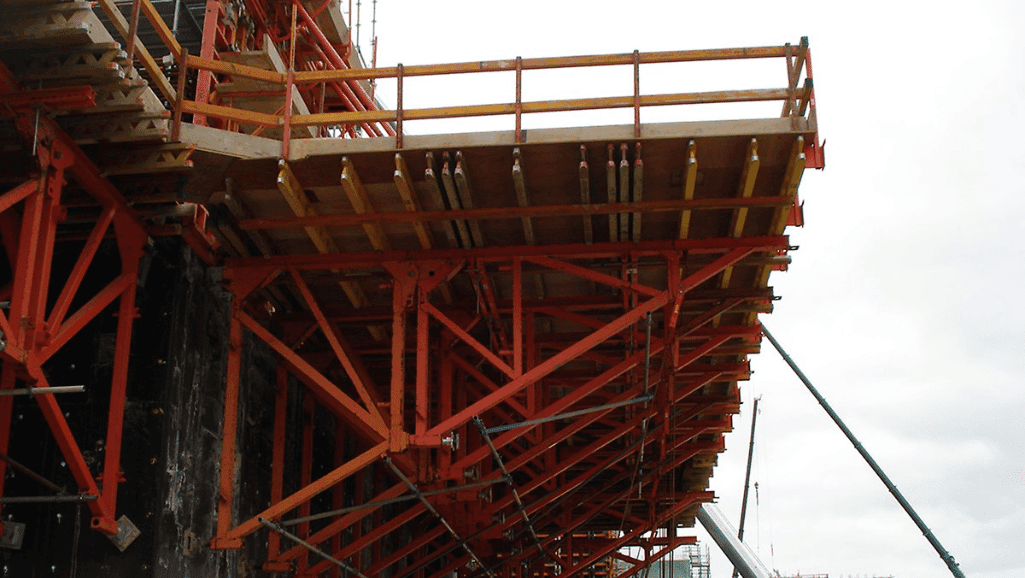

Bridge Construction

In the construction of bridges, cantilever scaffolding plays a vital role in providing support and access to workers. It offers a safe working platform during the construction process, enabling workers to assemble, install, and maintain various structural components. Cantilever scaffolding allows construction teams to work at different heights of the bridge, ensuring the project progresses smoothly and safely.

Window Installation

Cantilever scaffolding is also widely utilized in window installation projects. During the installation or replacement of windows, workers often require access to the exterior of buildings. Cantilever scaffolding provides them with a safe and stable platform to reach the necessary height, ensuring efficient and effective window installations.

The versatility of cantilever scaffolding in these applications highlights its importance in the construction industry. Its ability to provide safe access to façades, bridges, and windows makes it an indispensable tool for construction and maintenance projects.

Proscaf Capabilities for Cantilevered Scaffolding

Proscaf is a scaffold system that offers unique capabilities and advantages for cantilevered scaffolding projects. With its innovative design and high-quality construction, Proscaf provides efficient and safe solutions for accessing difficult-to-reach areas.

One of the key features of Proscaf is its load bearing cross-braces. These cross-braces have industry-leading compression load ratings, thanks to the use of high-grade steel. The high capacity of the braces allows for larger cantilevered spans, eliminating the need for additional support beams and reducing material requirements.

The scaffold design of Proscaf incorporates double-bolt standards and node-to-node connection, further enhancing the capacity and stability of the scaffolding structure. The double-bolt standards ensure a secure and rigid connection, providing a solid foundation for the scaffold. The node-to-node connection enhances the overall stability of the scaffold, preventing any swaying or movement that could compromise safety.

By leveraging the capabilities of Proscaf, scaffold designs can be optimized to meet project requirements, resulting in efficient and safe construction. The load-bearing capabilities, along with the double-bolt standards and node-to-node connection, offer increased stability and reliability. This allows construction professionals to confidently work on cantilevered scaffolding projects, knowing that they are utilizing a robust system.

Importance of a Good Cantilevered Scaffold Design

A proper design is crucial when constructing a cantilevered scaffold. It should consider the intended use, load capacity, and environmental conditions at the work site. The scaffold must be able to support the weight of workers, tools, and materials, while also accounting for external factors such as wind, rain, or snow.

Additionally, the design should ensure the scaffold is securely anchored to the building or structure and incorporate safety features such as guardrails and safety nets. Working with a professional scaffold engineer is recommended to ensure a safe and effective cantilevered scaffold design.

Benefits of a Good Cantilevered Scaffold Design

- Enhanced load capacity: A well-designed cantilevered scaffold can handle heavy loads, ensuring the safety of workers and the stability of the structure.

- Optimized performance: By considering the specific environmental conditions at the work site, the scaffold design can be tailored to withstand challenges such as high winds or extreme temperatures.

- Increased worker safety: Incorporating safety features such as guardrails and safety nets in the design helps prevent falls and protects workers from potential hazards.

- Efficient construction process: A well-designed scaffold minimizes the need for additional support beams or materials, streamlining the construction process and reducing costs.

Overall, investing in a good cantilevered scaffold design is essential for achieving a safe and efficient construction project. It provides the necessary support, load capacity, and safety features to ensure the well-being of workers and the successful completion of the project.

Cantilevered Scaffold Safety Measures

When working with cantilevered scaffolding, it is crucial to prioritize safety. By implementing proper training, secure anchoring, load capacity considerations, fall protection measures, and regular inspections, workers can ensure a safe and secure working environment.

Proper Training

Workers should receive comprehensive training on the use of cantilevered scaffolding systems. This includes instruction on proper erection and dismantling procedures, as well as safe work practices. By equipping workers with the necessary knowledge and skills, the risk of accidents and injuries can be significantly reduced.

Secure Anchoring

One of the key safety measures is ensuring that the cantilevered scaffold is securely anchored to the building or structure. This involves using appropriate anchoring systems and techniques that can withstand the anticipated load and environmental conditions. By securely anchoring the scaffold, the risk of collapse or instability is minimized.

Load Capacity Considerations

Before using a cantilevered scaffold, it is crucial to assess its load capacity. The scaffold should be designed and constructed to support the anticipated loads, including the weight of workers, tools, and materials. Overloading the scaffold can compromise its structural integrity and pose a significant safety hazard. By adhering to the recommended load limits, accidents can be prevented.

Fall Protection Measures

Falls from heights are one of the most significant risks when working with cantilevered scaffolding. To mitigate this risk, fall protection measures must be implemented. This includes the use of personal protective equipment such as safety harnesses and lanyards. By providing workers with proper fall protection equipment and ensuring its correct usage, the risk of severe injuries or fatalities can be minimized.

Regular Inspections

Regular inspections are essential to identify any signs of damage or wear on the cantilevered scaffold. Inspections should be carried out by qualified personnel who can assess the structural integrity of the scaffold and identify any potential hazards. By conducting regular inspections, any issues can be addressed promptly, ensuring the continued safety of workers and the stability of the scaffold.

Implementing these safety measures is crucial to ensure the well-being of workers and the structural integrity of the cantilevered scaffold. By prioritizing proper training, secure anchoring, load capacity considerations, fall protection measures, and regular inspections, construction projects can proceed safely and efficiently.

What is a Cantilever Scaffold and How Does it Work?

Defining Cantilever Scaffolding

A cantilever scaffold is a specialized type of scaffold system that is supported by cantilever beams or brackets anchored securely to a building or structure. Unlike traditional scaffolding, which relies on a ground-based support structure, cantilever scaffolding is designed to extend outwards without ground support, making it ideal for situations where ground access is limited or obstructed. This type of scaffolding is also known as needle scaffolding due to the ‘needle-like’ beams that support the scaffold platform.

Mechanics Behind the Cantilever Scaffold System

The mechanics of a cantilever scaffolding system revolve around the cantilever beam, which is a horizontal structure anchored at only one end. The beam extends outwards, supporting a platform for workers to perform their tasks. The cantilevered design allows for a work platform that is both stable and efficient, even in challenging environments. By employing trussed cantilever scaffolds or counterbalanced cantilever scaffolds, the system ensures that the load capacity is adequately managed, providing a safe working environment for construction workers.

Comparison with Traditional Scaffolding

Comparing cantilever scaffolding with traditional scaffolding systems reveals distinct differences in design and application. Traditional scaffolding typically relies on vertical supports that extend from the ground upwards, requiring ample space for setup. In contrast, cantilever scaffolds eliminate the need for ground-based support, proving advantageous in scenarios where ground space is restricted, such as in bridge construction or high-rise building maintenance. This flexibility is a significant benefit of cantilever scaffolding, offering solutions where conventional scaffolding cannot.

What are the Different Types of Cantilever Scaffolding?

Overview of Needle Scaffolding

Needle scaffolding, a type of cantilever scaffolding, involves the use of horizontal beams or ‘needles’ that are inserted into walls or structures to support the scaffold platform. This method is particularly useful in construction projects where maintaining ground space is crucial. The needles provide a sturdy base, allowing workers to perform tasks safely and efficiently. Needle scaffolding is often utilized in renovation projects where the building’s facade needs to remain undisturbed.

Exploring Bracket Scaffolding Systems

Bracket scaffolding systems utilize brackets that are fixed to a building or structure, replacing the need for traditional vertical supports. This type of scaffold is ideal for exterior construction projects where traditional scaffolding systems might pose challenges. By using brackets, workers can access hard-to-reach areas without compromising on safety or efficiency. The design allows for quick assembly and disassembly, providing a flexible solution for various construction tasks.

Suspended Scaffolding Explained

Suspended scaffolding, another variation of cantilever scaffolding, is characterized by a platform that is suspended by ropes or cables, allowing it to be raised or lowered as needed. This type of scaffold is frequently used in high-rise building projects, offering a safe and efficient way to access upper levels without extensive ground-based structures. The ability to adjust the height of the platform provides significant flexibility and efficiency in construction and maintenance operations.

What Safety Measures are Essential for Cantilever Scaffolding?

Importance of Load Capacity and Stability

Ensuring load capacity and stability is paramount in any cantilever scaffold system. The scaffold must be designed to withstand the weight of workers, tools, and materials without compromising structural integrity. Proper calculation of load distribution and the use of high-quality materials are essential safety measures that must be adhered to. Failure to do so can result in accidents, posing significant risks to both workers and the construction site.

Secure Design: A Good Cantilevered Scaffold

A well-designed cantilevered scaffold incorporates numerous safety features to provide a secure work environment. This includes the use of safety harnesses, guardrails, and non-slip surfaces to prevent falls. Additionally, regular inspections and maintenance of the scaffold structure are crucial to identify and rectify potential hazards. A scaffold must also comply with industry standards and regulations to ensure maximum safety during the construction process.

Safety Protocols for Construction Sites

Implementing strict safety protocols is essential for the safe use of cantilever scaffolding on construction sites. These protocols include thorough training for workers, proper use of personal protective equipment (PPE), and adherence to operational guidelines. Regular safety drills and emergency response plans should be in place to address any unforeseen incidents. By prioritizing safety measures, construction teams can minimize risks and ensure a safe working environment for all personnel involved.

What are the Benefits and Advantages of Using Cantilever Scaffolding?

Advantages of Cantilever Scaffolding in Construction Projects

One of the primary advantages of cantilever scaffolding in construction projects is its ability to provide access to areas that are otherwise difficult to reach with traditional scaffolding. The design offers flexibility and adaptability, making it suitable for various construction scenarios. Additionally, the reduced need for ground space allows for uninterrupted operations on busy construction sites, enhancing overall project efficiency.

Benefits of Cantilever Scaffolding for Building Maintenance

Cantilever scaffolding provides significant benefits for building maintenance tasks, particularly in high-rise structures. Its ability to support platforms at elevated heights without ground support allows for seamless access to exterior surfaces, facilitating cleaning, repairs, and inspections. This reduces downtime and enhances the productivity of maintenance teams, ensuring that buildings remain in optimal condition.

Why Choose a Cantilever Scaffold System for Your Needs?

Choosing a cantilever scaffold system is a strategic decision for many construction and maintenance projects. The system’s versatility, safety, and efficiency make it an attractive choice for contractors and builders. Its ability to overcome spatial limitations and provide a stable working platform for workers ensures that projects are completed on time and within budget. As a result, investing in cantilever scaffolding can significantly enhance project outcomes and safety standards.

What are the Applications of Cantilever Scaffolding in Modern Construction?

Using Cantilever Scaffolding for Bridge Construction

In bridge construction, cantilever scaffolding plays a pivotal role by providing a safe and stable platform for workers to execute tasks above waterways or busy roads. The cantilever design allows scaffolding to extend over obstacles, ensuring that construction activities are not impeded by environmental constraints. This application underscores the scaffold’s unique ability to adapt to complex construction environments, facilitating the efficient completion of bridge projects.

Applications in High-Rise Building Projects

High-rise building projects often require specialized scaffolding solutions to accommodate their unique challenges. Cantilever scaffolding is ideally suited for such projects, offering a reliable method to access upper floors without extensive ground-based support. The flexibility to adjust the scaffold height and position enhances the efficiency of construction and maintenance operations, reducing project timelines and costs.

Role in Complex Construction and Maintenance Tasks

Cantilever scaffolding’s role in complex construction and maintenance tasks cannot be overstated. Its ability to provide access to intricate architectural features and confined spaces makes it indispensable in modern construction. Whether it’s for the installation of decorative elements, facade repairs, or routine maintenance, cantilever scaffolding ensures that workers have a safe and efficient platform to perform their duties, ultimately contributing to the success of the construction process.

Safety Measures for Scaffolding and Their Benefits

Proper Training

- Implementing comprehensive training programs for workers reduces the risk of accidents and injuries. Educating employees on proper scaffold use, safety protocols, and emergency procedures ensures that they are prepared to handle the complexities of working at height safely and effectively.

Secure Anchoring

- Ensuring that scaffolds are securely anchored to their supporting structures is crucial for preventing collapses or instability. This measure not only protects the workers on the scaffold but also enhances overall site safety by maintaining a secure working environment.

Load Capacity Considerations

- Adhering to specified load capacities and distributing weight evenly across the scaffold helps maintain its structural integrity. This prevents overloading, which can lead to structural failures and potential accidents, ensuring that the scaffold remains safe and stable during use.

Fall Protection Measures

- Implementing comprehensive fall protection measures, such as safety harnesses, guardrails, and safety nets, minimizes the risk of severe injuries or fatalities from falls. These systems are essential for safeguarding workers operating at various heights, particularly in environments where falls are a prevalent hazard.

Regular Inspections

- Conducting regular inspections of scaffolding can identify and address potential hazards before they result in accidents. This proactive approach ensures that any signs of wear, damage, or improper assembly are dealt with promptly, maintaining the safety and functionality of the scaffolding over time.

What is Cantilever Scaffolding?

Cantilever scaffolding, also known as needle scaffolding, is an independent scaffold structure that extends outward from a building or structure. It is supported by needles to provide construction and maintenance workers with access to difficult-to-reach areas. Unlike conventional scaffolding structures, cantilever scaffolding is sustained at one end and extends horizontally. This makes it ideal for construction projects near the edges of buildings or in limited spaces where traditional scaffolding may not be feasible.

Construction and maintenance often require access to areas that are difficult to reach. Cantilever scaffolding provides a practical and efficient solution in such scenarios. By extending outward from the building or structure, cantilever scaffolding allows workers to access areas that would otherwise be challenging or impossible to reach.

The design of cantilever scaffolding eliminates the need for poles and frames in front of the structure, maximizing the available space and facilitating work in restricted areas. This makes it particularly useful for projects that involve renovation, maintenance, or construction work on building facades, bridges, or windows.

With cantilever scaffolding, construction and maintenance workers can safely access elevated surfaces and perform tasks such as cleaning, painting, repairs, and installations. The structure’s stability and support are ensured by the needles or struts that serve as anchor points, allowing workers to focus on their tasks without worrying about the scaffolding’s integrity.

Cantilever scaffolding offers several advantages over traditional scaffolding systems. Its unique design enables access to difficult-to-reach areas, enhancing productivity and efficiency on construction sites. Additionally, the absence of front poles and frames allows for easier movement and maneuverability around the scaffold, optimizing workflow and minimizing disruptions.

To summarize, cantilever scaffolding, also known as needle scaffolding, is an independent scaffold structure that extends horizontally from a building or structure. It provides construction and maintenance workers with access to difficult-to-reach areas, making it a versatile solution for various projects. The unique design ensures stability and support while maximizing space and facilitating work in limited areas.

Common Applications and Types of Cantilever Scaffolding

Cantilever scaffolding is widely used in various construction applications, offering efficient access to elevated surfaces and hard-to-reach areas. It is commonly employed for roof repairs, window installation, and bridge construction, among other tasks. The versatility of cantilever scaffolding makes it an essential tool in the industry.

Types of Cantilever Scaffolding

There are different types of cantilever scaffolding, each with its own unique design and features that cater to specific construction and maintenance tasks:

- Needle Scaffolding: This type of scaffolding provides access to difficult-to-reach areas, such as building facades and windows. It is commonly used for tasks like plastering, painting, and repair work.

- Double-Frame Cantilever Scaffold: Offering enhanced stability and increased load-bearing capacity, this type of scaffold is suitable for projects that require heavy materials and equipment.

- Counterbalanced Cantilever Scaffold: Designed with counterweights, this scaffold achieves load balance, making it ideal for situations where space is limited.

- Trussed Cantilever Scaffold: With diagonal bracing and truss-style structures, this scaffold provides improved stability and increased load-bearing capacity.

- Suspended Cantilever Scaffold: This type of scaffold is suspended from above, making it useful for projects that require access to elevated surfaces and overhead areas.

- Joint Tower Scaffold: This scaffold combines the benefits of cantilever and conventional scaffolding, providing a versatile solution for various construction needs.

Each type of cantilever scaffolding offers unique advantages and is tailored to specific construction requirements, ensuring efficient and safe operations on the job site.

To visually illustrate the different types of cantilever scaffolding, refer to the table below:

Types of Cantilever Scaffolding

Needle Scaffolding

- Needle scaffolding is designed to provide access to difficult-to-reach areas and is commonly used for tasks like plastering, painting, and repair work. Its ability to extend horizontally beyond the main structure makes it an ideal choice for working on the exterior of buildings without obstructing the space below.

Double-Frame Cantilever Scaffold

- This type of scaffold is known for its enhanced stability and increased load-bearing capacity, making it suitable for supporting heavy materials and equipment. The double-frame design adds an extra layer of support, which is essential for high-load tasks in construction and industrial environments.

Counterbalanced Cantilever Scaffold

- Counterbalanced cantilever scaffolds use counterweights to achieve load balance, making them particularly useful in limited-space situations where the base of the scaffold cannot extend freely. This balancing method allows for safe and stable construction work even in constrained areas.

Trussed Cantilever Scaffold

- Featuring diagonal bracing and truss-style structures, trussed cantilever scaffolds offer improved stability and a higher load-bearing capacity. This makes them well-suited for high-rise construction projects where additional support is crucial for safety and efficiency.

Suspended Cantilever Scaffold

- Suspended from above, this type of scaffolding is used to access elevated surfaces and overhead areas, such as under bridges or the exterior of tall buildings. Its suspended nature allows workers to reach heights without the need for a ground-based structure, providing flexibility and extensive reach.

Joint Tower Scaffold

- Combining the benefits of cantilever and conventional scaffolding, the joint tower scaffold provides versatility for various construction needs. This hybrid design allows for both horizontal and vertical extensions, making it a flexible solution for complex construction scenarios.

Understanding the different types of cantilever scaffolding allows construction professionals to select the most appropriate system for their specific project requirements, ensuring efficient and safe operations throughout the construction process.

Safety and Precautions for Cantilever Scaffolding

When working with cantilever scaffolding, safety should always be a top priority. Taking necessary precautions ensures a secure and stable structure, minimizing the risk of accidents and injuries. Here are some key safety measures to consider:

Secure Structure

Ensure that the scaffolding structure is securely anchored to the building or structure it is attached to. This helps maintain stability and prevents any potential collapses or accidents. Regularly inspect all connections, joints, and components to identify any signs of wear or damage. Reinforce weak points and repair any issues promptly.

Working Height and the 3 in 1 Rule

The 3 in 1 rule is an essential guideline to follow when setting up cantilever scaffolding. According to this rule, the total working height of the scaffold should be three times the distance from the narrowest side of the base to the highest point of contact. Adhering to this rule ensures stability and prevents tipping or tilting. If the scaffold does not meet this requirement, secure it with guide wires or additional support.

Proper Training and Supervision

Workers should receive proper training on the safe setup, use, and dismantling of cantilever scaffolding. They should be familiar with the specific safety procedures and precautions related to the scaffold system being used. Supervision by experienced personnel is also crucial to ensure compliance with safety guidelines and to address any potential risks or hazards.

Regular Inspections and Maintenance

Regular inspections are vital to identify any signs of wear, damage, or structural weaknesses in the scaffolding system. Inspections should be performed before each use, as well as periodically throughout the project. In addition, perform maintenance tasks such as tightening bolts, replacing worn components, and addressing any issues promptly to maintain the integrity and safety of the scaffold structure.

Fall Protection

Implement appropriate fall protection measures to safeguard workers from potential falls. This can include the use of personal protective equipment such as safety harnesses, guardrails, and safety nets. Properly train workers on the correct use of fall protection equipment and ensure that it is regularly inspected for effectiveness.

By following these safety measures and precautions, workers can create a secure working environment when using cantilever scaffolding. Prioritizing safety not only protects the well-being of workers but also helps prevent accidents and delays in construction projects.

Key Safety Measures for Scaffolding

Secure Structure

- It’s crucial to ensure that the scaffold is securely anchored to prevent movement. Regular inspections should be conducted to check for any signs of wear or damage. This includes examining connections, supports, and the base to ensure stability and safety at all times.

Working Height and the 3 in 1 Rule

- To maintain stability and prevent the scaffold from tipping or tilting, it’s important to follow the “3 in 1” rule. This rule typically dictates that the scaffold’s height should not exceed three times its base width unless stabilizing measures are in place. Adhering to this rule helps in creating a safer working environment by minimizing the risk of collapse.

Proper Training and Supervision

- Providing workers with proper training on scaffold safety is essential. This training should cover the correct use, risks, and preventative measures associated with scaffolding work. Additionally, experienced personnel should supervise the setup and use of scaffolding to ensure all safety protocols are followed.

Regular Inspections and Maintenance

- Scaffolding must be regularly inspected and maintained to ensure it remains in safe working condition. This involves checking for structural integrity, corrosion, and other potential hazards. Promptly addressing these issues through maintenance can prevent accidents and extend the lifespan of the scaffolding.

Fall Protection

- Implementing fall protection measures is critical to safeguard workers operating at heights. Safety harnesses, guardrails, and safety nets should be used as necessary to protect workers from falls, which are among the most common accidents associated with scaffold use.

Cantilever Scaffolding for Access in Derby

Cantilever scaffolding is an excellent access solution in Derby, providing easy erection and dismantling for construction projects. It offers a cost-effective and efficient way to access hard-to-reach areas and provides the necessary support and protection for workers. The unique design of cantilever scaffolding eliminates the need for additional poles and frames in front of the structure, making it an ideal choice in areas where traditional scaffolding may not be feasible.

By opting for cantilever scaffolding for access projects in Derby, businesses can benefit from its versatility and convenience. The scaffold can be quickly and conveniently erected and dismantled, saving valuable time and resources. It allows workers to safely access and work on elevated surfaces while maintaining stability and strength.

With cantilever scaffolding, businesses in Derby can minimize costs associated with traditional scaffolding systems. Its efficient design and ease of use make it a cost-effective solution for various construction and maintenance needs. Furthermore, the elimination of additional poles and frames reduces material and labor expenses, resulting in overall savings for the project.

Whether for construction, maintenance, or renovation projects, cantilever scaffolding offers a practical and reliable solution in Derby. Its versatility, cost-effectiveness, and ease of erecting and dismantling make it an ideal choice for businesses looking for efficient access scaffolding.

Different Types of Cantilever Scaffolding and Their Benefits

There are various types of cantilever scaffolding available, each offering unique benefits and advantages for construction and maintenance projects. Understanding the different types can help you choose the most suitable option for your specific needs.

Needle Scaffolding: Needle scaffolding is commonly used for tasks such as plastering, painting, or repair work. It consists of a single beam extended horizontally from the building, supported by needles embedded into the structure. This type of scaffolding provides a stable and reliable platform for workers to access hard-to-reach areas.

Double-Frame Cantilever Scaffold: The double-frame cantilever scaffold is designed for enhanced stability and increased load-bearing capacity. It features additional frames and cross-bracing, providing a secure structure to support heavy loads and ensure the safety of workers. This type of scaffolding is particularly suitable for large-scale construction projects or tasks that require the use of heavy equipment and materials.

Counterbalanced Cantilever Scaffold: The counterbalanced cantilever scaffold uses counterweights to achieve load balance, making it ideal for situations where space is limited. This type of scaffolding does not require support from the ground, as it is counterbalanced by weights at the opposite end. It offers flexibility and maneuverability, allowing workers to access areas that may otherwise be challenging to reach.

Trussed Cantilever Scaffold: The trussed cantilever scaffold is designed with diagonal bracing and truss-style structures to improve stability and increase load-bearing capacity. It provides a robust and secure platform for construction and maintenance tasks in challenging environments. This type of scaffolding is commonly used in high-rise buildings, bridges, or other structures that require additional support and stability.

By choosing the appropriate type of cantilever scaffolding for your project, you can ensure optimal safety, efficiency, and productivity. Consider the specific requirements of your construction or maintenance tasks to select the most suitable option, and consult with professionals if needed to ensure proper design and installation.

Benefits of Different Types of Cantilever Scaffolding

Needle Scaffolding

- This type of scaffolding is particularly useful for accessing hard-to-reach areas, making it ideal for tasks such as plastering, painting, and repair work. Its design allows it to extend beyond traditional scaffolding platforms, reaching otherwise inaccessible spots.

Double-Frame Cantilever Scaffold

- Known for its enhanced stability and increased load-bearing capacity, the double-frame cantilever scaffold is perfectly suited for large-scale construction projects. This scaffold type supports greater weights and provides a sturdier platform for heavy-duty construction activities.

Counterbalanced Cantilever Scaffold

- Utilizing counterweights to achieve load balance, this scaffold type is especially beneficial in limited space situations where traditional scaffolding bases cannot be used. Its design allows for safe and stable work environments even in constrained areas.

Trussed Cantilever Scaffold

- Offering improved stability and an increased load-bearing capacity, trussed cantilever scaffolds are commonly used in the construction of high-rise structures. Their trussed design provides additional support and safety, making them a reliable choice for challenging architectural projects.

Choosing the right type of cantilever scaffolding is crucial to ensure the safety and efficiency of your construction or maintenance project. Evaluate the specific requirements, consider the benefits of each type, and consult with experts to make an informed decision.

Conclusion

Cantilever scaffolding offers numerous advantages for construction and maintenance projects, allowing easy access to hard-to-reach areas and providing a cost-effective solution for working in limited spaces. However, it is crucial to prioritize safety measures and adhere to best practices to ensure the stability and security of the scaffold.

By working with professionals and following proper design practices, businesses can effectively utilize cantilever scaffolding to enhance their construction projects and safeguard the well-being of their workers. This includes providing proper training, ensuring secure anchoring, considering load capacity, utilizing fall protection equipment, and conducting regular inspections.

Implementing these safety measures and best practices will ensure that cantilever scaffolding remains a valuable asset in construction and maintenance, enabling workers to perform their tasks efficiently and securely. With the advantages it offers and the appropriate safety measures, cantilever scaffolding proves to be an indispensable tool in the construction industry.

FAQ

What is cantilever scaffolding?

Cantilever scaffolding is a specific type of scaffold that extends outward from a building or structure, providing access to difficult-to-reach areas.

What are the advantages of cantilever scaffolding?

Cantilever scaffolding offers easy access to hard-to-reach places, is cost-effective, and can be used in limited spaces where traditional scaffolding is not feasible.

What are some common applications of cantilever scaffolding?

Cantilever scaffolding is commonly used for façade maintenance, bridge construction, window installation, and other tasks that require access to elevated surfaces and hard-to-reach areas.

What is Proscaf and what are its capabilities for cantilevered scaffolding?

Proscaf is a scaffold system that offers unique capabilities for cantilevered scaffolding, including load bearing cross-braces that have high compression load ratings and a double-bolt standards and node-to-node connection that enhance the capacity and stability of the structure.

Why is a proper scaffold design important for cantilevered scaffolding?

A proper scaffold design ensures the scaffold can support the anticipated load capacity, accounts for environmental conditions, and incorporates safety features such as guardrails and safety nets.

What safety measures should be taken when working with cantilevered scaffolding?

Safety measures include proper training, secure anchoring, regular inspection, using fall protection equipment, and not overloading the scaffold.

What are the different types of cantilever scaffolding and their benefits?

The different types of cantilever scaffolding include needle scaffolding, double-frame cantilever scaffold, counterbalanced cantilever scaffold, and trussed cantilever scaffold. Each type has its own unique design and features that make it suitable for specific construction and maintenance tasks.

What are the safety and precautions for cantilever scaffolding?

Safety and precautions include following the 3 in 1 rule for stable scaffold height, securing the structure, and implementing safety measures such as using guide wires.

How can cantilever scaffolding be used for access in Derby?

Cantilever scaffolding provides easy erection and dismantling, making it a cost-effective solution for access projects in Derby.

What are the benefits of using cantilever scaffolding for access in Derby?

The benefits of using cantilever scaffolding for access projects in Derby include easy access to hard-to-reach places, protection and support, and cost-effectiveness.

In conclusion, what are the advantages and best practices of cantilever scaffolding?

Cantilever scaffolding offers easy access to difficult areas, is cost-effective, and can be used in limited spaces. Best practices include proper scaffold design, following safety measures, and working with professionals to ensure safe and effective construction projects.