Phone:

(+65)8319-0742

Scaffold inspection tags are an essential component of maintaining a safe construction site. Compliance with OSHA’s standards and regulations is crucial to prevent accidents and ensure the well-being of workers. By implementing an effective scaffold tag system, construction companies can communicate the safety status of scaffolding, track inspections, and prioritize proper maintenance and management.

The use of OSHA-compliant inspection tags provides valuable information about the condition of scaffolds, allowing workers to identify any potential hazards or maintenance needs. These tags serve as visual indicators for the safety status of scaffolds, promoting transparency and accountability.

Key Takeaways:

- The proper use of scaffold inspection tags is crucial for site safety and compliance with OSHA regulations.

- Inspection tags facilitate effective communication about the safety status of scaffolding systems.

- Compliance with OSHA standards helps prevent accidents and injuries on construction sites.

- Regular inspections and maintenance contribute to a safe working environment for construction workers.

- An efficient scaffold tag system enhances overall job site efficiency and productivity.

The Importance of Scaffold Safety

Scaffold safety is crucial to maintaining a secure work environment in the construction industry. With approximately 65% of workers using scaffolds, it’s essential to prioritize safety measures to prevent accidents and promote workplace well-being. In the United States alone, there are approximately 4,500 scaffold-related injuries and 60 fatalities reported annually.

Proper scaffold safety practices are pivotal in minimizing or completely eliminating potential hazards. These practices include thorough inspections, comprehensive training programs, and effective hazard controls. By implementing these safety measures, construction workers can significantly reduce risks associated with falls, electrocutions, and falling objects.

Building a safety culture through scaffold safety is of utmost importance. It not only protects workers but also helps in preventing workplace incidents. Regular inspections, adherence to safety protocols, and ongoing training can create an environment where safety becomes a natural part of every construction project.

Types of Scaffolds

In the construction industry, different types of scaffolds are utilized to provide safe working platforms for workers. Understanding the characteristics and applications of each scaffold type is crucial for implementing effective safety measures. The main types of scaffolds commonly used are:

Supported Scaffold

A supported scaffold is one of the most commonly seen scaffold types on construction sites. It is supported by sturdy poles, frames, and outriggers, ensuring stability and strength. The scaffold consists of one or more platforms that can accommodate workers, tools, and materials. Tailored to different construction needs, supported scaffolds are versatile and reliable, making them widely used across various projects.

Suspended Scaffold

**Suspended scaffolds** are another type frequently employed in construction. These scaffolds are suspended by overhead support using ropes or other means. Similar to supported scaffolds, suspended scaffolds consist of one or more platforms. This type of scaffold finds applications in situations where access from above is required, such as painting or repairs on tall buildings.

Machinery Scaffold

Machinery scaffolds differ from supported and suspended scaffolds, as they are machinery or vehicle-based. This type includes man lifts, hoists, and other similar equipment. Machinery scaffolds are valuable when accessing elevated areas where traditional scaffolding might be impractical or infeasible due to limited space or other constraints. They provide mobility and flexibility, allowing workers to reach difficult-to-access locations safely and efficiently.

The choice of scaffold type depends on various factors, including project requirements, site conditions, and safety considerations. Proper selection and utilization of the appropriate scaffold type enhance worker safety and contribute to the overall efficiency of construction operations.

Competent and Qualified Persons for Scaffold Safety

When it comes to ensuring scaffold safety on construction sites, having competent and qualified individuals is crucial. OSHA defines a competent person as someone with the knowledge and skill to identify and correct hazards in the surroundings or working conditions. These individuals play a vital role in eliminating risks and ensuring workplace safety.

On the other hand, a qualified person has demonstrated expertise in problem-solving related to scaffolding. They possess the necessary education or training, such as a degree in designing safe scaffolding, to make informed decisions and address safety concerns effectively. Their specialized knowledge allows them to contribute significantly to the overall safety of scaffold structures.

Both competent and qualified persons are essential in upholding scaffold safety and compliance with regulations. Their ability to identify potential hazards, implement corrective measures, and make informed decisions greatly reduces the risk of accidents and injuries.

The Role of Competent and Qualified Persons

Competent and qualified persons are responsible for overseeing scaffold safety by:

- Conducting regular inspections to identify potential hazards and ensure compliance with safety standards.

- Implementing necessary corrective measures to eliminate risks and improve the overall safety of scaffolds.

- Providing ongoing training and guidance to workers to enhance their understanding of scaffold safety protocols.

- Collaborating with designers, engineers, and other stakeholders to develop safe and efficient scaffold systems.

- Ensuring that all workers involved in scaffold activities have received adequate training and possess the necessary skills and qualifications.

Scaffold High-Risk Work License

In some regions, a scaffold high-risk work license is required for individuals performing high-risk work involving scaffolding. This license ensures that the person possesses the necessary skills and knowledge to undertake tasks involving complex scaffold structures and high-risk activities safely.

The scaffold high-risk work license demonstrates that the individual has undergone specialized training and assessments to develop a comprehensive understanding of scaffold safety. Obtaining this license is a testament to their commitment to upholding the highest safety standards in scaffold work.

Having competent and qualified persons, supported by proper education, training, and relevant licenses, is critical for maintaining scaffold safety and preventing accidents and injuries on construction sites.

| Competent Person | Qualified Person |

|---|---|

| A competent person has the authority to identify and eliminate hazards in the surroundings or working conditions. They ensure workplace safety. | A qualified person possesses specialized knowledge and expertise related to scaffolding and is capable of making informed decisions to address safety concerns. |

| They play a crucial role in eliminating risks and ensuring compliance with safety regulations. | They contribute significantly to the overall safety of scaffold structures and systems. |

| Regular inspections and implementation of corrective measures are part of their responsibilities. | They collaborate with stakeholders to design safe and efficient scaffold systems. |

| A competent person can provide ongoing training and guidance to workers. | Their specialized knowledge enhances scaffold safety and reduces the risk of accidents and injuries. |

Scaffolding Tag System and Requirements

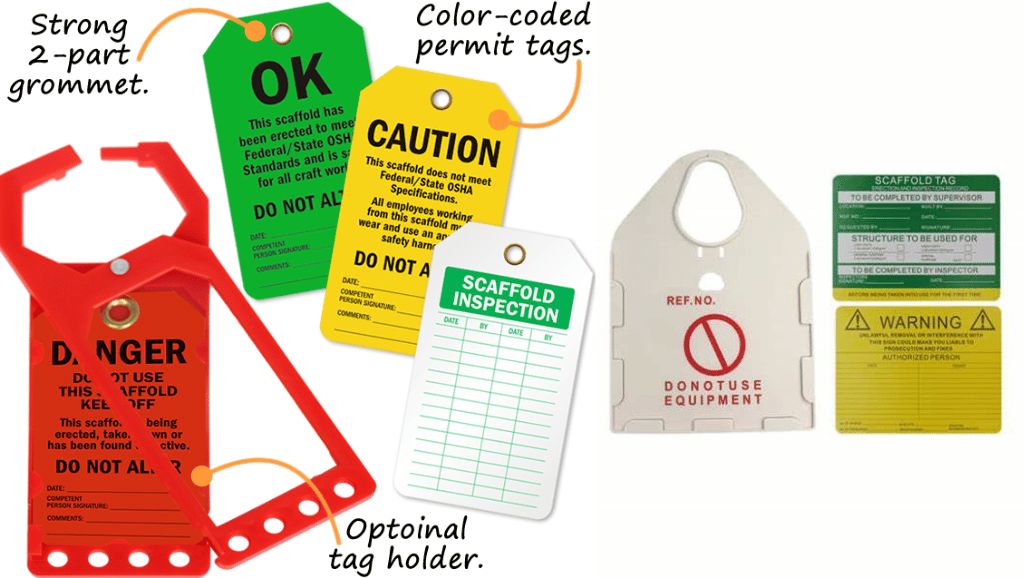

Scaffolding tags are essential visual indicators that provide vital information about the safety status of scaffolds. By following a standardized color-coding system, these tags help in quickly identifying the condition of the scaffold at a glance.

Green scaffold tags indicate that the scaffold has been inspected and is deemed safe for use. They assure workers that the scaffold meets all safety requirements and can be utilized without any concerns.

Yellow scaffold tags, on the other hand, serve as cautionary indicators. They signal that the scaffold may have minor issues or requires additional attention. Workers need to exercise caution while using a scaffold marked with a yellow tag and report any concerns to the appropriate personnel.

Red scaffold tags are used to denote an unsafe scaffold. They indicate that the scaffold is not fit for use and requires immediate repairs or modifications before it can be utilized again. Workers should refrain from using a scaffold marked with a red tag until the necessary remedial actions are taken.

It is crucial for scaffolding tags to contain specific information to effectively communicate the safety status of the scaffold. Here are some essential details that should be included:

- Unique Identification Number: A unique identifier helps in tracking and referencing the scaffold.

- Inspection Date: The date of the most recent inspection provides transparency and helps determine the validity of the safety status.

- Load Capacity: The maximum load-bearing capacity of the scaffold ensures that it is not overloaded.

- Inspection Results: Details of the inspection findings, such as any identified hazards or deficiencies, can help in addressing the issues promptly.

- Safety Status: The color-coded safety status, represented by the tag color, clearly communicates the condition of the scaffold to workers.

Proper placement and visibility of scaffolding tags are crucial to ensure effective communication and compliance with safety regulations. Tags should be clearly visible from the ground and positioned in a way that allows easy identification. Additionally, they should be securely attached to the scaffold to prevent tampering or removal.

| Tag Color | Meaning |

|---|---|

| Green | The scaffold is safe for use |

| Yellow | Caution: Minor issues or additional attention required |

| Red | The scaffold is unsafe and requires repairs |

Conclusion

Scaffold inspection tags play a crucial role in maintaining workplace safety on construction sites. By ensuring OSHA compliance, conducting regular inspections, and effectively communicating the safety status of scaffolds, workers can perform their tasks with confidence and minimize the risk of accidents and injuries. Prioritizing scaffold safety and implementing proper inspection tag management systems contribute to a culture of workplace safety and enhance overall job site efficiency.

FAQ

What is the purpose of scaffold inspection tags?

Scaffold inspection tags play a crucial role in communicating the safety status of scaffolds, providing information about inspections, and facilitating proper maintenance and management of scaffolding systems.

Why is scaffold safety important in the construction industry?

Scaffold safety is essential in preventing accidents and injuries. Proper safety practices can minimize or eliminate hazards such as falls, electrocutions, and falling objects, protecting workers and preventing workplace incidents.

What are the main types of scaffolds used in construction?

The main types of scaffolds used in construction are supported scaffolds, suspended scaffolds, and machinery scaffolds. Supported scaffolds are supported by poles and frames, suspended scaffolds are hung from overhead support, and machinery scaffolds are vehicle-based.

Who are competent and qualified persons in scaffold safety?

A competent person is someone who can identify and eliminate hazards in the working conditions, while a qualified person has expertise in problem-solving related to scaffolding. They play a crucial role in ensuring scaffold safety and compliance with regulations.

How does the scaffolding tag system work?

The scaffolding tag system uses color-coded tags to indicate the safety status of scaffolds. Green tags indicate a safe scaffold, yellow tags indicate caution, and red tags indicate that the scaffold is unsafe and should not be used until repairs are made. Tags should include necessary information such as inspection date, load capacity, and inspection results.

Why are scaffold inspection tags important for workplace safety?

Scaffold inspection tags help maintain a safe work environment by ensuring compliance with regulations, conducting regular inspections, and effectively communicating the safety status of scaffolds. They contribute to a culture of workplace safety and enhance overall job site efficiency.