Phone:

(+65)8319-0742

The shift towards professional-grade ladders & scaffolding is crucial for worker safety and completing projects accurately. Ladders offer quick access and are easy to move around. However, sturdy scaffolding solutions provide stability for tasks that need workers at high levels. The cherry picker is a mix of both, needing skill to use but giving fast access to roofs.

Choosing the right construction equipment affects costs, time, and worker safety.

Key Takeaways

- Choosing between ladders & scaffolding is key to meeting safety standards.

- Top-notch construction equipment is built to prevent accidents.

- Following OSHA rules, like keeping clear of dangers and checking regularly, is a must for safe ladders and scaffolding.

- Training workers and using sturdy scaffolding solutions correctly helps avoid injuries and deaths.

- The type of ladder, like aluminium or wood, affects its use and look in different projects.

- How well a solution works depends on the project’s size, terrain, and complexity.

- Using ladders & scaffolding wisely means planning well and using modern tools.

Ladders & Scaffolding: Essential Tools for Roofing Professionals

Roofing projects need precision, safety, and efficiency. The right tools make a big difference. Using aluminum ladders and scaffold towers helps professionals do their job well and safely. These tools give workers the access and movement they need for roofing tasks.

Overview of Ladders and Scaffolding in the Roofing Industry

In roofing, aluminum ladders are popular for being light and rust-resistant. They’re great for quick checks and big repairs. For tall and complex jobs, scaffolding systems are used. They give a solid base for workers to work safely above ground.

These systems include scaffolding planks and secure frames. They fit different architectural styles and project needs. Tools like the Baker scaffold and elevated work platforms help in tight spots.

Ladders are great for single-person tasks, while scaffolding is for bigger jobs with a team. Using roofing tools and hoists makes work safer and more efficient.

How Ladders & Scaffolding Facilitate Safe Work at Heights

Scaffold towers and aluminum ladders boost safety in roofing. Scaffold towers have guardrails and outriggers for stability. Scaffolding planks give a wide workspace, lowering the chance of accidents.

Choosing the right ladder or scaffold is key for safety. The job’s height, work type, and project length decide if you need a simple ladder or complex scaffolding. With options like fiberglass ladders and scaffolding systems, professionals can pick the best gear for their jobs. This ensures they work efficiently and safely.

The Advantages of Ladders for Quick Access and Portability

Ladders are key in both work and home settings for their versatility and easy transport. Extension ladders and step ladders are top choices for tasks needing quick access.

Industrial ladders like the extension ladder are great for reaching high places, like the roofs of two-story buildings. They can be retracted to 16 feet and extend to 40 feet. This makes them perfect for roofing projects where you need to reach high.

There are also ladder accessories and multi-position ladders available. These can change into a step ladder, extension ladder, or scaffold. They are a must-have for professionals with different work conditions.

For those with limited storage space, telescopic ladders are a smart choice. They can fully retract, making them easy to carry and store. They are a hit with homeowners and those living in apartments.

In some cases, like when you need to work with a partner, trestle ladders are the best option. They can hold two people, offering a stable and safe place for teamwork.

| Ladder Type | Key Features | Optimal Use |

|---|---|---|

| Extension Ladder | Extends from 16 to 40 feet | High reach tasks, e.g., roofing |

| Step Ladder | Self-supporting design | General utility work at moderate heights |

| Telescopic Ladder | Collapsible for compact storage | Space-constrained environments |

| Trestle Ladder | Supports two users | Collaborative tasks requiring stability |

Choosing between scaffolding and ladders depends on the project’s height, duration, and the number of workers. Scaffolding is better for big, long-term projects. But, ladders are great for short, budget-friendly tasks because they are affordable and easy to set up.

Always put safety first. Both scaffolding and ladders have their own benefits and safety tips. Knowing what your project needs will help you pick the right climbing tool. Whether it’s strong industrial ladders with useful ladder accessories or sturdy scaffolding, make the right choice.

Challenges of Using Ladders: Safety and Stability Concerns

Ladders are key tools in many industries, like construction and maintenance. But, they bring safety and stability challenges. It’s important to tackle these issues to keep workers safe and work efficiently.

Understanding Ladder Limitations in High-Roof and Complex Projects

Different ladders are made for different tasks and places. Not all are good for high-roof or complex projects. For example, step ladders work well for low heights but not for tasks over 20 feet high. In those cases, you should use extension ladders or safety ladders.

Ladder Safety Best Practices

Following ladder safety rules is key to staying safe. This means setting up ladders right, checking them often, and using them as they’re meant to be used. Ladders with the right weight limit and the 1:4 rule for leaning help a lot. But, you also need good training and to follow safety rules closely.

| Ladder Type | Weight Capacity | Recommended Usage |

|---|---|---|

| Step Ladders | Up to 375 lbs | Low height tasks, indoor usage |

| Extension Ladders | Up to 375 lbs | High-roof projects, outdoor constructions |

| Single Ladders | Up to 250 lbs | Quick access, straightforward tasks |

It’s important to keep three points of contact, use safety harnesses, and make sure ladders are on stable surfaces. Even with these steps, ladder injuries are still a big problem. This shows we need to keep being aware and using safety steps.

In conclusion, training, following safety rules, and choosing the right ladder are key to avoiding ladder accidents. This helps protect workers and makes work better.

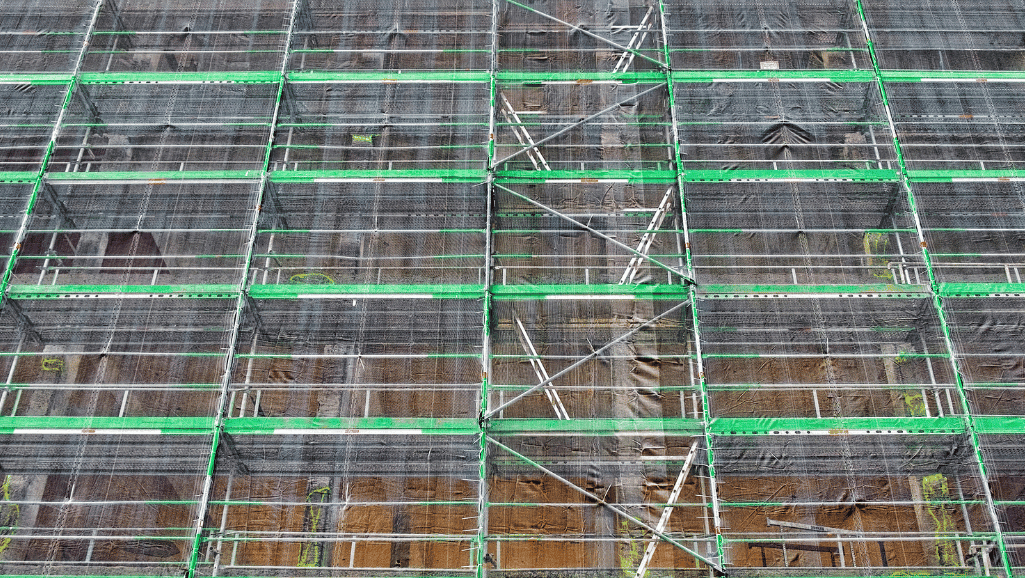

Why Scaffolding Solutions Excel in Stability and Versatility

Professional scaffolding solutions are top choices for roof projects. They are known for their stability and can handle many tasks. Ladders just can’t match the safety and flexibility of scaffolding.

Scaffolding platforms can be made to fit any project’s needs. XSPlatforms has created systems that focus on safety and ease. For example, their SafeScaffold makes putting it together easy and has a built-in ladder for easy movement between levels.

The SafeScaffold and SafeTower systems by XSPlatforms are great for heavy tasks. They can go up to 99 feet high and hold a lot of weight. They don’t need personal fall arrest systems, thanks to their special design.

Scaffolding rental services from Excel Modular Scaffold are key for many companies. They offer different scaffolding types for various needs. For instance, Excel has industrial scaffolding that focuses on safety with lots of accessories for better stability and protection.

| Feature | SafeScaffold | SafeTower |

|---|---|---|

| Maximum Working Height | 99 feet | 78’7” |

| Maximum Platform Load | 683 lbs | 683.4 lbs |

| Platform Width | N/A | 2’4” or 4’4” |

| Total Load Capacity (excluding self-weight) | N/A | 1874 lbs |

| Key Safety Feature | Integrated guardrail system | Advanced Guardrail design |

Modern scaffolding platforms from XSPlatforms and Excel Modular Scaffold are crucial in today’s industry. They make workers safer and more efficient. They fit well in many construction settings, proving they’re better than ladders.

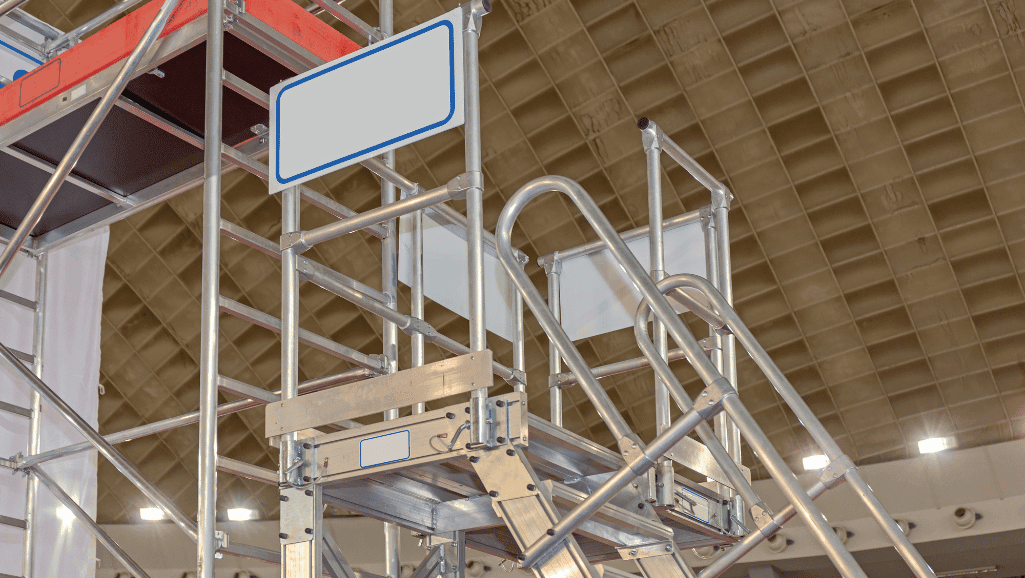

The Comprehensive Nature of Scaffold Towers and Systems

Scaffold towers and systems are key in construction and maintenance. They boost safety and efficiency on project sites. They are used on big projects and small repairs alike. Mobile scaffold towers, scaffold platforms, and scaffold towers are essential for many professionals.

Benefits of Spacious Platforms for Multi-Person Projects

Scaffold platforms make a big difference by providing a stable place to work. This is crucial on big job sites where many people work together. These platforms lower the risk of accidents and make it easier to move around. This lets teams work better and more safely.

Customizing Scaffolding for Unique Project Needs

Being able to change scaffold systems for different projects is very useful. Mobile scaffold towers are great for jobs that need the scaffolding moved often. They are perfect for tasks like painting or cleaning. This flexibility saves time and makes the site safer and happier for workers.

Let’s look at how scaffold towers and platforms are used in different situations:

| Type of Scaffold | Typical Use | Advantages |

|---|---|---|

| Standard Tower Scaffold | High-rise building construction | High stability, suitable for tall structures |

| Mobile Scaffold | Tasks requiring mobility (painting, maintenance) | Easy to move and reassemble |

| Coupler Scaffolding | Complex architectural structures | Highly customizable, robust construction |

| Cantilever Scaffolding | Areas with inadequate ground support | Utilizes extended beams for support, versatile setup |

| Bamboo Scaffolding | Regions rich in natural resources | Eco-friendly, flexible in use |

This detailed look into various scaffolding options shows how important scaffold towers and equipment are. They are crucial for keeping projects safe and efficient.

Cost and Time Implications of Scaffolding vs. Ladders

When looking at scaffolding and ladders for industrial projects, many factors matter. The choice between them depends on cost, time, and the project’s type.

Assessing Scaffolding Rental Options for Budget-Friendly Solutions

Scaffolding is often the better choice for big or long projects. It’s stable and gives workers a lot of room to move. This makes the site safer and work more efficient, saving time and money compared to using ladders.

The move from ladders to scaffolding is about safety and efficiency. It helps with managing big teams or complex projects. Renting scaffolding, like wheeled towers for inside use, is flexible and safe. Ladders are cheaper but not as reliable for hard work or big teams.

| Equipment Type | Cost Efficiency | Time Efficiency | Suitability |

|---|---|---|---|

| Ladders | High | Lower due to frequent relocations | Minor solo tasks |

| Scaffolding | Variable | High for prolonged tasks | Multifaceted team projects |

| Aerial Lifts | High initial but efficient | High | Dynamic sites with heavy equipment |

Choosing scaffolding over ladders means looking at long-term value, not just the upfront cost. Good planning and picking the right access solutions can make a project safer, cheaper, and faster.

Cherry Pickers: Combining the Best of Ladders and Scaffolding

Cherry pickers, also known as aerial work platforms, blend the ease of an extension ladder with the stability of heavy-duty scaffolding. They are perfect for jobs that need reaching high places safely and efficiently. This is especially true for industries where working at heights is common.

These machines can reach up to 58m high and have a strong outreach. For example, the JLG 1850SJ model is a top choice for reaching high places. It has a lot of outreach and is strong enough for tough tasks.

Cherry pickers make getting to hard spots easy, without the need for big setups like adjustable scaffold. They also have safety features like fall arrest systems. These systems help prevent falls, showing how much they care about keeping operators safe.

Cherry pickers are used in many areas, like building, picking fruit, emergency work, and filming. They are also supported by special training like IPAF. This training teaches operators how to use these machines safely and well.

For more info on how cherry pickers have evolved and their importance, check out the detailed history and innovations at Horizon Platforms.

| Feature | Cherry Picker | Other MEWPs |

|---|---|---|

| Maximum Reach | Up to 58m | Varies, generally lower |

| Common Uses | Construction, Rescue | General Aerial Tasks |

| Training Required | IPAF Certification | Varies by Equipment |

| Safety Features | Advanced Fall Arrest Systems | Basic Safety Compliance |

Using cherry pickers in work makes things safer and more efficient. It shows how access equipment is always getting better, combining the best of old and new technology.

The Importance of Choosing the Right Equipment for Your Project

Choosing the right equipment for construction or maintenance projects is key. It’s not just about making things go faster. It’s also about keeping everyone safe and keeping costs down. Using aluminum scaffolding or warehouse ladders can make a big difference in how well a project goes.

What you need depends on the size and complexity of the job. Scaffolding suppliers offer many options. They have everything from light-duty scaffolding for small tasks to heavy-duty for big projects.

Evaluating Project Scale and Worker Safety

The size of the project affects what equipment you should use. Scaffolding is safer and more stable for big jobs. It can hold more weight and reach higher places than ladders. It also gives workers a big space to work, making them safer and more mobile.

Choosing the right construction scaffolding means looking at risks and benefits. Different types of scaffolding, like Ringlock or system scaffolding, have their own advantages. They are easy to set up and last a long time.

Accessibility and Project Terrain Considerations

When deciding between scaffolding and ladders, think about the terrain and how easy it is to get to the project site. Aluminum scaffolding is great for uneven ground because it’s stable. Ladders are better for small, easy-to-reach jobs. Scaffolds need careful planning to fit the site and follow safety rules.

It’s important that all your equipment meets OSHA rules to avoid accidents. The American Journal of Industrial Medicine says many injuries come from falls on the job. These are often from using ladders or scaffolding the wrong way.

Deciding between aluminum scaffolding and warehouse ladders should be based on a careful look at your project and advice from experts. This way, you pick the right equipment for your needs and keep everyone safe.

Ensuring Compliance with Scaffolding Regulations and Safety Standards

Following strict scaffolding regulations is key for legal reasons and worker safety. It means picking the right safety equipment and industrial tools. Also, making sure OSHA-compliant access equipment is used in every project is crucial.

Industrial Scaffolding Regulations and Safety Protocols

About 65 percent of construction workers use scaffolds every year. This shows how important scaffolding is in construction. It’s why we must follow OSHA scaffold standards set in 1996. These standards cover falling object protection and when to use ladders or aerial lifts in different weather.

OSHA-Compliant Access Equipment and Accredited Contractors

Scaffolds must hold their weight and at least four times the max load they’re meant to carry. This makes sure they’re safe and strong. To meet these rules, OSHA-certified training for contractors and workers is a must. It covers safety rules for different scaffolds and how they’re used in building projects.

| OSHA Regulation | Requirement | Safety Tip |

|---|---|---|

| 29 CFR 1910.28 | General Safety for Scaffolding | Use of fall protection systems |

| 29 CFR 1910.29 | Falling Object Protection | Wear hard hats and secure tools |

| 29 CFR 1926.450 | Access Equipment Specifications | Non-slip work boots and maximum intended load adherence |

Keeping scaffolding safe on construction sites is more than just hiring certified contractors. For example, guardrails must handle 200 pounds at their top edge. This shows how detailed these rules are to make work areas safer. Regular checks and fixing hazards quickly by experts also make scaffolds safer.

So, it’s vital to follow these safety steps and stick to scaffolding regulations. Doing so not only keeps projects in line with the law. It also protects the health of workers doing high-level tasks.

Construction Equipment: Essential Scaffold Accessories and Ladder Types

The world of construction equipment is huge and diverse. It focuses on making projects safer and more efficient. Tools like ladder accessories and scaffolding materials are key to creating safe work areas for workers. This part looks at the must-have equipment for building, from small DIY projects to big commercial ones.

Enhancing Safety with Ladder Accessories and Fall Protection Equipment

Safety is top priority in construction. Using reliable ladder accessories and fall protection gear cuts down on accident risks. Safety harnesses are crucial for preventing falls and must meet strict safety standards. They keep workers safe when working high up.

Lanyards with shock absorbers link these harnesses to strong points, giving a vital safety line. This reduces the chance of getting hurt if you fall. Scaffold spanners help put scaffolding together and take it apart safely. They make sure everything is securely connected.

Hard hats and other protective gear like safety goggles and ear protectors also keep workers safe. They shield against common dangers on the job.

Scaffolding Planks, Platforms, and Elevated Work Solutions

Scaffolding is key for strong and safe construction sites. Scaffold boards are vital for making stable platforms and paths. They need to be picked based on their strength to handle the weight and stress they’ll see.

For DIY fans and pros, knowing the strength of materials like Aluminum Scaffold Planks is important. These can hold up to 75 lbs per square foot for 7′ planks.

Good scaffolding systems are more than just frames. Tools like scaffold ratchets and I-Beam Tube Clamps help hold the structure together. Using strong steel parts with a rust-resistant finish makes scaffolding last longer and work better.

TJR Scaffolding Ltd and AAIT Technocraft are leaders in the South-West, offering top-notch scaffolding solutions. Their products focus on safety and efficiency, making construction projects better.

Choosing the right ladder accessories, fall gear, and scaffolding materials helps workers and project managers work safer and more efficiently. Every piece, from steel ladders to adjustable scaffolding props, plays a big part in this goal.

Conclusion

In the world of professional ladder equipment and scaffold solutions, picking the right tool is key. It affects both safety and efficiency. Step ladders are great for low tasks, while extension ladders reach high places. Scaffolding offers stability for big projects, letting workers access high areas safely.

Ladders and scaffolding meet different needs. They’re used for painting, maintenance, and big construction jobs. Renting ladders and scaffolding is crucial for many tasks.

But safety is a top priority. It’s important to keep ladders and scaffolding at the right angle and distance apart. This keeps workers safe. Sadly, many accidents happen because of not following safety rules.

Regular checks and following safety guidelines can prevent many accidents. Things like guardrails and safety nets help a lot. They can stop many serious injuries.

New materials like aluminum ladders and scaffolding are changing the game. They’re strong, light, and good for the planet. These materials are becoming key in construction and maintenance.

Reviews show more people are choosing these new solutions. They help save money and protect the environment. Choosing the right ladder or scaffolding means meeting work needs while keeping everyone safe.