Phone:

(+65)8319-0742

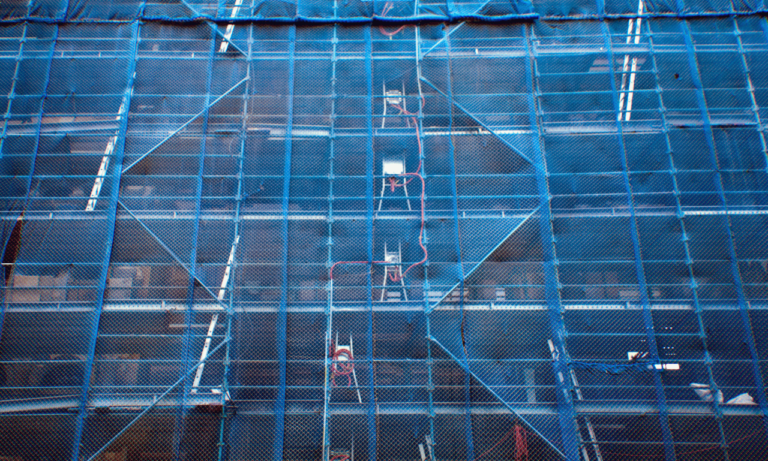

When it comes to construction projects, safety and efficiency are paramount. That’s where metal scaffolding comes into play. Metal scaffolding, also known as construction scaffolding or industrial scaffolding, provides a solid and reliable platform for workers to perform their tasks at elevated heights. Whether it’s aluminum scaffolding or steel scaffolding, these temporary structures are designed to ensure unmatched safety and efficiency in construction and industrial projects.

Key Takeaways:

- Metal scaffolding is essential for ensuring safety and efficiency in construction projects.

- It provides a stable platform for workers to perform tasks at various heights.

- Aluminum and steel scaffolding are the most commonly used types.

- Factors such as project size, work type, and surface conditions should be considered when choosing metal scaffolding.

- Regular inspection, proper training, and adherence to safety protocols are crucial for safe scaffolding use.

The Importance of Metal Scaffolding in Construction

Metal scaffolding plays a crucial role in ensuring the safety and efficiency of construction projects. It provides height accessibility, allowing workers to reach elevated work areas with ease. Metal scaffolding offers unmatched safety measures, mitigating the risk of falls and protecting workers from falling objects.

Construction projects often involve tasks that require working at various heights. Metal scaffolding provides a stable and secure platform for workers to perform these tasks safely. With easy access to elevated areas, workers can efficiently carry out their duties without the limitations posed by height restrictions.

When it comes to ensuring safety on the job site, metal scaffolding is an essential component. It significantly reduces the potential hazards associated with working at heights, providing a protective barrier for workers. The sturdy structure of metal scaffolding enhances stability, minimizing the risk of accidents and providing peace of mind to construction teams.

Efficiency is another significant advantage of using metal scaffolding in construction. The convenient access it offers to different areas of the project allows for smooth workflow and improved productivity. Workers can easily move between elevated work areas, optimizing their efficiency and reducing downtime.

Moreover, metal scaffolding provides a versatile and adaptable solution for construction projects. It is capable of accommodating various configurations to meet specific project requirements. Whether it’s a large-scale construction site or a small-scale renovation project, metal scaffolding can be customized to suit the needs of the project.

Construction teams understand the imperative need for safety and efficiency in their projects. Metal scaffolding serves as a critical tool that enables them to achieve both. By providing a secure work area at elevated heights, metal scaffolding ensures the well-being of workers while enhancing productivity and streamlining workflows.

Different Types of Metal Scaffolding

When it comes to construction projects, there are several types of metal scaffolding available to meet different needs and requirements. These types of scaffolding play a crucial role in providing a safe and stable platform for workers to perform tasks at various heights. Here are some of the most common types of metal scaffolding:

1. Tube and Coupler Scaffolding

Tube and coupler scaffolding is the most widely used type of metal scaffolding in construction. It consists of metal tubes and couplers that are interconnected to form a strong and stable frame. This type of scaffolding offers versatility as it can be customized to fit different structures and project requirements. Tube and coupler scaffolding provides reliable support and ensures worker safety throughout the construction process.

2. Frame Scaffolding

Frame scaffolding, also known as modular scaffolding, is another popular choice in the construction industry. It is made up of prefabricated frames that can be easily assembled and disassembled. Frame scaffolding offers convenience and flexibility, making it ideal for projects that require frequent movement and adjustment of scaffolding. This type of scaffolding is commonly used for smaller scale construction projects and maintenance work.

3. System Scaffolding

System scaffolding, also known as modular or ring-lock scaffolding, is a versatile option that offers both convenience and stability. It features pre-designed components that can be easily connected, creating a secure framework. System scaffolding allows for quick assembly and disassembly, making it a popular choice for complex construction projects with specific height and load requirements.

4. Suspended Scaffolding

Suspended scaffolding is commonly used for projects that involve working on the exterior of buildings, such as painting, maintenance, or window installation. It consists of a platform that is suspended from the roof or an elevated structure, allowing workers to access and work on different parts of the building. Suspended scaffolding provides a safe working environment at heights and increases efficiency for certain types of projects.

5. Mobile Scaffolding

Mobile scaffolding, often referred to as rolling scaffolding, is designed for projects that require frequent movement and access to different areas. It is equipped with wheels or casters, allowing for easy transportation and repositioning. Mobile scaffolding provides flexibility and efficiency, making it an excellent choice for projects that involve working on large areas or multiple locations.

It is important to choose the right type of metal scaffolding for your construction project. Consider factors such as project requirements, height accessibility, mobility needs, and safety regulations when making your selection. Each type of metal scaffolding offers unique advantages and is designed to meet specific project demands. By selecting the appropriate type of scaffolding, you can ensure a safe and efficient working environment for your construction team.

Advantages of Metal Scaffolding

Metal scaffolding offers numerous advantages in construction projects. Its safety, durability, and stability make it the preferred choice for providing a secure working platform for workers at various heights.

One of the key advantages of metal scaffolding is its safety features. It is designed to meet strict safety regulations, ensuring that workers can perform tasks without the risk of falls or accidents. Metal scaffolding provides a sturdy structure that can withstand heavy loads and adverse weather conditions, further enhancing worker safety.

The durability of metal scaffolding is another notable advantage. Made from high-quality materials such as aluminum or steel, it is built to endure the demanding conditions of construction sites. Metal scaffolding can withstand constant use, ensuring long-term performance and reliability.

In addition to safety and durability, metal scaffolding offers stability on the job site. Its robust structure and secure connections provide a stable platform for workers to perform their tasks. This stability reduces the risk of accidents and allows workers to focus on their work with confidence.

Another advantage of metal scaffolding is its ease of assembly. With its modular design and simple construction, metal scaffolding can be quickly and easily set up by construction teams. This saves time and effort, allowing projects to progress smoothly.

Whether it is aluminum scaffolding for light-duty work or steel scaffolding for heavy-duty tasks, metal scaffolding offers unmatched safety and efficiency on the job site.

Comparison of Metal Scaffolding Advantages:

| Advantages | Metal Scaffolding | Wooden Scaffolding |

|---|---|---|

| Safety | â | â |

| Durability | â | â |

| Stability | â | â |

| Ease of Assembly | â | â |

Factors to Consider When Choosing Metal Scaffolding

When looking for the right metal scaffolding for your project, it’s essential to consider several factors that can impact its effectiveness. By taking into account the project size, work type, surface conditions, and space availability, you can make an informed decision that meets your specific requirements.

- Project Size: Assess the scale of your project to determine the amount of scaffolding needed. Larger projects may require more extensive scaffolding systems, while smaller projects may benefit from compact and portable options.

- Work Type: Consider the nature of the work being performed on the scaffolding. Are you conducting heavy-duty construction or light maintenance? Different types of scaffolding are designed to accommodate specific work types and load capacities.

- Surface Conditions: Evaluate the condition of the surface where the scaffolding will be placed. Uneven or unstable surfaces may require specialized scaffolding designs or additional stabilization measures for optimum safety.

- Space Availability: Take into account the available space at your worksite. Limited space may necessitate the use of compact scaffolding systems or mobile scaffolding options that can be easily maneuvered.

By considering these factors, you’ll be able to choose the most suitable metal scaffolding option for your project, ensuring safety, efficiency, and convenience for your construction team.

Understanding the Importance of Each Factor

To further assist in your decision-making process, let’s explore each factor in more detail:

1. Project Size

The size of your project plays a crucial role in determining the amount and configuration of scaffolding required. Larger projects often involve multiple levels and extensive work areas, necessitating more scaffolding to ensure accessibility and safety for workers.

2. Work Type

The type of work being performed on the scaffolding is another vital consideration. Different scaffolding systems are designed to accommodate a variety of tasks, ranging from light-duty maintenance to heavy-duty construction. Choosing the right scaffolding for your specific work type ensures maximum safety and efficiency.

3. Surface Conditions

The condition of the surface where the scaffolding will be placed is crucial for stability and load-bearing capacity. Uneven, sloping, or otherwise challenging surfaces may require specialized scaffolding systems, such as adjustable or modular scaffolding, to compensate for the irregularities and provide a secure work platform.

4. Space Availability

The available space in your worksite should also be taken into account when selecting metal scaffolding. Limited space may require the use of space-saving scaffolding options, such as narrow frame scaffolding or compact mobile scaffolding, to ensure efficient utilization of the available area.

By carefully considering these factors, you can confidently choose the ideal metal scaffolding system that meets your project’s unique requirements, ultimately enhancing safety, productivity, and overall project success.

Safety Considerations for Metal Scaffolding

Safety is of paramount importance when using metal scaffolding in construction projects. By following essential safety considerations, construction teams can ensure the well-being of workers and minimize the risk of accidents. Here are key factors to keep in mind:

Inspection

Prior to using metal scaffolding, a thorough inspection should be conducted to ensure that all parts are intact and in good condition. This includes checking metal tubes, couplers, frames, planks, and any other components for signs of damage or wear. Any damaged or faulty parts should be replaced immediately.

Training

Workers should receive proper training on scaffold use and safety procedures. This training should cover topics such as assembling and dismantling scaffolding, working at heights, fall protection, and the proper use of personal protective equipment. Regular refresher courses should also be provided to reinforce safety knowledge.

Weight Capacity

It is essential to know the weight capacity of the metal scaffolding being used. Exceeding the weight limits can lead to structural failure and compromise safety. Construction teams should carefully consider the weight of workers, tools, equipment, and materials that will be placed on the scaffolding and ensure it does not exceed the manufacturer’s specified limits.

Stability

Proper stability is crucial to prevent scaffolding from tipping or collapsing. Ensure that the scaffold is set up on a level surface to maintain stability. If necessary, use leveling jacks or base plates to correct any unevenness. Additionally, secure the scaffolding by anchoring it to a stable structure or using appropriate tie-off methods.

Weather Conditions

Weather conditions can significantly impact the safety of metal scaffolding. High winds, rain, snow, and ice can all pose risks and make scaffolding unstable. Construction teams should closely monitor weather forecasts and take appropriate measures to secure or remove scaffolding when adverse conditions are anticipated.

By adhering to these safety considerations and implementing proper measures, construction teams can ensure the safe and efficient use of metal scaffolding in their projects.

| Safety Considerations | Actions to Take |

|---|---|

| Inspection | Thoroughly inspect all parts for damage or wear before use. |

| Training | Provide workers with proper training on scaffold use and safety procedures. |

| Weight Capacity | Ensure that the weight placed on the scaffolding does not exceed its capacity. |

| Stability | Set up the scaffolding on a level surface and secure it properly. |

| Weather Conditions | Monitor weather conditions and take appropriate measures to secure or remove scaffolding. |

Maximizing Efficiency with Metal Scaffolding

Metal scaffolding plays a crucial role in maximizing efficiency in construction projects. Its versatile design and functionality offer numerous benefits that streamline workflow, enhance productivity, and facilitate seamless access to different areas of the job site.

Streamlining Workflow and Reducing Downtime

With metal scaffolding, construction teams can effectively streamline their workflow. The stable and durable platform provided by metal scaffolding allows workers to efficiently carry out their tasks at various heights. By providing a safe and accessible workspace, metal scaffolding eliminates the need for time-consuming and makeshift arrangements, reducing downtime and optimizing productivity.

Enhanced Access, Materials, Tools, and Personnel

Metal scaffolding enables convenient access to different areas of the construction site. Its modular design allows for easy configuration and adjustment, ensuring that workers have the necessary access points to perform their tasks efficiently. Additionally, metal scaffolding provides a stable platform for transporting materials, tools, and personnel across the job site. This seamless mobility saves time and effort, boosting overall productivity.

Smooth Operations and Timely Project Completion

By utilizing metal scaffolding, construction projects can operate smoothly and meet deadlines. The robust construction and stability of metal scaffolding systems ensure that workers can carry out their tasks safely and efficiently. This not only prevents delays but also contributes to the overall quality of work. With metal scaffolding, projects can be completed within the specified timeframe, meeting client expectations and enhancing construction team reputation.

Optimizing Productivity and Efficiency

The integration of metal scaffolding into construction projects optimizes productivity and efficiency. The safe and accessible work platform provided by metal scaffolding eliminates unnecessary obstacles and hazards, allowing workers to focus on their tasks. By reducing the time spent on improvisation and ensuring easy access to elevated work areas, metal scaffolding improves the overall efficiency of the construction process.

| Benefits | Description |

|---|---|

| Enhanced Workflow | Metal scaffolding streamlines workflow, reducing downtime and optimizing productivity. |

| Convenient Access | Metal scaffolding provides easy and safe access to different areas of the construction site. |

| Efficient Transport | Materials, tools, and personnel can be easily moved across the job site using metal scaffolding. |

| Timely Project Completion | Metal scaffolding enables smooth operations, contributing to the timely completion of construction projects. |

| Improved Productivity | By enhancing accessibility and safety, metal scaffolding optimizes productivity in construction projects. |

Metal Scaffolding Products and Accessories

When it comes to metal scaffolding, there is a wide range of products and accessories available to enhance safety and convenience on the job site. Construction teams can choose from various sizes and configurations to meet their specific project needs. Let’s take a look at some of the essential metal scaffolding products and accessories:

Scaffold Frames

Scaffold frames are the backbone of any scaffolding structure. They provide the main framework, giving stability and support to the overall system. These frames are available in different sizes and materials, such as steel or aluminum, to accommodate various construction requirements.

Packages

Scaffolding packages offer a complete set of components needed for a specific job. They often include frames, cross braces, platforms, and guardrails, making it easy and convenient to set up scaffolding quickly and efficiently.

Planks

Planks are essential for creating a safe and sturdy work surface on the scaffolding. These platforms come in various lengths and materials, such as wood or aluminum, to suit different project needs. It is important to choose planks that meet safety standards and provide optimal strength and stability.

Accessories

In addition to the basic scaffolding components, there are various accessories available to enhance functionality and safety. Some of the common accessories include:

- Base Plates: These plates provide stability and distribute the weight of the scaffolding system.

- Clamps: Clamps are used to secure the scaffolding components together, ensuring a solid and secure structure.

- Guardrails: Guardrails add an extra layer of safety, preventing falls from the scaffolding platform.

- Casters: Casters are wheels that can be attached to the scaffold frames, allowing for easy mobility and positioning of the scaffolding system.

By incorporating these accessories into their scaffolding system, construction teams can optimize safety and efficiency on the job site.

Investing in high-quality metal scaffolding products and accessories is crucial to ensure a safe and productive construction environment. By choosing the right components and utilizing the necessary accessories, construction teams can create a reliable and efficient scaffolding system tailored to their specific project requirements.

Best Practices for Using Metal Scaffolding

When it comes to using metal scaffolding in construction projects, following best practices is crucial to ensure both safety and efficiency. By implementing these key practices, construction teams can mitigate risks and maximize the benefits of metal scaffolding.

Pre-Planning and Risk Assessment

Before using metal scaffolding, thorough pre-planning is essential. This includes conducting a comprehensive risk assessment to identify potential hazards and develop appropriate safety measures. By addressing these risks early on, construction teams can establish a foundation for a safe work environment.

Proper Design and Maintenance

Effective design and regular maintenance are vital for the optimal performance of metal scaffolding. The design should adhere to industry standards and specific project requirements to ensure stability and longevity. Ongoing maintenance and inspections are necessary to identify any issues or weaknesses promptly. This includes checking for loose fittings, damaged components, and overall structural integrity.

Clear Communication and Supervision

Clear communication and effective supervision play a crucial role in the safe use of metal scaffolding. It is important to establish communication protocols and ensure that all workers understand safety procedures, including the proper use of scaffolding equipment. Additionally, having competent supervisors on-site can help monitor operations, provide guidance, and address any potential safety concerns promptly.

Regular Training and Education

Training and education are key components of using metal scaffolding safely. All workers should receive comprehensive training on scaffold assembly, use, and dismantling procedures. Ongoing education helps reinforce safety best practices and ensures that workers stay updated with the latest industry standards and regulations.

Compliance with Safety Standards

Complying with safety standards and regulations is non-negotiable when working with metal scaffolding. This includes following guidelines set forth by regulatory bodies, such as OSHA (Occupational Safety and Health Administration). By adhering to these standards, construction teams can ensure a safe working environment for everyone involved.

Remember, adopting best practices is essential for the safe and efficient use of metal scaffolding. By prioritizing pre-planning, maintenance, communication, supervision, and compliance with safety standards, construction teams can create a work environment that promotes worker well-being and project success.

| Best Practices | Description |

|---|---|

| Pre-Planning and Risk Assessment | Thoroughly assess potential risks and develop safety measures. |

| Proper Design and Maintenance | Ensure scaffolding is designed properly and conduct regular maintenance. |

| Clear Communication and Supervision | Establish effective communication and provide competent on-site supervision. |

| Regular Training and Education | Instruct workers on proper scaffold assembly, use, and dismantling. |

| Compliance with Safety Standards | Adhere to regulatory guidelines and safety standards. |

Conclusion

In conclusion, metal scaffolding plays a vital role in ensuring safety and efficiency in construction projects. By providing a secure and stable platform at various heights, it allows workers to perform their tasks with confidence. With careful consideration of project requirements, safety considerations, and best practices, construction teams can leverage the benefits of metal scaffolding to enhance worker well-being and improve overall project productivity.

By investing in metal scaffolding, construction projects can prioritize safety, mitigating the risk of falls and protecting workers from potential hazards. Additionally, the use of metal scaffolding provides efficient access to different areas of the job site, streamlining workflow and reducing downtime. This increased efficiency leads to timely project completion and higher productivity.

Throughout the construction industry, the use of metal scaffolding has become indispensable. Its robust construction and durability ensure the longevity of scaffolding systems, offering a reliable solution for all types of construction projects. When properly utilized, metal scaffolding enhances safety, boosts efficiency, and contributes to the overall success of construction endeavors.

Frequently Asked Questions

What is metal scaffolding?

Metal scaffolding is a temporary structure made of metal pipes and tubes, typically steel or aluminum, and planks. It provides a stable work area at various heights in construction and industrial projects.

Why is metal scaffolding important in construction?

Metal scaffolding plays a crucial role in ensuring the safety and efficiency of construction projects. It provides height accessibility for workers and reduces the risk of falls and accidents, while also allowing convenient access to different areas of the project.

What are the different types of metal scaffolding?

There are several types of metal scaffolding, including tube and coupler scaffolding, frame scaffolding, system scaffolding, suspended scaffolding, and mobile scaffolding. Each type is designed to meet specific project needs.

What are the advantages of using metal scaffolding?

Metal scaffolding offers safety, durability, and stability. It provides a secure working platform for workers and is easy to assemble. Whether it is aluminum scaffolding for light-duty work or steel scaffolding for heavy-duty tasks, it ensures unmatched safety and efficiency on the job site.

What factors should be considered when choosing metal scaffolding?

When choosing metal scaffolding for a project, factors such as project size, work type, surface conditions, and space availability should be considered. These factors help determine the appropriate type and configuration of metal scaffolding.

What safety considerations should be taken into account when using metal scaffolding?

Safety is paramount when using metal scaffolding. Construction teams should inspect the scaffolding prior to use, provide proper training to workers, know the weight capacity, ensure stability, and consider weather conditions to avoid accidents.

How does metal scaffolding maximize efficiency in construction projects?

Metal scaffolding allows for convenient access to different areas, streamlining workflow and reducing downtime. It enables easy movement of materials, tools, and personnel around the job site, enhancing overall productivity and ensuring timely project completion.

What metal scaffolding products and accessories are available?

A wide range of metal scaffolding products and accessories are available, including scaffold frames, packages, planks, and various accessories like base plates, clamps, guardrails, and casters. These accessories enhance safety and convenience on the job site.

What are the best practices for using metal scaffolding?

Best practices for using metal scaffolding include adequate pre-planning, regular maintenance and inspections, effective communication and supervision on the job site, and adherence to safety protocols, ensuring the safe and efficient use of metal scaffolding.

Why is metal scaffolding important in construction projects?

Metal scaffolding is essential for ensuring safety and efficiency in construction projects. It provides a secure and stable platform for workers to perform tasks at various heights, ultimately enhancing worker well-being and improving project productivity.

[…] Metal Scaffolding: Ultimate Safety & Efficiency When it comes to construction projects, safety and efficiency are paramount. That’s where metal… Suspended Scaffolding Safety & Setup Guide Suspended scaffolding is an essential piece of construction safety equipment used to access hard-to-reach… Quality Aluminum Scaffolding Solutions top choices Aluminum scaffolding is the preferred choice for professionals in the construction and maintenance industry…. Haki Scaffolding: Your Trusted Access Solution […]