Phone:

(+65)8319-0742

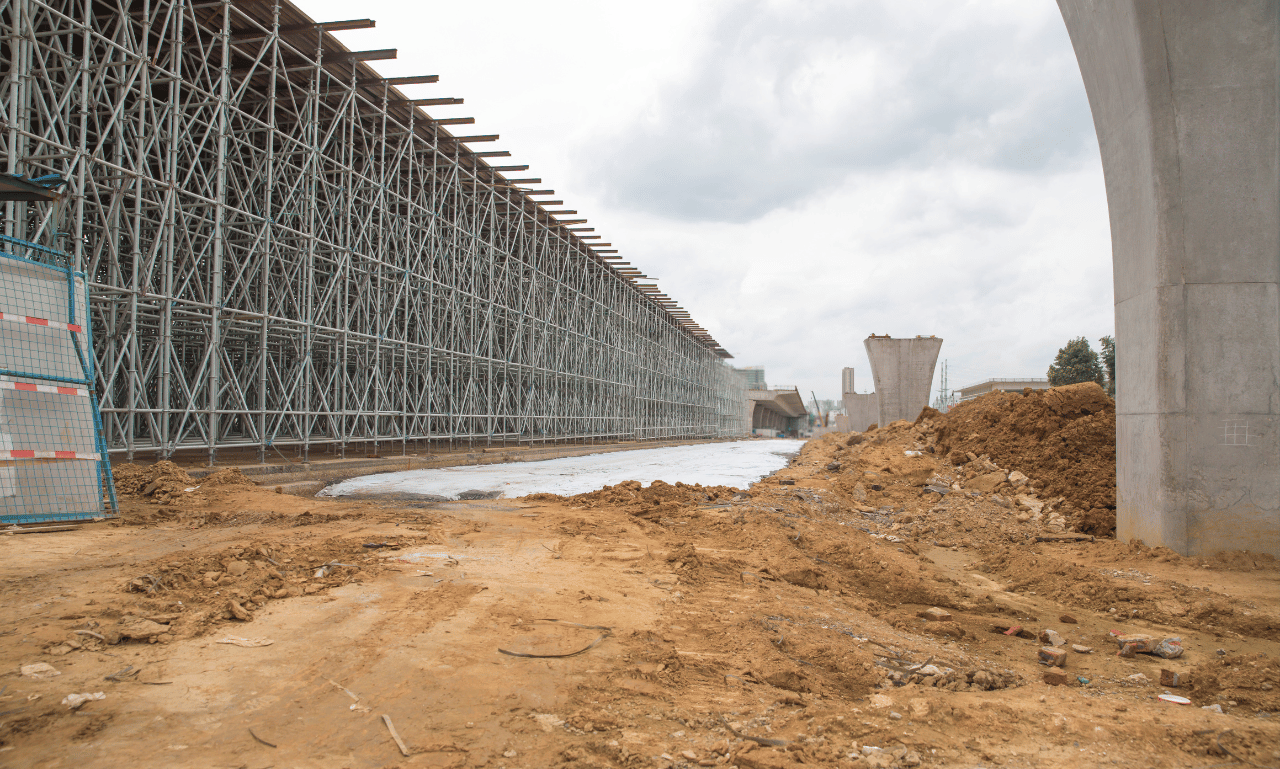

When it comes to constructing and maintaining the backbone of transportation infrastructure, railway scaffolding is pivotal. It offers not just a safe, sturdy platform for workers but is also integral to the smooth functioning and longevity of transportation networks. Utilizing scaffolding for railways ensures that projects are executed with precision, maintaining strict compliance with safety regulations. In an industry where efficiency is as critical as security, the capability to provide durable and reliable transportation infrastructure scaffolding systems is vital for success.

Safety is paramount, with specialized practices in place to guarantee that railway scaffolding is meticulously plumb and level, sustaining high stability and minimizing risks. Through diligent compliance with the H/4 and H/3 rules for indoor and outdoor usage, respectively, and reinforcing platforms with comprehensive guardrail systems, the risk of workplace incidents is substantially lowered, setting a benchmark for safety and efficiency in the sector.

Key Takeaways

- Railway scaffolding is a foundational element for safe construction and maintenance work on railways.

- Stability and level alignment of scaffolds are critical for security and efficiency in transportation infrastructure.

- Adhering to specific safety practices and regulations ensures the well-being of workers and the integrity of the railway projects.

- Thoroughly inspected and certified scaffolding systems are essential to foster a culture of safety within the industry.

- Emphasizing the importance of guardrail systems and scaffold duty can significantly reduce the risk of slips, falls, and related incidents.

- Professionally engineered scaffolding solutions are designed to meet the complex needs of railway construction and maintenance.

Understanding the Importance of Railway Construction Equipment Compliance

When it comes to constructing and maintaining vast and intricate railway networks, safety and efficiency are of utmost importance. Compliance with industry regulations for railway construction equipment is not just a legal requirement but a central factor that contributes to the reliability and credibility of industrial scaffolding for railways. Let’s delve into how adhering to standards and achieving specific accreditations assure that railway access solutions are suitable for the task at hand.

Adherence to Regulatory Standards

Strict adherence to regulatory standards guarantees that equipment used in railway projects meets essential safety and performance benchmarks. Industrial scaffolding for railways, a crucial component in the construction and maintenance phases, must comply with these standards to prevent jobsite accidents and ensure that projects progress smoothly.

Roles of RISQS Accreditation in Scaffolding Safety

Securing RISQS accreditation is a pivotal step that scaffolding service providers undertake. This accreditation is not just a badge of excellence but an assurance that the railway access solutions provided can withstand the rigors of the rail industry, including heavy loads and harsh weather conditions.

Reducing Scaffolding-Related Incidents in Rail Infrastructure Projects

To minimize the possibility of scaffolding-related incidents, it is essential to promote the use of durable, versatile, and strong systems. Employing robust railway construction equipment is an effective strategy for enhancing safety and reducing the number of accidents on railway infrastructure projects.

| Feature | Benefit |

|---|---|

| Durable materials | Withstands extreme forces, increasing longevity |

| Modular design | Customizable to complex geometries of railway landscapes |

| Compliance with regulatory standards | Reduces potential for accidents and enhances safety |

| RISQS Accredited | Ensures quality and reliability of scaffolding solutions |

| Efficient assembly and disassembly procedures | Minimizes disruption and downtime in busy railway corridors |

Key Features of Railway Scaffolding for Enhanced Worker Safety

In the realm of railway maintenance and construction, the robustness and reliability of railway scaffolding are paramount to the safety of workers. A meticulous approach to the design and implementation of train track scaffolding ensures that the complexities of railway environments are addressed, bolstering the protection of personnel on the site.

Firstly, an understanding of how railway maintenance platforms maintain their resilience against forces and loads can provide crucial insights into their fundamental safety features. At the heart of worker safety, ensuring that scaffolding remains plumb and level is essential.

Scaffolding Plumb and Level Considerations

Construction sites for railways often face uneven and sloped terrain. Here, scaffolding for railways must be engineered to remain both plumb and level despite these challenges. A stable base is crucial, not just for the safety and assurance of workers but also for the overall integrity of the construction effort.

Maintaining Base-to-Height Ratio in Scaffolding Stability

Another cornerstone of railway scaffolding safety is the rigorous maintenance of the base-to-height ratio. Adherence to established safety standards helps prevent the risk of tipping and collapse, catering to both indoor and outdoor settings with appropriate adjustments for each environment. This stringent use of industry protocols underscores the scaffolding’s stability.

Guardrail and Toeboard Systems for Fall Prevention

Safety on the railways does not stop at stability; it continues with comprehensive systems designed to prevent falls. The integration of guardrail and toeboard systems around the periphery of railway maintenance platforms forms a barrier, which not only secures the workers atop the scaffolding but also significantly mitigates the risk of falling tools or materials.

Collectively, these features encapsulate the commitment to safety that is fundamental in the design and use of train track scaffolding. This scaffolding ensures that workers can operate in the rigorous and demanding conditions of railway work with confidence and security, truly embodying the union of function and safety in construction innovation.

Railway Scaffolding: A Versatile Solution for Complex Access Challenges

Leveraging railway scaffolding solutions is pivotal for overcoming the intricate access challenges inherent to railroad scaffolding. The demand for customized configurations to navigate the environment around tracks, bridges, and station platforms requires a highly adaptable approach. It is this flexibility that enables construction teams to address complex scenarios, ensuring the seamless progression of vital maintenance and building works. The utilization of specialized railway construction equipment becomes indispensable for such tasks, as it must cater to the precise and varied requirements of each project.

One of the outstanding attributes of contemporary scaffolding used in railway applications is its ability to be tailored. It facilitates a secure and efficient work area in otherwise difficult-to-reach locations. Below is an overview of the various scenarios where railway scaffolding stands out as a preferred choice among construction professionals.

| Construction Scenario | Scaffolding Requirement | Benefit Provided |

|---|---|---|

| Bridge Maintenance | Customized shape and load-bearing capacity | Stable access and support for heavy equipment |

| Trackside Work | Minimal footprint for limited space | Safety in proximity to active rails |

| Platform Construction | Adjustable height levels | Access at varying elevations with ease |

| Overpass Repair | Overhung and cantilevered systems | Extended reach over tracks without disruption |

- Integration with railway safety protocols.

- Speedy assembly and disassembly to minimize operational downtime.

- Durable materials suitable for harsh outdoor environments.

Ultimately, the effectiveness of railroad scaffolding is measured not just in its physical adaptability but also its contribution to the overall safety and efficiency of railway construction and maintenance operations. High-quality railway construction equipment, including scaffolding, ensures that projects can meet tight deadlines and rigid safety standards, maintaining the robust flow of the transportation industry.

Cost-Effective and Environmentally Friendly Railway Access Solutions

In transportation infrastructure, economic and ecological considerations are paramount. When it comes to railway scaffolding, achieving a balance between cost-effectiveness and environmental sustainability is not just desirable but increasingly essential. These structures are a testament to the innovative progression within the industry, epitomizing the potential for scalable, adaptable, and environmentally friendly transportation infrastructure scaffolding solutions.

The design of cost-effective railway scaffolding plays a vital role in reducing project expenditures. Innovative engineering minimizes the need for diverse materials and streamlines construction processes, subsequently lowering labor costs and material waste. Such economical designs also enhance the adaptability of scaffolding systems, allowing for rapid assembly and disassembly, which not only speeds up project timelines but also reduces the environmental footprint of construction activities.

- Quick assembly and dismantling processes

- Reduced material waste with reusable components

- Minimization of required heavy machinery

The trend towards environmentally friendly transportation infrastructure scaffolding also emphasizes the importance of materials that are both durable and have a minimal environmental impact. Practices such as the reuse and recycling of scaffolding parts contribute to a more sustainable construction model, echoing the industry’s commitment to green initiatives.

| Feature | Cost-Effectiveness | Environmental Impact |

|---|---|---|

| Material Efficiency | Lower Expenses | Reduced Waste |

| Adaptability | Saves Time, Reduces Labor | Less Frequent Transport |

| Reuse Potential | Maximized Investment | Conservation of Resources |

The push for railway scaffolding that aligns with budgetary constraints without sacrificing environmental responsibility is reshaping the field. As the industry advances, the dual goals of cost reduction and environmental stewardship are being successfully merged in the development of access solutions for rail infrastructure.

Strategies for Mitigating Scaffolding Hazards in Railroad Construction

In the realm of railroad construction, the use of industrial scaffolding for railways demands comprehensive strategies to mitigate potential hazards. Scaffolding for railways not only enhances productivity but also necessitates stringent safety measures to protect the workforce from fall-related injuries and other risks.

Scaffolding Fall Protection Solutions

Implementing fall protection solutions is a pivotal step towards securing a safe environment around railway scaffolding. By installing essential components such as guardrails, midrails, and toeboards at appropriate heights, the risk of falls can be significantly reduced, thus safeguarding workers as they navigate the complex terrain of railroad construction sites.

Ensuring Adequate Scaffolding Safety Training and Inspection

Thorough training and inspection are critical in bolstering the safety of scaffolding for railways. Workers must be proficient in recognizing hazards and adept in carrying out their duties within the framework of prescribed safety standards. Regular inspections by trained professionals ensure that scaffoldings are continually assessed for stability and safety compliance.

Recognizing the Role of Competent Persons in Scaffolding Safety

Certified competencies in scaffold safety play a crucial role in maintaining a secure construction environment. These skilled individuals are vested with the responsibility to oversee the proper erection, modification, and dismantling of scaffoldings, ensuring that each phase aligns with regulatory safety protocols. Recognition of their expertise is vital to minimizing accidents and enhancing overall site security.

| Safety Component | Function | Benefit |

|---|---|---|

| Guardrails and Midrails | Prevent falls by providing a barrier | Decreases risk of severe injury from height |

| Toeboards | Block tools and debris from falling over the edge | Protects individuals below the scaffold structure |

| Regular Inspections | Identify and correct any potential scaffold hazards | Ensures ongoing safety and stability of scaffold structures |

| Competent Persons | Handle scaffold safety operations and compliance | Skilled oversight reduces scaffold-related incidents |

Conclusion

The integral role of railway scaffolding in the construction and maintenance of railways remains undeniable. At the core of this field is a commitment to scaffold safety, a commitment that transcends mere compliance and embeds itself into the very practices that keep our railway workers protected. This dedication is manifest in the industry’s rigorous application of safety standards and regulatory compliances, with certifications like RISQS accreditation serving as milestones of this unwavering dedication.

In every beam that is perfectly leveled and every guardrail system meticulously installed, we see the embodiment of a culture of safety that strives to minimize workplace injuries and fatalities. The industry continues to advance through the implementation of features critical to scaffolding stability, such as proper leveling and maintaining base-to-height ratios. These are not just guidelinesâthey are lifelines for those working on the front lines of rail service and development.

The dynamism of railway scaffolding is also reflected in its cost-effectiveness and environmental consideration, proving that operational efficiency and sustainability can indeed go hand in hand. As we look toward the future, the evolution of scaffold safety rests on the industryâs shouldersâto innovate, to educate, and to maintain an environment where safety comes first. Through steadfast training and inspection protocols, the railway scaffolding community continues to uphold the highest standards for the construction and maintenance of railways, underscoring its vital role in the facilitation of secure and efficient transportation infrastructure.

FAQ

What is railway scaffolding and why is it important?

Railway scaffolding is a specialized type of scaffolding designed to provide safe and efficient access solutions for construction and maintenance works on railway infrastructure. It is crucial for ensuring the safety of workers at height and for supporting the heavy loads and unique challenges associated with transportation infrastructure projects.

What are the benefits of adhering to regulatory standards in railway construction equipment?

Adherence to regulatory standards ensures that railway construction equipment, including scaffolding, meets the necessary safety and quality benchmarks required for railway projects. Such compliance minimizes the risk of accidents, enhances the durability of the structures, and safeguards workers and the public.

How does RISQS accreditation enhance scaffolding safety?

The Railway Industry Supplier Qualification Scheme (RISQS) accreditation verifies that scaffolding services and products have been thoroughly scrutinized for quality and safety, ensuring their reliability in supporting railway infrastructure work. RISQS accreditation is a mark of credibility that the scaffolding meets stringent industry standards.

What measures can be taken to reduce scaffolding-related incidents in rail infrastructure projects?

To reduce scaffolding-related incidents, it is important to implement a combination of comprehensive safety strategies including the use of durable and robust scaffolding systems, rigorous safety training for workers, regular scaffold inspections, and adherence to national safety regulations specific to railway projects.

Why is maintaining scaffolding plumb and level critical for worker safety?

Maintaining scaffolding plumb and level ensures the stability of the structure, preventing tipping or collapsing. A stable and secure scaffold provides a safe work platform for construction and maintenance personnel, which is especially critical when working at significant heights over railway lines.

What is the significance of maintaining the correct base-to-height ratio in scaffolding stability?

The correct base-to-height ratio, often referred to as the H/4 rule for indoor and H/3 rule for outdoor mobile scaffolding, is essential for maintaining scaffold stability. Adhering to these ratios helps prevent the scaffold from becoming top-heavy and prone to tipping, which is vital for worker safety.

How do guardrail and toeboard systems contribute to fall prevention on railway scaffolding?

Guardrail and toeboard systems act as protective barriers that help prevent workers from falling off the edges of the scaffolding platform. These systems are a critical component of scaffold safety, significantly reducing the risk of falls and associated injuries or fatalities.

In what ways is railway scaffolding a versatile solution for construction and maintenance?

Railway scaffolding is designed to be adaptable to fit around the complex and varying structures associated with railways, such as bridges, platforms, and tracks. Its versatility enables customized support and access, which is essential for the diverse range of work scenarios encountered in railway projects.

What makes scaffolding an environmentally friendly choice for railway projects?

Railway scaffolding is considered environmentally friendly because it often reduces the need for heavy machinery, which can emit pollutants. Additionally, the reusability of scaffolds and the efficiency with which they can be erected and dismantled contribute to lower carbon footprints and align with sustainable construction practices.

What are the key elements of an effective scaffolding fall protection solution?

An effective scaffolding fall protection solution includes the installation of guardrails, midrails, and toeboards at prescribed heights, alongside safety nets or personal fall arrest systems as needed. These elements are designed to prevent workers from falling and to arrest falls should they occur.

Why is adequate safety training and inspection essential for scaffolding in railroad construction?

Adequate safety training ensures that workers are aware of potential hazards, understand the proper procedures for assembling and dismantling scaffolding, and can use the equipment safely. Regular inspections by competent personnel are essential to identify and correct potential safety issues before they lead to accidents.

What is the role of a competent person in scaffolding safety?

The role of a competent person in scaffolding safety is to supervise the erection, alteration, and dismantling of scaffolds while ensuring all operations are performed following safety regulations. These individuals have the training and authority to identify and mitigate hazards, ensuring a safe working environment for all workers involved.