Phone:

(+65)8319-0742

At the core of construction site safety lies the importance of scaffolding outriggers. These key pieces of safety gear make sure the scaffolding stands steady and reduce risks from high places. Having scaffold stability is crucial for keeping workers safe and improving work efficiency. Using construction outriggers is more than just following rules; it’s a way to protect workers and ensure the project’s success.

Outrigger scaffold systems are vital for creating a strong base for various construction tasks. Counterweight scaffold systems must meet OSHA safety requirements, ensuring counterweights resist tipping moments and stabilize adjustable suspension scaffolds. They offer flexible solutions that fit the unique shapes of different sites. It’s vital to pick and use these scaffolding safety equipment items carefully. Securing outrigger beams to a stable load-bearing surface, such as a floor or roof deck, is essential to prevent tipping during operation. They affect how safe and effective scaffolding is.

Key Takeaways

Make sure to spread the weight of the scaffold evenly for better stability with scaffolding outriggers.

Choose scaffold safety gear that meets or beats ANSI and OSHA standards for safety and compliance.

Understand how crucial construction outriggers are for a safe and stable scaffold setup.

Invest in outrigger scaffold systems that can adjust to the specific needs of your site.

Always keep a safety buffer by making sure scaffolding parts, like planks, can hold four times their intended load.

Regularly check and maintain scaffold parts to fix any damage or wear.

Ensure safety training so a Competent Person can manage scaffolding, following safety rules and using outriggers correctly.

Understanding the Role of Scaffolding Outriggers in Construction Safety

In construction, safety is key. Multi point suspension scaffolds require careful attention to support devices and connections to ensure stability and adherence to safety regulations. Outrigger scaffold systems are crucial for keeping workers safe and creating solid work areas. They use outrigger beams and stabilizers to make scaffolds safer and more stable. This reduces risks in high places.

Defining Outrigger Systems for Scaffolds

An outrigger scaffold system has outrigger beams that go beyond the main scaffold. These beams help spread the weight out and make the scaffold more stable. Using these systems right makes sure the platform stays balanced, even when there are forces or heavy loads.

Scaffold stabilizers also help keep structures stable. They make sure everything meets strict safety rules.

The Significance of Scaffold Stability

Outrigger systems are key for safety and efficiency in construction. They make sure workers can move around safely and work without worrying about the scaffold tipping over. Mobile scaffold systems, such as rolling and Baker scaffolds, must adhere to strict safety standards, including OSHA regulations, to ensure proper assembly and fall protection. This is very important in dangerous work areas.

The table below shows what’s needed for baker scaffolds, including guardrails and outriggers:

Feature | Description | Requirement |

|---|---|---|

Guardrails | Mandatory for height over 6 feet | Prevents falls |

Outriggers | Required when height exceeds 10 feet | Enhances base width for stability |

Stability | Base-to-height ratio | Not to exceed 1:4 |

Fall Protection | For heights of 10 feet or more | Use of personal fall arrest or guardrail systems |

Putting a focus on stability shows how important good design and use of outrigger systems are. It follows the rules and lowers the chance of accidents. When done right, outrigger systems help keep scaffolds stable and make construction sites safer.

Selection and Usage of Scaffold Outrigger Arms

Choosing the right scaffold outrigger arms is crucial for safety and stability on construction sites. Suspension scaffold outrigger beams must meet specific safety and design criteria, including the use of strong materials, adequate load-bearing capabilities, proper connection methods, and necessary safety measures to ensure stability and prevent accidents. The right choice affects how well the scaffolding holds up. Look for materials like steel that are strong and follow safety standards like ASTM and CSA.

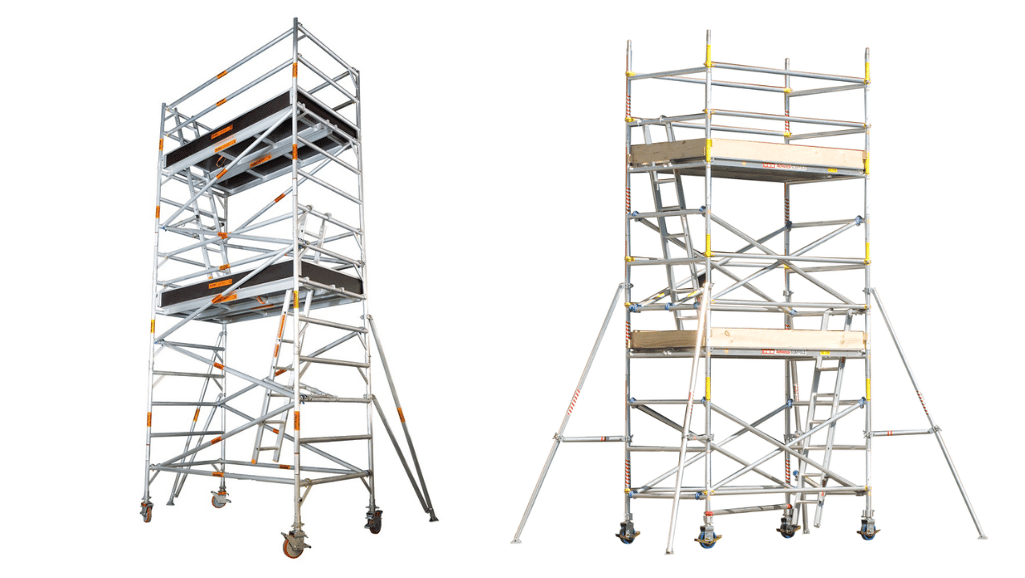

Types of Outrigger Scaffold Support Systems

There are many types of scaffold support systems to fit different projects. Suspension scaffold support devices are essential components that must meet stringent safety requirements to ensure stability and secure connections. Wellmade, a top manufacturer, meets ISO9001 standards. They offer adjustable outriggers and fixed-length ones. Their scaffolding suits both small and big projects in the USA and Canada.

Choosing the Right Scaffold Outrigger Extensions

Choosing the right scaffold outrigger extensions depends on the project’s needs and the environment. Scaffold planks must be well-supported and properly installed to ensure overall safety and compliance with regulations. Wellmade’s outriggers come in various sizes (30”, 18”, and 14”). This lets you set up scaffolding that meets your project’s needs. Safety and easy access improve when you match the right extension size with stable scaffolding.

Wellmade is a trusted supplier with a wide range of products like caster wheels and catwalk boards. Their scaffolding is safer and wider thanks to careful planning. Choosing the right scaffold outrigger brackets reduces risks and makes the workplace safer. This shows Wellmade meets industry standards and helps various construction projects.

Comprehensive Guide to Outrigger Beams and Their Impact on Safety

Outrigger beams are key to making scaffolding safer by widening the base and reducing stress that could cause it to collapse. They are essential for a safe work area at high levels. Understanding how outrigger beams and scaffold safety outriggers work is vital for safe work and following strict rules.

Rules like OSHA 1910.66 and ASME A-120.1 stress the importance of outrigger beams being strong and installed correctly. These parts make scaffolds stable and lower the chance of accidents. For more on safe scaffolding, check out this guide that covers best practices and rules.

Every year, scaffolding causes nearly 50 deaths and thousands of injuries in the U.S. This shows how crucial scaffold safety outriggers and proper training are for workers.

Fixed Outrigger Systems: These are set up permanently and come in backfed or I-beam styles. They’re great for long-term use in building upkeep.

Transportable Non-counterweighted Outrigger Systems: Made from aluminum or steel, these outriggers have casters for easy moving and adjusting for different jobs.

Push-thru Outrigger Systems: These have tubes that slide into stands on a building’s outside. They’re perfect for quick setup and frequent changes.

Adding the right outrigger accessories to your scaffolding is key for safety and making it more adaptable.

Here’s a look at how different outrigger systems compare:

Outrigger System Type | Material | Installation Type | Safety Enhancements |

|---|---|---|---|

Fixed Outrigger Systems | Steel, I-Beam | Permanent, Fixed | High stability, Suitable for heavy loads |

Transportable Non-counterweighted Outriggers | Aluminum, Steel | Mobile with Casters | Flexible positioning, Lightweight |

Push-thru Outrigger Systems | Steel | Slide-through Installation | Rapid adjustment, Strong hold |

Choosing and using outrigger beams and their accessories needs careful thought and following safety rules. This helps prevent accidents and keeps scaffolds safe and lasting longer.

Adjustable Outriggers: Key to Versatile and Secure Scaffolding

The construction world needs equipment that’s flexible and safe. Adjustable outriggers for scaffolding are leading the way with their versatility. Wire rope clips are also crucial for scaffold safety, as they must be installed and maintained according to safety standards. They work well on different terrains and meet various project needs. These outrigger legs make scaffolding safer and more stable.

Adjustable outrigger systems are vital for both big and small projects. They let workers change the outrigger legs’ length and angle. This means they can set up scaffolding that fits each site perfectly, boosting work efficiency and safety.

Advantages of Utilizing Adjustable Outrigger Systems

Using adjustable outriggers makes scaffolding more stable on uneven ground. A personal fall arrest system (PFAS) is crucial for fall protection, especially for workers operating on scaffolding at heights of 10 feet or more. It helps keep the scaffolding balanced, reducing the chance of accidents. Plus, features like automatic overload sensors and emergency systems, found in Spimerica Spider Access Equipment, add an extra layer of safety.

Comparison of Scaffold Stabilizers: Fixed vs. Adjustable Systems

Fixed stabilizers are good for even ground, but adjustable systems are better for tricky terrain. It is crucial to use properly manufactured wire ropes, and any swaged attachments or spliced eyes on wire suspension ropes must be made by the wire rope manufacturer or a qualified person to ensure scaffold safety. They handle surface changes and structural issues in complex construction areas.

Here’s a table that shows how adjustable outriggers beat fixed ones in flexibility and safety.

Feature | Fixed Scaffold Stabilizers | Adjustable Outriggers |

|---|---|---|

Adaptability to Terrain | Limited | High |

Set-up Time | Quick | Varies, but comprehensive |

Safety Features | Standard | Advanced, includes overload sensors and emergency systems |

Application Diversity | Good for consistent surfaces | Excellent for varied project requirements |

Customization | Minimal | High, allows precise positioning |

Adjustable outrigger systems are key for better scaffolding performance and safety. They adapt to different situations, improving safety and structural strength. This boosts worker confidence in tough construction jobs.

Implementing Outrigger Scaffold Systems for Enhanced Stability

Using outrigger scaffold systems makes construction sites safer and more stable. They are especially useful for tasks like putting up roofing chutes and getting rid of debris. Knowing how to use these systems right can make a big difference in safety.

Scaffold safety accessories and outriggers together reduce the chance of scaffolds falling. Adjustable scaffold outriggers do more than just make things stable. They also make putting up and taking down construction chutes safer and faster. This is crucial when working on tall buildings or big renovations.

Enhanced safety by preventing sudden shifts or collapses

Increased worksite efficiency with quicker setup and teardown

More versatility in scaffold building, fitting different terrain

Lower labor costs with efficient waste removal

Benefit | Details |

|---|---|

Stable platform creation | Outrigger scaffolding extends the base, providing stability on uneven surfaces |

Durability | High-quality materials like aluminum and steel ensure longevity and dependability |

Customization | Engineering to meet specific project needs, considering load factors and environmental conditions |

Safety Compliance | Regular inspections and adherence to standards prevent potential hazards |

Technological Integration | Use of smart technology for real-time monitoring of load distribution |

Scaffold outrigger safety is more than just setting things up right. It also means regular checks and following safety rules. These steps keep the scaffold outrigger systems safe and working well for everyone using them.

More and more builders are seeing the value in outrigger scaffold systems. They’re making projects safer and more efficient. Adding these solutions cuts down on risks and makes construction work go smoother.

Outrigger Pads: An Essential Component for Scaffolding Safety

Outrigger pads are key to making scaffolding safe and stable, especially on uneven or soft ground. They spread out the weight of the scaffolding evenly. This prevents damage to the ground below and keeps everyone safe. Properly manufactured and inspected wire suspension ropes are also crucial for scaffold safety, ensuring the integrity and safety of the scaffolding system.

Safety standards for scaffolds highlight the importance of outrigger pads. They work with scaffolding support arms and leveling jacks to keep the scaffold steady on any ground.

Choosing the Correct Outrigger Pads for Different Surface Conditions

Choosing the right outrigger pads is crucial for safe scaffolding. It is important to note that the use of repaired wire rope as suspension rope is prohibited to ensure the integrity and strength of the scaffolding system. You need to think about the ground’s strength, the weather, and how much the scaffold will weigh. Heavy-duty outriggers with strong pads help keep scaffolding stable on tricky grounds like mud or sand.

Maintaining and Inspecting Outrigger Pads

It’s important to regularly check and maintain outrigger pads for safety. The presence of six randomly distributed broken wires in one rope lay is a critical defect that mandates the replacement of wire ropes used in scaffolding. Look for any damage or signs of wear and replace any unsafe pads. Following OSHA guidelines for inspections and upkeep helps avoid accidents and keeps workers safe.

Using outrigger pads with support arms and leveling jacks makes construction sites safer and more compliant with the rules. This approach boosts scaffolding’s performance and helps prevent injuries at work.

Ensuring Compliance with Scaffold Safety Equipment Regulations

Following scaffold safety equipment rules is key for safe construction projects. Suspension scaffold safety requirements, including support devices, load capacity, and safety measures, are crucial according to OSHA regulations. These rules help keep the workplace safe and meet legal standards set by groups like OSHA. Construction work is risky, especially when workers are high up. So, it’s vital to know and follow the rules for scaffold safety outriggers and construction outriggers.

Understanding Scaffold Outrigger Regulations and Standards

Scaffold outrigger rules make sure scaffolding is strong and stable. OSHA’s rules say scaffolds must hold at least four times the weight they’re meant to. It’s important to use the right construction outriggers and have a pro check them.

Benefits of Regular Scaffold Safety Inspections and Personal Fall Arrest System Checks

Checking scaffolds often is key to a safe construction site. Regular inspections should include checking suspension ropes for any signs of damage and ensuring they meet the required specifications. These checks spot dangers like too much weight or weak spots. By making sure everything from guardrails to scaffolding pads meets OSHA standards, we make the site safer and cut down on accidents.

Safety Feature | Regulation | Importance |

|---|---|---|

Load Capacity | Scaffolds must be capable of holding up to four times their maximum load. | Prevents structural failure due to overloading. |

Fall Protection | Personal fall protection systems mandatory at 10 feet above a lower level. | Reduces the risk of injuries from falls. |

Competent Inspection | Only a competent person per OSHA can inspect scaffolds. | Ensures reliability and safety compliance of scaffold setups. |

Guardrails | Cross bracing for guardrails on supported scaffolds should be between 38 and 45 inches. | Provides necessary barrier to prevent falls. |

About 65 percent of U.S. construction workers use scaffolds every year. Knowing the rules for scaffold outriggers and doing safety checks is not just a must-do. It’s a key way to keep the workplace safe and avoid legal trouble. By following strict safety rules and doing thorough checks, we make the job site safer and lower the risk of accidents.

Maximizing Safety with Scaffold Outriggers and Suspension Scaffold in Varied Conditions

On construction sites, safety is key. Mobile scaffolds, also known as rolling scaffolds, must meet stringent safety standards to ensure worker protection. Outrigger scaffold systems are vital for stability and reliability. They adapt to changes, especially with scaffold safety outriggers. Knowing how to use scaffold outrigger dimensions and adjustable outriggers boosts safety and efficiency.

Weather changes like wind, rain, and cold affect scaffolds. Cold can weaken materials like concrete and metal. Using strong outrigger scaffold systems and adjusting scaffold safety outriggers is crucial.

Adjustable Outriggers: These outriggers offer flexibility and safety. They adjust to different scaffold outrigger dimensions and site needs.

Comprehensive Safety Trainings: Training workers in setting up and adjusting outriggers in various conditions is key.

Routine Safety Inspections: Regular checks ensure outriggers and scaffolds meet safety standards, despite weather damage.

Using outriggers with the right dimensions makes scaffolds more stable. Outriggers that adjust to the site’s needs improve safety even more.

On-site, scaffolds must handle changing conditions and safety risks. Using weather-resistant materials and adjustable outriggers keeps scaffolding safe and functional.

In conclusion, using well-measured scaffold outrigger dimensions and adaptable systems makes scaffolding more reliable. This protects workers and raises safety standards.

Scaffolding Outriggers: Best Practices in Scaffold Rigging

To keep construction sites safe and efficient, it’s key to follow strict outrigger assembly instructions. These steps make sure scaffolding outriggers are set up right. They carry the needed load and stop accidents. Additionally, using properly manufactured and inspected wire suspension ropes according to safety standards is crucial for suspension scaffolds.

Scaffolding outriggers for sale vary, and picking the best scaffold outriggers for each project boosts safety and job efficiency. Industry reports stress the importance of following guidelines to cut down on risks with scaffolds.

Outrigger Assembly Instructions for Optimal Safety

Setting up scaffolding outriggers right involves detailed steps. You must check load capacities, secure all parts, and make sure everything is in place. It’s also key to check the outriggers regularly to make sure they’re strong.

Outrigger Accessories and Their Role in Scaffold Safety

Outrigger accessories are crucial for scaffold safety and function. They help with balance and strength. Since about 4,500 people get hurt each year from scaffolding, using reliable outrigger accessories is essential.

Safety tags help show if the scaffolding is safe or not. Green means it’s ready, Yellow means be careful, and Red means it’s not safe. Using these tags wisely can stop many accidents.

Training workers well is very important. A lot of scaffold injuries happen because workers weren’t trained right. Following the right steps for setting up outriggers and using strong accessories cuts down on accidents. This makes a safer place for everyone.

Key Considerations for Procuring Scaffolding Safety Outriggers

When looking to buy scaffolding outriggers, it’s key to carefully check the price, quality, and specs. This ensures safety and efficiency on construction projects. Choosing high-quality outriggers is a must for safety.

Factors to Consider When Buying Scaffolding Outriggers

When deciding to buy scaffolding outriggers, consider several important factors. It’s vital to know the specifications, like load capacity and compatibility with other systems. The price must fit the project’s budget without cutting corners on quality or safety.

Evaluating Scaffold Outrigger Quality and Specifications

Checking the quality of scaffold outriggers is crucial for safety. Brands like Bil-Jax offer reliable scaffolding products. It’s important they meet safety standards, like OSHA rules, which require they can hold at least four times the maximum load.

Specifications to check include the material, load capacity, and how they handle different weather. They should last long and stay safe in various conditions.

Feature | Benefit |

|---|---|

Weight Capacity | Ensures stability and safety under load |

Material Quality | Provides durability and weather resistance |

Compliance Standards | Meets OSHA requirements to safeguard against liabilities |

Compatibility | Integrates seamlessly with existing scaffold systems |

The aim of careful buying is to save money and keep workers safe. Spending time to find the best outriggers that meet high standards can prevent accidents and make work more efficient.

Conclusion

Ensuring safety and stability in construction is very important. Using the best outriggers for scaffolding is key. This guide has shown us how important adjustable steel props, shoring towers, and modular scaffolding are for safety.

Cantilever scaffolding and flying formwork are also important. They help make high-rise construction safer. These methods show the industry’s effort to improve safety and stability.

Falls are a big risk in scaffold work, causing many deaths. Safety rules and protocols are crucial. Suspension scaffolds need extra attention because they’re often involved in accidents.

Most falls from these scaffolds come from equipment failure. This highlights the need for strict safety measures. Following OSHA’s safety standards since 1971 is important to keep workers safe.

Keeping workers safe is an ongoing task. It requires constant attention, learning, and acting to prevent hazards. Working with structural engineers and following OSHA’s safety rules can help reduce accidents.

Let’s make sure to follow the best safety practices outlined here. This will lead to a safer work environment. We should always put the safety and well-being of workers first.

FAQ

What are scaffolding outriggers and why are they important for scaffold safety?

Scaffolding outriggers are extra parts that make a scaffold wider. They are key for safety by making sure the scaffold doesn’t tip or move. This helps prevent accidents and injuries.

How do outrigger scaffold systems contribute to the stability of a scaffold?

Outrigger systems make the scaffold wider, balancing loads and adding support. This makes the work area stable and safe. It’s crucial for keeping workers safe and the structure sound.

What are the different types of outrigger scaffold support systems available?

There are many types, like fixed, telescopic, and articulating outrigger arms. They can be adjusted or not, and the choice depends on the project’s needs.

When choosing scaffold outrigger extensions, what factors should be considered?

Think about the load it can hold, if it fits with your scaffold, the ground type, and safety needs. Also, consider the cost and quality of the outrigger brackets.

How do adjustable outriggers provide flexibility in scaffolding?

Adjustable outriggers can change length and position. This is key for keeping platforms level and safe on different sites.

Why are outrigger pads critical for scaffolding safety?

Outrigger pads spread the scaffold’s weight over more ground. This keeps the scaffold stable on uneven or soft ground. It ensures safety no matter the ground conditions.

What are the regulatory standards for scaffold outriggers?

Outriggers must meet OSHA and other safety rules. These rules make sure outriggers are safe and support scaffolds well.

How often should scaffold outriggers be inspected?

Check outriggers before use, after changes, and while in use. Regular checks help spot and fix problems early to keep everyone safe.

How can scaffold outriggers be adjusted to cope with varied conditions?

Outriggers can be adjusted for uneven ground, changing weight, and site-specific needs. This keeps scaffolds stable in different situations.

What are the best practices for assembling scaffolding outriggers safely?

Follow the maker’s instructions closely. Make sure all parts fit and are in good shape. Outriggers should be set up and secured right. Training and the right tools are also key for safety.

What considerations should be made when purchasing scaffolding safety outriggers?

Think about the load it can take, if it fits your scaffold, the material it’s made of, safety rules, and where it will be used. Compare quality and price to get a good deal in safety and durability.

How does the quality of scaffold outriggers affect overall scaffold safety?

Good outriggers are strong and can handle stress and the elements. They’re less likely to fail, which is key for keeping workers safe on scaffolds.