Phone:

(+65)8319-0742

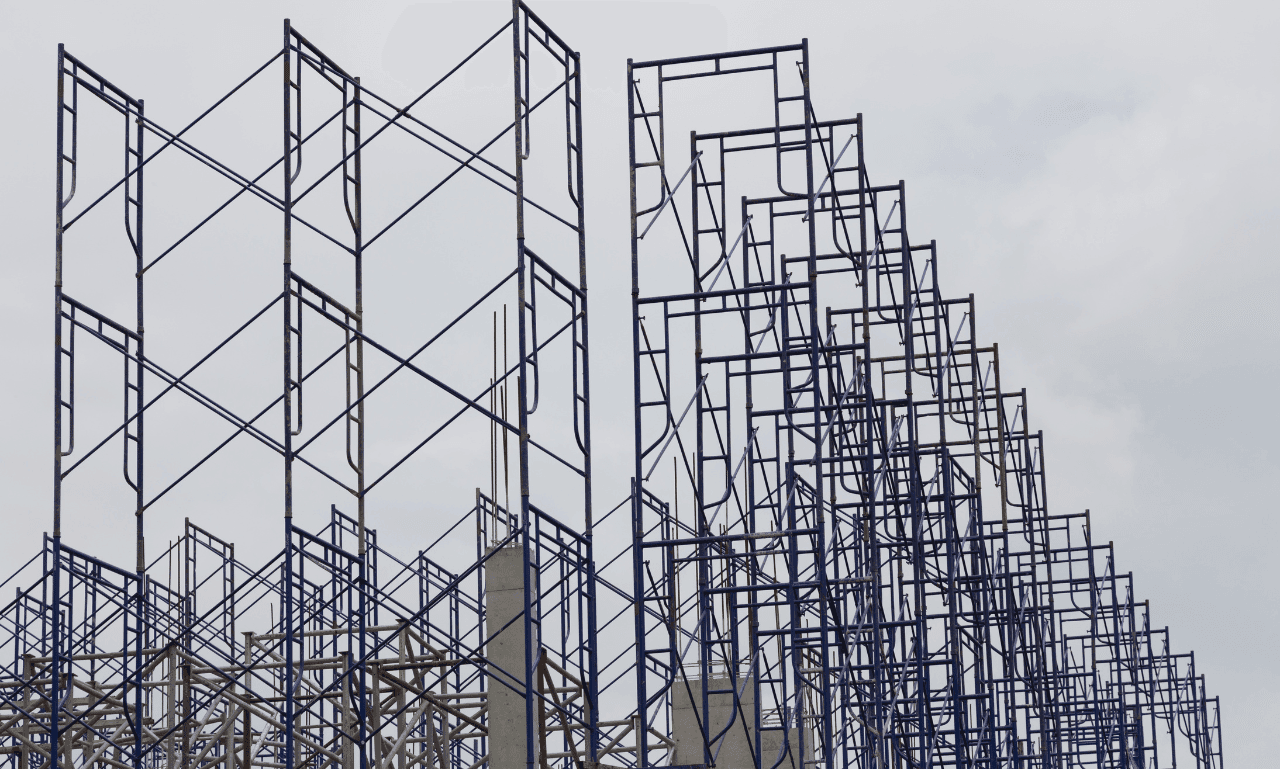

Welcome to our comprehensive guide on slung scaffolding, one of the essential scaffolding systems used in construction, maintenance, and various industries. In this article, we will explore the uses, types, safety practices, and benefits of slung scaffolding.

Key Takeaways:

- Slung scaffolding is a temporary platform used in construction, maintenance, and repair activities.

- It offers access flexibility, space-saving benefits, and efficient installation.

- Understanding the different types of scaffolding systems is crucial for choosing the right one for specific projects.

- In offshore environments, specific guidelines and regulations apply to scaffolding, including the use of guardrails, couplers, and fire retardant materials.

- Safety practices are essential for ensuring the well-being of workers and the success of scaffold solutions.

Types of Scaffolding

Slung scaffolding is just one type of scaffolding system. In addition to slung scaffolding, there are various other types that serve different purposes and have unique features. It is important to be familiar with these different types to determine which one is suitable for a specific construction or maintenance project.

1. Putlog Scaffold

The Putlog scaffold, also known as the bricklayer’s scaffold, is commonly used in masonry construction. It consists of a series of vertical standards connected by transverse ledgers, known as putlogs, which are placed in the wall openings to provide support.

2. Independent Tied Scaffold

The independent tied scaffold is a freestanding structure that doesn’t rely on the support of the building being worked on. It is secured to the structure using ties or braces to provide stability. This type of scaffold is often used in situations where the main building cannot support the weight of the scaffold.

3. Working Platform

A working platform scaffold is a simple configuration that provides a platform for workers to carry out tasks at various heights. It typically consists of a single level platform supported by adjustable legs or outriggers.

4. Birdcage Scaffold

A birdcage scaffold is a versatile system used for projects that require a large, open working area. It consists of multiple levels of platforms that are supported by vertical standards and horizontal ledgers, creating a cage-like structure.

5. Suspended Scaffold

Suspended scaffolds are commonly used for maintenance and repair work on buildings. They are suspended by ropes or cables from an overhead structure and can be raised or lowered to access different levels.

6. Cantilever Scaffold

A cantilever scaffold extends horizontally from a supporting structure, providing access to areas such as balconies or upper levels of buildings. It is ideal for situations where the ground beneath the scaffold cannot be used for support.

7. Mobile Scaffold

Mobile scaffolds are designed for ease of movement, allowing workers to quickly and efficiently access different areas of a job site. They are equipped with wheels or casters and are commonly used in construction and maintenance projects.

By understanding the different types of scaffolding systems, professionals can choose the most appropriate one for their specific project requirements, ensuring safety and efficiency throughout the construction or maintenance process.

| Scaffold Type | Purpose | Features |

|---|---|---|

| Slung Scaffolding | Used in various industries | Platform suspended from main structure |

| Putlog Scaffold | Masonry construction | Transverse ledgers support the platform |

| Independent Tied Scaffold | Freesupport system | Ties or braces provide stability |

| Working Platform | Simple configuration for tasks at different heights | Supported by adjustable legs or outriggers |

| Birdcage Scaffold | Large, open working area | Multiple levels of platforms |

| Suspended Scaffold | Maintenance and repair work on buildings | Can be raised or lowered |

| Cantilever Scaffold | Access to balconies or upper levels of buildings | Extends horizontally from a supporting structure |

| Mobile Scaffold | Quick and efficient movement | Equipped with wheels or casters |

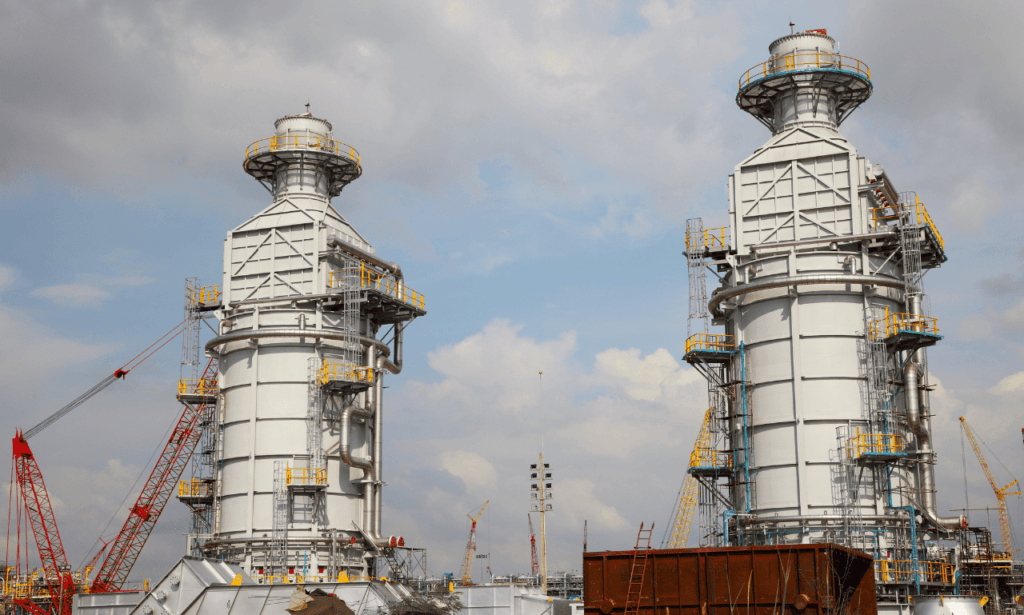

Offshore Specific Scaffolding Guidance

When it comes to scaffolding in offshore environments, adherence to specific requirements and regulations is crucial to ensuring safety and efficiency. Offshore scaffolding involves unique challenges and considerations that must be addressed to maintain a secure working environment.

One of the key aspects of offshore scaffolding is complying with guardrail requirements. Guardrails are essential for preventing falls and protecting workers while they are working at heights. The installation of sturdy guardrails is a vital safety measure that should never be overlooked.

Another important element in offshore scaffolding is the use of Gravlock/Girder couplers. These couplers are specially designed to secure scaffold tubes together, providing a strong and reliable connection. By using these couplers, scaffolding structures can withstand rigorous offshore conditions, ensuring stability and durability.

Scaffold ties are another critical component in offshore scaffolding. These ties serve as a means to secure and stabilize the scaffolding system, preventing any movement or instability. The proper installation and positioning of scaffold ties are essential for maintaining the structural integrity of the scaffolding.

Load-bearing scaffold fittings are specifically designed to support heavy loads in offshore scaffolding operations. These fittings are capable of withstanding the weight of equipment, materials, and workers, ensuring a safe and stable working platform. They are constructed to meet strict safety standards and provide reliable support in challenging offshore environments.

When it comes to the platform itself, the use of fire retardant scaffold boards is highly recommended in offshore scaffolding. These boards are designed to resist fire and limit the spread of flames, providing an additional layer of safety. In the event of a fire, fire retardant scaffold boards can significantly reduce the risk of structural damage and protect personnel.

Aluminum beams and tubes are commonly used in offshore scaffolding due to their lightweight yet durable properties. These materials offer corrosion resistance, which is crucial in marine environments. The use of aluminum beams and tubes ensures the scaffolding can withstand the harsh offshore conditions while remaining lightweight and easy to handle.

Offshore Specific Scaffolding Guidance - Summary:

To summarize, offshore scaffolding requires strict compliance with various guidelines, including guardrail requirements, the use of Gravlock/Girder couplers, scaffold ties, load-bearing scaffold fittings, fire retardant scaffold boards, and aluminum beams and tubes. By adhering to these offshore-specific requirements, scaffolding structures can provide a safe and stable working platform in challenging marine environments.

Benefits of Slung Scaffolding

Slung scaffolding offers numerous advantages in construction and maintenance projects. Its unique design provides access flexibility, enabling workers to navigate easily through different areas.

The first notable benefit of slung scaffolding is its access flexibility. With this type of scaffolding, workers can reach various heights and positions effortlessly. This versatility allows for efficient completion of tasks, enhancing productivity on the job site.

Another advantage is the space-saving aspect of slung scaffolding. By suspending the scaffold from the main structure, it frees up precious floor space. This is especially beneficial in tight or congested work areas where space efficiency is vital.

Furthermore, slung scaffolding is known for its efficient installation. Its modular components are easy to assemble and disassemble, saving time and effort during setup. The streamlined installation process contributes to smoother workflow and quicker project completion.

Slung scaffolding is also versatile and can be adapted to various applications. Whether it’s construction, maintenance, or repair work, this scaffold system can be customized to meet specific project requirements. Its adjustable features make it suitable for different structures, ensuring optimal performance and safety.

Lastly, slung scaffolding is a cost-effective solution for construction and maintenance projects. Its efficient design and ease of installation lead to reduced labor costs. Additionally, the flexibility and adaptability of slung scaffolding eliminate the need for multiple scaffold types, saving on equipment expenses.

Overall, slung scaffolding offers several benefits, including access flexibility, space-saving design, efficient installation, versatility, and cost-effectiveness. These advantages make it a favored choice for professionals in the construction and maintenance industry.

| Advantages of Slung Scaffolding |

|---|

| Access flexibility |

| Space-saving design |

| Efficient installation |

| Versatility |

| Cost-effectiveness |

Conclusion

Slung scaffolding plays a vital role in the construction and maintenance industry. It offers access flexibility, space-saving benefits, and efficient installation. Whether it’s for construction projects or routine maintenance, slung scaffolding provides a reliable solution that allows workers to safely reach different areas and efficiently complete their tasks.

However, it is crucial to prioritize safety practices and adhere to guidelines to ensure the well-being of workers. Implementing proper safety measures, such as using appropriate scaffold systems and equipment, conducting regular inspections, and providing comprehensive training, is essential to mitigate potential risks and accidents in construction and maintenance settings.

By understanding the uses and benefits of slung scaffolding, professionals can make informed decisions regarding scaffold solutions for their projects. Whether it’s for large-scale construction sites or smaller maintenance tasks, slung scaffolding offers versatility and cost-effectiveness, making it a practical choice for various applications.

Overall, slung scaffolding is an indispensable tool in the construction and maintenance industry. By prioritizing safety practices and staying informed about scaffold solutions, professionals can ensure the successful completion of their projects while safeguarding the well-being of their workers.

FAQ

What is slung scaffolding?

Slung scaffolding is a type of scaffolding system that is suspended from a structure, providing access to different areas. It is commonly used in construction and maintenance projects.

What are the different types of scaffolding systems?

There are various types of scaffolding systems, including slung scaffolding, putlog scaffold, independent tied scaffold, working platform, birdcage scaffold, suspended scaffold, cantilever scaffold, and mobile scaffold. Each type has its own purpose and features.

What are the specific requirements for offshore scaffolding?

Offshore scaffolding has specific guidelines and regulations, including guardrail requirements, the use of Gravlock/Girder couplers, scaffold ties, load-bearing scaffold fittings, fire retardant scaffold boards, and the use of aluminum beams and tubes.

What are the benefits of using slung scaffolding?

Slung scaffolding offers access flexibility, saving space, efficient installation, versatility, and cost-effectiveness compared to other types of scaffolding.

How does slung scaffolding contribute to the construction and maintenance industry?

Slung scaffolding plays a vital role in construction and maintenance projects by providing access flexibility, space-saving benefits, efficient installation, and cost-effective solutions. It is important to adhere to safety practices and guidelines for successful scaffold solutions.