Phone:

(+65)8319-0742

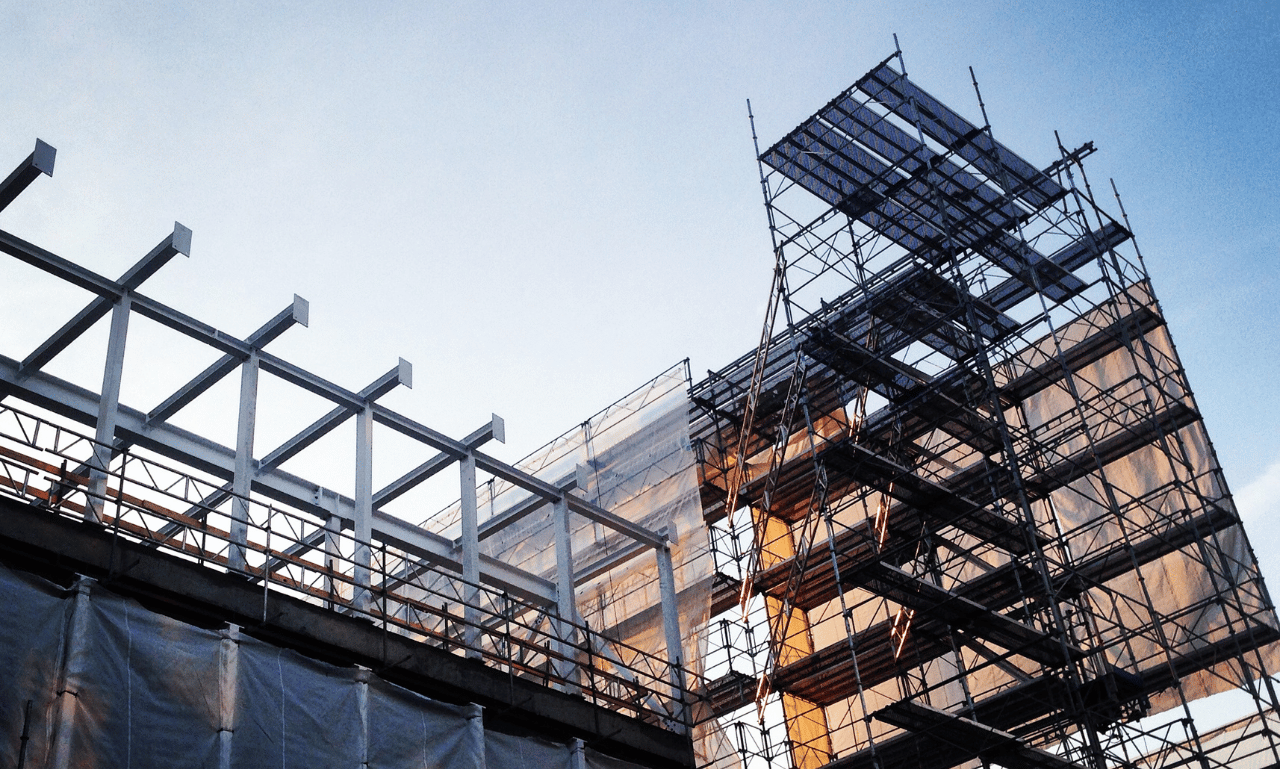

Vaulted scaffolding is an essential component of construction projects, ensuring both safety and efficiency. When it comes to scaffolding setup, it is crucial to follow OSHA-approved guidelines to minimize the risk of accidents and injuries. Interior scaffolding setups often lack proper guardrails, while exterior scaffolding setups tend to be more well-equipped. Investing in quality scaffolding systems, such as pipe scaffolds, can provide a safe and reliable solution for construction tasks.

Key Takeaways

- Vaulted scaffolding plays a vital role in construction projects, prioritizing safety and efficiency.

- Following OSHA guidelines is essential to minimize risks during scaffold setup.

- Interior scaffolding setups often lack proper guardrails, posing safety hazards.

- Exterior scaffolding setups typically have better safety features, including guardrails and walking surfaces.

- Investing in quality scaffolding systems, like pipe scaffolds, ensures reliability and safety.

Importance of Guardrails for Interior Scaffolding Setups

When it comes to interior scaffolding setups, safety should be paramount. These setups pose a significant risk if not properly constructed. One common issue with interior scaffolding is the lack of proper guardrails, which puts workers at an increased risk of falls and accidents.

According to OSHA, scaffold accidents contribute to numerous injuries and even fatalities each year. It is crucial to prioritize the implementation of robust guardrails to protect workers and prevent such incidents from occurring.

Guardrails are an essential safety feature that must be present on all types of scaffolding, including interior setups. They serve as a protective barrier, preventing workers from accidentally falling off the scaffolding platform. Guardrails should be strong, stable, and able to bear the weight of workers.

Using substantial materials such as wood or steel for guardrails is crucial to ensure their strength and durability. These materials can withstand the impact of falls and provide a reliable protective barrier.

Having properly installed guardrails not only protects workers from falls but also enhances overall work safety. It creates a secure working environment and instills confidence in the workforce.

Image: Interior scaffolding

Benefits of Guardrails for Interior Scaffolding Setups

The installation of guardrails on interior scaffolding setups offers several benefits, including:

- Preventing falls and accidents: Guardrails act as a physical barrier that prevents workers from accidentally falling off the scaffolding platform, reducing the risk of injuries and fatalities.

- Enhancing productivity: With guardrails in place, workers can focus on their tasks without worrying about their safety, leading to increased productivity and efficiency.

- Building worker confidence: Knowing that proper safety measures are in place, workers feel more secure and confident while working at heights, resulting in better job performance.

- Meeting regulatory compliance: Following OSHA guidelines and implementing guardrails on interior scaffolding setups ensures compliance with safety regulations, avoiding potential penalties and legal issues.

| Guardrails for Interior Scaffolding Setups | Benefits |

|---|---|

| Prevents falls and accidents | Reduces the risk of injuries and fatalities |

| Enhances productivity | Increases workers’ focus, leading to improved efficiency |

| Builds worker confidence | Creates a sense of security, resulting in better job performance |

| Meets regulatory compliance | Ensures adherence to safety regulations |

Advantages of Exterior Scaffolding Setups

Exterior scaffolding setups offer several advantages, making them the preferred choice for industrial projects. These setups are built to withstand long durations and provide enhanced safety features, including rigid guardrails, cross bracing, and secure walking surfaces. The prolonged presence of exterior scaffolds necessitates robust safety measures to protect workers.

Unlike larger scaffold systems commonly used for extensive construction projects, smaller setups are often improvised when working at lower heights. However, it is crucial to prioritize safety by investing in quality pipe scaffolds designed specifically for these tasks. Industrial scaffolding solutions provide a safe and versatile option, ensuring the well-being of workers and the smooth progress of the project.

Advantages of Exterior Scaffolding Setups:

- Rigid guardrails for enhanced worker safety

- Sturdy cross bracing to reinforce stability

- Secure walking surfaces for convenient maneuvering

- Safe and versatile industrial scaffolding

Through the utilization of exterior scaffolding, construction teams can carry out their work confidently, knowing they have a reliable and secure structure in place. The safety features of these setups, combined with the durability of industrial scaffolding systems, contribute to a more efficient and productive work environment.

Protecting People Below

While ensuring the safety of workers on scaffolding is paramount, it’s equally important to protect individuals below. Accidental falling objects can pose a serious risk to those working around scaffolds. Implementing toe boards or vertical boards along the edges of planks can help prevent objects from falling. Additionally, creating controlled access zones and using signage can help maintain safety protocols and ensure the protection of non-workers from potential hazards.

| Methods to Protect People Below Scaffolds | Description |

|---|---|

| Toe Boards | Placing boards perpendicular to the planks prevents objects from falling off the scaffold. |

| Vertical Boards | Installing vertical boards along the edges of the scaffold provides an additional barrier for falling objects. |

| Controlled Access Zones | Designating specific areas around the scaffold as controlled access zones restricts entry and reduces the risk of non-workers getting injured. |

| Signage | Using clear and informative signs helps communicate safety guidelines and alerts people to potential hazards. |

By implementing these safety measures, construction sites can greatly reduce the risk of objects falling from scaffolds and ensure the protection of everyone working in the vicinity.

Efficient Setup Solutions for Vaulted Scaffolding

Efficiently setting up vaulted scaffolding requires careful planning and coordination. By utilizing three-dimensional scanning and modeling, builders can determine the dimensions and design of the scaffolding system, especially in complex structures like vaulted ceilings. This advanced technology allows for precise measurements and ensures a customized fit for the construction scaffolding.

One efficient solution for vaulted scaffolding is the use of a modular facade scaffold. This type of scaffold is designed to be easily assembled and disassembled, making it ideal for vaulted structures. The modular components can be adjusted to fit the unique shape of the ceiling, providing a secure and stable platform for construction tasks.

Another aspect to consider for efficient setup is following a comprehensive safety and construction plan. This includes evaluating the specific requirements of the project, considering factors such as load capacity, height restrictions, and access points. Adhering to safety guidelines and regulations ensures the well-being of workers and the successful completion of the construction project.

Benefits of Efficient Setup Solutions for Vaulted Scaffolding:

- Saves time and reduces costs by using accurate three-dimensional scanning and modeling

- Improves productivity and efficiency with modular facade scaffolds

- Enhances worker safety by following comprehensive safety and construction plans

- Customizes scaffolding systems to fit the unique dimensions of vaulted structures

By implementing these efficient setup solutions, construction companies can minimize errors, optimize construction timelines, and ensure the seamless execution of projects involving vaulted scaffolding.

| Solution | Advantages |

|---|---|

| Three-dimensional scanning and modeling | Accurate measurements for customized scaffolding systems |

| Modular facade scaffold | Easy assembly and disassembly for vaulted structures |

| Comprehensive safety and construction plan | Ensures compliance and worker safety |

By employing efficient setup solutions, such as utilizing advanced scanning technology, incorporating modular facade scaffolds, and following comprehensive safety plans, construction companies can streamline the construction process and deliver high-quality results. These strategies not only save time and reduce costs but also prioritize worker safety in vaulted scaffolding projects.

Time-Saving Benefits of Scaffold Planning

Scaffold planning is a critical aspect of ensuring efficiency at construction sites. By utilizing Building Information Modeling (BIM) methods, construction teams can streamline and enhance the accuracy of their scaffold planning processes. This approach allows for better visualization and understanding of the project, leading to significant time savings during both the planning phase and on-site assembly.

With BIM, the entire scaffolding system can be virtually constructed, allowing builders to identify any potential clashes or design flaws ahead of time. By rectifying these issues beforehand, time-consuming reworks and potential delays can be avoided.

Another time-saving benefit of scaffold planning is effective coordination with the scaffolding provider. By engaging in open and clear communication, builders can ensure that the necessary scaffold materials and equipment are delivered just in time for assembly. This eliminates the need for excessive waiting periods or rush orders, enhancing overall project timelines and productivity.

Scaffold Planning Checklist:

- Utilize BIM methods for accurate visualization and clash detection

- Coordinate with the scaffolding provider for just-in-time material delivery

- Develop a comprehensive construction plan for efficient assembly

- Regularly review and update the scaffold plan as the project progresses

In summary, scaffold planning, supported by BIM methods and effective coordination, can bring significant time-saving benefits to construction projects. By leveraging technology and optimizing workflows, construction teams can enhance efficiency, reduce delays, and achieve project completion within the desired timeframe.

The Future of Scaffold Efficiency

The construction industry is constantly evolving, and advancements in technology are driving more efficient work processes. Digital tools and automation are revolutionizing the way scaffolding is designed and implemented. This includes the use of laser scanning, virtual modeling, and smart scaffold systems. These innovations not only improve safety but also increase productivity and reduce construction time.

Laser Scanning: Precision and Accuracy

Laser scanning technology enables the precise measurement and mapping of construction sites, allowing for accurate scaffold design and placement. By capturing detailed 3D data of existing structures, laser scanning helps designers identify potential clashes and ensure that scaffolding systems fit perfectly, minimizing rework and optimizing construction efficiency.

Virtual Modeling: Streamlined Planning

Virtual modeling software allows construction professionals to create digital representations of scaffolding systems. With virtual modeling, designers can visualize the structure in a simulated environment, identify any design flaws, and make adjustments before fabrication and installation. This streamlines the planning process and reduces errors, resulting in time savings and cost optimization.

Smart Scaffold Systems: Enhanced Safety and Productivity

Smart scaffold systems integrate sensors, connectivity, and automation to enhance safety and productivity on construction sites. These advanced systems can monitor scaffold stability, alert workers to unsafe conditions, and automate tasks such as scaffold assembly and dismantling. By automating repetitive and time-consuming processes, smart scaffold systems improve overall efficiency and reduce construction timelines.

| Advantages of Smart Scaffold Systems | Benefits |

|---|---|

| Real-time monitoring | Ensures scaffold stability and safety |

| Automated assembly and dismantling | Saves time and reduces labor costs |

| Remote accessibility | Allows for efficient management and troubleshooting |

| Data analytics | Provides insights for process improvement and optimization |

As technology continues to advance, scaffolding systems will become even more efficient, making construction sites safer and more productive. Embracing these technological advancements in scaffolding design and implementation will be key for construction companies looking to stay ahead in a highly competitive industry.

Conclusion

When it comes to construction projects, safety and efficiency are paramount. Vaulted scaffolding plays a crucial role in achieving both of these goals. By following proper safety guidelines, builders can ensure the well-being of their workers while optimizing construction timelines.

Investing in quality scaffold systems is essential for maintaining safety on the worksite. Renting reliable scaffolding equipment can provide builders with the peace of mind that their workers are using a secure and sturdy platform to perform their tasks.

Additionally, utilizing advanced planning methods, such as three-dimensional scanning and modeling, can enhance the efficiency of scaffold setup. By embracing technological advancements, the construction industry can continue to improve scaffold efficiency, resulting in increased productivity and reduced construction time.

As the future of scaffold efficiency unfolds, it is crucial to prioritize worker safety and leverage digital tools and automation to further enhance construction processes. By doing so, construction professionals can create a safer working environment, boost productivity, and maximize the overall success of their projects.

FAQ

What is vaulted scaffolding?

Vaulted scaffolding is a type of scaffolding specifically designed to be used in structures with vaulted ceilings or arches. It allows workers to safely access and work on these elevated areas during construction or maintenance projects.

Why is vaulted scaffolding important?

Vaulted scaffolding is important because it provides a safe and efficient solution for working at height in structures with vaulted ceilings. It ensures the safety of workers and allows for easier access to these hard-to-reach areas, increasing productivity and reducing the risk of accidents.

How can I rent vaulted scaffolding?

To rent vaulted scaffolding, you can contact a reputable scaffold rental company that specializes in providing scaffolding systems for various construction needs. They will assess your project requirements and recommend the appropriate vaulted scaffolding solution for your specific needs.

Why are guardrails important for interior scaffolding setups?

Guardrails are important for interior scaffolding setups because they provide a vital safety measure by preventing workers from falling off the scaffolding. They should be strong, able to bear the weight of workers, and properly installed to ensure maximum safety.

What are the advantages of exterior scaffolding setups?

Exterior scaffolding setups have several advantages. They generally have better safety features, including rigid guardrails, cross bracing, and walking surfaces, making them safer for workers. Additionally, exterior scaffolding setups can be used for longer durations, providing stability and access to higher areas of a building.

How can I protect people below when using elevated work platforms?

To protect people below when using elevated work platforms, it is important to implement measures such as toe boards or vertical boards along the edges of planks. These prevent objects from accidentally falling and posing a hazard to individuals working or passing by below the scaffolding. Controlled access zones and signage can also help maintain safety protocols.

What are some efficient setup solutions for vaulted scaffolding?

Efficient setup solutions for vaulted scaffolding include utilizing three-dimensional scanning and modeling to determine the dimensions and design of the scaffolding system. For complex structures, such as vaulted ceilings, modular facade scaffolds can simplify the assembly process and improve efficiency.

How can scaffold planning save time?

Scaffold planning, especially when using Building Information Modeling (BIM) methods, streamlines and accurately determines the requirements for scaffolding at a construction site. This allows for time savings during the planning process and on-site assembly. Effective coordination with the scaffolding provider and just-in-time material delivery further optimize the construction timeline.

What does the future hold for scaffold efficiency?

The future of scaffold efficiency lies in embracing technological advancements. This includes the use of laser scanning, virtual modeling, and smart scaffold systems. These innovations improve safety, increase productivity, and reduce construction time, enhancing the overall efficiency of scaffolding operations.