Phone:

(+65)8319-0742

Modular system scaffolding offers a secure and versatile solution for construction scaffolding needs. It utilizes prefabricated parts and components, providing a strong and reliable structure. This type of scaffolding is commonly used in various industries, including oil and gas, construction, marine, chemical plants, architecture, and engineering. It offers flexibility and versatility, allowing for customization based on specific project requirements.

Key Takeaways:

- Modular system scaffolding is a secure and versatile solution for construction scaffolding needs.

- It utilizes prefabricated parts and components, providing a strong and reliable structure.

- Modular scaffolding is commonly used in industries such as oil and gas, construction, marine, chemical plants, architecture, and engineering.

- It offers flexibility and versatility, allowing for customization based on specific project requirements.

- By choosing modular system scaffolding, construction projects can be completed efficiently and effectively.

What is a Modular Scaffold?

A modular scaffold is a type of system scaffolding that utilizes prefabricated parts and components, providing a secure and versatile solution for construction projects. This type of scaffolding is commonly used in various industries, including construction, oil and gas, marine, chemical plants, architecture, and engineering.

The modular scaffold is based on the tube coupling method, which allows for easy and secure connections between different components. Unlike tube and coupler scaffolding, which relies on couplers and fasteners, modular scaffolding is built using pre-fabricated modules that form the foundation of the scaffold structure.

Modular scaffolding is especially well-suited for exterior construction work on buildings, providing a reliable and stable platform for workers. It offers flexibility in terms of customization and can be adapted to fit specific project requirements. Whether it’s a small-scale construction project or a large industrial project, the modular scaffold system provides the necessary strength and stability.

Let’s take a closer look at the components and benefits of a modular scaffold:

Components of a Modular Scaffold

A modular scaffold consists of several key components that work together to create a sturdy and safe working platform:

- Vertical standards: These are the vertical tubes that serve as the main support for the scaffold. They are connected using horizontal ledgers or transoms, creating the framework of the scaffold.

- Horizontal ledgers: These horizontal bars connect the vertical standards, adding stability and supporting the scaffold platform.

- Diagonal braces: Diagonal braces provide additional strength and stability to the scaffold structure, preventing lateral movements and improving overall safety.

- Scaffold platform: Also known as the working or walking platform, this is the area where workers stand and perform their tasks. It is typically made of wooden planks or metal grating.

- Guardrails: Guardrails are installed along the edges of the scaffold platform to prevent falls and ensure worker safety.

- Base plates: Base plates are placed at the bottom of the scaffold standards to distribute the weight evenly and provide a stable foundation.

These components are carefully designed and engineered to meet safety standards and regulations, ensuring a secure and reliable working environment.

Benefits of a Modular Scaffold

Modular scaffolding offers several benefits that make it an ideal choice for construction projects:

- Safety and Security: The modular scaffold system provides a secure and stable working platform for workers, reducing the risk of accidents and injuries. The tube coupling method ensures strong connections between components, minimizing the chances of failure or collapse.

- Flexibility and Versatility: Modular scaffolding can be easily customized and adapted to fit different project requirements. It offers flexibility in terms of height adjustments, platform configurations, and the ability to add or remove components as needed.

- Convenience and Ease of Use: The prefabricated nature of the modular scaffold system makes it easy to assemble and dismantle. The standardized components and connections simplify the installation process, saving time and effort.

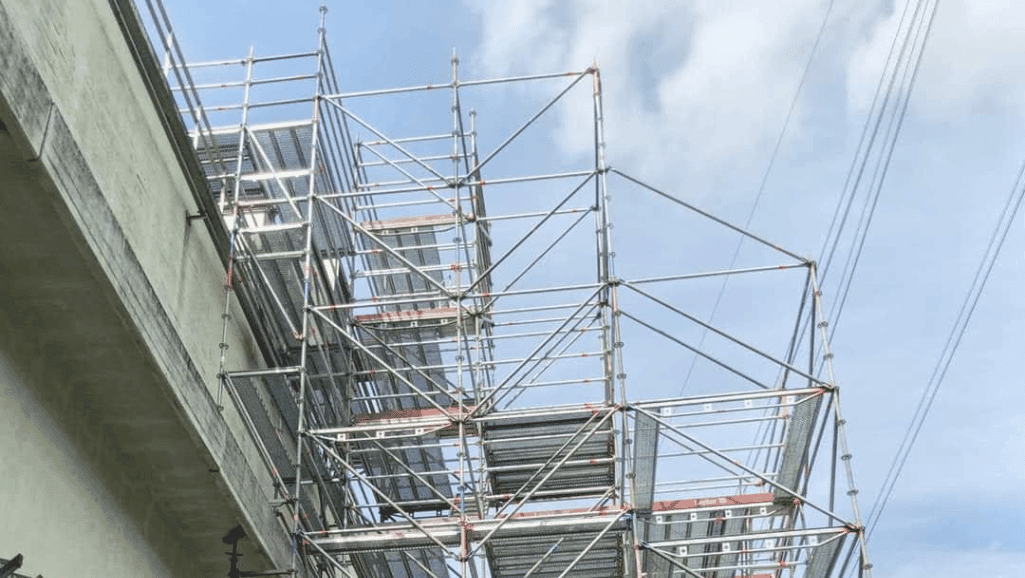

The image above showcases a modular scaffold in action, highlighting its secure and versatile nature.

Types of Scaffolding Systems

Scaffolding systems can be classified into different types, with two main categories being modular scaffolding and systems scaffolding. Let’s explore each type in detail:

Modular Scaffolding

Modular scaffolding involves the use of various modules to create a scaffold base. It is a popular choice for exterior construction work due to its effectiveness and versatility. The modular system allows for easy assembly and disassembly, making it convenient for projects that require frequent adjustments or relocations. This type of scaffolding relies on prefabricated components, such as metal tubes and connectors, ensuring a secure and stable structure. Modular scaffolding systems provide a safe working platform for construction workers, enabling them to carry out their tasks efficiently and effectively.

Systems Scaffolding

Systems scaffolding, also known as system scaffolding or frame scaffolding, utilizes fixed connections with ready-to-attach posts. It offers excellent linking points for different types of jobs, providing flexibility and adaptability. The system scaffolding components are designed to interlock and create a stable framework, supporting workers and materials during construction activities. This type of scaffolding is commonly used in commercial, industrial, and residential construction projects. Systems scaffolding is known for its strength, durability, and ease of installation, making it a preferred choice for many construction professionals.

| Types of Scaffolding Systems | Description |

|---|---|

| Modular Scaffolding | Involves the use of various modules to create a scaffold base. Provides versatility and convenience for exterior construction work. |

| Systems Scaffolding | Utilizes fixed connections with ready-to-attach posts. Offers excellent linking points for different types of jobs. |

Both modular scaffolding and systems scaffolding use tubes and joints for construction. However, they differ in the materials used and the assembly methods. While modular scaffolding relies on prefabricated modules, systems scaffolding utilizes fixed connections to create a secure framework. Choosing the right type of scaffolding system depends on the specific requirements of the project and the preferences of the construction professionals involved.

Major Types of Modular Scaffolding in Construction

Modular scaffolding in construction encompasses a range of types, with cuplock scaffolding, ringlock scaffolding, and kwikstage scaffolding being the major options available in the market. Each of these types offers unique features and advantages, catering to different project requirements and preferences.

Cuplock Scaffolding

Cuplock scaffolding is a highly popular type of modular scaffolding that utilizes metal cups to interlock and join standards or metal beams together. This unique interlocking design eliminates the need for nuts, bolts, and threads, making it quick and easy to assemble and disassemble. Cuplock scaffolding is known for its exceptional strength and stability, making it ideal for various construction applications.

Ringlock Scaffolding

Ringlock scaffolding, also known as rosette scaffolding, is another widely used modular scaffolding system. Instead of cups, it utilizes rings to join different components together. The ringlock system provides a secure and rigid connection, offering superior stability and load-bearing capacity. This type of scaffolding is known for its versatility and adaptability, making it suitable for a wide range of construction projects.

Kwikstage Scaffolding

Kwikstage scaffolding is a popular choice in the construction industry, known for its efficiency and flexibility. It is made up of steel tubes and specific fasteners, allowing for quick and easy assembly. Kwikstage scaffolding offers a safe and stable working platform, making it suitable for various applications, including both interior and exterior construction work.

These major types of modular scaffolding play a crucial role in construction projects, providing secure and reliable access solutions for workers. The choice of scaffold type depends on factors such as project requirements, load-bearing capacity, ease of installation, and adaptability. By selecting the appropriate type of scaffold, construction professionals can ensure efficient and safe work processes.

| Scaffolding Type | Main Features | Advantages |

|---|---|---|

| Cuplock Scaffolding | Metal cups for interlocking and joining; eliminates the need for nuts, bolts, and threads |

|

| Ringlock Scaffolding | Rings for joining components; secure and rigid connection |

|

| Kwikstage Scaffolding | Steel tubes and specific fasteners; quick and easy assembly |

|

Advantages of Modular Scaffolding

Modular scaffolding offers several advantages for construction projects. Its design prioritizes safety and security, providing a secure and reliable structure that reduces the risk of failure, property damage, and injuries. The interlocking system ensures a strong and stable scaffold platform, giving workers peace of mind while working at heights.

Flexibility and versatility are key features of modular scaffolding. It allows for customization and adaptation to different project requirements. With modular scaffolding systems, various modules can be combined to create a scaffold base that suits specific construction needs. This flexibility enables easy adjustments and modifications during the construction process, saving time and effort.

Convenience and ease of use are also significant advantages of modular scaffolding. The prefabricated parts and components make assembly and disassembly quick and efficient. Workers can set up the scaffold platform without the need for complex tools or extensive training. The modular design also provides a workable and efficient working height and space, ensuring productivity and comfort for workers throughout the project.

Other benefits of modular scaffolding include durability, low maintenance, efficient storage, and ease of transport. The modular components are typically made from high-quality materials that can withstand harsh weather conditions and heavy loads. Maintenance requirements are minimal, reducing downtime and additional costs. Additionally, modular scaffolding can be disassembled and stored compactly, maximizing available space and minimizing clutter. The ease of transport allows for efficient movement between different job sites, saving time and resources.

The table showcases the advantages of modular scaffolding:

| Advantages of Modular Scaffolding |

|---|

| Safety and Security |

| Flexibility and Versatility |

| Convenience and Ease of Use |

| Durability |

| Low Maintenance |

| Efficient Storage |

| Ease of Transport |

Disadvantages of Modular Scaffolding

While modular scaffolding offers numerous advantages, it is not without its drawbacks. Understanding the disadvantages is crucial in evaluating the suitability of modular scaffolding for construction projects.

Higher Initial Costs and Expenses

One significant disadvantage of modular scaffolding is the higher initial costs and expenses compared to other types of scaffolding. The prefabrication process and specialized components involved in modular scaffolding contribute to its higher price. However, it’s important to note that the long-term benefits of modular scaffolding can outweigh the upfront investment.

Complex Design Requirements

The complex design requirements associated with modular scaffolding can pose challenges during the planning and implementation stages. Additional expertise may be required to ensure accurate design and efficient assembly. This complexity may also increase the overall project duration.

Limited Flexibility and Adaptability

Modular scaffolding’s pre-made or pre-fabricated materials limit its flexibility and adaptability compared to other scaffolding systems. Modifications and adjustments may be more difficult, impacting the versatility of the scaffold for different project needs. It is important to carefully consider the specific requirements of the project before opting for modular scaffolding.

Despite these disadvantages, modular scaffolding remains a viable option for construction projects, especially when the benefits such as safety and efficiency outweigh the drawbacks. By carefully weighing the advantages and disadvantages, project managers can make informed decisions and select the most suitable scaffolding system.

OCTO® Scaffolding: The Preferred Choice

OCTO® scaffolding is the preferred choice when it comes to system scaffolding. This reliable and safe scaffolding option offers a wide range of benefits for construction projects. With its high load capacity and superior stability, OCTO® scaffolding ensures a secure working environment for workers at various heights. This system scaffolding meets or exceeds safety standards, providing peace of mind to project managers and workers alike.

One of the standout features of OCTO® scaffolding is its versatility. It is adaptable to different types of structures and can be customized to fit specific project requirements. The long bay length of OCTO® scaffolding allows for unobstructed worker access, improving efficiency on the job site. The unique safety locking mechanism ensures a secure connection, reducing the risk of accidents and ensuring worker safety.

In addition to its safety and versatility, OCTO® scaffolding is also cost-effective. Its streamlined design and fewer components make transportation, installation, and storage easier and more efficient. By choosing OCTO® scaffolding, contractors can save both time and money without compromising on quality and safety.

Overall, OCTO® scaffolding is the preferred choice for system scaffolding due to its exceptional safety, reliability, versatility, and cost-effectiveness. It provides a secure working platform, adaptability to various structures, and significant cost savings for construction projects.

Conclusion

In conclusion, modular system scaffolding is a secure and versatile solution for construction scaffolding needs. It offers various advantages such as safety, flexibility, and convenience. With modular scaffolding, construction projects can be carried out efficiently and effectively.

However, it is important to consider the disadvantages of modular scaffolding, such as higher initial costs, complex design requirements, and limited adaptability. When choosing a scaffolding system, factors like project requirements, budget, and industry standards should be taken into account.

One of the preferred choices for system scaffolding is OCTO® scaffolding. Known for its safety, reliability, versatility, and cost-effectiveness, OCTO® scaffolding meets or exceeds safety standards and offers a high load capacity. It provides a streamlined design, fewer components, and ease of transportation, installation, and storage.

By selecting the right system scaffolding, such as OCTO® scaffolding, construction projects can be completed efficiently and effectively, ensuring the safety and success of the construction process.

Frequently Asked Questions

What is modular system scaffolding?

Modular system scaffolding is a secure and versatile solution for construction scaffolding needs. It utilizes prefabricated parts and components to create a strong and reliable structure.

How does modular scaffolding differ from tube and coupler scaffolding?

Modular scaffolding is based on the tube coupling method, allowing for easy and secure connections. On the other hand, tube and coupler scaffolding relies on couplers and fasteners for assembly.

What are the major types of modular scaffolding in construction?

Cuplock scaffolding, ringlock scaffolding, and kwikstage scaffolding are some popular types of modular scaffolding used in the construction industry.

What are the advantages of modular scaffolding?

Modular scaffolding prioritizes safety and security, offers flexibility and versatility, and is convenient and easy to use. It is also durable, requires low maintenance, and enables efficient storage and transportation.

What are the disadvantages of modular scaffolding?

The higher initial costs, complex design requirements, and limited flexibility and adaptability are some drawbacks of modular scaffolding.

Why is OCTO® scaffolding a preferred choice for system scaffolding?

OCTO® scaffolding is known for its safety, reliability, versatility, and cost-effectiveness. It offers a high load capacity, superior stability, and ease of handling. OCTO® scaffolding also features a unique safety locking mechanism and is streamlined for efficient transportation, installation, and storage.