Phone:

(+65)8319-0742

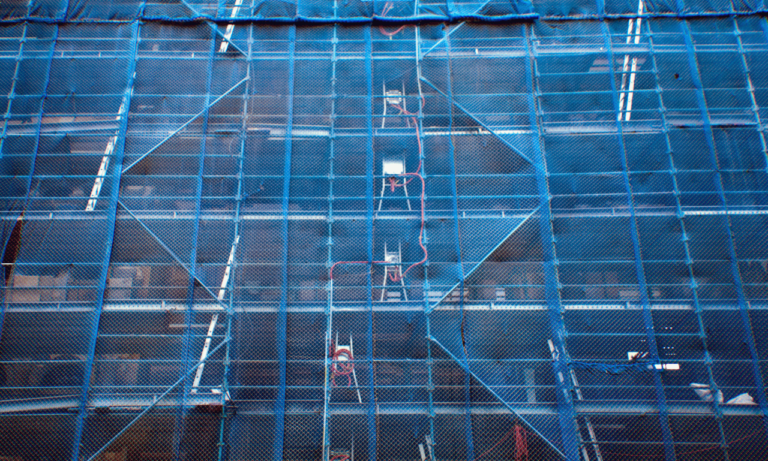

Welcome to our comprehensive guide on Scaffold Inspection and Maintenance. In this section, we will highlight the importance of complying with scaffold safety regulations and OSHA requirements. As a responsible employer or contractor, it is crucial to prioritize the safety of workers who rely on scaffolds for their daily tasks.

Proper scaffold inspection and maintenance not only ensure the well-being of workers but also help prevent accidents and injuries. By understanding and adhering to scaffold safety regulations and OSHA requirements, you can create a secure working environment.

Key Takeaways

- Compliance with scaffold safety regulations and OSHA requirements is essential for worker safety.

- Scaffold Inspection & Maintenance is crucial to identify potential hazards or issues that may compromise safety.

- Regular maintenance practices contribute to ensuring the long-term durability and safety of scaffolds.

- Developing a scaffold maintenance schedule helps in establishing proactive maintenance routines.

- By following the guidelines in this guide, employers can create a secure and compliant working environment.

Scaffold Inspection Checklist for Compliance

Ensuring compliance with safety regulations is of utmost importance when it comes to scaffold inspections. By following a comprehensive scaffold inspection checklist, you can identify potential hazards and address any issues promptly.

Here is a step-by-step guideline to help you conduct thorough scaffold inspections:

- Check the scaffold’s foundation: Make sure the scaffold is built on a solid and stable surface. Assess the soil or ground condition to ensure it can support the weight of the scaffold.

- Inspect the scaffold structure: Examine the scaffold for any signs of damage, such as bent or missing components, loose connections, or cracks. Pay particular attention to the base plates, braces, and guardrails.

- Verify the scaffold’s stability: Ensure that the scaffold is level, plumb, and properly supported. Check if it sways or tilts when pressure is applied. Stabilize the scaffold by using outriggers, ties, or braces if necessary.

- Inspect the platform: Examine the scaffold’s working platform for any deformations, breaks, or weak spots. Ensure that the platform is free from debris, tools, or any obstacles that may cause tripping hazards.

- Check the access points: Verify that there are proper access points, such as ladders or stairways, to safely enter and exit the scaffold. Ensure that the access points are secure, stable, and free from obstructions.

- Review fall protection measures: Evaluate the presence and functionality of guardrails, mid-rails, toe boards, and personal fall arrest systems. Confirm that these safety measures are in place and meet the required standards.

- Inspect the scaffolding environment: Assess the surroundings of the scaffold for any potential hazards, such as overhead power lines, environmental conditions, or nearby equipment that may pose risks to worker safety.

Best Practices for Scaffold Maintenance

Maintaining scaffolds is crucial for ensuring the long-term safety and durability of these essential structures. By implementing proper maintenance practices, you can prevent accidents and create a secure working environment. Here are some valuable scaffold maintenance tips and best practices:

- Regular Inspections: Schedule routine inspections to identify any signs of wear, damage, or structural weaknesses. This proactive approach allows you to address potential issues before they lead to accidents or failures.

- Repair and Replace: Promptly repair or replace any damaged or worn-out components. This includes inspecting and addressing loose connections, cracks, rust, or missing parts. By ensuring all scaffold parts are in good condition, you minimize the risk of accidents.

- Cleanliness: Keep the scaffold clean from debris, dirt, or other substances that may compromise its structural integrity. Regular cleaning also helps prevent corrosion or other forms of deterioration.

- Proper Storage: When not in use, store scaffolding components in a dry and secure location. Protect them from exposure to harsh weather conditions or corrosive elements that could weaken the materials over time.

- Training: Ensure that workers using the scaffold are properly trained on its safe usage, maintenance, and inspection procedures. Encourage a culture of safety and accountability among all employees.

Recommended Scaffold Maintenance Schedule

Developing a scaffold maintenance schedule will help you stay organized and ensure that the necessary maintenance tasks are performed regularly. Here is an example of a scaffold maintenance schedule:

| Type of Maintenance | Frequency |

|---|---|

| Visual Inspection | Before each use |

| Full Inspection | Monthly |

| Component Replacement | As needed |

| Cleaning | Regularly |

By following this scaffold maintenance schedule and incorporating the above best practices, you can maximize the lifespan of your scaffolds while ensuring a safe and productive work environment.

Developing a Scaffold Maintenance Schedule

In order to ensure scaffold safety and compliance, it is crucial to establish a thorough maintenance schedule. A scaffold maintenance schedule outlines the regular activities and inspections required to maintain the integrity and safety of the scaffold system. By following a well-planned maintenance schedule, potential hazards and issues can be identified and addressed promptly, reducing the risk of accidents and ensuring a secure working environment.

Developing an effective scaffold maintenance schedule involves several essential steps:

- Evaluate Your Scaffold Needs: Assess the specific requirements of your scaffolding system, including its dimensions, materials, and usage. Consider factors such as the frequency of use, weather exposure, and the potential risks associated with your work environment.

- Research Industry Standards: Familiarize yourself with scaffold maintenance best practices and industry guidelines, such as those provided by OSHA. These standards will serve as a foundation for your maintenance schedule and ensure compliance with safety regulations.

- Identify Maintenance Activities: Determine the maintenance tasks that need to be performed regularly to keep your scaffold in optimal condition. This can include inspections, cleaning, repair, and replacement of components.

- Set a Frequency: Establish how often each maintenance activity should be conducted based on the specific needs of your scaffold system. Consider factors such as manufacturer recommendations, OSHA requirements, and the frequency of use.

- Assign Responsibilities: Clearly define who will be responsible for carrying out each maintenance task. Assigning roles and responsibilities will ensure that no maintenance activity is overlooked or forgotten.

| Maintenance Task | Frequency | Responsible Party |

|---|---|---|

| Inspect scaffold components for damage | Weekly | Qualified inspector |

| Clean scaffold surfaces | Monthly | Scaffold maintenance team |

| Replace worn or damaged components | As needed | Scaffold maintenance team |

| Perform load capacity tests | Annually | Qualified engineer |

Remember that different scaffolding systems may have specific maintenance requirements, so it is essential to tailor your maintenance schedule to the unique characteristics of your scaffold. Regularly review and update your maintenance schedule as needed to ensure ongoing compliance with safety regulations and the well-being of workers who rely on the scaffold system.

Conclusion

In conclusion, this essential scaffold inspection and maintenance guide has provided a comprehensive overview of the importance of scaffold safety regulations and OSHA requirements. By following the scaffold inspection checklist, implementing best maintenance practices, and developing a maintenance schedule, employers can create a safe and compliant working environment for their employees.

FAQ

What are the key components of scaffold safety regulations?

Scaffold safety regulations encompass various aspects such as proper scaffold design and construction, regular inspections, adherence to weight-bearing capacity limits, thorough employee training, and implementation of fall protection measures.

Why is scaffold inspection important?

Scaffold inspection is crucial to identify and address any potential hazards or defects in the scaffold structure. Regular inspections help ensure that scaffolds remain safe and secure, minimizing the risk of accidents and injuries to workers.

What should be included in a scaffold inspection checklist?

A scaffold inspection checklist should include items such as checking the scaffold’s foundation, verifying proper bracing and tie-ins, assessing the stability of the structure, examining guardrails and toeboards, inspecting access points, and reviewing scaffold planking for any damage or wear.

How often should scaffold inspections be conducted?

Scaffold inspections should be conducted before each work shift, after any significant changes to the scaffold system, and after incidents or severe weather events that may affect its integrity. Additionally, regular inspections should be scheduled based on the frequency of scaffold use and the specific requirements of applicable regulations.

What are some best practices for scaffold maintenance?

Some essential scaffold maintenance practices include removing debris and obstructions from scaffold platforms, promptly addressing any damage or defects, inspecting and tightening connections regularly, ensuring proper anchorage and bracing, and providing adequate training and supervision for scaffold users.

How can employers develop an effective scaffold maintenance schedule?

Employers should develop a scaffold maintenance schedule based on the manufacturer’s recommendations, applicable regulations, and the specific conditions and usage of the scaffold. The schedule should include routine inspections, maintenance tasks, and intervals for more thorough examinations or repairs.

Protection Scaffolding: Ensuring Site Safety

Safety is of paramount importance when working at height, and proper protection scaffolding is crucial…

Curriculum Scaffolding Techniques for Educators

Enhancing the educational experience for students involves a delicate balance of effective teaching methods,…

Aluminum vs Tube Couplers: Secure pros and cons

Choosing the right material for tube coupling is key in many industries. The comparison of aluminum vs…

Essential Scaffold User Training Components

Scaffold user training is key to keeping workers safe and following the law in construction. Good training…

OSHA Standards: Sources and Exceptions

The Occupational Safety and Health Administration (OSHA) works to make sure workplaces are safe for everyone….

No posts found