Phone:

(+65)8319-0742

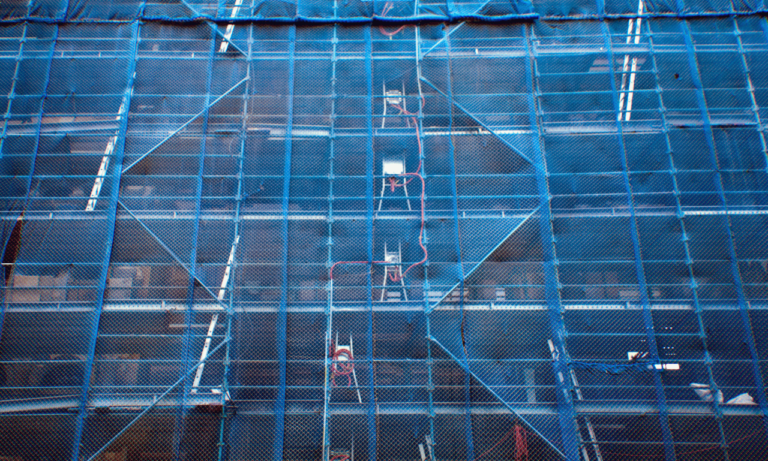

Aerial lifts, also known as lift equipment or industrial lifting equipment, are essential for various industries, offering a safe and efficient solution for working at heights. Whether you’re in the construction, maintenance, or cleaning industry, aerial lifts provide a versatile platform to carry out tasks with ease and precision.

When it comes to operating aerial lifts, it’s imperative to prioritize safety. OSHA-compliant training is necessary to ensure proper operation and minimize the risk of accidents or injuries. With the right training and equipment, you can enhance productivity and create a secure work environment for your team.

Key Takeaways:

- Aerial lifts, such as boom lifts and scissor lifts, are essential for working at heights in various industries.

- OSHA-compliant training is crucial for safe operation and to reduce the risk of accidents.

- Prioritizing safety and using the appropriate equipment can enhance productivity and maintain a secure work environment.

- Choosing the right aerial lift for your specific project needs is essential for efficient and effective work.

- Regular maintenance and inspections are necessary to ensure the continued safe operation of aerial lifts.

What Is an Aerial Work Platform?

An aerial work platform, also known as an AWP, is an alternative to ladders and scaffolding for tasks at great heights. It provides a safe and efficient solution for working at elevated levels. Aerial work platforms consist of a base structure, an extending structure with a chassis, and a flat workspace with controls. They offer a stable and spacious platform for operators to carry out their tasks effectively.

Safety precautions should be a top priority when using an AWP. Operators must use proper fall protection gear, including a body harness, to prevent accidents and ensure personal safety. Following OSHA-compliant training is essential for operators to understand the safe operation and maintenance of aerial work platforms. This training equips them with the necessary knowledge and skills to navigate and operate the equipment safely.

Popular Types of Aerial Lifts

When it comes to aerial lifts, there are several popular types available that cater to different tasks and job site requirements. Let’s explore the diverse range of options:

Boom Lift

A boom lift is a versatile and durable aerial lift that provides excellent reach and flexibility. It features an extendable arm or boom that can move vertically and horizontally, allowing operators to access elevated areas with ease. Boom lifts come in various sizes and configurations, including straight booms and articulated booms.

Articulated Boom Lift

An articulated boom lift is specifically designed for maneuverability in tight spaces. It consists of multiple jointed sections that allow the lift to bend and reach over obstacles, making it ideal for navigating cluttered work areas or accessing areas with limited access points. Articulated boom lifts are commonly used in construction, maintenance, and film production.

Telescopic Boom Lift

For maximum reach at heights, a telescopic boom lift is an excellent choice. This type of lift features an extendable arm that can reach significant vertical and horizontal distances. Telescopic boom lifts are popular in construction projects that require access to high, hard-to-reach areas. They offer excellent stability and lifting capacity.

Scissor Lift

Scissor lifts are versatile aerial lifts that are commonly used for indoor work. They are equipped with crisscrossing metal supports that vertically lift the platform. Scissor lifts provide a stable and spacious workspace, making them suitable for various tasks such as maintenance, installation, and painting. They are available in electric and engine-powered options.

Aerial Platform

An aerial platform, also known as a cherry picker, is a type of aerial lift commonly found in outdoor job sites. It features a platform attached to a hydraulic arm that can be maneuvered to access elevated areas. Aerial platforms are often used for tasks such as tree trimming, maintenance, and construction. They provide stability and versatility in outdoor environments.

Each type of aerial lift has its own unique characteristics and advantages, allowing operators to choose the most suitable option for their specific job requirements. Understanding the different types of lifts can help ensure safe and efficient operations at elevated heights.

Types of Aerial Lifts and Construction Lifts

Aerial lifts and construction lifts are crucial equipment for various construction projects. While aerial lifts are often used as a general term for boom lifts and scissor lifts, their original purpose was for outdoor job sites. On the other hand, construction lifts encompass a wider range of equipment, including bucket trucks, articulated boom lifts, and telescoping boom lifts.

The demand for aerial work platforms and construction lifts continues to grow due to the increasing number of construction projects. These lifts offer enhanced mobility, reach, and stability, making them indispensable tools in the construction industry. Let’s explore the different types and capabilities of aerial lifts and construction lifts in more detail.

Questions to Ask Before Renting or Buying an Aerial Lift

Before making the decision to rent or buy an aerial lift, it’s essential to consider several important factors. By asking the right questions, you can ensure that you select the most suitable equipment for your specific needs and requirements.

Project Type: Indoors or Outdoors?

Determine whether your project will take place indoors or outdoors. This distinction is crucial as it will impact the type of aerial lift you choose. Indoor projects may require compact lifts that can maneuver through tight spaces, while outdoor projects often call for heavy-duty lifts that can handle rough terrains.

Space Constraints: Compact or Heavy-Duty?

Consider the space constraints of your work environment. Do you have narrow passages or limited room for maneuvering? If so, a compact aerial lift may be the best option. However, if you have ample space and need to reach greater heights, a heavy-duty lift with a larger platform may be more suitable.

Vertical and Horizontal Distances: How High and Far?

Determine the vertical and horizontal distances that your project requires. Consider the height you need to reach vertically, as well as the reach distance horizontally. This information will help you select an aerial lift with the appropriate maximum height and horizontal reach capabilities.

Weight Capacity: How Much Weight?

Assess the total weight that the aerial lift needs to support. Consider not only the weight of the operator but also any tools, equipment, or materials that will be transported on the lift. By knowing the weight capacity required, you can choose a lift that can safely handle the load.

By analyzing these important aspects, you can make an informed decision when renting or buying an aerial lift. Take the time to assess the project type, space constraints, vertical and horizontal distances, and weight capacity to ensure that the lift you choose meets your equipment requirements.

| Question | Considerations |

|---|---|

| Is the project indoors or outdoors? | Indoor vs. outdoor suitability |

| Do you need a heavy-duty lift for rough terrain or a compact platform for tight spaces? | Space constraints and terrain requirements |

| What vertical and horizontal distances will be required? | Maximum height and horizontal reach capabilities |

| What is the total weight the lift needs to hold? | Weight capacity considerations |

By carefully considering these questions, you can confidently select the right aerial lift for your specific project needs. Making the right choice will not only ensure the safety and efficiency of your operations but also contribute to the overall success of your project.

When to Use a Vertical Mast Lift

Vertical mast lifts are versatile machines that are particularly useful in certain scenarios, such as inventory management and stock-picking projects in even-surfaced warehouses. These lifts are specifically designed to navigate narrow aisles and tight spaces, making them an ideal choice for confined working environments.

With their lightweight and compact design, vertical mast lifts are maneuverable and easy to use. They can accommodate a single operator and handle loads up to 500 pounds. This makes them suitable for tasks that involve moving and organizing inventory efficiently.

Vertical mast lifts are available in both electrically self-propelled and manually pushed models. The electrically powered lifts are convenient for continuous operation, while the manually pushed lifts offer flexibility and are cost-effective for shorter-duration projects.

When it comes to work heights, vertical mast lifts typically have a range of 15 to 40 feet, providing ample reach for most stock-picking and inventory management tasks in warehouses. This allows operators to access elevated shelves and efficiently retrieve materials or products without the need for ladders or other cumbersome equipment.

Using a vertical mast lift in inventory management and stock-picking projects offers several benefits, including increased efficiency, reduced risk of injuries, and improved productivity. These lifts enable operators to move swiftly and safely, streamlining the workflow and reducing the time required to complete tasks.

In summary, vertical mast lifts are an excellent choice for inventory management and stock-picking projects in even-surfaced warehouses. Their compact size, maneuverability, and adequate working heights make them an invaluable asset for optimizing efficiency and productivity in these specific applications.

Electric-Powered vs. Engine-Powered Articulating Boom Lifts

Articulating boom lifts are versatile and maneuverable, making them suitable for a wide range of worksites. Whether you’re tackling complex construction projects or navigating tight spaces, articulating boom lifts provide the flexibility and reach you need.

When choosing an articulating boom lift, you’ll have to decide between electric-powered and engine-powered options. Each type of lift has its own set of advantages and considerations, depending on the nature of your project.

Electric-Powered Articulating Boom Lifts

Electric-powered boom lifts are an excellent choice for indoor areas with even surfaces. These lifts operate quietly and produce zero emissions, making them environmentally friendly. With their precise controls and smooth operation, electric-powered boom lifts are ideal for tasks that require precision and accuracy.

Benefits of electric-powered articulating boom lifts:

- Silent operation, reducing noise pollution

- Zero emissions, contributing to a sustainable work environment

- Precise controls for enhanced maneuverability

- Efficient operation on even surfaces

Engine-Powered Articulating Boom Lifts

Engine-powered boom lifts offer more power and mobility, making them suitable for outdoor projects and rough terrain. These lifts are equipped with robust engines that provide the necessary strength to handle challenging worksites. Engine-powered boom lifts are designed for durability and can navigate uneven surfaces and inclines with ease.

Benefits of engine-powered articulating boom lifts:

- Greater power and lifting capability

- Enhanced mobility for rough terrain

- Ability to handle outdoor projects with ease

- Durable construction for long-lasting performance

When choosing between electric-powered and engine-powered articulating boom lifts, consider the specific requirements of your worksite. If you’re working indoors, require a quieter operation, and prioritize sustainability, an electric-powered boom lift is the ideal choice. On the other hand, if you need more power and mobility for outdoor projects or rough terrains, an engine-powered boom lift is the better option.

Investing in the right type of articulating boom lift will ensure that you have the necessary equipment to complete your project safely and efficiently.

When to Use a Telescopic Boom Lift

Telescopic boom lifts are a versatile and practical choice for outdoor projects, especially those that require larger vertical and horizontal reach distances. When compared to articulated boom lifts, telescopic boom lifts offer extended reach and simplicity in their design. These lifts excel in large-scale construction projects, providing the height and maneuverability necessary for efficient work.

Telescopic boom lifts have a wide range of applications in various industries, including construction, maintenance, and infrastructure development. Their impressive height capabilities make them ideal for tasks that require access to elevated areas, such as installing utility poles, repairing roofs, or constructing tall structures.

With heights ranging from 40 to over 100 feet, telescopic boom lifts can handle the demands of even the tallest construction projects. Their robust build enables them to navigate rough terrain, making them suitable for outdoor worksites that require sturdy and reliable equipment.

Advantages of Telescopic Boom Lifts for Large-Scale Construction

- Extended reach: Telescopic boom lifts offer exceptional vertical and horizontal reach, allowing workers to access elevated areas that may be difficult to reach with other equipment.

- Efficiency: These lifts enable workers to complete tasks at height more quickly, improving overall project productivity.

- Rough terrain capabilities: Telescopic boom lifts are built to handle uneven and challenging outdoor terrain, providing stability and mobility on construction sites.

- 4-wheel drive: In situations where 4-wheel drive is necessary, telescopic boom lifts are equipped with features that ensure safe and efficient operation.

When considering outdoor projects and large-scale construction, a telescopic boom lift is a reliable and efficient choice. Its extended reach and rugged design enable workers to tackle tasks at height with confidence and ease.

| Advantages | Disadvantages |

|---|---|

| Extended reach | More limited maneuverability compared to articulated boom lifts |

| Efficient for large-scale construction | Not suitable for tight spaces or areas with limited accessibility |

| Can handle rough terrain | Higher cost compared to other types of aerial lifts |

| Provides stability and mobility on construction sites | Requires proper operator training and certification |

When to Use a Scissor Lift

Scissor lifts are a versatile and efficient solution for various projects, particularly those involving warehouse inventory and outdoor tasks on uneven terrain. With their crisscrossing metal supports, scissor lifts lift the platform vertically, providing a stable and secure work area.

For indoor workspaces with low emissions requirements, electric scissor lifts are an excellent choice. They operate quietly and are environmentally friendly, making them ideal for warehouse inventory projects. On the other hand, if you’re tackling outdoor projects on uneven terrain, an engine-powered scissor lift with 4-wheel drive capabilities is the best option. These rugged machines can handle rough surfaces and provide the necessary stability and maneuverability.

Scissor lifts are commonly used in warehouses for inventory management tasks, making it easy to reach items at various heights while ensuring worker safety. Their vertical lift capabilities also make them suitable for a range of vertical tasks, such as electrical installations, maintenance work, and more.

Benefits of Using a Scissor Lift:

- Increased efficiency and productivity in warehouse inventory operations

- Enhanced worker safety with stable and secure platforms

- Easy maneuverability in tight spaces

- Ability to work on uneven terrain with engine-powered scissor lifts

- Reduced emissions and noise pollution with electric scissor lifts

Considerations When Using a Scissor Lift:

Although scissor lifts are versatile and reliable, there are a few important considerations to keep in mind when using them:

- Ensure that the scissor lift is properly rated to handle the required weight capacity.

- Follow all safety guidelines and regulations, including wearing appropriate personal protective equipment.

- Avoid overloading the platform and maintain a stable center of gravity.

- Regularly inspect and maintain the scissor lift to ensure optimal performance and safety.

With their ability to handle warehouse inventory tasks and outdoor projects on uneven terrain, scissor lifts provide a practical solution for a range of vertical work. Whether you need to reach high shelves in a warehouse or perform maintenance tasks in an outdoor setting, a scissor lift offers the stability, versatility, and efficiency you need to get the job done safely and effectively.

Conclusion

Aerial lifts provide safe and efficient options for working at heights. Whether you need to install fixtures, conduct maintenance, or clean windows on tall buildings, aerial lifts offer the necessary height and stability. With various equipment options available, including boom lifts, scissor lifts, and more, you can choose the right lift for your specific project needs.

However, it’s crucial to prioritize safety by ensuring proper training and compliance with safety regulations. Safety training for aerial lift operators is essential for both the operators’ well-being and the overall productivity of your job site. By providing the necessary safety training, you can reduce the risk of accidents and create a safe work environment for everyone involved.

By investing in aerial lifts and ensuring proper safety training, you can experience increased productivity on your job site. These lifts enable workers to access hard-to-reach areas quickly and efficiently, minimizing downtime and maximizing efficiency. With enhanced productivity, you can complete projects in a timely manner and achieve your goals more effectively.

Whether you choose to rent or buy aerial lifts, it’s essential to consider your specific equipment requirements and the nature of your projects. Evaluate the type of work you’ll be doing, the height and reach you require, and the terrain in which the lifts will be operated. This way, you can select the most suitable aerial lifts for your needs and optimize your job site performance.

FAQ

What industries require aerial lifts?

Aerial lifts are essential for various industries, including construction, maintenance, cleaning, and more.

What is an aerial work platform?

An aerial work platform, also known as an AWP, is an alternative to ladders and scaffolding for tasks at great heights.

What types of aerial lifts are available?

There are several types of aerial lifts, including boom lifts, articulated boom lifts, telescopic boom lifts, scissor lifts, and aerial platforms.

How do aerial lifts differ from construction lifts?

Aerial lifts are originally designed for outdoor job sites, while construction lifts include bucket trucks, articulated boom lifts, and telescoping boom lifts.

What questions should I ask before renting or buying an aerial lift?

You should consider whether the project is indoors or outdoors, if you need a heavy-duty lift for rough terrain or a compact platform for tight spaces, the vertical and horizontal distances required, and the total weight the lift needs to hold.

When should I use a vertical mast lift?

Vertical mast lifts are ideal for inventory management and stock-picking projects in even-surfaced warehouses.

What are the differences between electric-powered and engine-powered articulating boom lifts?

Electric-powered boom lifts are suitable for indoor areas with even surfaces, while engine-powered boom lifts offer more power and mobility for rough terrain and outdoor projects.

When should I use a telescopic boom lift?

Telescopic boom lifts are ideal for outdoor projects that require larger vertical and horizontal reach distances, especially in large-scale construction projects and rough terrain.

When should I use a scissor lift?

Scissor lifts are commonly used for warehouse inventory projects and vertical tasks, both indoor and outdoor, with the option of electric scissor lifts for low emissions requirements and engine-powered scissor lifts for uneven terrain.