Phone:

(+65)8319-0742

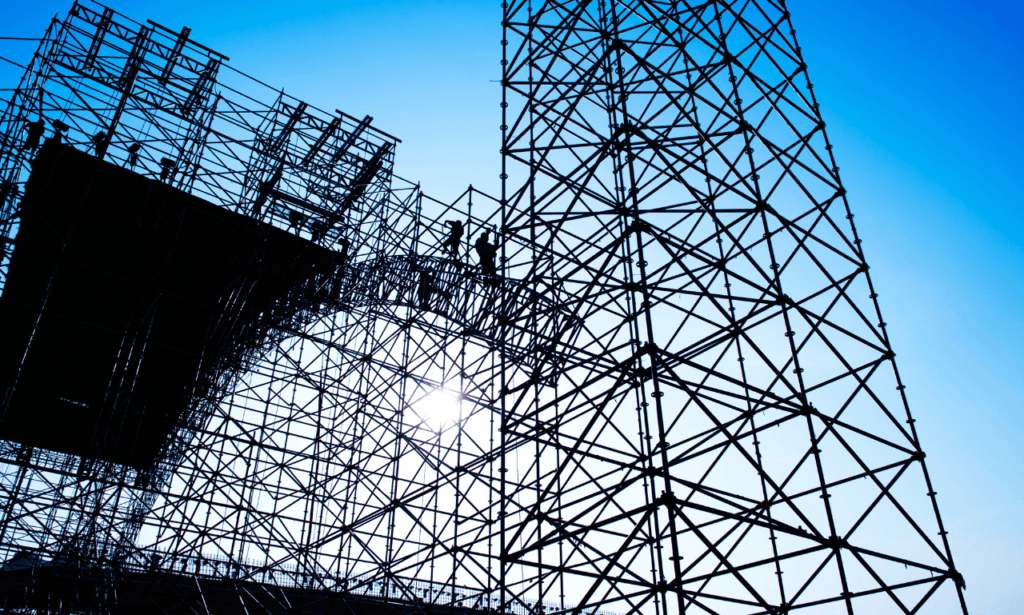

In construction, scaffolding couplers are key for safety and stability. They connect scaffolding tubes, making a strong framework. This framework supports workers, tools, and materials at different heights during projects.

Scaffolding couplers are made from strong materials like steel or aluminum. Steel is best for heavy-duty jobs. Aluminum is lighter but still strong for most tasks. Hot dip galvanized scaffolding couplers are preferred for their superior anti-corrosion properties and longer lifespan. Knowing how important scaffold connectors are helps keep construction sites safe and efficient.

Scaffold fittings join scaffolding tubes together. This makes the structure stable and safe for heavy loads. These couplers are built to handle tough construction environments. They are vital for modular scaffolding systems.

Key Takeaways

Scaffolding couplers are essential for securely connecting scaffolding tubes

They create a strong framework to support workers, tools, and materials at heights

Couplers are made from durable materials like steel or aluminum

Understanding scaffold connectors is crucial for maintaining safe construction sites

Scaffold fittings ensure structures remain stable and can support heavy loads safely

Understanding Tube and Coupler Scaffolding Systems

Tube and Coupler Scaffolding systems are key on construction sites around the world. They offer a strong and flexible setup for workers to safely tackle complex projects. These scaffold systems are built for top stability and flexibility. They make sure workers have a safe place to work on different construction sites.

Components and Configuration

The setup of Tube and Coupler Scaffolding uses important parts. Each part is vital for building a strong and reliable structure. The main parts are:

Strong scaffold tubes that go up and down

Swivel couplers for flexible connections

Sleeve couplers for joining tubes for longer spans

Putlog couplers for attaching transoms or putlogs

Girder couplers for connecting scaffold tubes to beams

Double couplers for connecting scaffold tubes at right angles, known for their load capacity

Board retaining couplers for scaffold boards

Base plate couplers to keep scaffold standards stable

These scaffold fittings make it easy to adjust the setup. This boosts safety and efficiency on-site.

Strengths of Tube and Coupler Scaffolding

Tube and Coupler Scaffolding systems are known for their strong load-carrying ability. They can handle the weight of construction materials and tools. Heavy-duty systems can hold up to 75 lbs. per square foot. This makes them great for tall sites and complex structures.

The adaptability of Tube and Coupler Scaffolding allows it to conform to irregular work surfaces and project specifications, ensuring a tailored fit for each unique construction endeavor.

Following OSHA standards is key for the safety and efficiency of these scaffolding systems. Scaffold designs must be strong enough to hold at least four times the maximum load. This ensures the safety of workers and the success of the project.

Design Flexibility for Complex Structures

Tube and coupler scaffolding is great because it can fit into complex shapes. It’s perfect for construction projects that need precision and customization.

Construction pros use tube and coupler scaffolding to make scaffold designs that fit unique building shapes. They pick and arrange different couplers to build scaffolds that support workers well. This lets them reach every part of the building.

This flexibility is key for construction projects like historic buildings or ones with irregular building shapes. Tube and coupler scaffolding lets workers safely work on tough facades and surfaces.

“The inherent design flexibility of tube and coupler scaffolding sets it apart, allowing the customization of scaffolds to fit the most intricate and irregular building shapes. Construction professionals rely on these adaptable components to erect scaffolds that precisely align with the unique contours of each construction project, ensuring precision and dependability.”

The modular design of tube and coupler scaffolding adds to its flexibility. By mixing standard parts in new ways, designers can make custom access solutions. This approach saves materials and cuts costs.

In short, tube and coupler scaffolding changes the game in construction. It lets pros work on complex structures with confidence. This ensures every project, no matter how tough, can be done safely and well.

Key Features of Tube and Coupler Scaffolding

Tube and coupler scaffolding is known for its strength and flexibility. It’s perfect for heavy-duty scaffolding needs. It lets workers work at different heights at the same time, making construction work better.

This scaffolding system follows strict safety rules. Each part is made to handle big weights and side pressures. This is especially true when it’s covered in mesh.

Heavy-Duty Construction

The scaffolding is made from top-quality steel. Steel makes it strong and stable, even for big scaffolds. It also doesn’t catch fire easily, keeping workers safe.

Adherence to Standards

Following safety rules is very important in building. Tube and coupler scaffolding meets these standards. It’s tested to make sure it’s safe and strong, giving workers a secure place to work.

Protective Measures

Guardrails and toeboards are key parts of the scaffolding. They help prevent falls and stop things from falling off. These features make the scaffolding a safe place for workers.

Toe board couplers are used to attach timber or steel toe boards to scaffolding structures, preventing objects from falling from the work platform and ensuring worker safety.

Feature | Benefit |

|---|---|

Steel Components | High strength and stability |

Fire Resistance | Enhanced safety in case of fire |

Guardrails and Toeboards | Fall protection and prevention of falling objects |

Compliance with Standards | Ensured safety and reliability |

Tube and coupler scaffolding offers a solid base for building projects. It focuses on keeping workers safe and helps them work efficiently at high places.

Tube and Coupler Scaffolding in Construction Projects

In the world of construction, scaffolding structures, including tube and coupler scaffolding, are a big deal. It’s versatile and strong, perfect for many projects. It meets different needs, making it key for builders.

Heavy-Duty Load Capacity

Tube and coupler scaffolding can hold a lot of weight. It’s built to support heavy materials and equipment. It can handle up to 75 lbs. per square foot, giving builders confidence.

Scaffolding Configuration | Length (feet) |

|---|---|

T-4 | 4′ |

T-6 | 6′ |

T-8 | 8′ |

T-10 | 10′ |

T-13 | 13′ |

T-16 | 16′ |

Adaptability to Unique Building Structures

Construction scaffolding fits unique buildings well. It works with complex designs and shapes. Its design lets builders adjust it to fit any building.

The versatility of tube and coupler scaffolding is unmatched. It allows us to tackle complex architectural designs with confidence, knowing that we can adapt the scaffolding to fit any unique structure.

Tube and coupler scaffolding comes in many sizes and shapes. Badger Ladder offers it in lengths from 4 feet to 16 feet. This lets builders pick the right setup for their projects.

Tube and coupler scaffolding is a top choice for builders. It’s strong, fits many buildings, and makes work safer. It’s a must-have in the construction world.

Evaluation of Scaffold Types Light Medium and Heavy Duty

Tube and coupler scaffolding is known for its strength and flexibility. It’s perfect for heavy-duty scaffolding needs. It lets workers work at different heights at the same time, making construction work better.

This scaffolding system follows strict safety rules. Each part is made to handle big weights and side pressures. This is especially true when it’s covered in mesh.

Heavy-Duty Construction

The scaffolding is made from top-quality steel. Steel makes it strong and stable, even for big scaffolds. It also doesn’t catch fire easily, keeping workers safe.

Adherence to Standards

Following safety rules is very important in building. Tube and coupler scaffolding meets these standards. It’s tested to make sure it’s safe and strong, giving workers a secure place to work.

Protective Measures

Guardrails and toeboards are key parts of the scaffolding. They help prevent falls and stop things from falling off. These features make the scaffolding a safe place for workers.

Toe board couplers are used to attach timber or steel toe boards to scaffolding structures, preventing objects from falling from the work platform and ensuring worker safety.

Feature | Benefit |

|---|---|

Steel Components | High strength and stability |

Fire Resistance | Enhanced safety in case of fire |

Guardrails and Toeboards | Fall protection and prevention of falling objects |

Compliance with Standards | Ensured safety and reliability |

Tube and coupler scaffolding offers a solid base for building projects. It focuses on keeping workers safe and helps them work efficiently at high places.

Tube and Coupler Scaffolding in Construction Projects

In the world of construction, scaffolding structures, including tube and coupler scaffolding, are a big deal. It’s versatile and strong, perfect for many projects. It meets different needs, making it key for builders.

Heavy-Duty Load Capacity

Tube and coupler scaffolding can hold a lot of weight. It’s built to support heavy materials and equipment. It can handle up to 75 lbs. per square foot, giving builders confidence.

Scaffolding Configuration | Length (feet) |

|---|---|

T-4 | 4′ |

T-6 | 6′ |

T-8 | 8′ |

T-10 | 10′ |

T-13 | 13′ |

T-16 | 16′ |

Adaptability to Unique Building Structures

Construction scaffolding fits unique buildings well. It works with complex designs and shapes. Its design lets builders adjust it to fit any building.

The versatility of tube and coupler scaffolding is unmatched. It allows us to tackle complex architectural designs with confidence, knowing that we can adapt the scaffolding to fit any unique structure.

Tube and coupler scaffolding comes in many sizes and shapes. Badger Ladder offers it in lengths from 4 feet to 16 feet. This lets builders pick the right setup for their projects.

Tube and coupler scaffolding is a top choice for builders. It’s strong, fits many buildings, and makes work safer. It’s a must-have in the construction world.

Evaluation of Scaffold Types Light Medium and Heavy Duty

Choosing the right scaffolding is key for a project’s success and safety. Projects need different scaffolding, from light-duty for simple tasks to heavy-duty for tough jobs. It’s important to match the scaffolding to the project’s needs.

Light-duty scaffolding can hold up to 25 lbs. per square foot. It’s great for tasks like painting and electrical work. It’s cost-effective for projects that don’t need much weight.

Medium-duty scaffolding can handle 50 lbs. per square foot. It’s good for general construction and can hold a bit more than light-duty. It’s a popular choice because it’s strong yet flexible.

For heavy tasks, heavy-duty scaffolding is the best choice. It can hold 75 lbs. per square foot, making it perfect for big projects and heavy materials. It’s used for large construction jobs and industrial settings.

Scaffold Type | Load Capacity | Typical Applications |

|---|---|---|

Light Duty | 25 lbs./sq. ft. | Light work, few workers, hand tools |

Medium Duty | 50 lbs./sq. ft. | General construction, moderate materials |

Heavy Duty | 75 lbs./sq. ft. | Extensive construction, material storage |

When picking scaffolding, think about the work, workers, materials, and project length. The right scaffolding ensures a safe and efficient work area. It meets the project’s specific needs.

Choosing the right scaffolding is not just about meeting the project’s needs; it’s about prioritizing the safety and well-being of the workers who rely on these structures every day.

In conclusion, knowing the differences between light, medium, and heavy-duty scaffolding is vital. By carefully choosing the right scaffolding, construction pros can improve safety, efficiency, and productivity on site.

Safety Measures and Hazard Prevention

Keeping workers safe on scaffolding is key in construction. Over 62% of construction workers face heights over five feet, says the Bureau of Labor Statistics (BLS). So, it’s vital to have strong scaffolding safety protocols. These start with a detailed hazard assessment to spot and fix risks. This includes preventing falls, making sure the structure is stable, and protecting against weather damage.

Hazard Assessments and Safety Protocols

First, you need to do a hazard assessment. This step is crucial for setting up safety plans. It looks for dangers like falls, scaffold collapse, and electrocution, which are common. By finding these risks, teams can make plans to keep workers safe.

Importance of Qualified Scaffold Design

A qualified scaffold design is vital for safe scaffolding, especially over 125 feet. Certified experts must design these to meet safety standards. They make sure the scaffolding can handle at least four times the expected load, as OSHA requires. The design also considers support, stability, and how to prevent collapse.

Guardrails, Toeboards, and Fall Protection

Guardrail systems and toeboards are key for fall protection scaffolding. They stop falls and protect against dropped objects. Following the rules for installing these is a must. Active fall protection, like personal fall arrest systems, also plays a big role in safety. OSHA says to use fall protection at 10 feet, but many use it at 6 feet or higher.

Safety Measure | Purpose | OSHA Requirement |

|---|---|---|

Guardrail Systems | Prevent falls from scaffolding | Required on scaffolds over 10 feet |

Toeboards | Prevent tools and materials from falling | Required on scaffolds over 10 feet |

Personal Fall Arrest Systems | Catch workers in the event of a fall | Required when working over 10 feet |

Scaffold Inspection | Identify visible defects | Required before each work shift |

By following these safety steps and OSHA rules, construction teams can lower accident risks. Training, keeping equipment in good shape, and a strong safety focus are all key. Together, they make scaffolding work safer.

Practical Insights: Erection, Use, and Dismantling

Building safe and reliable structures depends on scaffolding erection, use, and dismantling. Properly assembling the scaffolding is key. This includes using tubes and couplers to create a stable framework. It’s important to follow guidelines and standards to ensure the structure’s safety.

After setting up the scaffolding, its use must be closely watched. Regular checks for wear, rust, or damage are crucial. If problems are found, replace the parts right away to keep the scaffolding safe. OSHA says scaffolds must support their own weight and at least four times the maximum load without failing.

When the project ends, dismantling the scaffolding starts. This means carefully taking it apart, including removing couplers. It’s important to collect and store couplers properly. Keeping track of them helps for future projects.

Scaffolding must be inspected continuously by users to ensure they are maintained in a safe condition.

Storing scaffolding couplers right is key to their long life. If stored well, couplers can be used many times. But, preventing rust is vital. Any couplers with rust should be removed and treated. Also, small parts can get lost, so collect them quickly.

Inspection Type | Frequency | Key Points |

|---|---|---|

Pre-shift Inspection | Before each work shift | Check for visible defects and structural integrity |

Post-incident Inspection | After any occurrence that could affect structural integrity | Assess damage and make necessary repairs or replacements |

Continuous User Inspection | Ongoing during use | Users should continuously monitor the scaffolding for safety |

Following best practices in scaffolding erection, use, and dismantling is crucial. This ensures worker safety and project success. Regular checks, proper care, and following standards are key to a safe and efficient work site.

Types of Scaffolding Coupler

Scaffolding couplers are key in the construction world. They connect scaffolding tubes for stable frameworks. These scaffolding connectors come in many types, each for different needs and angles. Knowing the types is key for safe and efficient scaffolding.

Swivel Couplers

Swivel couplers are flexible, allowing tubes to connect at unique angles. They rotate for various angles, keeping connections strong. These are great for scaffolding around odd shapes or over obstacles.

Right-Angle Couplers

Right-angle couplers, or 90-degree couplers, are common. They connect tubes at right angles, making joints strong. These couplers are vital for scaffolding’s basic structure, supporting workers safely.

Sleeve Couplers

Sleeve couplers join tubes end-to-end, extending lengths without weakening. They ensure a solid connection. Useful for longer scaffolding, they help build extended platforms.

Putlog Couplers

Putlog couplers, or single couplers, attach horizontal beams to scaffolding. They support platforms, keeping them stable. Crucial for safe working heights.

Beam Couplers

Beam couplers connect tubes to beams, adding support. They anchor scaffolding to structures, enhancing stability. Useful when scaffolding meets the building’s framework.

Beam clamps, including fixed and swivel types, play a crucial role in securing scaffolding to beams of various flange thicknesses, ensuring adherence to specific manufacturing standards.

Board Retaining Couplers

Board retaining couplers keep scaffold boards in place. They prevent boards from slipping, ensuring a safe platform. They’re key for safety and stability.

Board clamps also play a crucial role in securing scaffold boards or toe-boards to the scaffolding structure, preventing them from shifting and maintaining a safe working environment.

Joint Pin Couplers

Joint pin couplers connect tubes with pins inside. They’re easy to install, making scaffolding setup quick. They’re reliable for extending tubes while keeping structures strong.

Coupler Type | Weight (kg) | Fits (mm) |

|---|---|---|

BS DF Double Coupler | 1 | 48.3*48.3 |

JIS Pressed Double Coupler | 0.5-0.65 | 48.6*48.6 |

Korea Pressed Double Coupler | 0.67 | 48.6*48.6 |

Pressed Fencing Coupler | 0.36 | 48.3 |

BS Pressed Sleeve Coupler | 1 | 48.3 |

Casting Fixed Coupler | 1 | 48.3*48.3 |

The table shows weights and sizes of scaffolding couplers. Weights range from 0.4 kg to 1.75 kg. For example, the drop forged fixed coupler weighs 0.97 kg, while the drop forged swivel coupler American type is 1.75 kg. They come in various finishes for different projects.

Couplers must meet standards like EN74 and BS1139 for quality and safety. Regular checks are vital to avoid accidents and keep scaffolding safe. Inspections should happen before use, weekly, or every two weeks, and after incidents.

In summary, scaffolding couplers are crucial in construction. They help build safe scaffolding. Knowing each type’s function helps choose the right ones for projects. This ensures safety, efficiency, and strong structures.

Importance of Scaffolding Couplers in Construction

Scaffolding couplers are key in the construction world. They connect scaffolding tubes to make stable platforms for workers and materials at different heights. These couplers are crucial for building scaffolding frames, helping workers stay safe and efficient on projects.

They connect horizontal parts to vertical poles, making strong frameworks that hold heavy loads. A single scaffold tube can support up to 35kN, meeting structural needs. The couplers ensure the structure is safe and stable by joining two scaffold tubes, either end-to-end or at an angle, using different types of couplers like sleeve and swivel couplers.

Steel tubes are a critical component in tube and coupler scaffolding systems, known for their adaptability to complex structures and strength.

Couplers also offer flexibility, fitting scaffolding around complex shapes or obstacles. This is useful for reaching hard-to-access areas or unique building designs. Different types of couplers meet various connection needs, making scaffolding systems more versatile.

Safety is a big deal in construction, and couplers play a big role. Board retaining couplers keep scaffold boards in place, and anchor couplers secure scaffolding to buildings. These features help prevent accidents and injuries on construction sites. “Scaffolding couplers are the unsung heroes of the construction world. They may seem small and insignificant, but without them, we wouldn’t be able to build the incredible structures that shape our cities and communities.” Couplers are also durable and long-lasting, made from materials like forged steel. They can last over a decade with proper care. This saves money and resources for construction companies. Well-designed scaffolding also leads to better economic results and lower costs for projects.

Scaffold Tube Diameter | Common Length | Material |

|---|---|---|

1.5 inches to 4 inches | 5 feet to 10 feet | Steel or Aluminum |

Scaffolding couplers are essential in many construction areas, like government projects and sports stadiums. Their demand is growing, especially in countries like Pakistan. As construction needs for safe work platforms increase, so will the importance of scaffolding couplers.

Scaffolding Coupler Materials

Scaffolding couplers are typically crafted from high-strength steel alloys, ensuring they can support heavy loads and endure harsh environmental conditions. The most common materials used for scaffolding couplers include:

Carbon Steel: This material is a popular choice due to its high strength-to-weight ratio, excellent corrosion resistance, and affordability. Carbon steel couplers are robust and reliable, making them ideal for various construction projects.

Alloy Steel: Enhanced with elements such as chromium, manganese, and vanadium, alloy steel offers superior strength, toughness, and corrosion resistance. These properties make alloy steel couplers suitable for demanding construction environments.

Stainless Steel: Known for its corrosion resistance, stainless steel contains a minimum of 10.5% chromium. This makes it perfect for use in harsh environments where corrosion is a significant concern, ensuring long-lasting performance.

Galvanized Steel: Galvanized steel couplers are coated with a layer of zinc, providing additional corrosion resistance and extending their lifespan. This makes them a durable option for outdoor and long-term projects.

In addition to these materials, scaffolding couplers may also be made from aluminum or fiberglass. Aluminum couplers are lightweight yet strong, making them easy to handle and install. Fiberglass couplers offer excellent corrosion resistance and are non-conductive, making them ideal for specific applications where these properties are required.

By choosing the right material for scaffolding couplers, construction professionals can ensure the durability and safety of their scaffolding systems, adapting to the specific needs of each project.

Common Scaffolding Coupler Mistakes

Scaffolding couplers are a critical component of scaffolding systems, and improper use or installation can lead to serious safety risks and accidents. Here are some common mistakes to avoid when working with scaffolding couplers:

Incorrect Installation: Failing to properly install scaffolding couplers can lead to a weakened scaffolding structure, which may collapse under load. It’s crucial to follow manufacturer guidelines and ensure all connections are secure.

Overloading: Exceeding the weight capacity of scaffolding couplers can cause them to fail, leading to a collapse of the scaffolding structure. Always adhere to the specified load limits to maintain structural integrity.

Poor Maintenance: Regular inspection and maintenance of scaffolding couplers are essential. Neglecting this can lead to corrosion, wear, and tear, compromising their strength and integrity. Routine checks help identify and address issues before they become serious problems.

Mixing and Matching: Using scaffolding couplers from different manufacturers or with different specifications can lead to compatibility issues and safety risks. It’s important to use couplers that are designed to work together to ensure a stable and secure scaffolding structure.

Ignoring Safety Guidelines: Failing to follow safety guidelines and regulations when working with scaffolding couplers can lead to accidents and injuries. Always adhere to industry standards and best practices to ensure a safe working environment.

By avoiding these common mistakes, scaffolding professionals can ensure the safe and effective use of scaffolding couplers, preventing accidents and injuries on the job site. Proper installation, regular maintenance, and adherence to safety guidelines are key to maintaining a safe and efficient scaffolding structure.

Girder Couplers: Connecting Scaffold Tubes to Structural Sections

Girder couplers, also known as gravlock couplers, SK couplers, and beam couplers, are key in linking scaffold tubes to beams and columns. They can handle sections up to 45 mm thick. It’s important to use them in pairs, on both sides, for safety and stability.

Mechanism of Girder Couplers

Girder couplers clamp onto the flanges of structural sections. This prevents slipping and keeps the scaffold stable. For example, the Gravlock Girder Coupler connects to steel I beams up to 45 mm thick. It’s made from forged steel and has a zinc-plated exterior for durability.

Load Capacity and Safety Limits of Girder Couplers

The load capacity of girder couplers depends on their position. Here are the maximum safe working loads for different scenarios:

Girder couplers are also essential in suspended scaffolding systems, where their load capacity and stability are crucial for providing elevated access in challenging architectural environments.

Position | Load Type | Maximum Safe Working Load |

|---|---|---|

Y-axis (vertical) | Uniformly loaded | 30 kN per pair |

Y-axis (vertical) | Eccentrically loaded (hanging load) | 15 kN on leading coupler |

Z-axis (horizontal) | Uniformly loaded (slip of tube through couplers) | 6.5 kN per pair |

X-axis (horizontal) | Uniformly loaded (slip of couplers along section) | 10 kN per pair |

Essential Safety Guidelines for Using Girder Couplers

To use girder couplers safely and effectively, follow these guidelines:

Always use girder couplers in pairs

Ensure that the couplers are properly tightened

Avoid overloading the scaffold

Regularly inspect the scaffold for any signs of damage

Immediately replace any damaged couplers

Best Practices for Installation and Maintenance

Proper installation and maintenance are key for safe use. When installing, make sure to tighten the set screws well. Regular checks are vital to keep the couplers in good shape.

The Gravlock Girder Coupler is supplied to AS-15762.2-1991 standards for quality assurance, ensuring that it meets the highest safety and performance standards in the industry.

George Roberts (North West) Ltd, a leading supplier in the UK, delivers scaffold couplers nationwide in 48 hours. They stand out for their values, expertise, and commitment to employee engagement through their Employee Ownership Trust.

Conclusion

Scaffolding couplers are key in the construction world. They ensure scaffolding safety and boost construction efficiency. These small parts connect scaffolding tubes, making stable structures for workers and materials at high places.

Knowing about different couplers and how to use them is important. It helps keep the work area safe and efficient. This knowledge is crucial for construction pros.

There are many types of couplers, like right-angle and swivel couplers. Each has its own role in a strong scaffolding system. They can handle heavy loads and are built to last.

Following safety rules and checking couplers often is vital. It keeps accidents away and makes scaffolding last longer.

Couplers are vital for finishing construction projects safely and on time. They make sure structures are solid and help work flow better. This means less downtime and more efficiency.

By focusing on safety and using top-notch couplers, the construction world can keep building great things. And it can do so while keeping everyone safe and productive.

FAQ

What are scaffolding couplers, and why are they important?

Scaffolding couplers are key parts that connect scaffolding tubes. They make a strong framework for workers and tools at high places. They are vital for safety and efficiency on construction sites.

What are the main components of a tube and coupler scaffolding system?

A tube and coupler system includes scaffold tubes and various couplers. These include swivel, right-angle, and sleeve couplers. They help create a strong and flexible scaffolding structure.

How do tube and coupler scaffolding systems handle complex building shapes?

These systems are very flexible. They can be customized to fit complex building shapes. This ensures scaffolds fit perfectly, making construction work precise and reliable.

What are the load capacities of different types of scaffolding?

Light-duty scaffolding can hold 25 lbs. per square foot. It’s good for light work. Medium-duty scaffolding can hold 50 lbs. per square foot, suitable for general construction. Heavy-duty scaffolding can hold 75 lbs. per square foot, ideal for storing materials.

What safety measures are crucial when working with scaffolding?

Safety is key. Conduct thorough hazard assessments and follow safety rules. Make sure scaffolds are designed and installed correctly. Use guardrails, toeboards, and fall protection systems. Regularly check and maintain scaffolding for a safe work environment.

What are the different types of scaffolding couplers, and how are they used?

There are many types of couplers. Swivel couplers connect tubes at angles. Right-angle couplers connect tubes perpendicularly. Sleeve couplers connect tubes end-to-end. Putlog couplers support platforms. Beam couplers attach tubes to beams. Board retaining couplers secure boards. Joint pin couplers connect tubes easily.

How do girder couplers work, and what are their load capacities?

Girder couplers, or beam couplers, connect tubes to beams. They must be used in pairs for stability. Their load capacity depends on the load type and position.

What are the best practices for installing and maintaining scaffolding couplers?

Always use couplers in pairs and tighten screws well. Avoid overloading and check for damage regularly. Replace any damaged couplers. Proper installation and maintenance ensure the scaffolding’s reliability.