Phone:

(+65)8319-0742

Welcome to our comprehensive guide to Pump Jack Scaffolding systems. In this article, we will explore the world of adjustable scaffolding systems, focusing on the versatile and efficient Industrial Pump Jack Scaffold. Whether you are a construction professional or simply interested in learning about this essential equipment, this guide will provide valuable insights and information.

Key Takeaways

- Pump Jack Scaffolding offers versatility and adaptability for efficient construction projects.

- Understanding the components and functionality of Pump Jack Scaffolding is crucial for safe and successful operation.

- Proper setup and maintenance are essential to ensure the longevity and safety of Pump Jack Scaffolding systems.

- Working with Pump Jack Scaffolding requires adherence to safety guidelines and best practices.

- Industrial Pump Jack Scaffolds are widely used in various construction applications, showcasing their advantages and effectiveness.

Understanding Pump Jack Scaffolding

In the world of construction, efficiency and safety are of paramount importance. That’s where Pump Jack Scaffolding comes in. This versatile and adjustable scaffolding system offers numerous benefits for construction projects of all sizes. In this section, we will explore the basic components and functionality of Pump Jack Scaffolding, highlighting its advantages in the construction industry.

Components of Pump Jack Scaffolding:

To truly understand how Pump Jack Scaffolding works, it’s essential to familiarize yourself with its key components. These include:

- Pump Jacks: These adjustable mechanisms provide vertical mobility to the scaffold, allowing workers to easily raise or lower the platform.

- Scaffold Frames: The sturdy framework holds the scaffold platform in place, providing stability and support.

- Braces and Platforms: Braces connect the frames, ensuring structural integrity, while the platform serves as the working area for construction tasks.

The combination of these components forms a reliable and efficient Pump Jack Scaffolding system that can be tailored to meet specific project requirements.

Functionality and Benefits:

Pump Jack Scaffolding offers several notable advantages for construction projects:

- Adjustable Height: The adjustable feature of Pump Jack Scaffolding allows workers to easily modify the platform’s height. This adaptability ensures accessibility to different work areas, enhancing productivity and safety.

- Easy Assembly: With its straightforward design and intuitive assembly process, Pump Jack Scaffolding can be set up quickly, minimizing downtime and maximizing work efficiency.

- Versatility: Pump Jack Scaffolding is suitable for a wide range of construction projects, from small residential renovations to large-scale commercial developments. Its versatility makes it a valuable asset for contractors, enabling them to tackle various tasks with ease.

- Portability: Pump Jack Scaffolding is designed to be lightweight and portable, allowing for easy transportation and repositioning on the worksite. This flexibility contributes to increased workflow and adaptability on the construction site.

By understanding the components and functionality of Pump Jack Scaffolding, construction professionals can harness its benefits and unlock its potential for enhanced project efficiency and safety.

What is a Pump Jack?

A pump jack is a device used to extract crude oil from oil wells, with a large percentage of oil wells requiring artificial lift. It is a type of reciprocating pump that uses a pivoting beam to move a sucker rod up and down, creating a reciprocating motion that lifts oil from the well. Pump jacks are commonly used in onshore wells in oil-rich areas and are powered by an electric motor or a combustion engine. This mechanical marvel ensures that even wells with insufficient pressure can continue to produce valuable crude oil, making it an indispensable tool in the oil extraction process.

Pump Jack Configurations and Variations

Pump jacks come in various configurations and variations, each designed to meet specific needs and requirements. Some common types of pump jacks include:

Beam Pump: This is the most common type of pump jack, which uses a pivoting beam to move the sucker rod up and down. Its simple yet effective design makes it a staple in many oil fields.

Sucker Rod Pump: Unlike the beam pump, this type of pump jack uses a sucker rod to lift oil from the well without the pivoting beam. It is often used in wells where a more direct lifting mechanism is required.

Electric Submersible Pump: This type of pump jack uses an electric motor to drive a pump located at the bottom of the well. It is particularly effective in deep wells where traditional pump jacks might struggle.

Gas Lift Pump: This type of pump jack uses compressed gas to lift oil from the well. It is an excellent choice for wells where gas is readily available and can be used to assist in the lifting process.

Each of these configurations offers unique advantages, allowing operators to choose the best solution for their specific well conditions and production goals.

Role of Pump Jacks in the Oil and Gas Industry

Pump jacks play a vital role in the oil and gas industry, enabling the extraction of crude oil from underground reservoirs. They are commonly used in onshore wells in oil-rich areas and are an essential component of the oil extraction process. Beyond crude oil, pump jacks are also instrumental in extracting natural gas from underground reservoirs, making them a crucial component of the oil and gas industry. Additionally, pump jacks are used to support solids control and to extract oil from wells with low pressure, ensuring that even challenging wells can remain productive. Their versatility and reliability make pump jacks an indispensable tool in the ongoing quest to harness the earth’s natural resources.

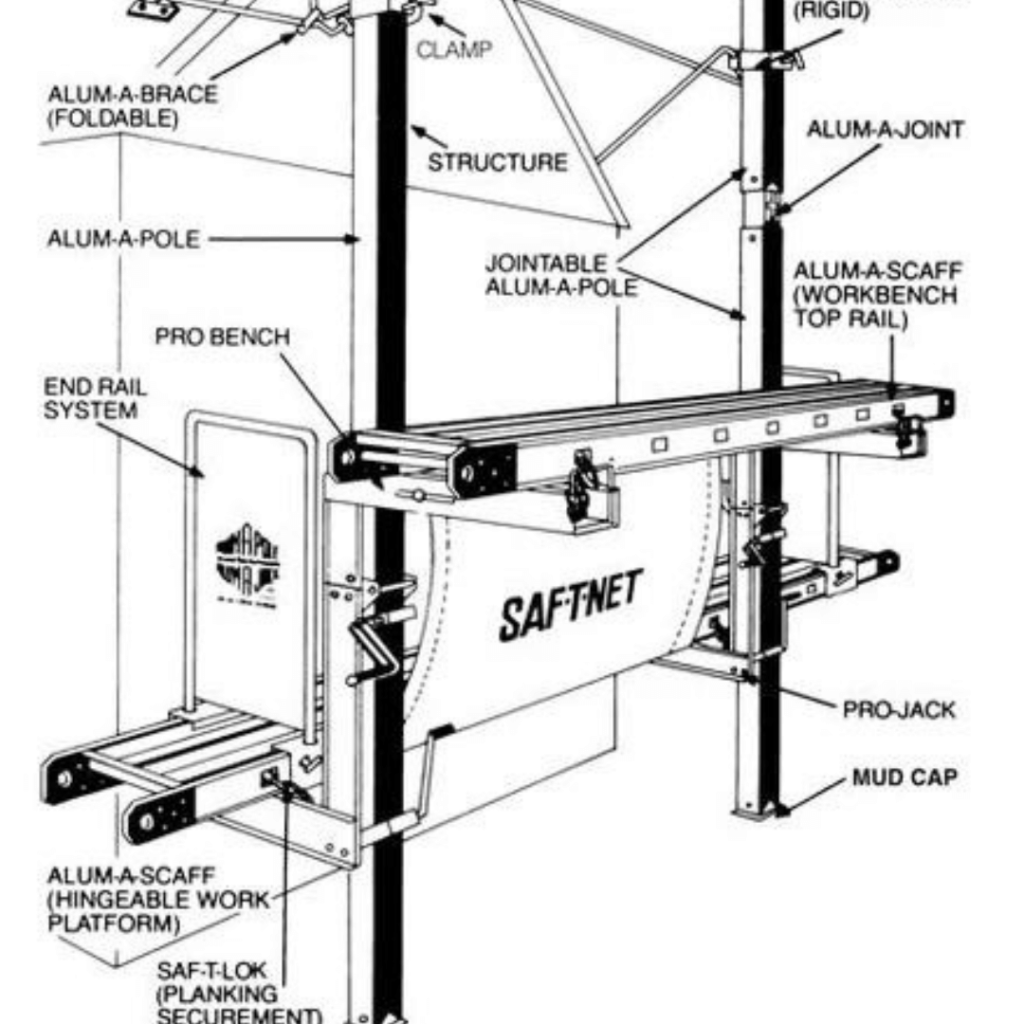

Components of a Pump Jack Scaffolding System

A Pump Jack Scaffolding system comprises several essential components that work together to create a safe and reliable construction platform. Understanding each component’s purpose is crucial for ensuring a successful setup. Let’s take a closer look at the key components:

Pump Jacks

The pump jacks are the heart of the system. These mechanical devices are adjustable and facilitate vertical movement, allowing workers to raise or lower the scaffolding platform. Pump jacks provide stability and support for the entire system.

Scaffolding Platform

The scaffolding platform is where workers stand and carry out their construction tasks. It serves as the base for supporting workers, tools, and materials. The platform’s sturdy construction and proper installation are essential for ensuring the safety and stability of the entire system.

Support Braces

Support braces play a critical role in reinforcing the scaffolding system’s structure. They provide additional stability and structural integrity to the scaffold platform, ensuring it can withstand the weight and stress placed upon it during construction activities.

Guardrails

Guardrails are installed around the scaffolding platform to prevent falls and accidents. They serve as a protective barrier that allows workers to move freely without the risk of falling off the platform. Guardrails are typically made of durable materials and must comply with safety regulations.

Stabilizing Base Plates

Stabilizing base plates are placed at the bottom of the pump jacks to distribute the scaffold’s weight evenly and prevent it from sinking into the ground. These plates provide stability and help maintain the system’s balance when subjected to different loads and conditions.

By understanding the function and importance of these components, construction professionals can ensure a safe and reliable Pump Jack Scaffolding system. Now, let’s move on to Section 4 and learn how to set up a Pump Jack Scaffolding system.

Setting Up a Pump Jack Scaffolding System

In this section, we will guide you through the process of setting up a Pump Jack Scaffolding system. From selecting the appropriate location to assembling the components, we will provide step-by-step instructions to help you create a sturdy and secure scaffolding platform.

Step 1: Selecting the Location

Before setting up your Pump Jack Scaffolding system, it is essential to choose the right location. Look for a flat, stable surface that can support the weight of the scaffolding platform and the workers. Make sure the area is clear of any obstacles that may hinder the setup process or pose a safety risk. Assess the site for potential hazards such as uneven terrain or overhead power lines.

Step 2: Assembling the Pump Jacks

Start by assembling the pump jacks, the pivotal components of the system. Follow the manufacturer’s instructions to ensure proper assembly. Connect the pump jack sets and secure them using the provided locking mechanisms. Double-check that all connections are tight and secure before proceeding.

Step 3: Attaching the Scaffolding Platform

Next, attach the scaffolding platform to the pump jacks. Position the platform at a suitable height, allowing easy access to the working area. Use the appropriate attachments to secure the platform to the pump jacks, ensuring a stable connection. Confirm that the platform is level and secure before proceeding.

Step 4: Check for Stability and Safety

Once everything is set up, take a moment to inspect the entire Pump Jack Scaffolding system for stability and safety. Check that all components are securely in place and there are no loose connections or potential hazards. Ensure the scaffolding platform is level, and the pump jacks are properly aligned. Be mindful of weight restrictions and load capacity to prevent overloading the system.

By following these step-by-step instructions, you can set up a Pump Jack Scaffolding system that provides a secure and stable platform for construction projects. Remember to prioritize safety throughout the setup process and regularly inspect the system for any signs of wear or damage.

Tips for Working with Pump Jack Scaffolding

Working with Pump Jack Scaffolding requires careful attention to safety and efficiency. By following these expert tips and insights, you can ensure a smooth and successful construction project.

1. Prioritize Safety

Always prioritize safety when working with Pump Jack Scaffolding. Ensure that all workers are trained in proper usage and adhere to safety protocols. Provide personal protective equipment (PPE) such as hard hats, safety harnesses, and non-slip footwear.

2. Conduct Regular Inspections

Inspect the Pump Jack Scaffolding system before each use to identify any signs of wear, damage, or instability. Pay close attention to the scaffolding platform, pump jacks, and support structure. If any issues are found, repair or replace the components immediately to prevent accidents.

3. Secure Proper Foundation

Ensure that the foundation for the Pump Jack Scaffolding is stable and able to support the weight. If working on uneven terrain, use adjustable base plates, leveling screws, or other leveling devices to ensure a secure and level platform.

4. Follow Load Capacity Guidelines

Respect the load capacity guidelines provided by the manufacturer for the Pump Jack Scaffolding system. Overloading the scaffolding can compromise its stability and increase the risk of accidents. Remember to consider the weight of workers, tools, and materials when calculating the load capacity.

5. Securely Attach Platforms

Properly secure the scaffolding platforms to the pump jacks, ensuring that they are level and stable. Use locking pins or clamps to prevent any movement or shifting during use. Regularly check the platform connections to ensure they remain secure throughout the project.

6. Maintain a Clean and Organized Work Area

Keep the work area around the Pump Jack Scaffolding system clean and free from clutter. Remove any debris, tools, or materials that could pose a tripping hazard or impede safe movement on the scaffolding. Maintain clear pathways for workers to minimize the risk of accidents.

7. Use Fall Protection Systems

Implement fall protection systems, such as guardrails, safety nets, or personal fall arrest systems, to prevent falls from heights. Ensure that all workers are familiar with their proper usage and are equipped with the necessary safety equipment.

8. Regularly Train and Communicate

Continuously train workers on the safe and proper use of Pump Jack Scaffolding. Regularly communicate updates, changes, and safety reminders to the entire team. Foster an open and transparent environment where workers feel comfortable reporting any safety concerns or near-misses.

9. Maximize Efficiency

To maximize efficiency when working with Pump Jack Scaffolding, streamline workflows, and plan tasks in advance. Use the adjustable features of the system to optimize working heights and minimize unnecessary repositioning of the scaffolding.

10. Monitor Weather Conditions

Stay vigilant of changing weather conditions when working with Pump Jack Scaffolding. Strong winds, rain, or snow can compromise the stability of the scaffolding. If adverse weather conditions are forecasted, secure the scaffolding system and suspend work until conditions improve.

By following these tips, you can work safely and efficiently with Pump Jack Scaffolding, ensuring the success of your construction project.

Maintenance and Safety Guidelines for Pump Jack Scaffolding

Safety is of utmost importance when working with Pump Jack Scaffolding. By following essential maintenance tasks and safety guidelines, you ensure the longevity of the system and prioritize the well-being of construction workers.

Maintenance Tasks

Regular maintenance is key to keeping your Pump Jack Scaffolding system in optimal working condition. Here are some important tasks to include in your maintenance routine:

- Inspect the components: Regularly inspect all components of the Pump Jack Scaffolding system, including the pump jacks, scaffolding platforms, and accessories. Look for signs of wear, damage, or faulty mechanisms.

- Clean and lubricate: Keep the system clean from debris and dirt that may hinder its functionality. Additionally, lubricate moving parts to ensure smooth operation.

- Replace worn or damaged parts: If any component shows signs of wear or damage, replace it immediately. Using compromised parts puts the safety of workers at risk.

Safety Guidelines

When working with Pump Jack Scaffolding, it’s crucial to prioritize safety. Follow these guidelines to create a safe working environment:

- Proper training: Ensure that all workers using the Pump Jack Scaffolding system are properly trained on its assembly, use, and safety procedures. This training reduces the risk of accidents and promotes efficient work practices.

- Secure foundations: Before assembling the system, ensure that the ground is level, stable, and can support the weight of the scaffolding platform and workers. This prevents the system from tipping or collapsing.

- Use appropriate personal protective equipment (PPE): Construction workers should always wear PPE such as hard hats, safety harnesses, and non-slip footwear when working on the Pump Jack Scaffolding system.

- Adhere to weight limits: The Pump Jack Scaffolding system has weight limits specified by the manufacturer. Ensure that these limits are never exceeded to maintain stability and prevent accidents.

- Securely fasten components: Properly secure all components of the system, including the pump jacks, platforms, and guardrails. Loose or improperly fastened components can lead to instability and falls.

- Maintain a clean work area: Keep the work area clean and clear of tools, materials, and debris that may pose tripping hazards. A clutter-free work environment promotes safe movement on the scaffolding platform.

By adhering to these maintenance tasks and safety guidelines, you can ensure the reliable performance of your Pump Jack Scaffolding system while prioritizing the well-being of everyone involved in your construction projects.

Applications and Advantages of Pump Jack Scaffolding

Pump Jack Scaffolding offers a versatile and adaptable solution for a wide range of construction projects. Whether it’s a small-scale residential renovation or a large-scale industrial construction site, this adjustable scaffolding system proves to be an invaluable asset. Let’s explore the various applications and advantages of utilizing Pump Jack Scaffolding, highlighting its effectiveness in different scenarios.

1. Residential Construction

When it comes to residential construction projects, Pump Jack Scaffolding provides the perfect balance of stability and flexibility. Its adjustable system allows for precise height adjustments, making it suitable for tasks such as exterior painting, siding installation, and roof repairs. The ease of setup and mobility of this scaffolding system ensures efficiency and safety while working on residential properties.

2. Commercial Building Maintenance

In commercial buildings, routine maintenance and repair work often require scaffolding systems that can provide access to different heights and angles. Pump Jack Scaffolding excels in this aspect, offering adjustable platforms and stable support for tasks like window cleaning, exterior inspections, and HVAC maintenance. Its adaptability allows workers to navigate complex structures while ensuring optimal safety measures.

3. Industrial Projects

When it comes to large-scale industrial projects, Pump Jack Scaffolding proves its worth by providing a reliable and efficient solution. From constructing new industrial facilities to carrying out extensive renovations, this scaffolding system offers the necessary support and stability. Its adjustable nature allows workers to access various heights while ensuring a secure and well-balanced working platform, even in challenging industrial environments.

Advantages of Pump Jack Scaffolding

In addition to its versatile applications, Pump Jack Scaffolding offers several advantages that make it a preferred choice in the construction industry. These advantages include:

- Easy Assembly: With its straightforward setup process, Pump Jack Scaffolding enables quick and hassle-free installation, saving valuable time and effort on construction sites.

- Height Adjustability: The adjustable nature of this scaffolding system allows workers to easily modify the platform’s height to suit their specific project requirements.

- Enhanced Safety: Pump Jack Scaffolding ensures worker safety with features like sturdy platforms, secure guardrails, and reliable support mechanisms.

- Portability: The lightweight design of Pump Jack Scaffolding makes it easy to transport and move between work areas, enhancing job site efficiency.

- Durability: Built with sturdy materials, Pump Jack Scaffolding is designed to withstand harsh environmental conditions and heavy-duty work, ensuring longevity and reliability.

Pump Jack Scaffolding’s versatility, adjustability, and range of advantages make it an invaluable asset in the construction industry. Whether it’s a residential, commercial, or industrial project, this scaffolding system provides the necessary support, safety, and mobility to ensure efficient and successful construction operations.

Conclusion

In conclusion, Pump Jack Scaffolding is a versatile and adjustable system that plays a crucial role in construction projects. Its unique design and functionality allow construction professionals to optimize their work and enhance productivity. By understanding the components and setup process, workers can create a secure and reliable platform for working at heights.

Safety is paramount when using Pump Jack Scaffolding, and adherence to maintenance and safety guidelines is essential. Regular inspections, proper equipment usage, and training will help ensure a safe working environment for everyone involved. Taking these precautions mitigates the risks associated with working at heights, promoting accident prevention and overall project success

Furthermore, the applications and advantages of Pump Jack Scaffolding are extensive. Its adaptability makes it suitable for various projects, including construction, maintenance, repairs, and renovations. The adjustability of the system allows for efficient work at different heights, while its portability enables easy relocation and increased productivity on job sites.

Ultimately, Pump Jack Scaffolding is a reliable solution for construction professionals looking to enhance their workflow and ensure the safety of their workers. By considering its benefits and implementing proper usage and maintenance practices, construction projects can be completed efficiently, effectively, and with optimum safety.

FAQ

What is Pump Jack Scaffolding?

Pump Jack Scaffolding is a type of adjustable scaffolding system commonly used in construction projects. It consists of pump jacks, which are mechanical devices, and a scaffolding platform that can be raised or lowered as needed. This system provides a safe and sturdy platform for workers to perform various tasks at elevated heights.

How does Pump Jack Scaffolding work?

Pump Jack Scaffolding works by utilizing pump jacks to raise or lower the scaffolding platform. The pump jacks are mounted on vertical poles and operated using a hand crank or electric motor. As the pump jacks are raised, the scaffolding platform moves up, allowing workers to access different areas of the construction site. Conversely, lowering the pump jacks brings the platform down to the desired height.

What are the main components of a Pump Jack Scaffolding system?

The main components of a Pump Jack Scaffolding system include the pump jacks, poles, connecting brackets, and the scaffolding platform. The pump jacks are positioned on either side of the scaffolding platform and connected to the poles via connecting brackets, which allow for adjustable height settings. The scaffolding platform provides a stable working surface for construction workers to perform their tasks safely.

How do I set up a Pump Jack Scaffolding system?

To set up a Pump Jack Scaffolding system, start by selecting a suitable location and ensuring the ground is stable and level. Next, assemble the pump jacks and poles, making sure they are securely connected. Attach the connecting brackets to the pump jacks and position them at the desired height. Finally, install the scaffolding platform on top of the pump jacks and secure it in place. Always follow the manufacturer’s instructions and safety guidelines when setting up the system.

What are some tips for working with Pump Jack Scaffolding?

When working with Pump Jack Scaffolding, it is essential to prioritize safety. Ensure that all components are properly assembled and secured before use. Regularly inspect the system for any signs of damage or wear and make necessary repairs or replacements. Use personal protective equipment, such as harnesses and safety lines, when working at heights. Additionally, follow proper lifting and communication protocols to prevent accidents and ensure efficient workflow.

How should I maintain and ensure the safety of Pump Jack Scaffolding?

Maintenance and safety are crucial aspects of working with Pump Jack Scaffolding. Perform regular inspections of all components, checking for any signs of damage or wear. Lubricate moving parts, such as the hand cranks or motor mechanisms, as recommended by the manufacturer. Keep the scaffolding platform clean and free from debris. Implement safety measures, such as using guardrails and safety nets, and provide proper training to workers on safe operating procedures and emergency protocols.

What are the advantages and applications of Pump Jack Scaffolding?

Pump Jack Scaffolding offers several advantages, including adjustable height settings, versatility, and ease of use. It is suitable for a wide range of construction projects, such as building maintenance, exterior painting, roofing repairs, and installations. The adjustable height feature allows workers to access different levels, making it ideal for projects with varying elevation requirements. Its compact and portable design also facilitates easy transport and setup on different job sites.