Phone:

(+65)8319-0742

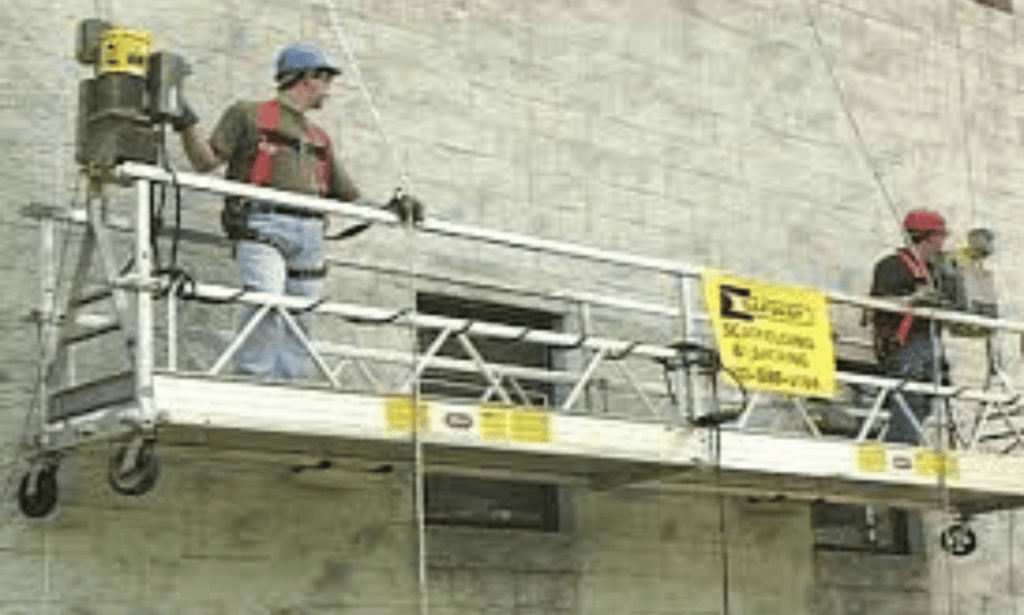

In the world of construction, renovation, and maintenance, new ways of working are emerging. Scaffolding Solutions leads this change with cutting-edge work platforms and powered access equipment. They focus on safety and customer happiness, making them a top choice for many industries.

They’re known for their great customer service, helping clients from start to finish. Their team, with over 3 years of experience, works with clients to create custom solutions. They use advanced 3D planning tools to design scaffolding that’s safe and efficient.

The company has a perfect safety record, completing projects without incidents. This shows their dedication to safety and their team’s ongoing training. They’ve handled scaffolding up to 24 feet tall, showing their skill in complex projects.

What makes Scaffolding Solutions stand out is their strong partnerships with clients. These partnerships last an average of 8 years, showing their commitment to working together for success. Clients love their communication, quick responses, and staying within budget. In fact, 100% of clients recommend them for their top-notch service and reliable solutions.

Key Takeaways

- Scaffolding Solutions provides innovative suspended access solutions for construction, renovation, and maintenance projects

- Their commitment to construction safety and customer satisfaction sets them apart in the industry

- With a team of experienced professionals and advanced 3D digital planning tools, they deliver tailored solutions that meet the highest safety standards

- Scaffolding Solutions has a 100% success rate in completing projects without any safety incidents

- They establish strong, long-term partnerships with clients built on trust and shared values

Understanding Suspension Scaffolds and Their Benefits

In construction and maintenance, reaching high places is tough. That’s where suspension scaffolds, or swing stages, help. They let workers safely do tasks high up, changing how we handle big projects.

What is a Suspension Scaffold?

A suspension scaffold hangs from above, giving workers access to high places. They’re great for areas that are hard to reach, like above uneven ground or where there’s water. These scaffolds are mainly used for jobs like cleaning and painting because they’re not as heavy as other types.

Key Advantages of Using Suspension Scaffolds

Suspension scaffolds have many benefits that make them popular for many projects:

- Flexibility and Adaptability: They can fit into complex shapes and designs, perfect for tricky access spots.

- Cost-Effectiveness: They need less material and labor, saving money for project owners.

- Enhanced Safety: With the right setup and care, they offer a safe place to work, reducing fall risks. Safety features like guardrails and personal fall arrest systems add to the safety.

- Increased Efficiency: They let workers quickly get to where they need to go, saving time and boosting productivity. This is key for projects with tight deadlines.

Suspended scaffolds are key in many fields, like construction and oil and gas. They give safe and easy access to high areas, helping teams complete tough projects with ease and accuracy.

Types of Suspension Scaffolds Available

For elevated projects, the right suspension scaffold is key for safety and efficiency. There are many types of suspension scaffolds, each for different project needs. It’s important to know the differences and pick the best one for your project.

Single-point Suspension Systems

Single-point systems are anchored at one end. They are great for projects with few access points. Ideal for painting, cleaning, and maintenance on tall buildings, these scaffolds are easy to move and fit different building shapes.

Two-point Suspension Systems

Two-point systems offer a bigger working area and more stability. They hang between two anchorages, making them safe and efficient for construction and renovation. These are often used in high-rise buildings, allowing workers to safely access large areas.

“Modular scaffolding, like Doka’s Ringlock system, offers unparalleled flexibility and cost savings for complex projects. Its adaptable design allows for quick assembly and reconfiguration, making it a top choice for efficient scaffold solutions.”

Multi-point Suspension Systems

Multi-point suspension systems are for the toughest projects. They have many anchorages for extra stability and can hold more weight. These are crucial for big industrial projects, ensuring a safe and productive work area at high heights.

When choosing a suspension scaffold, think about the building’s design, the work needed, and how much weight it will hold. Investing in quality suspended access equipment and safety is vital for successful projects and protecting workers.

Safety Measures for Scaffold Operations

When working on scaffolds, safety is the most important thing. It’s crucial to keep workers safe and the work area secure. By focusing on construction safety, fall protection, and following safety rules, we can work safely and efficiently.

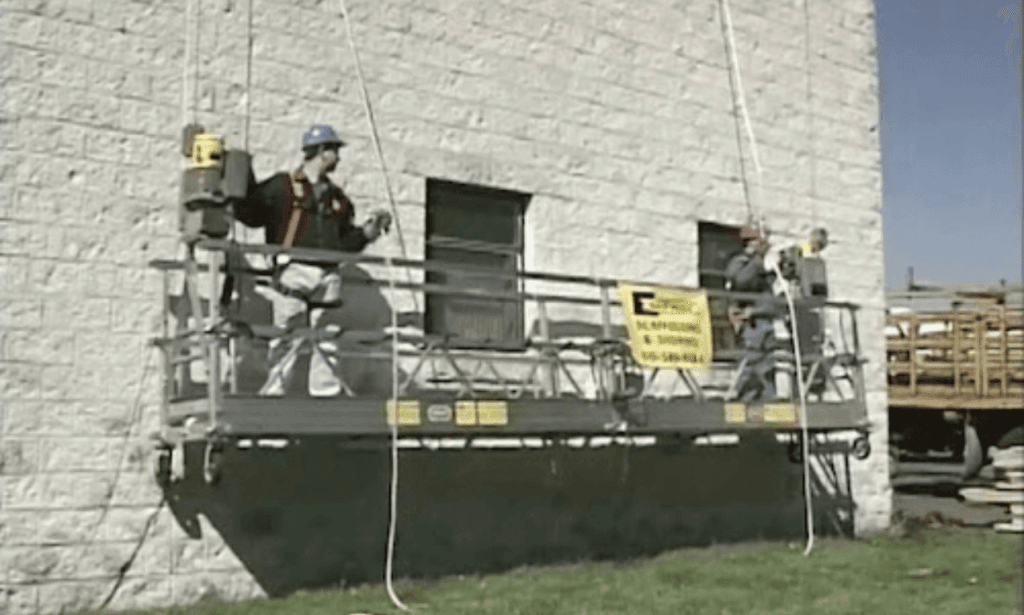

Personal Protective Equipment (PPE)

Using the right Personal Protective Equipment (PPE) is key to scaffold safety. Workers need things like harnesses and helmets to stay safe in case of accidents. OSHA says ropes on scaffolds must hold at least 6 times the maximum load to keep the scaffold stable.

Proper Training and Certification

Workers need the right training and certification for scaffold work. OSHA calls someone competent if they can spot hazards and fix them. Supervisors must be trained and have the power to oversee scaffolding work. This training helps workers use scaffolds safely, reducing the chance of accidents.

“Approximately 4,500 injuries related to scaffold incidents occur each year, resulting in an estimated cost of $90 million in lost workdays.”

Regular Inspection Protocols

Regular checks are vital to keep scaffold equipment safe. OSHA says ropes must be checked by a trained person before each shift and after any damage. These checks help find and fix problems, like damage from too much weight or rust.

Following safety rules, keeping the area clean, and using safe electrical tools are also important. By putting safety first and following standards, we can work safely and effectively.

Applications of Suspension Scaffolds in Various Industries

Suspension scaffolds are key in many industries. They offer flexibility, safety, and efficiency for hard-to-reach areas. From skyscrapers to bridge construction, they’ve changed how we do construction, maintenance, and renovation.

In construction, they’re crucial for high-rise buildings and projects. Swing stage scaffolding is used for window cleaning, painting, and facade work. It’s easy to use and perfect for reaching high places.

Construction and Renovation Projects

Suspension scaffolds are vital in building and renovating famous structures. For example, the Danube River Bridge in Austria was built with Doka’s scaffolding. They fit any project, making work safe and efficient.

Maintenance of Tall Structures

The maintenance of tall structures depends on suspension scaffolds. Motorized systems can move fast, up to 35 feet per minute. This saves time and effort in industries like skyscraper maintenance.

“Suspension scaffolds have transformed the way we approach building maintenance. The ability to quickly and safely access even the most challenging areas has been a game-changer for our industry.” – David Herbert, Maintenance Manager

Industrial and Commercial Uses

Suspension scaffolds are also used in many industrial and commercial settings. Catenary scaffolding is efficient for high-rise work. It’s faster and cheaper than traditional scaffolding.

Float/ship scaffolds are great for small tasks like riveting, bolting, and welding. They’re light and can hold up to three workers and tools. This makes industrial access safe and easy.

Choosing the Right Suspension Scaffold for Your Project

Choosing the right suspension scaffold is key for a safe and efficient work area. There are many options, so it’s important to think about what your project needs. By looking at these factors, you can pick a scaffold that boosts productivity and keeps workers safe.

Factors to Consider

When picking a suspension scaffold, several important factors come into play. First, think about the size and height of your project. This will help you decide on the right scaffold size and type. Also, consider the load-bearing capacity needed to safely hold workers, tools, and materials. Look at the site’s accessibility, project length, and any location challenges too.

Material Options and Durability

Suspension scaffolds come in different materials, each with its own benefits. Steel scaffolds are strong and durable, great for heavy jobs. Aluminum scaffolds are light and resistant to corrosion, perfect for projects that need to move around or face harsh weather. Choose materials that can handle your project’s specific needs.

“Selecting the right scaffolding materials is not just about meeting project requirements; it’s about ensuring the safety and well-being of every worker on the job site.”

Load Capacity and Weight Considerations

When choosing a suspension scaffold, its load-bearing capacity is crucial. Make sure it can handle the weight of workers, tools, and materials without breaking. Talk to scaffold experts or manufacturers to find the right load capacity for your project. Remember, overloading can cause accidents and harm.

By carefully evaluating factors like project scope, material options, and load-bearing capacity, you can make a smart choice for your suspension scaffold. Focus on safety, efficiency, and following industry standards for a successful and safe project.

Future Innovations in Suspension Scaffolding

The future of suspension scaffolding looks bright with new innovations coming. The construction world is changing, and so are the scaffolding technologies and materials. New materials like lightweight composites and strong alloys are being made. These will make scaffolds better and easier to move.

Smart Scaffold Solutions

Digital solutions are being added to scaffolding systems too. Smart scaffolds with sensors and monitoring devices can give real-time data. This data helps improve safety and maintenance.

Companies like Doka are already using sensors to monitor concrete curing. As these technologies get better, we’ll see even smarter scaffolds.

Sustainable Practices in Scaffold Design

Sustainability is key in construction, and scaffolding is no exception. Eco-friendly materials like recycled steel and aluminum are being used. This reduces the environmental impact of projects.

Energy-efficient designs and renewable power are also being added to scaffolds. This makes them better for the planet. Sustainable practices in design will help the industry be more eco-friendly.

Advancements in Material Technology

The future of suspension scaffolding is bright with digital solutions, new materials, and sustainability. By keeping up with these advancements, scaffolding experts can offer safer, more efficient, and greener solutions. With the right tools and knowledge, the possibilities for suspension scaffolding are endless.