Phone:

(+65)8319-0742

Safety is key in the construction world. That’s why reliable scaffolding systems are crucial. They help workers do their jobs safely at heights. It’s important to pick scaffolding that meets standards and fits your project needs.

At Instant Upright Scaffold, we know how important safety is. We’ve been offering top scaffolding products for almost 30 years. Our range includes both lightweight aluminum and heavy-duty steel scaffolds, like the Span 300, 400, and 500 series. These are easy to set up and take down, perfect for many construction tasks.

Our scaffolding is great for any project, from government buildings to homes. We focus on the Maryland, Virginia, and DMV area. Our customers love our service and products, giving us great reviews and high ratings.

Key Takeaways:

- Scaffolding products are key for keeping workers safe and projects on track in construction.

- Instant Upright Scaffold offers a wide range of top-notch scaffolding systems, including aluminum and steel.

- Our scaffolding is easy to put together and take apart, making it versatile for different jobs.

- We have a strong history of supporting projects in Maryland, Virginia, and the DMV area.

- Our customers give us great reviews and high ratings, showing our dedication to quality service and products.

The Importance of Scaffolding Safety

Scaffolding safety is key in construction, affecting worker well-being on high platforms. About 65% of construction workers use scaffolds, making safety rules and best practices crucial. Every year, scaffolding causes around 4,500 injuries and 60 deaths in the U.S., showing the need for proper training and safety measures.

To lower risks, scaffolding parts are made with a 4 to 1 safety factor for strong support. OSHA says scaffolds must be at least 10 feet away from electrical dangers. A trained person must watch over the setup and take down of scaffolds. Workers should always keep three points of contact with the scaffold to avoid falls.

Scaffold tags are key in showing if a scaffold is safe or not. Green tags mean it’s safe, yellow tags mean it’s been changed for a specific job with safety steps. Red tags warn of danger and mean the scaffold is not safe. Following these signs is key for a safe work area.

| Scaffolding Safety Dos | Scaffolding Safety Don’ts |

|---|---|

| Inspect the scaffold before work | Overload the scaffold |

| Provide proper training to workers | Use unstable objects for support |

| Use appropriate personal protective equipment (PPE) | Use a damaged scaffold |

Training is vital for scaffolding safety, but 25% of workers got no safety training, says the Bureau of Labor and Statistics. Employers must give regular training by experts to help workers spot hazards and lower risks. Training should include how to set up scaffolds, their load limits, safety gear, and what to do in emergencies.

Employers also need to make sure scaffolds are safely reached from the ground if they’re more than two feet off the ground. Using Ground Fault Circuit Interrupters (GFCIs) for electrical tools on scaffolds cuts down electric shock risks. Keeping a 20-foot zone clear of big vehicles helps prevent accidents.

Putting safety first in scaffolding can greatly cut down on injuries, deaths, and lost workdays. Following OSHA rules, giving thorough training, and keeping safety platforms well-made are key to a safe work place for construction workers.

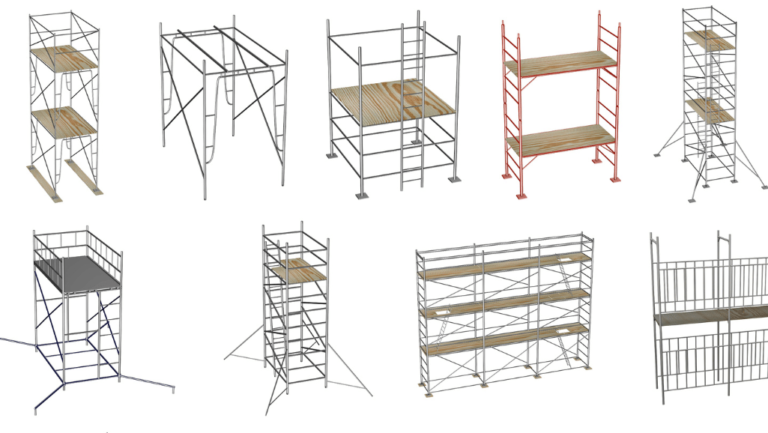

Types of Scaffolding Products

Construction projects need different scaffolding types for safety and efficiency at various heights. Modular scaffolding systems, suspended scaffolding, and mobile scaffolding are top choices for temporary worker platforms.

Modular Scaffolding Systems

Modular scaffolding is very versatile and fits many construction projects. It has standard parts that can be put together to meet project needs. Cuplock scaffolding is a top choice for its strong connections and easy setup, often used in shipbuilding and other industrial tasks.

Suspended Scaffolding

Suspended scaffolding is great for projects hard to reach from the ground. It hangs from roofs or structures with ropes or chains, giving workers a safe place for tasks like painting or repairs. There are different types, like catenary and swing stage systems, for various projects.

Mobile Scaffolding Towers

Mobile scaffolding towers move easily from one spot to another. They have wheels or casters for easy transport without taking them apart. These are often used in homes, small projects, and maintenance, making reaching different areas safe and efficient.

| Scaffolding Type | Key Features | Common Applications |

|---|---|---|

| Cuplock Scaffolding | Strong connection points, easy assembly | Shipbuilding, industrial projects |

| Kwikstage Scaffolding | Quick assembly, stable, affordable | Widely used in Australia, South Africa, Scotland, Ireland |

| Ringlock Scaffolding | Adaptable, stable, suitable for complex structures | Offshore construction, industrial maintenance, shipbuilding |

Picking the right scaffolding is key for safe and efficient construction work. Think about the work, site, and project needs when choosing the best scaffolding.

Key Features of High-Quality Scaffolding Products

When picking scaffolding for your project, focus on top-notch products. They should be durable, versatile, and easy to use. Bil-Jax offers such products, designed for today’s construction needs. They ensure worker safety and help projects run smoothly.

Durability and Strength

Great scaffolding stands up to construction site challenges. It’s made from high-grade steel and aluminum. These materials are strong and resist corrosion well.

Features like galvanized coatings and proper welding make scaffolding last longer. They also cut down on upkeep. Choosing durable scaffolding lowers the risk of accidents and saves money over time.

Versatility and Adaptability

For different projects, versatile scaffolding is key. Modular systems are very flexible, fitting various building shapes and sizes. They can be adjusted to fit different needs.

Some accessories, like multi-purpose span frames, work in many ways. This cuts down on the need for extra parts and makes setup quicker. It saves time and money, and scaffolding can adapt to project changes easily.

Easy Assembly and Dismantling

On construction sites, time is precious. Scaffolding that’s easy to put together and take apart helps work go faster. High-quality products often have simple designs and connections. This makes assembly quick and secure.

Using materials like aluminum makes scaffolding lighter and easier to move. This makes setting up and taking down scaffolding quicker. Choosing easy-to-use scaffolding helps keep projects on track.

| Feature | Benefit |

|---|---|

| High-grade steel and aluminum | Exceptional strength and corrosion resistance |

| Galvanized coatings | Extended lifespan and reduced maintenance |

| Modular scaffolding systems | Unparalleled flexibility and adaptability |

| User-friendly connections | Quick and secure assembly |

| Lightweight materials | Streamlined setup and dismantling processes |

Investing in top-quality scaffolding is key for a safe and efficient project. By focusing on durability, versatility, and ease of use, contractors can boost productivity and reduce risks. This leads to great results.

Scaffolding Materials

When picking scaffolding materials, you have two main choices: aluminum and steel. Each has its own benefits for different uses. Picking the right one is key for safety, stability, and project success.

Aluminum Scaffolding

Aluminum scaffolding is getting popular for its light weight and easy handling. Its main advantages are:

- Portability: It’s much lighter than steel, making it easy to move and set up.

- Corrosion resistance: It doesn’t rust or corrode, perfect for outdoor use in tough conditions.

- Flexibility: It can be adjusted to fit different building shapes and sizes easily.

The Aluminum Scaffold Plank 10′ is a top-notch example. It costs $168.00 and is a budget-friendly choice for many projects.

Steel Scaffolding

Steel scaffolding is still a favorite for its strength and durability. Its benefits include:

- High load capacity: It can handle heavy loads and withstand more stress than aluminum.

- Stability: Its strength means it’s stable, great for tall structures and complex projects.

- Versatility: You can easily connect and configure it for different structures, like towers and platforms.

The 7′ CupLock Horizontal Trusses are a prime example of steel scaffolding. They’re strong and stable for tough tasks.

| Scaffolding Material | Key Benefits | Example Product |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, flexible | Aluminum Scaffold Plank 10′ |

| Steel | High load capacity, stability, versatility | 7′ CupLock Horizontal Trusses |

Choosing between aluminum and steel scaffolding depends on your project’s needs, the loads it will carry, and the site conditions. Think about these factors to pick the right materials for a safe and successful project.

Scaffolding Accessories

High-quality scaffolding accessories are key for safety and functionality. They make sure the scaffolding is stable and secure. This lets workers do their jobs safely and efficiently.

Cross Braces and Diagonal Braces

Cross and diagonal braces stop stacked frames from sliding and keep the scaffolding stable. Galvanized cross braces meet OSHA standards and provide strong support. Diagonal bracing adds more strength to the scaffolding.

On average, cross braces weigh about 7.00 lbs, and diagonal braces weigh around 6.50 lbs.

Guard Rail Systems

Guard rail systems keep the scaffold safe and prevent falls. You can customize these systems for your needs. They include guard rail posts in different heights and corner guard rail posts for full coverage.

The average price of a corner guard rail post is $66.00. Intermediate guard rail panels cost about $128.00 and provide extra protection.

Access Ladders and Stair Units

Safe access to the scaffold is crucial. Access ladders and stair units provide this safety. The 6′ Access Ladder is a reliable way to climb up.

Access ladder brackets and hand rails enhance safety. Steel stair units have inside and outside handrails for extra security. Access ladder brackets and hand rails cost around $58.00 and $77.00, respectively.

Casters and Leveling Jacks

Casters and leveling jacks make moving and leveling the scaffolding easy on uneven surfaces. Industrial casters with a locking mechanism are available at an average price of $62.00 each.

Leveling jacks come in various options, including the Leveling Jack with Swivel Base Plate. The average price of a leveling jack is $45.00. Shoring heads for leveling jacks are also available at an average price of $33.00.

| Accessory | Average Price | Average Weight |

|---|---|---|

| Toggle Pin | $2.10 | – |

| Scaffold Cross Braces | – | 7.00 lbs |

| Locking Pin/Hair Pin | $2.00 | – |

| Pigtail Locking Pin | $2.00 | – |

| Leveling Jack with Base Plate | $46.00 | – |

| Leveling Jack | $45.00 | – |

| Caster | $62.00 | – |

| Corner Guard Rail Post | $66.00 | – |

| Access Ladder | – | 12.00 lbs |

| Diagonal Braces | – | 6.50 lbs |

With over 30 years of experience, trusted suppliers offer a wide range of scaffolding accessories. These include cross braces, guard rail systems, access ladders, and leveling jacks. Investing in quality accessories that meet OSHA requirements ensures worker safety and project success.

Scaffolding Rentals vs. Purchasing

When you need scaffolding for your projects, you can either rent or buy it. Each option has its pros and cons, depending on your project’s needs and your budget. Renting scaffolding is great for short-term projects or when you don’t need it often. It saves money and you don’t have to worry about storing or maintaining it.

Buying scaffolding costs more upfront but is better for projects you do often. It lets you customize it for your needs and gives you more control over the equipment. You won’t have to worry about finding it or scheduling it, which can be a problem with rentals.

Think about how long your project will last when deciding to rent or buy. If it’s over 8 months, buying might be cheaper in the long run. Renting can add up in costs over time.

Think about safety too when choosing between renting and buying scaffolding. Owning it lets you know the quality and condition of the equipment. This means you can fix it faster and keep your workers safe. For big projects, aluminum or steel scaffolds are best because they’re strong, last a long time, and easy to set up and take down.

| Factor | Scaffolding Rentals | Purchasing Scaffolding |

|---|---|---|

| Cost | Lower upfront costs | Higher initial investment |

| Project Duration | Ideal for short-term projects | Suitable for long-term or frequent use |

| Customization | Limited options | Can be tailored to specific needs |

| Maintenance | Handled by rental company | Responsibility of the owner |

Before you decide, look at prices from different suppliers to find the best deal without sacrificing quality or safety. When buying, consider the size, how much weight it can hold, and if it meets safety standards for big projects.

The choice between renting or buying scaffolding depends on your project, budget, and goals. Think about these things and look at your options to make a choice that works for your construction needs and keeps your workers safe.

Scaffolding Erection and Dismantling Services

Working with experts in scaffolding erection and dismantling is key. Scaffold erectors are crucial for making sure scaffolding meets all the rules. They know how to set up and take down different scaffolding types safely and efficiently.

Professional Scaffold Erectors

Professional scaffold erectors are well-trained and have lots of experience. They know all about safety rules and OSHA guidelines. They make sure scaffolding is set up right and can work with your project’s schedule.

When picking a scaffolding service, look for companies with certified erectors. These pros can handle many projects, from big buildings to events. They know about different materials and can suggest the best scaffolding for your project.

Scaffold Inspection and Maintenance

Checking and keeping scaffolding in good shape is very important. Experts do thorough checks to spot any problems. They fix or replace anything that’s not right to keep the scaffolding safe.

It’s important to check scaffolding often, before and after use. Doing this helps avoid accidents and keeps the scaffolding safe. Companies like Sunbelt Rentals Scaffold Services offer great inspection and maintenance plans.

| Service | Description |

|---|---|

| Scaffolding Erection | Professional assembly of scaffolding structures by certified and experienced scaffold erectors |

| Scaffolding Dismantling | Safe and efficient removal of scaffolding structures after project completion |

| Scaffold Inspection | Regular inspections to identify potential issues and ensure compliance with safety regulations |

| Scaffolding Repair | Prompt repairs and maintenance to keep scaffolding structures in optimal condition |

Choosing top-notch scaffolding services is key for your project’s success and safety. Working with trusted erectors and providers means your scaffolding will be set up and kept in great shape. This creates a safe place for your team to work.

Scaffolding Products for Different Industries

Scaffolding is key in many industries for safe and efficient work at heights. It’s used in construction, building upkeep, and in industrial settings. It also helps in the event and entertainment world for setting up stages and lighting.

Construction and Building Maintenance

In construction and building upkeep, scaffolding is a must-have. It gives workers a safe way to reach high places for tasks like laying bricks or painting. These scaffolds are made to hold a lot of weight and keep workers safe while they work.

Industrial and Manufacturing

Industrial scaffolding is a big deal in factories for upkeep, putting in new equipment, and checking things out. It’s made tough to handle the tough conditions of factories and lets workers get to places they can’t easily reach. Workers can get to equipment safely with these scaffolds.

| Industry | Scaffolding Applications |

|---|---|

| Petrochemical | Maintenance access to boilers, vats, pressure vessels, steam generators, and chimneys |

| Refinery | Access to heating exchangers, cooling towers, pressure vessels, and piping |

| Construction | Structural support and safe passage for workers, bearing static and dynamic loads |

Event and Entertainment

Scaffolding is big in the event and entertainment world for setting up temporary stuff. It’s used for outdoor concerts and indoor shows, helping with stages, lights, and seats. These scaffolds are easy to put up and take down, making events run smoothly.

Companies like ScaffoldMart and Southwest Scaffolding offer scaffolding for different needs. They have many types of scaffolds, frames, and accessories. These products follow strict safety rules, making sure workers are safe in many fields.

Scaffolding Safety Regulations and Standards

Keeping workers safe on scaffolding is crucial in construction. To do this, rules and standards from groups like OSHA and ANSI are followed. These cover many things, like how scaffolds are made and how workers are trained.

OSHA Requirements

OSHA has strict rules for scaffolding safety in the U.S. It says guardrails and fall systems are needed for heights over 10 feet. Scaffolds must hold up to four times their load and have solid platforms. A trained person must be there to make sure everything is safe.

Employers must teach workers about scaffold safety and how to spot dangers. They need to give workers the right gear like harnesses and lifelines for heights over 6 feet. Workers who need more training get it if they’re not good enough or if the work site changes.

ANSI Standards

ANSI gives more rules for making scaffolding safe. These rules help make sure scaffolding is up to the highest safety levels. Some important ANSI rules are:

- Scaffold design must have a height-to-base ratio of over 4:1

- The recommended crosspoint of cross bracing for top rail should be between 38 inches and 48 inches above the work platform

- The crosspoint of cross bracing for midrail should be between 20 inches and 30 inches above the work platform

- Scaffold footings must be leveled and capable of supporting the loaded scaffold

Following OSHA and ANSI rules is key for a safe work area on scaffolding. Instant Upright’s scaffolding meets and beats these rules, focusing on safety. By choosing top-notch scaffolding, companies can lower the chance of accidents and injuries.

| Regulation/Standard | Key Requirements |

|---|---|

| OSHA |

|

| ANSI |

|

Choosing the Right Scaffolding Products for Your Project

Choosing the right scaffolding is key for worker safety, efficiency, and project success. You need to think about the project’s size, height, and what tasks will be done. Also, consider the work environment.

There are three main types of scaffolding: supported, suspended, and mobile. Each has its own benefits and best uses. Supported scaffolding is great for tall buildings, offering easy access and safety. Suspended scaffolding is good for places where you can’t disturb the ground. It helps reach hard spots and speeds up building work. Mobile scaffolding is ideal for small, moving jobs, making transport easy and saving time and money.

| Scaffolding Type | Best Suited For | Key Benefits |

|---|---|---|

| Supported Scaffolding | Large job sites, high-rise construction, indoor applications | Easy access to materials and tools, improved worker safety, good stability, secure base indoors |

| Suspended Scaffolding | Smaller job sites with limited access, window washing and maintenance work, outdoor projects | Access to difficult-to-reach areas, quick construction, flexibility and maneuverability outdoors |

| Mobile Scaffolding | Projects requiring frequent mobility, outdoor projects | Easy transportation between locations, saves time and money, flexibility and maneuverability outdoors |

When picking access systems, look at safety features, durability, and how easy they are to set up. Talking to scaffolding experts, like those at Instant Upright, is a good idea. They can help pick the best scaffolding for your project and follow industry rules, like the Australian standard AS/NZS 4576.

Other things to think about when choosing scaffolding include:

- Load-bearing capacity

- Durability and strength of materials

- Versatility and adaptability to different project needs

- Ease of assembly and dismantling

- Availability of safety features like guardrails, toeboards, and safe access points

By looking at these factors and getting advice from experts, businesses can find the right scaffolding. This ensures worker safety, increases productivity, and helps projects succeed.

Conclusion

Scaffolding products are key for safe building work in many fields. Choosing the right scaffolding and following safety rules helps make a safe work area. This leads to successful projects. Instant Upright, with over 60 years of experience, offers top-notch scaffolding. This lets workers do their jobs safely and efficiently.

Instant Upright focuses on safety with things like guardrails and fall protection gear. Their scaffolding is strong, flexible, and easy to set up and take down. They also stress the importance of using safety gear like hard hats and harnesses.

Employers must train workers and provide the right gear. They also need to make sure scaffolding is set up and checked right. Instant Upright helps with this by offering setup, maintenance, and inspection services. They are a top choice for scaffolding in various sectors, including construction and events.

Working with Instant Upright means getting safe and effective scaffolding solutions. They are dedicated to safety, quality, and helping customers. This makes them a reliable partner for secure and productive work areas.