Phone:

(+65)8319-0742

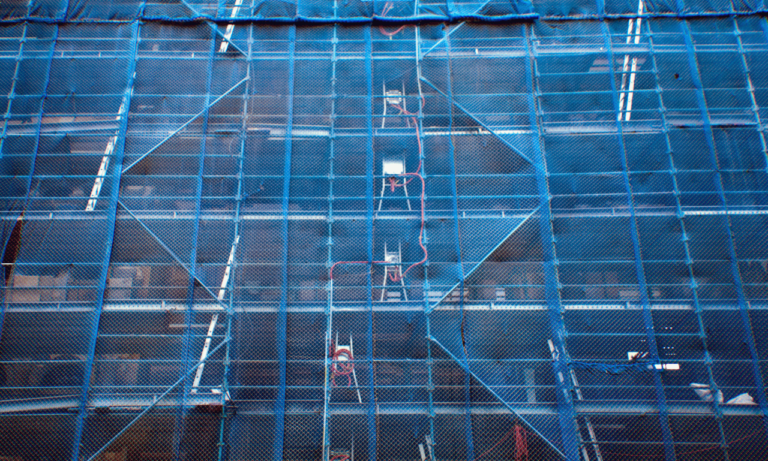

When it comes to construction safety, implementing the proper scaffolding solutions is of utmost importance. Bridge Scaffolding provides a range of reliable and efficient options that cater to the unique needs of construction projects, offering complete systems that ensure safety and efficiency throughout various stages of bridge projects.

Whether it’s scaffold rental, construction scaffolding, temporary works platforms, or bridge access equipment, Bridge Scaffolding has got you covered. Their expertise in designing and constructing scaffolding solutions ensures a safe and secure working environment for all construction personnel.

Key Takeaways:

- Bridge Scaffolding offers a comprehensive range of industrial scaffolding services.

- Their solutions include scaffold rental, construction scaffolding, temporary works platforms, and bridge access equipment.

- Bridge Scaffolding specializes in custom bridge scaffolding for various construction and maintenance needs.

- Ensuring compliance with OSHA regulations is essential for construction safety.

- Regular maintenance and inspection of scaffolding systems are crucial for safe operations.

Important Scaffolding Design Guidelines and Safety Rules

When it comes to scaffolding, following design guidelines and safety rules is crucial for maintaining a secure work environment. Employing the appropriate safety measures, like guardrails, scaffold platforms, and safety training, ensures the well-being of workers and prevents accidents.

Guardrails

One of the most important safety features in scaffolding is the installation of guardrails. Guardrails act as a protective barrier, preventing falls and ensuring worker safety. According to scaffolding safety rules, guardrails, along with fall arrest systems, are mandatory when working at heights over 10 feet. These guardrails should be between 38 and 45 inches high to provide adequate protection.

Scaffold Platforms

Scaffold platforms must be fully decked or planked. This means that the platforms should have a solid and secure surface to support workers and equipment without any gaps or holes. Ensuring the stability and integrity of scaffold platforms is integral to prevent accidents and maintain worker safety.

Supported Scaffolding

Supported scaffolding, also known as frame scaffolding, is a common type of scaffolding used in construction. Following scaffold design guidelines, it’s crucial to consider the height-to-base ratio and load capacity when erecting supported scaffolding. The height-to-base ratio determines the stability of the scaffold, while the load capacity ensures that it can support the weight placed on it. Scaffolds must be capable of holding up to four times their maximum load to ensure safety.

Scaffold Inspection and Safety Training

Regular scaffold inspections are essential to identify any potential hazards or defects. According to safety regulations, a competent person should perform an inspection before each work shift to ensure the scaffold’s structural integrity. Additionally, providing comprehensive safety training for workers is paramount. This includes educating them on proper scaffold usage, hazard identification, and emergency procedures.

By adhering to these important scaffolding design guidelines and safety rules, companies can create a safer work environment, prevent accidents, and protect their workers from potential dangers.

| Safety Measure | Key Guidelines |

|---|---|

| Guardrails and Fall Arrest Systems | Install guardrails and fall arrest systems when working at heights over 10 feet. |

| Scaffold Platforms | Ensure scaffold platforms are fully decked or planked, providing a stable surface. |

| Supported Scaffolding | Consider height-to-base ratio and load capacity for stable supported scaffolding. |

| Scaffold Inspection | Perform regular inspections by a competent person before each work shift. |

| Safety Training | Provide comprehensive safety training to workers on scaffold usage and hazard identification. |

Specific Requirements for Safe Scaffolding Systems

When it comes to implementing scaffolding systems, adhering to OSHA standards and regulations is crucial. These guidelines ensure the safety and well-being of workers on construction sites. Let’s explore some specific requirements that must be met to ensure the safe use of scaffolding.

Supported Scaffolds and Suspension Platforms

Supported scaffolds are commonly used in construction projects to provide a stable working platform. According to OSHA standards, guardrail installation is mandatory when working at heights over 10 feet. The guardrails must be between 38 and 45 inches high to prevent falls and provide adequate protection for workers.

In addition to guardrails, cross bracing is an essential component of supported scaffolds. It helps enhance stability, preventing any structural failures and ensuring the safety of workers. Cross bracing should be installed at the required height to provide optimal support and scaffolding stability.

Suspension platforms are another type of scaffolding commonly used in construction projects. These platforms are suspended from overhead supports, allowing workers to access elevated areas. To ensure the safety of workers using suspension platforms, it is essential to follow OSHA guidelines for their installation, maintenance, and usage.

Planking and Loading Capacity

An integral part of scaffolding safety is the use of proper planking. Planking refers to the wooden boards that create the working platform on scaffolds. According to OSHA standards, planking must be able to support at least four times its intended load. This requirement ensures that the planking can withstand the weight of workers and materials without compromising their safety.

Guardrail Installation and Scaffolding Stability

In addition to guardrails and planking, scaffolding stability is a critical aspect of ensuring safety. Scaffold structures must be properly stabilized to prevent tipping or collapse. This can be achieved through the use of secure and sturdy base plates, leveling leg screws, and proper anchoring to the supporting structure.

By adhering to OSHA standards and following these specific requirements for safe scaffolding systems, construction companies can create a secure working environment for their workers. Prioritizing scaffold stability, guardrail installation, correct planking, and loading capacity ensures the overall safety and well-being of everyone involved in the construction project.

Bridge Construction Scaffolding Systems

Bridge construction scaffolding systems are designed to provide safe and efficient access to working areas on bridges. There are several types of scaffolding systems used in bridge construction, including:

Modular scaffolding: This type of scaffolding is ideal for providing access to working areas on bridges. It is quick and easy to assemble and dismantle, making it suitable for projects with tight deadlines.

Suspended scaffolding: When it is not possible to erect a freestanding scaffold on a bridge, suspended scaffolding is the go-to solution. It is perfect for accessing hard-to-reach areas, such as the substructure of a bridge.

Movable scaffolding system: Used for span-by-span in-situ construction of bridges, this lightweight and practical system is easy to assemble and operate, making it highly efficient for bridge projects.

Façade scaffolding: While commonly used for commercial and residential construction projects, façade scaffolding is also employed for smaller corrosion protection

Maintaining and Inspecting Scaffolding

Regular maintenance and inspections are essential for ensuring the safety and integrity of scaffolding on construction sites. By following proper maintenance practices and conducting frequent inspections, employers can prevent accidents and promote a secure working environment for their employees. This section discusses the importance of scaffold maintenance, the role of a competent person in inspections, and the process of cleaning and pressure washing scaffolding.

The Importance of Scaffold Maintenance

Proper scaffold maintenance is crucial for identifying and addressing any issues or damages that may compromise its structural integrity. After each job, employers should wash down the scaffolding to remove dirt, debris, and other contaminants that may accumulate during construction activities. This regular cleaning helps to prevent corrosion and ensures the longevity of the scaffold components.

Additionally, regular maintenance allows employers to inspect the scaffolding for broken or damaged components. Any damaged or weakened parts should be promptly repaired or replaced to ensure the scaffold’s stability and prevent accidents. By prioritizing scaffold maintenance, employers demonstrate their commitment to safety and comply with regulatory requirements.

Frequent Inspections by a Competent Person

Frequent inspections conducted by a competent person are a crucial part of scaffold maintenance. A competent person, as defined by OSHA, is an individual who possesses the necessary knowledge and experience to recognize scaffold hazards and has the authority to take corrective measures.

An inspection by a competent person should be performed before each work shift to identify any potential hazards or defects. This inspection should cover all aspects of the scaffold, including the structural integrity, guardrails, platforms, and other safety features. By conducting frequent inspections, employers can ensure that the scaffold is in good condition and safe for use.

Cleaning Scaffolding and Pressure Washing

Cleaning scaffolding is an essential maintenance practice that not only promotes safety but also enhances the overall appearance of the construction site. Disassembly and pressure washing are effective methods for cleaning scaffolding. However, caution must be exercised to avoid loosening or disengaging any components during the cleaning process.

Pressure washing should be done with the appropriate equipment and at an appropriate pressure to prevent damage to the scaffold and its components. Cleaning agents can also be used to remove stubborn stains or contaminants. Proper cleaning ensures that the scaffolding remains free from debris and other substances that may pose a safety risk.

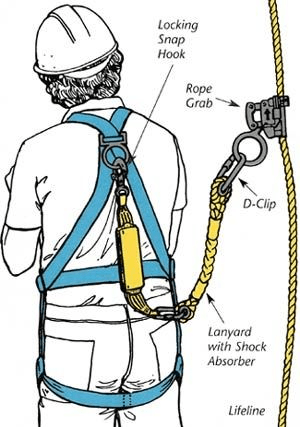

Personal Fall Protection and Safety Equipment

When it comes to working at heights, personal fall protection and safety equipment are essential for ensuring the well-being and protection of workers. Employers are required to implement fall arrest systems and provide personal protective equipment (PPE) to mitigate hazards and prevent accidents.

Fall Arrest Systems

Fall arrest systems are crucial in protecting workers from falling and should be utilized for tasks performed at heights over 10 feet. These systems include harnesses, lifelines, and anchorage points that collectively work to arrest falls and minimize the risk of severe injuries.

Personal Protective Equipment (PPE)

Employers must provide appropriate personal protective equipment to workers as part of their safety measures. PPE includes items such as hard hats, safety glasses, gloves, and protective clothing. Hard hats, for example, play a critical role in safeguarding workers from falling objects and head injuries, while safety glasses protect the eyes from hazardous materials.

Toeboards and Barricades

To prevent falling items from causing harm, toeboards should be installed on scaffolding platforms. These serve as a protective barrier, ensuring that tools and materials do not accidentally fall from elevated positions. Similarly, barricades can be used to secure the area around the working platform, further reducing the risk of objects reaching ground level.

Training and Hazard Mitigation Procedures

Proper training is essential to equip workers with the necessary knowledge and skills to identify and mitigate potential hazards when working at heights. Employees should be trained on how to use fall arrest systems and other safety equipment, as well as hazard mitigation procedures specific to their working environment. By creating a culture of safety and providing comprehensive training, employers can significantly reduce the risk of accidents and injuries.

| Safety Equipment | Description |

|---|---|

| Fall Arrest Systems | Includes harnesses, lifelines, and anchorage points to prevent falls and minimize injuries. |

| Personal Protective Equipment (PPE) | Includes hard hats, safety glasses, gloves, and protective clothing to protect workers from various hazards. |

| Toeboards | Protective barriers installed on scaffolding platforms to prevent tools and materials from falling. |

| Barricades | Secures the area around the working platform, reducing the risk of falling objects. |

| Training and Hazard Mitigation Procedures | Comprehensive training and procedures to identify and mitigate potential hazards at heights. |

Compliance with Scaffolding Safety Standards

When it comes to scaffolding safety, compliance with the relevant guidelines and regulations is crucial. Contractors and industry experts play a key role in ensuring that scaffolding structures meet the necessary safety standards.

Scaffolding safety guidelines are established by regulatory bodies, such as OSHA, to protect workers and promote safe working conditions. These guidelines encompass various aspects of scaffolding, including design, construction, and usage.

Industry expertise is essential for understanding and implementing these guidelines effectively. Contractors who specialize in scaffolding design and erection possess the necessary knowledge and experience to ensure regulatory compliance.

By partnering with contractors who prioritize regulatory compliance, companies can benefit from their in-depth understanding of scaffolding safety standards. These contractors stay updated with any changes to regulations and adapt their practices accordingly.

Ensuring regulatory compliance involves adhering to specific requirements, such as proper guardrail installation, planking that can support the intended load, and scaffold stability. Contractors with expertise in scaffolding safety are equipped to meet these requirements and ensure a safe working environment.

Compliance with scaffolding safety standards is not just a legal obligation; it is a commitment to the well-being of workers and the overall success of construction projects. By engaging contractors who prioritize safety and regulatory compliance, companies can mitigate risks and promote a culture of safety on their worksites.

Key Points:

- Compliance with scaffolding safety guidelines is crucial for worker safety.

- Contractors with industry expertise ensure regulatory compliance.

- By partnering with compliant contractors, companies can mitigate risks and promote a safe working environment.

Customer Testimonials and Reviews

At Scaffolding Solutions, our commitment to customer satisfaction is our top priority. Don’t just take our word for itâhere are some testimonials and reviews from our happy customers:

“Working with Scaffolding Solutions has been an absolute pleasure. Their customer service is unparalleled, and they always go the extra mile to ensure our needs are met. We’ve never had a more reliable partner.”

John Thompson, XYZ Construction

“I highly recommend Scaffolding Solutions for their professionalism and expertise. From the initial contact to project completion, they provided prompt pricing and excellent service. We can always count on them to deliver top-quality scaffolding solutions.”

Sarah Johnson, ABC Contractors

“Scaffolding Solutions exceeded our expectations in every aspect. Their knowledgeable team guided us through the entire process, making sure our unique project requirements were met. Their attention to detail and commitment to safety make them our go-to partner for all our scaffolding needs.”

Michael Davis, DEF Builders

We take pride in the positive feedback we receive from our satisfied customers. Their testimonials reinforce our dedication to providing exceptional service and reliable solutions. Whether it’s prompt pricing, professionalism, or superior customer service, Scaffolding Solutions is here to exceed your expectations.

For more customer testimonials and reviews, please visit our website.

Customer Satisfaction Ratings:

| Category | Ratings (out of 5) |

|---|---|

| Customer Service | 4.8 |

| Reliability | 4.9 |

| Professionalism | 4.7 |

| Overall Satisfaction | 4.8 |

Join our growing list of satisfied clients and experience firsthand why Scaffolding Solutions is the reliable partner you can trust.

Scaffolding Solutions' Product Offerings

Scaffolding Solutions is committed to providing a comprehensive range of products for construction and rehabilitation projects. Our offerings are designed to meet the diverse needs of our clients and ensure secure access and improved efficiency. Here are some of the key products we offer:

Bridge Platforms

Our Bridge Platforms are specifically designed to provide safe and efficient access for bridge construction, maintenance, and inspection. These platforms are built to withstand varying environmental conditions and offer stability for workers at height.

Scaffolding

Our versatile scaffolding systems cater to a wide range of construction projects. Whether it’s a simple structure or a complex configuration, our scaffolding solutions are designed to provide a stable working platform that ensures worker safety and productivity.

Fastrac Platforms

The Fastrac Platforms we offer are renowned for their rapid installation and dismantling capabilities. These highly adaptable platforms enable efficient workflow and are ideal for projects with tight timelines.

Fastflange Shielding

Fastflange Shielding is an essential safety accessory that ensures the protection of workers and the surrounding environment. These shielding systems are fast and easy to install, providing an effective barrier against falling debris.

Mast Climbers

Our Mast Climbers provide reliable vertical access solutions for construction projects. With adjustable working platforms and efficient lifting mechanisms, mast climbers offer enhanced productivity and flexibility.

GEDA Construction Hoists

GEDA Construction Hoists are designed to facilitate the vertical transportation of personnel and materials, ensuring a smooth workflow and increased productivity. These robust hoists are engineered for safety and efficiency on construction sites.

At Scaffolding Solutions, we understand the unique demands of construction projects and provide tailored solutions to meet those needs. Our products are built to the highest standards of quality and safety, ensuring optimal performance and customer satisfaction.

| Product | Key Features |

|---|---|

| Bridge Platforms | Secure access for bridge construction, maintenance, and inspection |

| Scaffolding | Versatile systems for various construction projects |

| Fastrac Platforms | Rapid installation and dismantling capabilities for tight timelines |

| Fastflange Shielding | Effective barrier against falling debris |

| Mast Climbers | Flexible vertical access solutions for enhanced productivity |

| GEDA Construction Hoists | Efficient transportation of personnel and materials |

Importance of Regular Maintenance and Inspection

Regular maintenance and inspection of scaffolding are vital for ensuring safe use and compliance with regulatory standards. Employers must prioritize the proper cleaning, inspection, and repair of scaffolding to maintain its integrity and prevent potential hazards. Neglecting routine maintenance and inspection can lead to accidents, injuries, and costly legal consequences.

A competent person should perform thorough inspections before each work shift to identify any broken components or structural deficiencies that may compromise the scaffold’s stability. Additionally, inspections should be conducted after any events, such as heavy wind or impact, that could weaken the structure. Prompt action should be taken if any issues are identified during the inspection, including repairing or replacing broken components as necessary.

Maintenance Guidelines:

- Regularly clean scaffolding to remove debris, dirt, and other contaminants that can compromise its stability.

- Inspect the scaffold for any signs of wear and tear, including rust, corrosion, or damaged components.

- Address and repair any broken or weakened components promptly to ensure the scaffold’s structural integrity.

- Check all fasteners, connections, and joints to ensure they are secure and properly tightened.

- Ensure that the scaffold’s load capacity is not exceeded and that the weight distribution is balanced.

By adhering to a comprehensive maintenance and inspection program, employers can mitigate the risk of accidents and ensure the safe use of scaffolding. Compliance with regulatory standards is not only a legal requirement but also a commitment to the well-being of workers and the overall success of construction projects.

Regular maintenance and inspection of scaffolding are crucial for safe usage. Employers should prioritize cleaning, inspection, and repair to maintain scaffold integrity. A competent person should perform inspections before each shift and recheck scaffold structures for any issues. Proper maintenance promotes compliance and ensures a secure working environment.

Pedestrian Safety and Object Protection

When it comes to working with scaffolding, ensuring pedestrian safety and protecting objects from falling are of utmost importance. Adequate measures need to be in place to prevent accidents and injuries. Multiple layers of defense, such as barricades, overhead canopies, and debris netting, can be implemented to provide enhanced safety for both workers and the public.

Barricades act as physical barriers, creating a clear separation between the construction site and pedestrian areas. They help redirect foot traffic and prevent unauthorized access, reducing the risk of accidents. Barricades can be constructed using sturdy materials such as steel or plastic, ensuring durability and effectiveness.

Overhead canopies are particularly useful in areas where there is a higher chance of objects falling from scaffolding. They provide an additional layer of protection by shielding pedestrians from any potential hazards above. Overhead canopies can be customized to fit the specific needs of the construction site while ensuring optimal safety.

Debris netting is another essential component of object protection. It acts as a barrier, catching any loose materials or debris that may fall from scaffolding. This not only protects pedestrians but also prevents objects from causing damage to nearby structures or property. Debris netting is available in various sizes and strengths, making it adaptable to different construction environments.

Benefits of Implementing Pedestrian Safety Measures and Object Protection:

- Minimize the risk of accidents and injuries to pedestrians

- Prevent objects from falling and causing damage or injury

- Safeguard nearby structures and property

- Enhance overall safety culture at the construction site

Comparison of Object Protection Measures

| Object Protection Measure | Advantages | Considerations |

|---|---|---|

| Barricades |

|

|

| Overhead Canopies |

|

|

| Debris Netting |

|

|

Conclusion

In conclusion, Bridge Scaffolding is an integral component of ensuring construction safety. Adhering to scaffolding regulations, performing regular maintenance and inspections, and providing the necessary safety equipment are crucial factors in creating a secure working environment. At Scaffolding Solutions, we offer a wide range of product offerings and have a proven track record of customer satisfaction, making us a reliable partner in the industry.

By prioritizing compliance and safety, construction companies can not only meet their project goals but also safeguard the well-being of their workers. Bridge Scaffolding serves as a critical infrastructure that supports construction projects while enhancing worker safety and efficiency.

With our commitment to compliance, customer satisfaction, and continuous product improvement, Scaffolding Solutions is well-equipped to meet the needs of your construction projects. We understand the importance of maintenance and inspection in ensuring the longevity and safety of scaffolding systems. Trust us to provide you with top-notch products and services that exceed your expectations and contribute to a successful and secure construction process.

FAQ

What are some important scaffolding design guidelines and safety rules?

Important scaffolding design guidelines and safety rules include requirements for guardrails, scaffold platforms, height-to-base ratio, load capacity, scaffold inspection, and safety training. For example, guardrails and/or fall arrest systems are mandatory when working over 10 feet up, and scaffold platforms must be fully decked or planked. Scaffolds must be able to hold up to four times their maximum load, and a competent person must perform an inspection before each work shift.

What are the specific requirements for safe scaffolding systems?

OSHA standards require specific requirements for safe scaffolding systems. For supported scaffolds, guardrail installation is required at heights over 10 feet. The guardrails should be between 38 and 45 inches high, and cross bracing should reach the required height. Planking must support at least four times its intended load, and scaffolding should be stabilized to prevent tipping.

Why is maintaining and inspecting scaffolding important?

Maintaining and inspecting scaffolding is crucial for safety. Employers should wash down scaffolding after each job and inspect it for any broken or damaged components. Frequent inspections by a competent person are necessary to ensure its safe use. Cleaning scaffolding can be done through disassembly and pressure washing, using caution to prevent loosening or disengaging any components.

What personal fall protection systems and safety equipment are required for working at heights?

Personal fall protection systems, such as fall arrest systems or guardrails, are required for workers at heights over 10 feet. Employers must provide personal protective equipment (PPE) like harnesses, lifelines, and anchorage points. Hard hats should be worn to protect against falling objects, and toeboards or barricades should be installed to catch falling items. Training on working at height hazards and safety procedures is essential for all employees.

How can contractors ensure compliance with scaffolding safety standards?

Compliance with scaffolding safety standards requires industry expertise. Contractors specializing in scaffolding design and erection are well-versed in the laws and regulations governing scaffolding safety. Staying updated and maintaining compliance with these standards ensures a safe working environment.

What is the customer feedback for Scaffolding Solutions?

Scaffolding Solutions has received positive reviews and testimonials from satisfied customers. Clients praise the company’s customer service, prompt pricing, and professionalism. The team at Scaffolding Solutions is knowledgeable, responsive, and goes above and beyond to exceed customer expectations.

What products does Scaffolding Solutions offer?

Scaffolding Solutions offers a range of products for construction and rehabilitation projects. These include Bridge Platforms, Scaffolding, Fastrac Platforms, Fastflange Shielding, Mast Climbers, and GEDA Construction Hoists. Each product is designed to provide secure access and improved efficiency in different project scenarios.

Why is regular maintenance and inspection important for scaffolding?

Regular maintenance and inspection of scaffolding are vital for safe use. Employers should prioritize proper cleaning, inspection, and repair of scaffolding to ensure its integrity. A competent person should perform inspections before each work shift and recheck the scaffold if any events occur that might weaken its structure.

How can pedestrian safety and object protection be ensured when working with scaffolding?

Pedestrian safety and object protection are essential considerations when working with scaffolding. Multiple layers of defense, such as barricades, overhead canopies, or debris netting, help protect both workers and the public from falling materials. Prioritizing safety in these areas is crucial for preventing accidents and injuries.