Phone:

(+65)8319-0742

Welcome to our comprehensive guide on Tube and Coupler Scaffold systems, your go-to solution for all your scaffolding needs. Whether you’re working on a small-scale construction project or a large-scale development, these versatile scaffolding systems provide the support and flexibility required for safe and efficient work. Designed to meet the highest industry standards, Tube and Coupler Scaffolds offer a range of benefits that make them an ideal choice for both contractors and construction professionals.

Throughout this article, we will delve into the various components, advantages, and proper usage of Tube and Coupler Scaffold systems. We will also provide essential guidelines for assembly, safety, maintenance, and troubleshooting. By the end of this guide, you will have a solid understanding of how to select, assemble, and maintain a Tube and Coupler Scaffold system while ensuring the utmost safety for your workers.

Key Takeaways:

- Tube and Coupler Scaffold systems provide versatile solutions for construction projects of all scales.

- Understanding the components and proper usage of a Tube and Coupler Scaffold is crucial for constructing a stable and secure scaffolding system.

- The advantages of using Tube and Coupler Scaffold systems include durability, adaptability, ease of assembly, and increased efficiency.

- When choosing a Tube and Coupler Scaffold system, consider your project requirements and explore different variations available.

- Follow the recommended assembly and safety guidelines to ensure the proper usage and protection of workers.

Understanding Tube and Coupler Scaffold Components

When it comes to constructing a stable and secure scaffolding system, it’s essential to have a deep understanding of the key components of a Tube and Coupler Scaffold. These components include Scaffold Tubes, Scaffold Couplers, Tube and Clamp Scaffold, and Scaffold Fittings.

Scaffold Tubes

Scaffold Tubes are the structural elements that form the main framework of the scaffold. These tubes are typically made of steel, providing strength and durability to the system. Scaffold Tubes come in various lengths, ranging from 1.5 meters to 6 meters, allowing for flexible configurations to suit different project requirements.

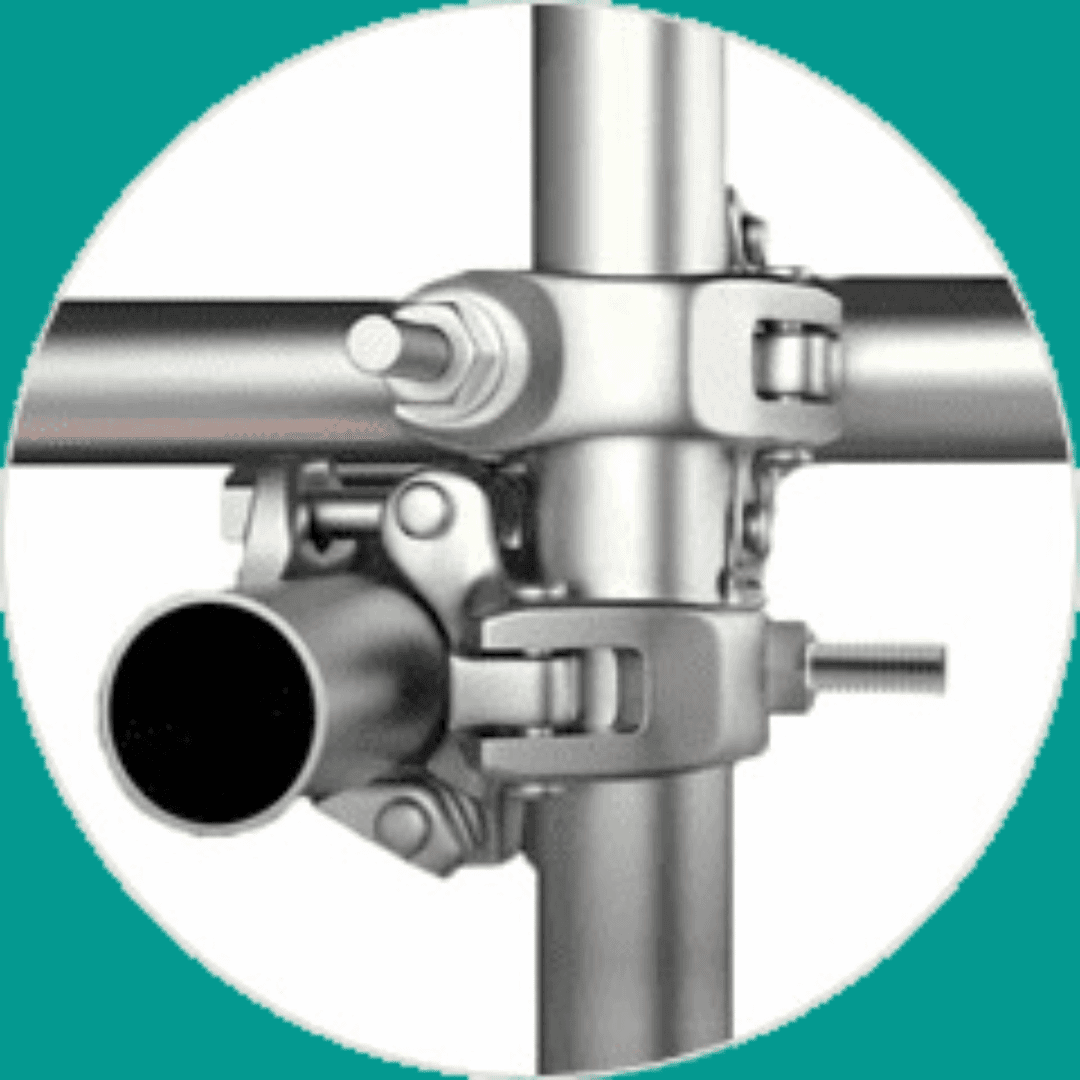

Scaffold Couplers

Scaffold Couplers are the connecting pieces that fasten the Scaffold Tubes together, ensuring a secure and rigid structure. There are several types of Scaffold Couplers, including swivel couplers, right-angle couplers, and putlog couplers, each designed for specific connection needs. These couplers provide versatility, allowing for different angles and connections, enabling the scaffold to adapt to various project requirements.

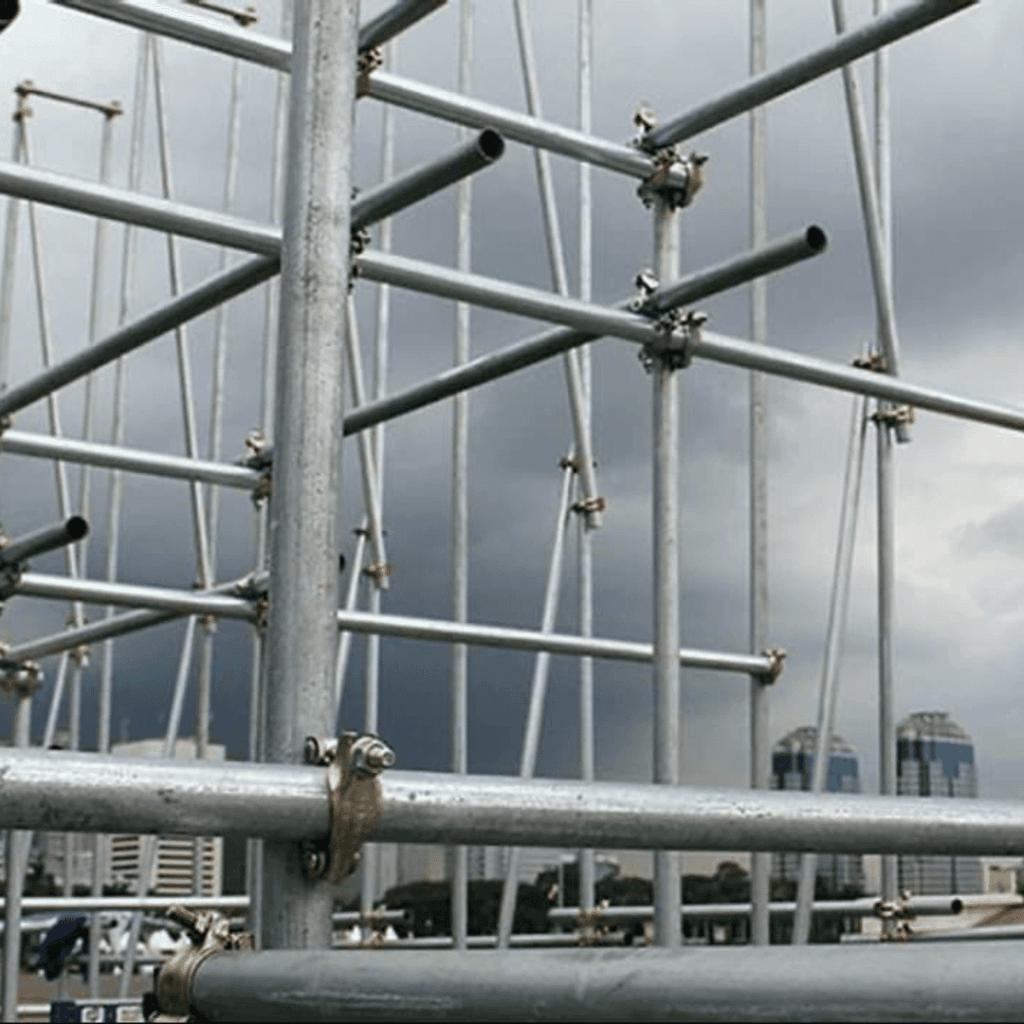

Tube and Clamp Scaffold

Tube and Clamp Scaffold is a versatile system that utilizes Scaffold Tubes and Couplers to create a robust scaffolding framework. This system allows for high flexibility, as scaffolders can assemble and adapt the structure to fit the unique needs of the project. Tube and Clamp Scaffold is widely used in construction and maintenance projects that require customizable and adaptable scaffolding solutions.

Scaffold Fittings

Scaffold Fittings are the various accessories and components that complement the Tube and Coupler Scaffold system. These fittings include base plates, adjustable legs, guardrails, stairs, and other safety features that enhance the functionality and safety of the scaffold. Scaffold Fittings are designed to provide stability, secure attachment points, and safe working platforms for workers.

In summary, understanding the function and proper usage of Scaffold Tubes, Scaffold Couplers, Tube and Clamp Scaffold, and Scaffold Fittings is crucial in constructing a stable and secure Tube and Coupler Scaffold system. By utilizing these components effectively, construction professionals can create a scaffolding system that meets the specific needs of their projects, ensuring safety and efficiency.

Advantages of Tube and Coupler Scaffold Systems

When it comes to construction projects, having a reliable and efficient scaffolding system is crucial. Tube and Coupler Scaffold systems offer a wide range of advantages that make them the preferred choice for many contractors. Let’s explore the key benefits of using these systems:

Durability and Strength

Tube and Coupler Scaffold systems are known for their exceptional durability and strength. The scaffold tubes, couplers, and fittings are made from high-quality materials that can withstand heavy loads and harsh weather conditions. This ensures the safety and stability of the scaffolding structure, allowing workers to perform their tasks with confidence.

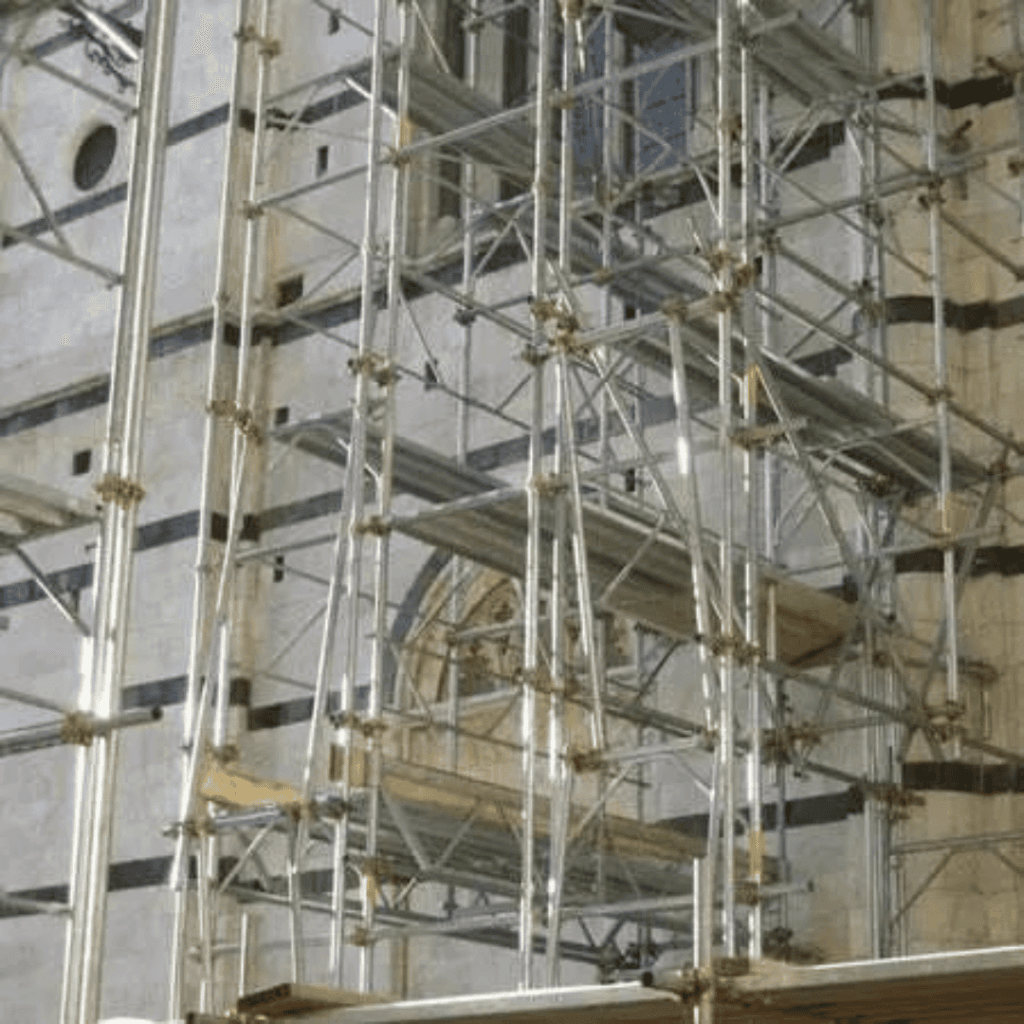

Adaptability and Flexibility

One of the biggest advantages of Tube and Coupler Scaffold systems is their adaptability. These systems can be easily modified and adjusted to fit the specific requirements of different construction projects. Whether it’s a small-scale renovation or a large-scale construction site, Tube and Coupler Scaffold systems can be tailored to meet the unique needs of each project.

Easy Assembly and Dismantling

Another significant advantage of Tube and Coupler Scaffold systems is their ease of assembly and dismantling. The components of these systems can be quickly and securely connected using couplers, eliminating the need for complex tools or specialized training. This not only saves time and labor but also reduces the risk of errors during the construction process.

Enhanced Safety Measures

Construction sites are inherently risky environments, and ensuring the safety of workers is of paramount importance. Tube and Coupler Scaffold systems provide enhanced safety measures to protect workers at height. With proper installation and adherence to safety guidelines, these systems offer a stable and secure platform for workers to perform their tasks safely and efficiently.

Furthermore, Tube and Coupler Scaffold systems are designed to provide easy access and maneuverability, reducing the risk of accidents and injuries associated with working at height. The versatility of these systems allows for the safe navigation of complex architectural structures and irregular building shapes.

Overall, Tube and Coupler Scaffold systems offer construction professionals a reliable and effective solution for their scaffolding needs. From their durability and adaptability to their ease of assembly and enhanced safety measures, these systems provide numerous advantages that contribute to increased efficiency and safety on construction sites.

The table below summarizes the main advantages of Tube and Coupler Scaffold systems:

| Advantages | Description |

|---|---|

| Durability and Strength | High-quality materials ensure the scaffold’s stability and support heavy loads. |

| Adaptability and Flexibility | Can be easily modified to fit the requirements of different construction projects. |

| Easy Assembly and Dismantling | Components can be quickly and securely connected, saving time and labor. |

| Enhanced Safety Measures | Provides a stable and secure platform for safe work at height. |

Choosing the Right Tube and Coupler Scaffold for Your Project

When it comes to selecting a Tube and Coupler Scaffold system for your construction project, it’s essential to consider several factors. By understanding your project requirements and exploring different variations of tube and coupler systems, you can make an informed decision that ensures efficiency and safety on the job site.

Here are some key points to consider:

1. Project Scope and Scale

Consider the size and complexity of your project. Does it involve multiple levels or require customized scaffold configurations? Understanding the scope and scale of your project will help determine the type and quantity of scaffold components you’ll need.

2. Load Capacity and Durability

Assess the weight-bearing requirements of your project. Different tube and coupler systems have varying load capacities, so it’s crucial to choose a system that can safely support the expected loads. Additionally, consider the durability of the scaffold components to ensure they can withstand the demands of your project.

3. Flexibility and Adaptability

Flexibility is key in scaffolding systems, especially when working on complex structures or projects with changing requirements. Look for tube and coupler systems that offer versatility and easy adaptability, allowing you to modify or expand the scaffold as needed.

4. Compatibility with Existing Components

If you already have some scaffold components from previous projects, it’s important to choose a tube and coupler system that is compatible with the existing components. This will save you time and costs by avoiding the need to replace or supplement your inventory.

5. Safety Features

Prioritize the safety of your workers by selecting tube and coupler systems that come with built-in safety features. Look for systems that provide secure connections, anti-slip surfaces, and easy-to-use locking mechanisms to minimize the risk of accidents and ensure a safe working environment.

By considering these factors and consulting with scaffold experts, you can choose the right tube and coupler system that meets your project requirements. This will not only help you achieve optimal productivity and efficiency but also ensure the safety of your workers throughout the construction process.

| Factors to Consider | Tubular Scaffold System A | Tubular Scaffold System B | Tubular Scaffold System C |

|---|---|---|---|

| Project Scope and Scale | â | â | |

| Load Capacity and Durability | â | â | â |

| Flexibility and Adaptability | â | â | |

| Compatibility with Existing Components | â | ||

| Safety Features | â | â | â |

Assembly and Safety Guidelines for Tube and Coupler Scaffold

When it comes to Tube and Coupler Scaffold systems, proper assembly and adherence to safety guidelines are paramount for a secure and efficient work environment. By following these guidelines and implementing necessary safety measures, you can protect your workers and ensure regulatory compliance throughout your construction project.

Erecting the Scaffold

The first step in assembling a Tube and Coupler Scaffold is to carefully lay out the foundation and determine the proper placement of scaffold tubes and couplers. Ensure that the scaffold is sturdy and level before proceeding with the construction process. Pay special attention to weight limits and load capacities to prevent overloading the scaffold system.

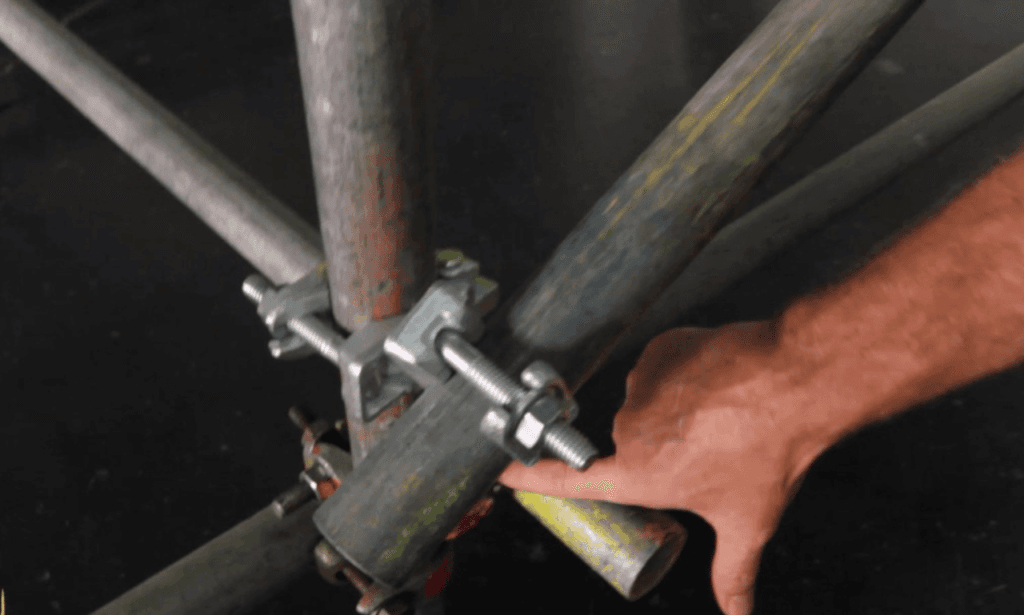

Securing Scaffold Tubes

In order to maintain stability and structural integrity, scaffold tubes must be securely connected using scaffold couplers. Make sure to use the appropriate couplers that are compatible with the size and type of scaffold tubes being used. Regularly inspect the connections to ensure they are tight and free from any signs of wear or damage.

Implementing Safety Measures

Safety should always be a top priority when working with Tube and Coupler Scaffold systems. Some essential safety measures include:

- Providing adequate personal protective equipment (PPE) such as hard hats, safety harnesses, and non-slip footwear.

- Installing guardrails, toe boards, and midrails to prevent falls and ensure worker safety at heights.

- Regularly inspecting the scaffold system for any signs of damage or instability and taking necessary corrective actions.

- Implementing proper communication channels and establishing a clear chain of command to ensure effective coordination and response in case of emergencies.

Training and Certification

It is crucial to provide comprehensive training to all workers involved in the assembly, usage, and dismantling of Tube and Coupler Scaffold systems. They should be educated on safety protocols, equipment handling procedures, and the correct use of scaffold fittings. Workers should also undergo appropriate certification programs to ensure they have the necessary skills and knowledge to work safely with the scaffolding system.

By following these assembly and safety guidelines for Tube and Coupler Scaffold systems, you can create a secure and reliable scaffolding structure for your construction project. Prioritizing safety and ensuring proper assembly will not only protect your workers but also contribute to increased productivity and successful project outcomes.

Scaffold Assembly and Safety Guidelines

| Guidelines | Key Points |

|---|---|

| 1. Erecting the Scaffold |

|

| 2. Securing Scaffold Tubes |

|

| 3. Implementing Safety Measures |

|

| 4. Training and Certification |

|

Maintaining and Inspecting Tube and Coupler Scaffold Systems

Maintenance and regular inspection are vital for ensuring the longevity and safety of your Tube and Coupler Scaffold systems. By implementing effective maintenance practices and conducting routine inspections, you can identify and address any issues promptly, preventing potential accidents and delays in your construction projects.

1. Establishing a Maintenance Schedule

Creating a maintenance schedule will help you stay organized and ensure that all necessary maintenance tasks are carried out regularly. It is recommended to consult the manufacturer’s guidelines for specific maintenance requirements. However, some general maintenance practices for Tube and Coupler Scaffold systems include:

- Inspecting scaffold tubes, couplers, and fittings for signs of damage, such as cracks, bends, or missing components.

- Cleaning scaffold components to remove dirt, debris, and any corrosive substances.

- Applying protective coatings or lubricants to prevent rust and enhance the durability of the scaffold components.

- Tightening any loose connections or fasteners to ensure stability.

By following a comprehensive maintenance routine, you can extend the lifespan of your scaffold system and maintain its structural integrity.

2. Performing Routine Inspections

Regular inspections are crucial for identifying any potential safety hazards and addressing them before they escalate into more significant problems. When conducting inspections of your Tube and Coupler Scaffold system, pay close attention to the following areas:

- Scaffold tubes: Check for signs of bending, deformations, or corrosion that may compromise the strength of the tubes.

- Couplers and fittings: Inspect these components for any damage, including cracks, breaks, or excessive wear.

- Connections: Ensure that all connections are secure and that there are no loose or missing bolts, pins, or wedges.

- Baseplates and leveling: Verify that the baseplates are stable and properly leveled to ensure a secure foundation for the scaffold.

It is advisable to record your inspection findings in a logbook and address any identified issues promptly to maintain the safety of your scaffolding system.

3. Training and Awareness

Proper training plays a crucial role in ensuring the effectiveness of your Tube and Coupler Scaffold maintenance and inspection efforts. Train your team members on how to recognize signs of damage, perform routine maintenance tasks, and conduct thorough inspections.

In addition to training, it is important to raise awareness among your workers about the importance of maintenance and inspections. Encourage them to report any observed issues promptly and provide a clear communication channel for such reports.

4. Expert Assistance

If you encounter any complex maintenance or inspection issues with your Tube and Coupler Scaffold system, do not hesitate to seek expert assistance. Engaging the services of a qualified scaffolding professional will ensure that all necessary repairs or modifications are conducted safely and accurately.

Remember, regular maintenance and inspections are essential for the safety of your workers and the integrity of your construction projects. By following these practices and guidelines, you can ensure that your Tube and Coupler Scaffold system remains in optimal condition throughout its lifespan.

Troubleshooting Common Issues with Tube and Coupler Scaffold

While Tube and Coupler Scaffold systems are known for their reliability and versatility, occasional issues may arise during their use. This section aims to address common problems that you might encounter and provide troubleshooting tips to help you minimize disruptions and maintain productivity.

Problem 1: Unstable Scaffold Structure

One of the most common issues with Tube and Coupler Scaffold systems is an unstable structure. This can occur due to improper assembly or insufficient bracing. To troubleshoot this problem:

- Double-check the assembly instructions to ensure all components are properly connected.

- Inspect the connections between scaffold tubes and couplers for any signs of damage or looseness.

- Add additional diagonal braces or ties to increase stability if necessary.

Problem 2: Uneven or Unequal Platform Leveling

Uneven or unequal platform leveling can create safety hazards and affect the efficiency of work. If you encounter this issue:

- Inspect the scaffold platform for any unevenness or sagging.

- Adjust the height of individual scaffold legs using adjustable base plates or screw jacks.

- Ensure the couplers connecting the scaffold platform are tightly secured and aligned.

Problem 3: Insufficient Fall Protection

Ensuring proper fall protection is crucial for the safety of workers on Tube and Coupler Scaffold systems. If you find that fall protection is inadequate:

- Verify that guardrails, mid-rails, and toe-boards are installed at the required height and securely fastened.

- Inspect the quality and integrity of safety netting or personal fall arrest systems.

- Train workers on the correct use of fall protection equipment and reinforce adherence to safety protocols.

Problem 4: Corrosion and Rust

Corrosion and rust can weaken the structural integrity of scaffold components, compromising safety. If you notice signs of corrosion:

- Regularly inspect scaffold tubes, couplers, and fittings for rust or deterioration.

- Remove any loose rust or debris and apply anti-corrosion coatings or paint as necessary.

- Replace heavily corroded or damaged components to ensure the strength and stability of the scaffold system.

By addressing these common issues promptly, you can maintain the functionality and safety of your Tube and Coupler Scaffold system, ensuring efficient and successful construction projects.

Conclusion

In conclusion, Tube and Coupler Scaffold systems are the go-to solution for construction projects of all sizes. With their versatile components and ease of assembly, these scaffolding systems provide the necessary support and flexibility for safe and efficient work.

By understanding the key components, such as scaffold tubes, couplers, and fittings, you can construct a stable and secure scaffolding system that meets your project requirements. The durability, adaptability, and ease of assembly and dismantling offered by Tube and Coupler Scaffold systems contribute to increased efficiency and safety on the job site.

Furthermore, proper assembly and adherence to safety guidelines are crucial for the successful use of Tube and Coupler Scaffold systems. By implementing the recommended practices and regularly inspecting and maintaining your scaffolding system, you can ensure its longevity and the well-being of your workers.

With Tube and Coupler Scaffold systems, you can overcome common issues and troubleshoot any challenges that may arise during construction projects. By following the guidelines and tips provided in this article, you can minimize disruptions and maintain productivity throughout the duration of your project.

FAQ

What is Tube and Coupler Scaffold?

Tube and Coupler Scaffold is a versatile scaffolding system commonly used in construction projects. It consists of scaffold tubes and couplers that are interconnected to create a stable and secure working platform.

What are the main components of a Tube and Coupler Scaffold?

The main components of a Tube and Coupler Scaffold are scaffold tubes, couplers, and fittings. Scaffold tubes provide the structure, while couplers and fittings secure the tubes together.

What are the advantages of using Tube and Coupler Scaffold systems?

Tube and Coupler Scaffold systems offer several advantages, including durability, adaptability to different structures, ease of assembly and dismantling, and the ability to create custom configurations to suit specific project requirements.

How do I choose the right Tube and Coupler Scaffold for my project?

When selecting a Tube and Coupler Scaffold system, consider factors such as the project requirements, load capacity, height, and terrain. It’s essential to choose a system that meets safety standards and regulations.

What are the assembly and safety guidelines for Tube and Coupler Scaffold?

Proper assembly and adherence to safety guidelines are crucial when using Tube and Coupler Scaffold systems. Follow manufacturer instructions, ensure stability by bracing the scaffold, secure all connections with couplers, and implement necessary safety measures such as guardrails and fall protection.

How should I maintain and inspect Tube and Coupler Scaffold systems?

Regular maintenance and inspections are important for the longevity and safety of Tube and Coupler Scaffold systems. Perform routine checks for wear and tear, clean and lubricate components as needed, and conduct thorough inspections to identify any potential issues.

What are some common issues with Tube and Coupler Scaffold systems, and how can I troubleshoot them?

Common issues with Tube and Coupler Scaffold systems include instability, missing or damaged components, and misalignment. To troubleshoot these problems, ensure proper bracing and securing of all connections, replace any damaged components, and realign the scaffold if necessary.

In conclusion, what are the advantages of using Tube and Coupler Scaffold systems?

Tube and Coupler Scaffold systems offer versatility, durability, and ease of use. By understanding the components, assembly guidelines, and maintenance practices, you can maximize the efficiency, safety, and longevity of your scaffolding system.