Phone:

(+65)8319-0742

When it comes to construction safety, high-quality panels are essential. Designed to meet modern demands, these products ensure optimal functionality and durability. They are engineered to handle debris effectively, keeping sites clean and secure.

Precision in sizing allows these panels to adapt to various site requirements. Whether you need standard or custom dimensions, the design ensures a perfect fit. This technical accuracy makes them a reliable choice for professionals.

Competitive pricing adds to their appeal, offering excellent value without compromising quality. The panels are easy to install and remove, making them a practical solution for any project. Their construction adheres to industry standards, ensuring safety and efficiency.

Key Takeaways

- High-quality panels designed for construction safety and debris control.

- Precision sizing ensures adaptability to various site needs.

- Competitive pricing offers great value for money.

- Easy installation and removal for convenience.

- Meets industry standards for durability and functionality.

Introduction to Scaffold Screen Panels

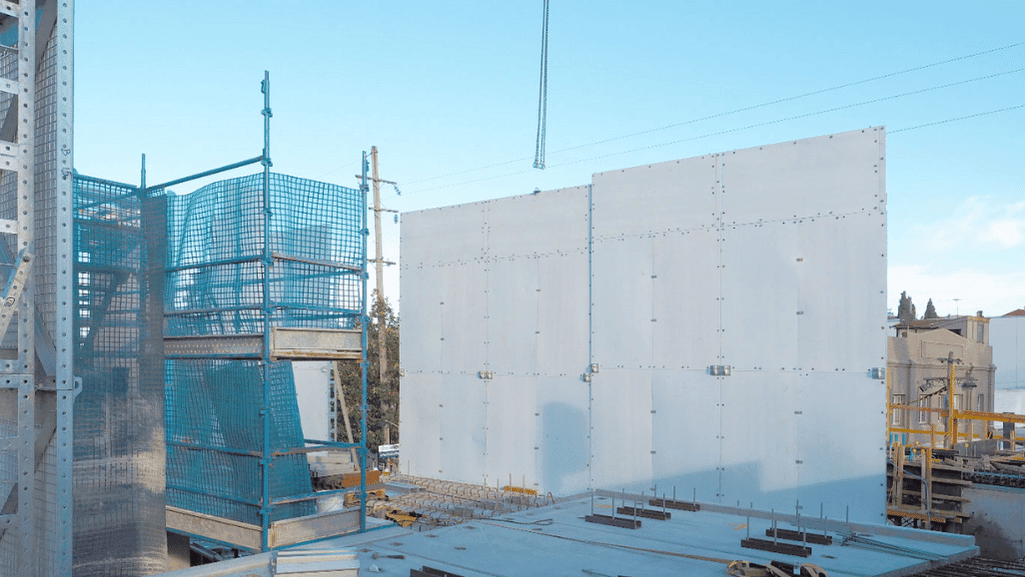

Construction sites demand robust safety measures, and scaffold screen panels play a pivotal role. These panels are essential for maintaining a secure environment, protecting workers, and ensuring compliance with industry standards. Their design focuses on durability and functionality, making them a reliable choice for professionals.

High-density netting is a key feature of these panels. It enhances safety by preventing debris from falling while allowing airflow. This balance ensures that workers are protected without compromising ventilation on the site. The netting’s strength and flexibility make it ideal for various construction needs.

Scaffold screen panels act as a protective barrier, shielding workers and pedestrians from potential hazards. They are engineered to control debris effectively, reducing the risk of accidents. This makes them an indispensable tool for maintaining safety and order on construction sites.

Safety features such as reinforced edges and fire-rated materials further enhance their effectiveness. These panels help prevent falls and ensure compliance with strict safety regulations. Their evolution over the years has led to advanced designs that meet modern construction demands.

For more information on how these panels enhance safety, explore our detailed guide on Scaffold Safety Nets. This resource highlights their role in fall protection and debris containment, ensuring a secure work environment.

Key Features and Benefits

Modern construction projects require reliable solutions to ensure safety and durability. High-quality panels are designed to meet these demands, offering exceptional performance in even the toughest conditions. Their advanced features make them an indispensable tool for professionals.

Durability and Lifespan

These panels are built to last. Engineered with tear-resistant materials, they withstand heavy use without compromising performance. UV treatment ensures they remain effective under prolonged sun exposure, making them ideal for long-term projects.

Even in harsh weather, the panels maintain their integrity. Their robust construction acts as a reliable barrier against wind, debris, and other environmental challenges. This durability translates to cost savings, as replacements are rarely needed.

Enhanced Safety Mechanisms

Safety is a top priority on any construction site. These panels are designed with features that minimize risks. Reinforced edges and fire-rated materials provide added protection, ensuring compliance with strict safety standards.

Their versatility allows for multiple applications, from debris control to wind resistance. This adaptability makes them a valuable asset in various phases of construction. By reducing hazards, they create a safer environment for workers and pedestrians alike.

- Exceptional durability for long-term performance in demanding conditions.

- UV treatment and tear resistance ensure a prolonged lifespan.

- Acts as a robust barrier against environmental elements.

- Integrated safety features reduce risks on construction sites.

- Multiple applications enhance versatility and efficiency.

With these features, high-quality panels are a smart investment for any project. They combine strength, safety, and adaptability to meet the needs of modern construction sites.

Innovative Design and Material Specifications

Innovative design and premium materials are at the core of modern construction safety solutions. These elements ensure that every product meets the rigorous demands of today’s construction environments. By focusing on advanced features, manufacturers deliver solutions that prioritize both protection and durability.

High-Density Poly Mesh Construction

The panels are crafted from high-density knitted poly mesh, a material known for its strength and reliability. This mesh design provides exceptional protection against debris while maintaining airflow. Its non-unraveling quality ensures longevity, even when cut or exposed to harsh conditions.

This material is engineered to withstand heavy use without compromising performance. Its tear-resistant properties make it ideal for long-term projects, offering consistent protection throughout the construction process.

Reinforced Button Holes and Eyelet Edges

Reinforced button holes and eyelet edges are key design features that enhance the panels’ functionality. These elements ensure secure attachments, preventing accidental detachment during use. The reinforced edges add an extra layer of protection, making the panels more durable and reliable.

These design specifics are tailored to meet the demands of construction sites. By using premium materials and innovative techniques, manufacturers create products that offer both safety and longevity.

Creative design elements are integrated to address the unique challenges of construction environments. From reinforced edges to precise mesh construction, every detail is engineered to provide optimal protection and performance. This focus on quality ensures that these panels are a trusted choice for professionals.

Advanced Safety and Compliance Standards

Ensuring safety on construction sites involves meeting advanced compliance standards and leveraging innovative technologies. These measures not only protect workers but also enhance operational efficiency. By adhering to strict regulations, construction professionals can minimize risks and maintain a secure environment.

NFPA 701 Certification Details

The NFPA 701 certification is a critical benchmark for fire retardancy in construction materials. This certification ensures that the panels meet stringent fire safety standards, reducing the risk of fire hazards. Materials with this certification are tested for flame resistance, making them ideal for high-risk environments.

By using NFPA 701-certified products, construction sites can comply with safety regulations and protect workers from potential fire incidents. This certification is a testament to the product’s reliability and commitment to safety.

UV Treatment for Extended Longevity

UV treatment is a key feature that enhances the durability of construction materials. This process protects the panels from sun damage, ensuring they remain effective over time. UV-treated materials resist fading and degradation, even in harsh weather conditions.

This treatment not only extends the lifespan of the panels but also maintains their white, clean aesthetic. By incorporating UV treatment, manufacturers ensure that the panels remain visually appealing while providing long-term performance.

These panels are engineered to control dust and debris effectively, keeping construction sites clean and safe. Their design minimizes the spread of dust, enhancing both safety and visual appeal. The combination of advanced safety features and compliance standards makes these panels a reliable choice for modern construction projects.

For more insights on maintaining safety and compliance, explore our guide on Scaffold Tagging Systems. This resource highlights best practices for ensuring safety and regulatory adherence on construction sites.

Application and Installation Insights

Efficient installation of safety barriers is crucial for maintaining a secure construction environment. Proper setup ensures optimal performance and minimizes risks. This guide provides step-by-step instructions to help you install debris netting and other protective barriers with ease.

Step-by-Step Installation Tips

1. Prepare the Area: Clear the installation site of any obstacles. Ensure the surface is clean and stable for secure attachment.

2. Unroll the Mesh: Carefully unroll the mesh to avoid tangling. Check for any defects or damage before proceeding.

3. Attach the Netting: Use reinforced button holes and eyelet edges for secure attachment. This ensures the debris netting stays in place even in windy conditions.

4. Secure the Edges: Reinforce the edges with durable fasteners. This step prevents accidental detachment and enhances longevity.

5. Inspect the Setup: Double-check all attachments to ensure they are secure. Address any loose ends or gaps immediately.

Handling the mesh properly is essential for optimum performance. Avoid excessive force during installation to prevent tears or damage. For more detailed guidance, explore our resource on Scaffold debris netting.

Common Challenges and Solutions

- Wind Resistance: High winds can cause the netting to detach. Use additional fasteners and ensure tight attachment.

- Mesh Tangling: Carefully unroll the mesh to avoid knots. Work with a partner for larger installations.

- Edge Wear: Reinforce edges with durable materials to prevent fraying over time.

Safety precautions are vital during installation. Always wear protective gear and follow industry standards. Proper installation not only enhances safety but also ensures compliance with regulations.

scaffold screen: The Ultimate Construction Barrier

In the construction industry, maintaining safety and efficiency is non-negotiable. A scaffold screen serves as the ultimate barrier, designed to prevent debris and enhance site security. Its robust construction ensures it can withstand harsh conditions while keeping work areas safe.

These panels are often rolled out for full coverage, providing a seamless protective layer. Engineered for high effectiveness, they contain debris and prevent hazardous conditions. This makes them indispensable for both small and large-scale projects.

The structural benefits of these barriers are unmatched. They are lightweight yet durable, offering flexibility without compromising strength. This balance ensures they can adapt to various site requirements, from high-rise buildings to ground-level constructions.

During different stages of a project, these panels secure work areas effectively. Whether it’s during demolition or finishing touches, they provide consistent protection. Their versatility and reliability make them a key component in modern construction safety.

By integrating these barriers, construction sites can meet safety standards while improving overall efficiency. Their ability to control debris and enhance safety makes them a smart investment for any project.

Enhancing Worksite Safety and Efficiency

Improving safety and efficiency on construction sites requires strategic planning and the right tools. By implementing effective measures, professionals can create a secure environment that minimizes risks and maximizes productivity. This section explores key strategies and best practices to achieve these goals.

Debris, Dust, and Wind Control

Controlling debris, dust, and wind is essential for maintaining a safe worksite. High-quality barriers act as an enclosure, preventing debris from spreading and reducing hazards. These barriers are designed to withstand strong winds, ensuring they remain effective in challenging conditions.

Dust control is another critical aspect. Properly installed barriers minimize dust dispersion, improving air quality and visibility. This not only enhances safety but also ensures compliance with environmental regulations. For comprehensive guidance on safety protocols, consider our resource on OSHA scaffold training.

Optimizing Barrier Placement

Strategic placement of barriers is key to maximizing their effectiveness. Position them to cover high-risk areas, such as edges and open spaces. This creates a secure enclosure that protects workers and pedestrians from potential hazards.

Using fire retardant materials adds an extra layer of safety. These materials reduce the risk of fire hazards, ensuring the barriers remain effective in emergencies. Proper placement and material selection are crucial for achieving optimal results.

Real-world examples demonstrate the impact of these strategies. Sites that prioritize barrier placement and material quality report fewer accidents and improved efficiency. By focusing on these elements, construction professionals can create safer, more productive worksites.

Custom Sizes and Material Options

Customization is a game-changer in construction safety solutions, offering tailored options to meet diverse project needs. From roll widths to material choices, these features ensure flexibility and precision for any site. Whether you’re working on a high-rise or a small renovation, custom solutions enhance both performance and aesthetics.

Roll Width Selections and Custom Sewing

Multiple roll widths are available to suit various construction requirements. These options allow for seamless coverage, reducing gaps and enhancing safety. Custom sewing ensures panels fit perfectly, even in irregular spaces. This precision minimizes waste and improves overall efficiency.

Fire-rated properties are a key feature of these custom panels. They meet strict safety standards, reducing the risk of fire hazards on-site. This makes them a reliable choice for high-risk environments. Compared to standard fence alternatives, custom options offer superior durability and adaptability.

Custom sizing also enhances aesthetic integration. Panels blend seamlessly with the site’s design, maintaining a professional appearance. This attention to detail ensures compliance with local regulations while improving site safety. For more information on tailored solutions, explore our scaffold netting options.

Here’s why custom options stand out:

- Flexibility: Multiple roll widths and sewing options adapt to unique site needs.

- Safety: Fire-rated materials ensure compliance and reduce hazards.

- Efficiency: Precise sizing minimizes waste and enhances performance.

- Aesthetics: Seamless integration maintains a professional site appearance.

Custom panels are designed to meet precise project specifications. This ensures they perform effectively in any construction scenario. By choosing tailored solutions, professionals can enhance safety, efficiency, and site aesthetics.

Comparing with Traditional Netting and Fencing Solutions

Choosing the right safety solution for construction sites can significantly impact both cost and environmental footprint. Modern scaffold screens offer a compelling alternative to traditional netting and fencing, combining durability, efficiency, and eco-friendliness. Let’s explore how these advanced solutions outperform conventional methods.

Cost-Effective Advantages

Investing in modern scaffold screens provides long-term savings. Unlike traditional fencing, these panels require minimal maintenance and fewer replacements. Their UV-treated materials resist wear and tear, ensuring a longer lifespan even in harsh conditions.

Additionally, their lightweight design reduces installation costs. They can be easily tied to existing structures, eliminating the need for additional supports. This efficiency translates to lower labor expenses and faster project completion.

For more insights on cost-effective solutions, explore our guide on netting for privacy.

Environmental Impact Considerations

Modern scaffold screens are designed with sustainability in mind. Their high-density materials effectively tie together various sections of a construction site, minimizing dust and debris spread. This reduces environmental contamination and ensures compliance with regulations.

Unlike traditional fencing, these panels are recyclable and made from eco-friendly materials. Their UV treatment not only extends their lifespan but also reduces waste. By choosing these solutions, construction sites can contribute to a greener future.

For advanced safety systems, consider our reveal tie scaffold options, which enhance stability and efficiency.

Here’s why modern scaffold screens stand out:

- Durability: UV-treated materials ensure long-term performance.

- Cost Savings: Reduced maintenance and installation expenses.

- Eco-Friendly: Recyclable materials and minimal environmental impact.

- Efficiency: Easy to tie and install, saving time and labor.

By comparing these solutions, it’s clear that modern scaffold screens offer superior value. They combine cost-effectiveness, environmental responsibility, and advanced functionality, making them the ideal choice for modern construction sites.

Quality Assurance and Testing Processes

Quality assurance is the backbone of reliable construction safety solutions. Every product undergoes rigorous testing to ensure it meets the highest standards. This process guarantees durability, safety, and compliance with industry regulations.

Stringent testing methods are applied to evaluate every aspect of the product. Fire rating tests ensure the materials can withstand high temperatures, reducing fire hazards. UV exposure tests confirm the panels remain effective under prolonged sun exposure, maintaining their integrity over time.

These tests are conducted in controlled laboratory environments to simulate real-world conditions. By replicating harsh weather and heavy use, manufacturers can identify potential weaknesses and address them before the product reaches the market.

Ensuring Industry Standards

Every cover and barrier is designed to meet strict industry standards. From debris retention to cover integrity, each test ensures the product performs as expected. This attention to detail ensures that construction sites remain safe and secure.

Quality control is a continuous process, starting during production and extending post-manufacturing. Inspections are conducted at every stage to identify and rectify any issues. This proactive approach minimizes defects and enhances product reliability.

- Fire Rating Tests: Ensures materials meet NFPA 701 standards for fire retardancy.

- UV Exposure Tests: Confirms durability under prolonged sun exposure.

- Debris Retention Tests: Evaluates the product’s ability to contain debris effectively.

- Cover Integrity Tests: Assesses the strength and durability of the cover under stress.

Transparency in testing underpins product reliability. Detailed reports are provided to customers, showcasing the results of each test. This openness builds trust and ensures that every screen meets the promised standards.

By investing in thorough quality assurance, manufacturers deliver products that exceed expectations. These processes not only enhance safety but also contribute to the longevity and efficiency of construction projects.

Real-World Case Studies in Construction

Real-world applications of advanced safety solutions demonstrate their effectiveness in construction projects. From high-rise buildings to ground-level sites, these products have proven their value in enhancing safety and efficiency. Let’s explore documented installations and customer feedback that highlight their impact.

Successful Site Installations

One notable project involved a high-rise development in Chicago. The reinforced eyelet design ensured secure attachment, even in strong winds. This feature prevented detachment, maintaining safety throughout the project.

Another example is a renovation project in New York. The panels’ durability and ease of installation reduced downtime, allowing the team to meet tight deadlines. The scaffolding system’s adaptability was key to its success.

These installations showcase how advanced safety solutions address real-world challenges. Their design and functionality make them indispensable for modern construction sites.

Customer Testimonials

Customers consistently praise the reliability of these products. One contractor noted, “The reinforced eyelet design saved us time and ensured safety during a complex project.”

Another client highlighted the panels’ durability: “Even after months of use, the scaffolding system remained intact, proving its long-term value.”

These testimonials underscore the product’s quality and effectiveness. For more insights on efficient installations, explore Scaffolding Solutions.

- Reinforced eyelets ensure secure attachment in challenging conditions.

- Durable materials withstand heavy use, reducing replacement costs.

- Easy installation enhances efficiency on-site.

- Customer feedback highlights reliability and long-term value.

These case studies and testimonials validate the product’s role in advancing construction practices. By addressing specific challenges, they provide practical solutions for professionals.

Simple Ordering and Excellent Customer Support

Ordering high-quality construction products has never been easier. Our streamlined process ensures you get what you need quickly and efficiently. From browsing to checkout, every step is designed with your convenience in mind.

Our user-friendly platform allows you to place orders online in just a few clicks. Whether you need standard sizes or custom solutions, we provide personalized estimates tailored to your project. This ensures you get the perfect fit without any guesswork.

Excellent customer support is our hook. Our team is available to assist you throughout the ordering and installation phases. From answering questions to guiding you through custom orders, we’re here to make the process seamless.

Need additional help? Contact us via our form or phone for prompt assistance. We’re committed to providing the support you need, when you need it. Our goal is to ensure your experience is smooth from start to finish.

One of the key benefits of working with us is the no-obligation pricing review. You’ll receive full details before making a decision, so there’s no pressure to commit until you’re ready. This transparency is part of what makes us a trusted partner.

With fast delivery times and ongoing post-purchase assistance, we’re dedicated to your satisfaction. Our products and services are designed to meet your needs, ensuring a hassle-free experience every step of the way.

Conclusion

For construction professionals seeking reliable safety solutions, advanced panels offer unmatched protection and efficiency. Their innovative design ensures durability, while safety features like reinforced edges and fire-rated materials set them apart. These panels are rigorously tested to meet industry standards, providing peace of mind on any site.

Customization options allow for precise fitting, ensuring optimal performance in diverse environments. The ability to withstand wind and debris makes them a practical choice for challenging conditions. Their advanced materials and rigorous testing guarantee long-term reliability.

By choosing these panels, you invest in a solution that enhances safety and efficiency. Their unique features ensure they remain effective against environmental challenges. Ready to elevate your site’s safety? Contact us today to learn more or place your order.