Phone:

(+65)8319-0742

In the construction industry, scaffold load ratings and safety standards play a crucial role in ensuring the well-being of workers and the structural integrity of scaffolding systems. Compliance with OSHA requirements for scaffold weight limits is of paramount importance to prevent accidents, injuries, and potential collapse. This includes understanding the distinctions between light duty and medium duty scaffolds, which are designed to support different load capacities.

It is also essential to use scaffold grade lumber instead of construction grade lumber, as the latter is significantly weaker and poses safety risks if used improperly, particularly in scaffolding applications. Using construction grade lumber in such contexts is not only against OSHA regulations but also compromises worker safety.

In this article, we will delve into the intricacies of scaffold load ratings and safety regulations, providing valuable insights into how they contribute to a safe working environment. Understanding the significance of proper load capacity management and compliance with OSHA standards is essential for all construction professionals and workers involved in scaffold installation and usage.

Key Takeaways:

- Scaffold load ratings and safety standards are vital for worker safety and structural stability.

- Compliance with OSHA requirements for scaffold weight limits is crucial to prevent accidents and potential collapse.

- Proper load capacity management is essential for a secure working environment.

- Workers should receive comprehensive training on scaffold load management and safety protocols.

- Exceeding scaffold load ratings can lead to structural risks and increased accident likelihood.

What are Scaffold Load Ratings?

Scaffold load ratings play a crucial role in ensuring the safety and stability of scaffolding structures. These load ratings determine the maximum weight that a scaffold can safely support, taking into account factors such as materials, design, and intended usage. By adhering to scaffold weight limits, workers can minimize the risk of accidents, injuries, and structural failures on construction sites.

There are different types of scaffold load ratings that are assigned based on the specific requirements of each scaffold system. Working load limit (WLL) is the maximum load capacity recommended for normal use, while ultimate load capacity represents the maximum load that a scaffold can withstand before failure.

The weight allowance on scaffolding is determined by careful calculations considering various factors, including the type and quality of materials used, the configuration and strength of the scaffold system, and the distribution of weight across the structure. It is essential to remember that exceeding scaffold load ratings can compromise the structural integrity of the scaffold and pose a significant risk to workers.

Understanding Scaffold Load Ratings & Safety Standards

In the realm of construction and maintenance, scaffolding plays an indispensable role in ensuring that work at heights is carried out safely and efficiently. Understanding scaffold load ratings and the associated safety standards is crucial for both safety and compliance. This article delves into the intricacies of scaffold load capacity, examining how it is calculated, the factors affecting it, and the regulations governing it, primarily focusing on the Occupational Safety and Health Administration (OSHA) guidelines.

What is Scaffold Load Rating and Why is it Important?

Scaffold load rating is a critical measure of the scaffold’s ability to support weight safely. It is essential because it dictates the maximum intended load that the scaffold can carry without compromising its structural integrity. This rating ensures that scaffolds are used within their designed and constructed limits, thereby preventing accidents and ensuring scaffold safety. Load ratings are calculated based on various factors, including the type of scaffold, material strength, and the intended use, such as light-duty, medium-duty, or heavy-duty applications.

How is Scaffold Load Rating Calculated?

The calculation of scaffold load rating involves assessing the weight capacity that a scaffold can safely support. This includes considering the rated load capacity of all scaffold components, like the scaffold plank and platform. The load rating is influenced by the design and construction of the scaffold system, ensuring that it can evenly distribute weight across the scaffold structure. For instance, light-duty scaffolds are designed to support 25 pounds per square foot, medium duty up to 50 pounds per square foot, and heavy-duty scaffolds can support up to 75 pounds per square foot.

Why Does Load Rating Matter for Scaffold Safety?

Load rating is vital for scaffold safety as it ensures that the scaffold structure can support the maximum intended load without risk of collapse. It is designed to prevent overloading, which can lead to deflection and potential failure of scaffold components. Ensuring scaffolds operate within their rated load capacity helps in mitigating risks associated with scaffold weight and load limits, thus protecting workers and equipment.

What are the Different Load Ratings for Scaffolds?

Scaffolds are classified based on their load ratings, which dictate their safe load capacity. Light-duty scaffolds are rated for loads of 25 pounds per square foot, suitable for tasks involving minimal weight. Medium-duty scaffolds can handle 50 pounds per square foot, appropriate for tasks with moderate weight requirements. Heavy-duty scaffolds are capable of supporting up to 75 pounds per square foot, often used for construction tasks requiring substantial weight support. Understanding these ratings is crucial for selecting the appropriate scaffold for specific projects.

By following scaffold weight limits, construction companies can ensure a secure working platform and maintain compliance with industry regulations, such as the Occupational Safety and Health Administration (OSHA) requirements. OSHA sets specific guidelines and standards for scaffold load ratings to protect the well-being of workers and prevent accidents resulting from overloaded scaffolds.

The Importance of Scaffold Weight Limits

Understanding and adhering to scaffold load ratings is crucial for maintaining a safe working environment on construction sites. By respecting weight allowances on scaffolding, workers and employers can:

- Promote worker safety by reducing the risk of structural collapses or scaffold failures.

- Prevent accidents and injuries resulting from overloading a scaffold.

- Ensure compliance with OSHA safety regulations.

- Extend the lifespan of scaffolding equipment by avoiding excessive stress and wear.

- Enhance productivity and efficiency by providing a secure and stable platform for workers to perform their tasks.

By prioritizing scaffold load ratings and weight limits, construction companies demonstrate their commitment to workplace safety, protecting their workers, and avoiding potential legal and financial consequences. It is crucial to educate workers about scaffold weight limits, monitor load capacities regularly, and implement appropriate safety measures to maintain a secure working environment.

| Type of Load Rating | Description |

|---|---|

| Working Load Limit (WLL) | The maximum load capacity recommended for normal use. |

| Ultimate Load Capacity | The maximum load a scaffold can withstand before failure. |

Understanding Load Capacity Calculations

When it comes to working with scaffolds, understanding load capacity calculations is crucial for ensuring a safe and secure environment. Scaffold load ratings determine the maximum weight a scaffold can handle, preventing potential accidents and structural failures. Let’s delve into the calculations and factors involved in determining the load capacity of a scaffold.

One of the key considerations in load rating calculations is the strength of the materials used in the scaffold construction. High-quality materials with appropriate strength properties are essential for safe load handling. Manufacturers provide load capacity information based on the structural design and strength of the scaffold.

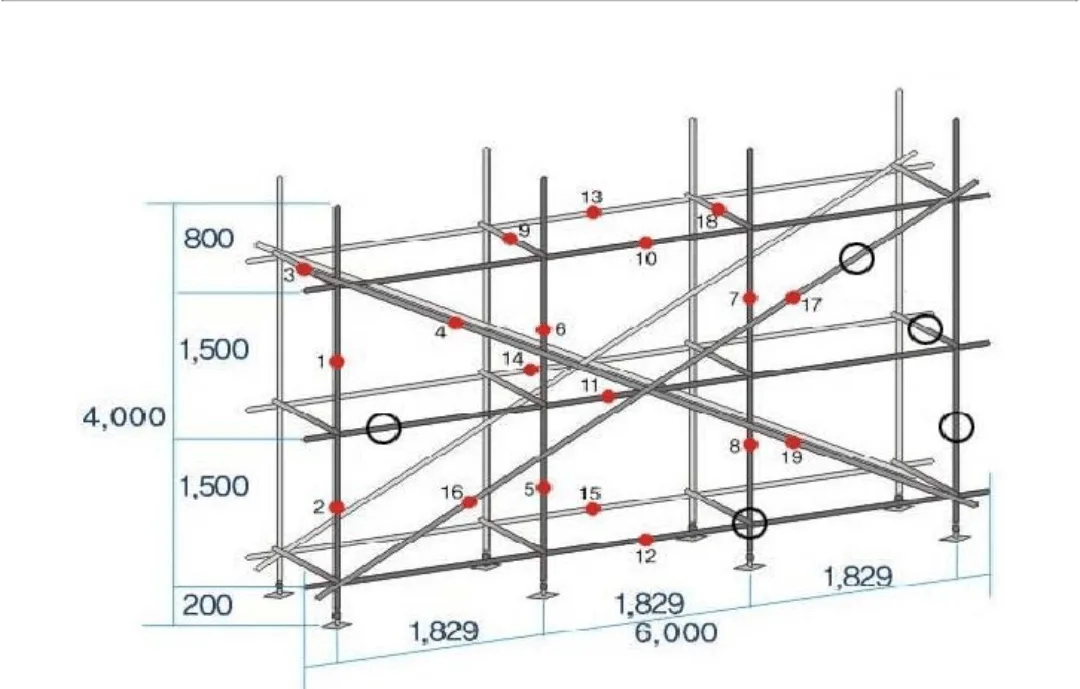

The design of the scaffold system also plays a vital role in load capacity calculations. The configuration, including the arrangement of braces, cross braces, and diagonal bracing, affects the overall stability and load-bearing capacity. Factors such as the height and width of scaffolds, as well as the placement of platforms and guardrails, are considered in load rating calculations.

Additionally, the distribution of weight across the scaffold is crucial for maintaining stability. Uneven weight distribution or concentrated loads can significantly impact the load capacity. To ensure safe load handling, it is necessary to distribute the weight evenly across the scaffold and avoid exceeding the maximum load for scaffolds as determined by the load ratings.

How Much Weight Can a Scaffold Support?

The weight that a scaffold can support depends on its load rating and the type of scaffold system used. Each scaffold is designed to handle a specific weight capacity, which ensures that it can safely support the maximum intended load. This understanding helps in planning and executing tasks efficiently, without exceeding the scaffold’s load limits.

Understanding Weight Capacity of Scaffold Systems

The weight capacity of scaffold systems is determined by various factors, including the material and design of the scaffold components. A scaffold can safely support a certain maximum weight, which is critical for maintaining scaffold safety. The rated load capacity and the scaffold’s ability to uniformly distribute weight are key in determining how much weight a scaffold can handle.

What Factors Affect Scaffold Load Limits?

Several factors affect the load limits of scaffolds, including the type of scaffold, the materials used, and environmental conditions. The scaffold’s design and construction play a significant role in its ability to support weight. Additionally, the use of guardrails and personal fall arrest systems can influence load limits. It’s essential to consider these factors to ensure that scaffolds are used within their safe load parameters.

How to Determine the Maximum Load for Your Scaffold?

Determining the maximum load for a scaffold involves assessing the scaffold’s load capacity and the intended use. It requires a thorough understanding of the scaffold’s rated load and the weight distribution across the scaffold platform. Consulting the manufacturer’s guidelines and adhering to OSHA requirements for scaffold safety are crucial steps in ensuring that the scaffold is not overloaded.

Scaffolding Load Rating Calculation Example:

To illustrate load capacity calculations, let’s consider a scaffolding system with specific specifications:

| Component | Material | Dimensions | Load Capacity |

|---|---|---|---|

| Vertical Standards (Uprights) | Steel | 2 inches diameter | 4,000 pounds |

| Horizontal Cross Braces | Steel | 2 inches diameter | 2,500 pounds |

| Platform Boards | Wood | 2 inches thick | 50 pounds per square foot |

In this example, the load capacity of the scaffold would be determined by the weakest component, which is typically the vertical standards with a load capacity of 4,000 pounds. Thus, the maximum load for this scaffold would be 4,000 pounds.

It is essential to note that load capacity calculations may vary depending on the specific scaffolding system and its intended use. Manufacturers provide detailed guidelines and specifications for load ratings, ensuring optimal safety and performance.

Understanding load capacity calculations allows workers and supervisors to make informed decisions regarding the maximum load the scaffold can handle. By adhering to load ratings and implementing proper weight distribution techniques, the risk of accidents and structural failures can be minimized, providing a secure working environment for all.

OSHA Requirements for Scaffold Weight Limits

In order to ensure the safety of workers and prevent accidents, injuries, and structural failures, OSHA has established specific requirements and standards for scaffold weight limits. Compliance with these regulations is crucial for maintaining a secure working environment and preventing any potential hazards.

OSHA mandates that scaffolds must be designed and constructed to support their own weight, as well as four times the maximum intended load. This means that scaffold load ratings must account for the weight of the workers, materials, and any equipment or tools used on the scaffold. Failure to adhere to these weight limits can lead to structural instability and potentially catastrophic incidents.

When determining scaffold weight limits, OSHA considers various factors, including the type and design of the scaffold, the materials used, and the safety factors employed. Scaffold load ratings are typically displayed on the scaffold and must be clearly visible to ensure that workers are aware of the maximum load capacity.

It is essential for employers, supervisors, and workers to fully understand and follow OSHA’s requirements for scaffold weight limits. Regular inspections should be conducted to ensure that scaffold load ratings are accurate and up-to-date, and that there are no signs of overloading or structural deficiencies.

By complying with OSHA regulations for scaffold weight limits, employers can create a safe working environment, reduce the risk of accidents, and protect the well-being of their workers. It is crucial to prioritize safety and ensure that scaffold load ratings are never exceeded.

Key OSHA Requirements for Scaffold Weight Limits:

- Scaffolds must be designed and constructed to support their own weight and four times the maximum intended load.

- Scaffold load ratings should be visibly displayed on the scaffold.

- Regular inspections must be carried out to ensure compliance with weight limits and identify any signs of overloading or structural deficiencies.

| Scaffold Type | Maximum Intended Load |

|---|---|

| Supported Scaffolds (Tube and Coupler) | 25 pounds per square foot |

| Mobile Scaffolds | 25 pounds per square foot |

| Mast Climbing Work Platforms | 75 pounds per square foot |

Safety Measures for Load Capacity Management

Ensuring the safety of workers and the stability of scaffolding structures requires the implementation of various safety measures. By adhering to scaffold load ratings and scaffold safety regulations, employers can create a secure working environment. Here are some key safety measures to manage load capacity effectively:

1. Proper Weight Distribution:

One of the crucial factors in maintaining scaffold stability is proper weight distribution. It is essential to evenly distribute the load across the scaffold to prevent overloading and uneven stress. This includes taking into account the weight of workers, tools, and materials. By following weight allowance on scaffolding, employers can prevent structural failures and potential accidents.

2. Regular Inspections:

To ensure the ongoing safety of scaffolding systems, regular inspections should be conducted. Inspections help identify any signs of damage, wear and tear, or faulty components that may compromise the load capacity. By identifying and addressing issues promptly, employers can mitigate risks and maintain a safe working environment.

3. Use of Safety Devices:

Employers must prioritize the use of safety devices to enhance load capacity management. Fall protection equipment, such as guardrails, safety nets, and personal protective gear, should be provided to workers. These safety devices provide an additional layer of protection and help prevent accidents resulting from overloading or mismanaged loads.

To sum it up, practicing proper weight distribution, conducting regular inspections, and utilizing safety devices are essential safety measures for managing load capacity on scaffolding systems. By following scaffold load ratings, scaffold safety regulations, and weight allowance on scaffolding, employers can prioritize the well-being of their workers and minimize the risk of accidents or structural failures

| Safety Measures | Description |

|---|---|

| Proper Weight Distribution | Evenly distribute the load across the scaffold to prevent overloading and uneven stress. |

| Regular Inspections | Conduct inspections to identify signs of damage, wear and tear, or faulty components that may compromise load capacity. |

| Use of Safety Devices | Prioritize the use of safety devices such as guardrails, safety nets, and personal protective gear to enhance load capacity management. |

Training and Education for Scaffold Load Management

Proper training and education are crucial aspects of ensuring scaffold load management and complying with scaffold safety regulations, including the OSHA requirements for scaffold weight limits. Comprehensive training programs play a vital role in equipping workers with the knowledge and skills necessary for maintaining the integrity of scaffold structures. By promoting a thorough understanding of scaffold load ratings, weight limits, and safety protocols, training programs aim to mitigate potential risks and enhance on-site safety.

Training sessions should cover various essential topics, such as:

- The importance of scaffold load ratings and their role in determining weight allowances on scaffolding.

- OSHA requirements for scaffold weight limits to prevent overloading and ensure structural stability.

- Proper calculation and distribution of loads to maintain a safe working platform.

- Recognizing signs of overloading and potential hazards associated with exceeding scaffold load ratings.

- Effective use of safety devices and equipment to enhance load capacity management and reduce the risk of accidents.

Furthermore, workers should receive hands-on training to develop practical skills in load management, such as:

- Correctly assembling and disassembling scaffolds to ensure stability and load-bearing capacity.

- Safely handling and positioning materials on scaffolds without exceeding weight limits.

- Inspecting scaffolding components for signs of wear, damage, or improper load distribution.

- Utilizing proper communication techniques to coordinate load movement and ensure the safety of all workers involved.

The Benefits of Training and Education:

Investing in training and education for scaffold load management brings several advantages to both workers and employers. These benefits include:

- Enhanced Safety: By equipping workers with the knowledge and skills needed to manage scaffold loads effectively, training programs reduce the risk of accidents, injuries, and structural failures.

- Regulatory Compliance: OSHA requires employers to provide adequate training to workers involved in scaffold erection, use, and dismantling. By adhering to these regulations, employers can avoid penalties and legal consequences.

- Improved Efficiency: Proper training enables workers to handle scaffold loads more efficiently, resulting in increased productivity and reduced downtime.

- Cost Savings: By preventing accidents and damage caused by overloading, comprehensive training programs help reduce repair and replacement costs associated with scaffold structures.

- Worker Confidence: Training empowers workers and instills confidence in their ability to recognize and manage scaffold load risks, promoting a positive work environment.

Ultimately, prioritizing training and education for scaffold load management is essential for maintaining a safe and compliant worksite. By equipping workers with the necessary knowledge and skills, employers can ensure the proper management of scaffold loads while safeguarding the well-being of their workforce.

What are the OSHA Requirements for Scaffold Safety?

The Occupational Safety and Health Administration (OSHA) provides comprehensive guidelines on scaffold safety, including load limits and structural requirements. These regulations are designed to ensure the safety of workers and to prevent accidents related to scaffold use.

OSHA Guidelines on Scaffold Load Limits

OSHA’s guidelines on scaffold load limits are detailed in 1926 subpart L, which specifies the weight capacities for different types of scaffolding equipment. These guidelines ensure that scaffolds are used within their designed limits, preventing overloading and potential hazards. Compliance with these regulations is mandatory for maintaining occupational safety and health standards.

Ensuring Compliance with Scaffold Safety Standards

Ensuring compliance with scaffold safety standards involves regular inspections and adherence to OSHA’s requirements for scaffold use. This includes verifying that scaffolds are correctly assembled and that all components meet the necessary load ratings. Compliance not only ensures the safety of workers but also helps in avoiding legal liabilities associated with non-compliance.

What are the Safety Standards for Scaffold Planks?

Scaffold planks are critical components of a scaffold system, and their safety standards are governed by strict regulations. Planks must be capable of supporting the load without excessive deflection. They should be inspected for damage and replaced if necessary to maintain their rated load capacity. Adhering to these standards is vital for preventing accidents and ensuring the overall safety of the scaffold structure.

How to Ensure Scaffold Components Can Support the Load?

Ensuring that scaffold components can support the load involves careful selection and testing of scaffold parts. This includes choosing the right components based on the scaffold’s load rating and intended use.

Choosing the Right Scaffold Components for Load Support

Choosing the appropriate scaffold components is crucial for supporting the intended load. Components such as scaffold planks, guardrails, and support frames must be selected based on their rated load capacity. Using components designed and constructed for the specific type of scaffold ensures that the entire system can safely support the required weight.

What are the Risks of Overloading Scaffold Components?

Overloading scaffold components can lead to catastrophic failure and significant safety hazards. Exceeding the weight limits can cause components to deflect or collapse, posing severe risks to workers and equipment. Understanding the load capacities and adhering to safety standards is essential to prevent overloading and to ensure the integrity of the scaffold system.

How to Test Scaffold Components for Load Capacity?

Testing scaffold components for load capacity involves conducting regular inspections and load tests to verify their ability to support the maximum intended load. These tests help identify any potential weaknesses or defects in the components, ensuring that they meet the necessary safety standards. Regular testing is a proactive measure to ensure the scaffold’s reliability and safety.

What Types of Scaffold Systems are Best for Heavy Loads?

Choosing the right type of scaffold system is crucial for projects that involve heavy loads. Different scaffold systems offer varying load capacities, and selecting the appropriate one is key to ensuring safety and efficiency.

Comparing Different Scaffold Systems for Load Capacity

Different scaffold systems, such as suspension scaffolds and adjustable suspension scaffolds, offer varying load capacities. Comparing these systems based on their rated load and suitability for the project requirements is essential. Heavy-duty scaffold systems are often preferred for tasks that require substantial weight support due to their enhanced load capacity.

Advantages of Using Heavy-Duty Scaffold Systems

Heavy-duty scaffold systems provide significant advantages for projects involving high weight demands. They are designed to support heavy loads, making them ideal for construction and industrial applications. These systems offer a higher safety margin, reducing the risk of overloading and ensuring the scaffold can safely support the intended weight.

How to Select the Appropriate Scaffold System for Your Project?

Selecting the appropriate scaffold system for your project involves assessing the load requirements and the specific tasks to be performed. Considerations should include the type of scaffold, the rated load capacity, and the need for additional safety features such as guardrails and personal fall arrest systems. Consulting with experts and following OSHA guidelines can aid in making an informed decision, ensuring both safety and project success.

Consequences of Overloading Scaffolds

When it comes to scaffold load ratings and weight allowance on scaffolding, understanding the potential consequences of overloading is crucial for maintaining safety on construction sites. Exceeding scaffold load ratings can have severe repercussions, ranging from structural risks to increased accidents and injuries.

Structural Risks

Overloading scaffolds puts immense strain on the entire structure, potentially compromising its stability and integrity. The excess weight can cause components to bend, crack, or even collapse, posing a significant threat to workers on the scaffold and those below. The structural risks associated with overloading cannot be overstated, emphasizing the importance of adhering to scaffold load ratings and weight limits.

Potential Collapses

Overloaded scaffolds are at a higher risk of collapsing, endangering both workers and the surrounding area. The weight imbalance created by excessive loads can make the scaffold unstable, leading to catastrophic failures. Collapses can result in serious injuries or fatalities, highlighting the need for strict adherence to scaffold load ratings and safety regulations.

Increased Likelihood of Accidents

Overloading scaffolds compromises the overall stability of the working platform, increasing the likelihood of accidents. The excessive weight can make the scaffold wobbly and difficult to navigate, making falls, slips, and trips more probable. This jeopardizes the safety of workers, heightening the importance of maintaining weight allowance on scaffolding within the prescribed limits.

It is crucial to prioritize scaffold safety regulations and adhere to scaffold load ratings to mitigate the potential hazards associated with overloading. By doing so, construction workers can ensure a secure working environment and minimize the risks posed by exceeding weight limits.

| Consequences of Overloading Scaffolds | |

|---|---|

| 1 | Structural Risks |

| 2 | Potential Collapses |

| 3 | Increased Likelihood of Accidents |

Conclusion

In conclusion, understanding scaffold load ratings and following safety standards is of utmost importance in ensuring safe and secure scaffold use. Compliance with OSHA requirements for scaffold weight limits is crucial to prevent accidents, injuries, and structural failures. By adhering to load capacity calculations and implementing proper safety measures, workers can create a secure working platform and mitigate potential hazards.

Proper training and education on scaffold load management are essential for workers to be aware of load ratings, weight limits, and safety protocols. Regular inspections and the use of safety devices further enhance load capacity management and contribute to a safe working environment.

Overloading scaffolds poses significant risks, including structural instabilities and an increased potential for accidents. Therefore, it is vital to strictly adhere to scaffold load ratings and avoid exceeding the prescribed weight allowance. By prioritizing load capacity management, construction professionals can ensure the well-being of workers and maintain the integrity and stability of scaffold structures.

FAQ

What are scaffold load ratings?

Scaffold load ratings refer to the maximum weight that a scaffold can safely support. These ratings are determined based on the strength and design of the scaffold system and are crucial for ensuring the safety of workers and preventing structural failures.

How do scaffold load ratings impact safety?

Scaffold load ratings play a vital role in maintaining a secure working platform. By adhering to these ratings, workers can prevent overloading the scaffold, which could lead to accidents, injuries, and potential collapses. Following load capacity guidelines ensures a safer working environment for all.

What factors are considered in load capacity calculations?

Load capacity calculations take into account various factors, including the strength of materials used in the scaffold, the design of the scaffold system, and the proper distribution of weight. It is important to understand these calculations to ensure that the scaffold is capable of safely supporting the intended loads.

What are the OSHA requirements for scaffold weight limits?

OSHA has set specific requirements for scaffold weight limits to ensure worker safety. These requirements include specifying the maximum intended load capacity, marking the weight capacity on the scaffold, and inspecting the scaffold for any signs of overload. Compliance with OSHA regulations is essential for preventing accidents and maintaining a safe work environment.

What safety measures should be taken for load capacity management?

To effectively manage load capacity, it is important to implement several safety measures. These include properly distributing the weight on the scaffold, conducting regular inspections to identify any signs of overload or structural damage, and using safety devices such as guardrails and harnesses. By following these measures, workers can minimize the risk of accidents and ensure a safe working environment.

How important is training and education for scaffold load management?

Training and education play a crucial role in scaffold load management. It is essential for workers to undergo comprehensive training programs that cover load ratings, weight limits, and safety protocols related to scaffolding. Proper knowledge and understanding in this area enable workers to make informed decisions and maintain a safe working environment.

What are the consequences of overloading scaffolds?

Overloading scaffolds can have serious consequences. It puts excessive stress on the scaffold structure, increasing the risk of collapse and potential injuries to workers. Additionally, overloading can lead to a violation of safety regulations, resulting in legal consequences and liability issues. It is important to always adhere to scaffold load ratings and avoid exceeding weight limits.