Phone:

(+65)8319-0742

Tube end caps are essential for ensuring secure sealing and protection of various types of tubing. They serve a dual purpose by safeguarding the product during shipping, storage, and finishing, while also functioning as masking caps to prevent contamination or material build-up. There are different types of end caps available, including threaded and non-threaded designs, tapered fits, and various materials such as plastic and metal. These cost-effective components are easy to install and remove, providing pipe end and thread protection. They are suitable for a wide range of applications, from furniture finishing to sealing, masking, and powder coating.

Key Takeaways:

- Tube end caps ensure secure sealing and protection of tubing

- They serve as masking caps to prevent contamination or material build-up

- Available in different types, including threaded and non-threaded designs

- Come in various materials such as plastic and metal

- Cost-effective and easy to install and remove

Types of Tube End Caps

When it comes to tube end caps, there are various types available to meet specific needs and ensure secure sealing for different tubing applications. Let’s explore some of the most common types:

1. Round Tube End Caps

Round tube end caps are widely used for tubing applications and come in different styles, providing flexibility in sealing options. Some common styles include:

- Screw-in caps: These caps feature threads that securely screw into the end of the tube, offering a tight seal.

- Push-on caps: These caps are designed to be pushed onto the end of the tube, providing a secure fit without the need for threading.

2. Square Tube End Caps

Square tube end caps are specifically designed for square tubing, ensuring a secure seal and protection. They are available in various styles:

- Tapered ribs: These end caps feature tapered ribs that provide added layers of security and a snug fit on the edges of the square tubing.

- Plastic extension: Some square end caps have a plastic extension that fits over the square tubing shape, providing a secure seal and protection.

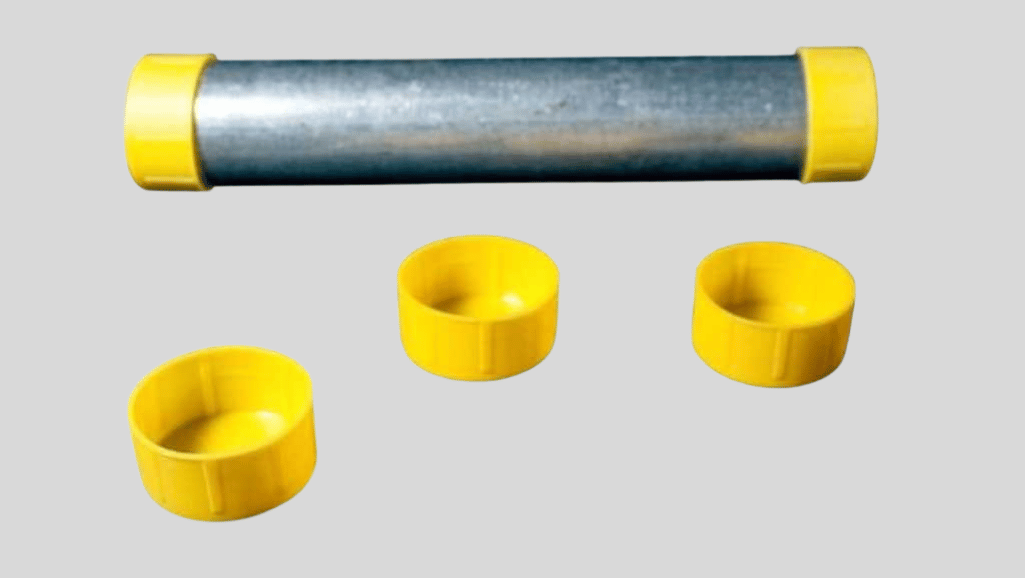

3. Long Plastic End Caps

Long plastic end caps offer extended coverage for tube ends, preventing corrosion and the buildup of dirt or moisture. They are ideal for applications that require extra protection and corrosion resistance.

4. Tapered End Caps

Tapered end caps serve a dual purpose as both plugs and caps. They are designed with a stopper that prevents them from falling into the tube, making removal easy when needed.

These are just a few examples of the different types of tube end caps available in the market. Each type serves a specific purpose and offers unique features to cater to different application requirements.

Benefits of Using Tube End Caps

Using tube end caps offers several benefits in various applications. These cost-effective components are designed for push-fit purposes, providing reliable pipe end and thread protection. With a wide range of materials and styles available, tube end caps are suitable for a wide range of applications such as furniture finishing, sealing, masking, and powder coating.

- Cost-Effective: Tube end caps are cost-effective options for projects, making them a budget-friendly choice.

- Long-Term Lifespan: These mass-produced components have a long-term lifespan. They ensure durability and longevity, providing reliable protection for your tubing.

- Versatile Applications: Tube end caps can be used in a wide range of applications, from furniture finishing to sealing, masking, and powder coating. They offer flexibility and versatility for different project needs.

Tube end caps are not only affordable but also provide long-term protection for your pipes and threads. Their easy installation and removal process make them a convenient choice for various industries.

Whether you need to protect the end of a pipe during transportation or prevent contamination or material build-up, tube end caps ensure a secure seal. Their high-quality construction ensures that your tubes are safeguarded and ready for any application.

Choosing the Right Tube End Cap

When it comes to selecting the perfect tube end cap for your specific needs, it’s crucial to consider all the relevant factors and requirements of your application. From thread styles to industry standards, finding the right tube end cap ensures a secure and effective sealing solution.

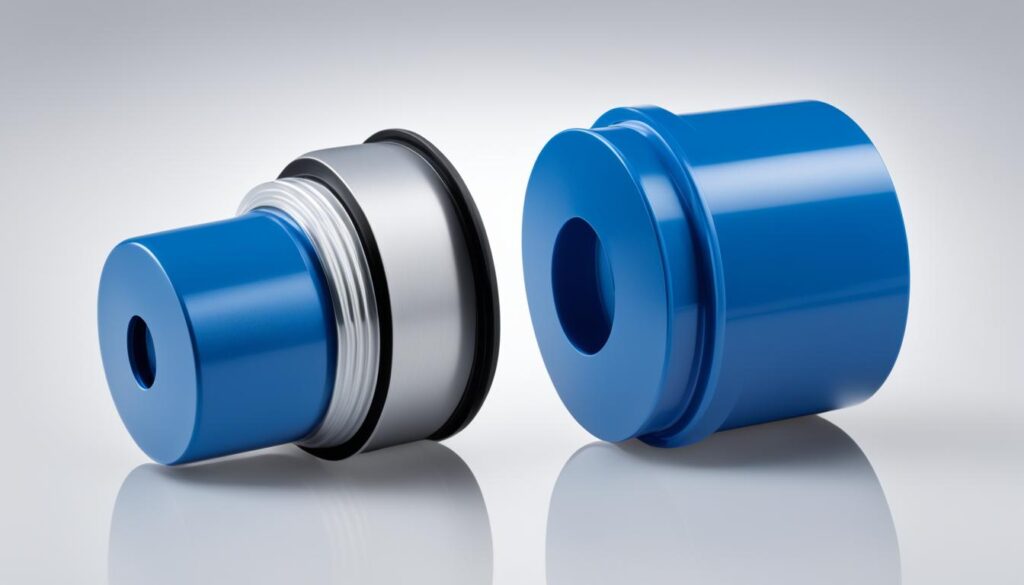

Thread Styles

Thread styles play a significant role in ensuring a proper fit for your tube end cap. Various styles, such as JIC (Joint Industry Council) and UNF (Unified National Fine), are available to match different thread types and sizes. By selecting the appropriate thread style, you can achieve a tight and secure seal that meets your specific needs.

Industry Standards

Industry standards provide a framework for ensuring compatibility and functionality across different applications. When choosing a tube end cap, it’s essential to consider the relevant standards such as ANSI (American National Standards Institute), DIN (Deutsches Institut für Normung), and SAE (Society of Automotive Engineers). These standards define key parameters and specifications that contribute to the overall performance and reliability of tube end caps.

Application Requirements

Your application requirements are a critical factor in choosing the right tube end cap. Consider the specific needs of your project, whether it’s furniture finishing, sealing, masking, or powder coating. By understanding your application requirements, you can select a tube end cap that is designed to meet your unique needs and provide optimal performance and sealing capabilities.

By carefully considering thread styles, industry standards, and application requirements, you can confidently choose the right tube end cap for your project. Whether you need ANSI-compliant caps for industrial applications or DIN-certified caps for international projects, there is a tube end cap available to meet your specific needs.

| Thread Styles | Industry Standards | Application Requirements |

|---|---|---|

| JIC | ANSI | Furniture finishing |

| UNF | DIN | Sealing |

| SAE | Masking | |

| Powder coating |

Ultimate Guide to Tube End Caps

To gain further knowledge about tube end caps, you can refer to the ultimate guide to caps and plugs. This guide provides comprehensive information about different types of caps and plugs, including tube end caps. Additionally, there is a specific guide dedicated to plastic end caps, offering detailed insights into their uses and benefits. For those interested in thread protection, there is a guide specifically focused on thread protection caps and plugs. These resources serve as valuable references when selecting the right tube end caps for various applications.

Round Tube End Caps

Round tube end caps are essential components used in various tubing applications. They provide a reliable seal and protection for round tubing, ensuring its integrity during shipping, storage, and finishing processes. These end caps are versatile and widely available, making them a popular choice for many industries.

There are different styles of round tube end caps to suit different needs. Screw-in caps feature threading that allows them to securely seal the pipe by twisting them into place. This design ensures a tight and secure fit, providing excellent protection for the tubing. On the other hand, push-on caps are designed to cover the end of the pipe by simply pushing them until they are secure. This style offers convenience and ease of use, making it a preferred option for quick applications.

Round tube end caps are widely used in a variety of industries and applications. They are commonly used in furniture manufacturing to provide a clean and finished look to tubular structures. Additionally, they are frequently utilized in various sealing, masking, and powder coating processes where the secure sealing of round tubing is crucial.

Whether you require screw-in caps for a secure and threaded fit or push-on caps for convenience, there is a round tube end cap suitable for your specific needs. These versatile components offer reliable sealing and protection for round tubing, ensuring its longevity and performance in a wide range of applications.

Square Tube End Caps

Square tube end caps are essential for finishing work on square tubing, ensuring the longevity and reliability of the structure. These specific end caps are designed to fit square tubing perfectly, providing added layers of security and protection.

One type of square tube end cap features tapered ribs, which create a tight seal at the end of the pipe, preventing any potential leakage or damage. The tapered design ensures a secure fit and enhances the overall structural integrity of the square tubing.

Another type of square tube end cap utilizes a plastic extension that fits precisely over the shape of the tubing, offering an extra layer of protection against external elements such as dirt, moisture, and corrosion. This plastic extension not only safeguards the tubing but also provides a seamless and aesthetically pleasing finish.

These square tube end caps are widely used in various applications, including fencing, furniture, and other construction needs. Whether you are working on a DIY project or a large-scale construction, using square tube end caps is crucial for maintaining the durability and reliability of square tubing.

Advantages of Square Tube End Caps

- Enhanced Security: Square tube end caps with tapered ribs or plastic extensions offer increased protection and minimize the risk of leaks or damage.

- Long-lasting Protection: These end caps ensure the longevity and structural integrity of square tubing, making them suitable for both indoor and outdoor applications.

- Professional Finishing: Square tube end caps provide a seamless and clean finish to square tubing, enhancing its overall appearance.

- Versatile Applications: Square tube end caps are ideal for a wide range of projects, including fencing, furniture, and other construction needs.

- Easy Installation: These end caps are easy to install and remove, allowing for convenient maintenance and replacement.

Conclusion

Tube end caps are essential components that play a crucial role in achieving secure sealing and protection for various types of tubing. Whether you are working with round, square, or rectangular tubing, there are specific end caps available to meet your unique needs. These versatile components are widely used in industries such as construction, furniture, and manufacturing, offering a wide range of applications.

By choosing the right tube end caps, you can ensure the longevity and reliability of your tubing applications. These cost-effective components are not only easy to install and remove but also provide reliable pipe end and thread protection. With a wide variety of materials, styles, and sizes available, there is a tube end cap suitable for every application.

Whether you need secure sealing, protection, or a combination of both, tube end caps are the ideal solution. Their versatile nature allows them to be used in various industries and applications, making them an indispensable component. So, when it comes to protecting your tubing and ensuring its functionality, don’t compromise â choose tube end caps for a secure and reliable solution.

FAQ

What are tube end caps?

Tube end caps are components used for secure sealing and protection of various types of tubing. They serve to safeguard the product during shipping, storage, and finishing, while also preventing contamination or material build-up.

What types of tube end caps are available?

There are different types of tube end caps, including round tube caps, square tube end caps, and rectangular tube end caps. They are available in various styles, such as screw-in caps and push-on caps, to meet specific application needs.

What are the benefits of using tube end caps?

Tube end caps provide pipe end and thread protection and are cost-effective components. They have a long lifespan and are suitable for a wide range of applications, including furniture finishing, sealing, masking, and powder coating.

How do I choose the right tube end cap?

When choosing a tube end cap, consider specific requirements such as thread styles (JIC, UNF), standards (ANSI, DIN, SAE), and the application’s needs. There is a tube end cap designed to meet different application requirements.

Where can I find more information about tube end caps?

You can refer to the ultimate guide to caps and plugs, which provides comprehensive information about different types of caps and plugs, including tube end caps. There are also specific guides dedicated to plastic end caps and thread protection caps and plugs.

What are round tube end caps?

Round tube end caps are commonly used in tubing applications and come in various styles, including screw-in caps and push-on caps. They are versatile and widely available, ensuring secure sealing and protection of round tubing.

What are square tube end caps?

Square tube end caps are designed specifically for finishing work on square tubing. They provide a secure seal with tapered ribs or a plastic extension that fits perfectly over the tubing shape, maintaining the durability and reliability of square tubing.