Phone:

(+65)8319-0742

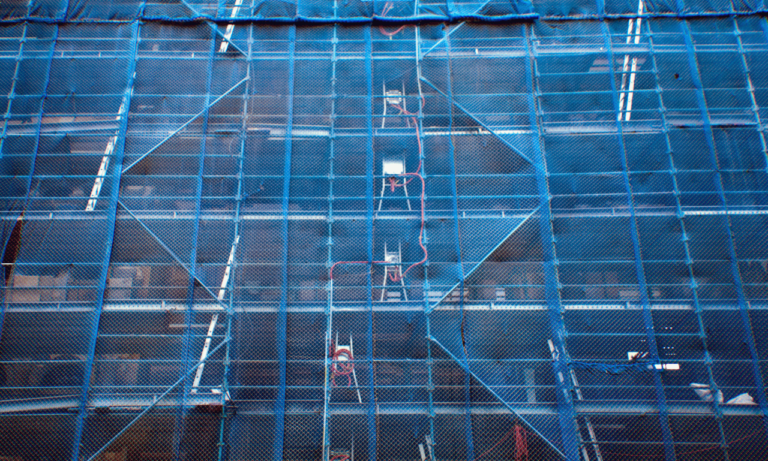

In construction and renovation, scaffolding is key for safe access to heights. 20 ft scaffolding is a top pick for its flexibility and dependability. It’s great for both big commercial jobs and smaller home renovations, offering stability and ease of movement. Additionally, it provides a competitive price, ensuring cost-effectiveness without compromising on quality.

Non-Stop Heavy-Duty crank-up scaffolding can reach up to 552 feet, perfect for big commercial projects. For smaller jobs, Non-Stop Standard-Duty is the way to go, reaching up to 40 feet. These systems are easy to set up and take down, saving time and money.

Non-Stop scaffolding keeps workers on the job longer, without stopping. This means more work gets done, saving money and time. The scaffolding’s design makes it easy for workers to move around and reach high spots safely.

20 ft scaffolding offers versatility and reliability for both commercial and residential projects

Non-Stop Heavy-Duty crank-up scaffolding can reach heights up to 552 feet for commercial masonry work

Non-Stop Standard-Duty crank-up scaffolding is perfect for residential and light commercial projects up to 40 feet

Modular design allows for easy assembly and disassembly, saving time and labor costs

Non-Stop scaffolding keeps workers on the scaffold until the wall is topped out, increasing productivity

Understanding the Basics of 20 ft Scaffolding

Construction projects need the right scaffolding for safety and efficiency. 20 ft scaffolding is great for mid-to-high-rise jobs. It gives workers a stable place to work at heights. Before buying scaffolding, knowing the basics is key. Feel free to reach out with any questions you might have about 20 ft scaffolding.

What Is 20 ft Scaffolding?

20 ft scaffolding reaches about 20 feet or six meters high. It’s a key height for many construction jobs. Workers can safely reach and work on high places. It’s made from materials like aluminum, which is strong and easy to set up.

Components of a Scaffolding System, Including Cross Braces

A scaffolding system has several important parts. These parts work together to make a safe place to work. The main parts are:

Standards: Vertical poles that support the scaffolding structure

Ledgers: Horizontal poles that connect the standards and provide stability

Transoms: Poles that support the decking or walking surface

Decking: The platform on which workers stand and perform tasks

Guardrails: Safety barriers that prevent falls from the scaffolding

Knowing how these parts work is key to setting up your scaffolding right.

Safety Standards and Regulations

Safety is crucial with scaffolding, and 20 ft scaffolding is no different. OSHA has rules for scaffolding to keep workers safe. These rules include:

Guardrails must be installed on scaffolding platforms that are 10 feet or more above the ground

Scaffolding with a height-to-base ratio greater than 4:1 must be secured to prevent tipping

Scaffolding must be capable of supporting up to four times its maximum intended load

Following these safety rules makes your scaffolding a reliable and safe part of your job site. For detailed safety regulations, refer to OSHA guidelines when using 20 ft scaffolding.

Benefits of Using 20 ft Scaffolding

Construction scaffolds like the 20 ft type have many benefits. They make work safer, more efficient, and cheaper. They give workers a solid place to work from, even at high heights.

Enhanced Reach and Mobility for Construction Projects

20 ft scaffolding lets workers reach higher places safely. This means they can do jobs that were hard or impossible before. It saves time and makes work easier for everyone.

Increased Safety and Stability

Safety is key in construction, and 20 ft scaffolding helps a lot. Its flat surface helps workers stay balanced. Plus, it’s built strong, which lowers the chance of accidents.

“Scaffolding increases productivity due to greater efficiency provided by increased safety and access.” – Construction Industry Expert

Cost-Effectiveness in the Long Run

20 ft scaffolding can save money in the long run. It’s easy to set up and take down, saving time. High-quality scaffolding lasts a long time, making it a smart investment. Many choose to rent instead of buy, which cuts down on costs. Images of scaffolding products are for reference only and the actual items may vary.

Choosing the Right Type of 20 ft Scaffolding

Choosing the right 20 ft scaffolding is key for your project. There are many out there, each for different needs. Making the right choice is important for your project’s success and safety.

Different Types of Scaffolding Available, Including Rolling Scaffold Tower

There are many scaffolding types, from simple frames for low-rise projects to mast climbing scaffolds for high-rise ones. Modular scaffolding is great for projects that change height and shape. Suspended scaffolding is perfect for outdoor tasks like repairs and painting. A rolling scaffold is a versatile mobile working platform with safety features and ease of assembly.

The weight and type of work also matter. Light-duty scaffolding works for painting or plastering. Medium-duty scaffolding is for heavier tools or building materials. Heavy-duty scaffolding is for big projects that need to hold a lot of weight and workers. A rolling scaffold tower is a versatile and mobile scaffolding solution designed for safety and high performance.

Factors to Consider When Selecting

When picking 20 ft scaffolding, think about these:

The height and scope of the project

Load requirements and weight capacity

Ease of assembly and disassembly

Adaptability to confined spaces or unique configurations

Weather resistance for outdoor projects

Compliance with safety regulations and standards

“Selecting the appropriate scaffolding system is not just about efficiency; it’s about prioritizing the safety of our workers and the integrity of the structure we’re building.”

Brands like Badger Ladder have over 30 years of experience. They offer many scaffolding products for different construction needs across the country. By understanding your project needs and working with trusted providers, you can find the perfect 20 ft scaffolding for your project.

Setting Up Your 20 ft Scaffolding

Setting up a 20 ft scaffolding requires following the right steps and safety rules. A well-built scaffolding system keeps workers safe and boosts job site productivity. With careful planning and attention to detail, you can create a strong and dependable structure for your project.

Step-by-Step Assembly Instructions

First, collect all needed parts like scaffold frames, braces, castors, and more. Ensure the scaffold frames are made from high-carbon steel and virgin materials for durability and safety. Make sure the base is stable and level to hold the scaffolding, workers, and materials. Here’s how to assemble it smoothly:

Start with the base plates and adjusting screws for leveling on uneven ground.

Build the frames, making sure they’re straight and level, and spaced right for support.

Add diagonal braces and cat-a-corner braces for stability.

Put on castors for mobility and outriggers for extra stability.

Install walk boards, end panels, side panels, and toe boards for a safe platform.

Use locking pins for secure assembly if needed. When using scaffolding systems with rolling towers, follow the 3 to 1 rule for platform height.

Safety Tips for Installation

Always prioritize safety when setting up and using scaffolding. Here are key safety tips:

Make sure only qualified workers or supervised people assemble, alter, and dismantle the scaffolding.

Install guardrails on open sides of the platform where falls could be 10 ft. or more.

Use toe boards on open sides to stop tools and materials from falling.

Do daily checks to ensure the scaffolding is safe and in good condition.

Avoid unstable objects under scaffold legs and don’t overload it.

Remember, metal scaffolding conducts electricity. Avoid using it near power lines or live circuits. By following these safety tips and using the right job site safety equipment, you can ensure a safe and efficient work area.

“Safety is not just a slogan, it’s a way of life. When it comes to scaffolding, taking the time to set it up correctly and follow safety protocols can make all the difference in ensuring a successful project and protecting the well-being of your team.”

Maintenance Tips for 20 ft Scaffolding

Keeping your 20 ft scaffolding systems in good shape is key. Regular checks, fixes, and the right storage are vital. They help avoid accidents and keep your scaffolds strong.

Regular Inspections and Repairs

Bil-Jax, Inc. says scaffolding needs a daily check by someone who knows what they’re doing. This catches problems early. Look for rust, damage, or missing parts. Never use equipment that’s corroded and its strength is unknown.

“Scaffolding violations are among the most frequently cited safety issues in the construction industry according to the Occupational Safety and Health Administration (OSHA).”

Fixing scaffolds right means using approved parts and following the right steps. Don’t try to fix things with ladders or boxes. Falls are the top cause of injuries and deaths on scaffolds. So, having good guardrails and fall protection is very important.

Storing Scaffolding Properly

Storing scaffolding parts right is key to keeping them in good shape. Keep them dry and safe from the weather. When taking down scaffolds, do it carefully and don’t pile parts up messily.

Make safety a big deal by encouraging workers to speak up if they see something wrong. Regular upkeep and proper storage mean your 20 ft construction scaffolds will last longer. And your team will be safer at work.

Real-Life Applications of 20 ft Scaffolding

20 ft scaffolding is used in many areas of our lives. It offers safe and efficient access for various projects. From big construction sites to small home fixes, scaffolding is key in today’s world.

Construction Projects

The construction world relies on scaffolding for safety at high heights. 20 ft scaffolding is used in many building projects and repairs. It helps workers follow safety rules from groups like OSHA and ANSI/ASSP. Scaffolding comes in different types, from simple to complex, meeting each site’s needs.

Home Renovations

Homeowners use 20 ft scaffolding for hard-to-reach areas in renovations. It’s great for painting, roof repairs, or installing gutters. These platforms are flexible, helping homeowners overcome project challenges and achieve success.

Event Setups

At music festivals and sports events, 20 ft scaffolding is vital. It helps create amazing displays and spaces. Event planners use it for stages, lights, and seats. This setup allows for quick setup and teardown, making events run smoothly.

“Scaffolding is like a trusted friend, always there to support you as you reach new heights in your projects.”

As we explore new heights in construction, home improvement, and events, 20 ft scaffolding will be there. It provides a solid base for success and safety in many areas.

Innovations in Scaffolding Technology

The scaffolding industry has made huge strides in recent years. New materials and designs have made scaffolding systems better, safer, and more flexible. Let’s look at some key innovations that are changing scaffolding technology.

Advances in Materials and Design

One big change is the use of aluminum scaffold towers. These are strong, yet light, making them easy to move and set up. For example, Werner’s Multi-Purpose Pro Scaffold can hold 1,250 lbs and reaches over 11 ft high. It has a wide, deep work surface, making it safe and efficient for workers.

Modular scaffolding systems are also popular. They are flexible and can be customized for any project. Layher’s Allround Scaffolding is a great example, offering more strength and adaptability for complex jobs.

Smart Scaffolding Solutions

The scaffolding industry has also adopted smart technology. This includes products like the Climb-N-Go®, which makes it easy to access high platforms. It’s powered by a battery and can change height with just a button. It lasts for 4,500 feet on one charge, saving time and effort.

“The Climb-N-Go® complies with CSA S269.2-16 and OSHA standards 1926.452(W), ensuring the highest level of safety for workers on the job site.”

Also, scaffolding systems now use sensors and data analytics. This lets them monitor safety and structure in real-time. These smart systems can spot dangers like overloading and alert supervisors, preventing accidents and reducing downtime.

Inspiring Projects Completed with 20 ft Scaffolding

20 ft scaffolding systems have been key in building and restoring famous structures worldwide. They help workers reach high places safely and efficiently. This makes it possible to create amazing buildings and landmarks.

Iconic Buildings

The Burj Khalifa in Dubai is the tallest building, standing at 829 meters. Scaffolding was used to hide its height during construction. This ensured it remained the tallest building in 2010.

The Statue of Liberty also used scaffolding in 1984. A huge aluminum scaffold was built for its renovation. It cost about $2 million.

Community Projects

Scaffolding has helped restore community spaces too. Victoria Station in London was renovated for three years without closing. Custom scaffolding was built to hang over the trains.

Canterbury Cathedral in England is also being restored. The work includes fixing the nave ceiling and the Great South Window. This window is 16.76m high and 7.56m wide.

Artistic Installations

Scaffolding has also been used for artistic projects. The Eden Project in Cornwall, UK, is a great example. It used 230 miles of scaffolding for its domes, which are 55 meters and 35 meters high.

This shows how 20 ft scaffolding systems are vital. They help in creating iconic buildings, community spaces, and artistic installations.

What are the benefits of using 20 ft scaffolding?

20 ft scaffolding lets workers reach high places safely. It makes projects safer and more productive. This can save money by reducing accidents and boosting work speed.Non-Stop scaffolding helps masons work comfortably, doubling profits at a fraction of the cost of mast-climbers.

What types of 20 ft scaffolding are available?

There are many types of 20 ft scaffolding, like supported scaffolds and suspension platforms. Non-Stop offers heavy-duty and standard-duty crank-up scaffolding for different projects. The heavy-duty is great for big commercial jobs, while the standard-duty is better for smaller projects.

What safety regulations should be followed when using 20 ft scaffolding?

OSHA has strict rules for scaffolding. These include guardrails for heights over 10 feet and making sure scaffolds can hold four times their maximum load. Workers over 10 feet high need fall arrest systems or guardrails.A trained person must check the scaffold at the start of each shift. They should also inspect it again if anything changes that might weaken it.

How do I set up 20 ft scaffolding?

Setting up 20 ft scaffolding involves following assembly instructions and safety tips. Make sure the scaffold is fully decked or planked. A trained person must inspect it before each shift.Storing scaffolding properly is key to keeping it safe and lasting longer.

What are some real-life applications of 20 ft scaffolding?

20 ft scaffolding is used in many real-life situations, like construction and home renovations. Non-Stop scaffolding has been trusted by contractors for over 25 years. It’s used in famous buildings and community projects all over the world.

What innovations have been made in scaffolding technology?

Scaffolding technology has seen big improvements, like using lightweight aluminum. Smart features, like Non-Stop’s push-button lifting, make adjusting the height easier. This improves safety and efficiency on the job site.