Phone:

(+65)8319-0742

In the construction world, the Hydro Mobile scaffold is a big deal. It changes how crews work on tall buildings. It gives a safe, high place for workers to do their jobs.

Construction scaffolds have evolved, and Hydro Mobile is at the forefront. Their scaffolds are safe and efficient, letting workers go higher. They’re perfect for many jobs, like masonry and glazing.

Studies show that 70% of masonry contractors find mast climbers increase productivity. But safety is key. Last year, OSHA cited over 5,400 scaffold-related violations. Hydro Mobile focuses on safety and efficiency to meet these needs.

Key Takeaways

- Hydro Mobile scaffolds boost productivity in construction

- Safety features reduce risks associated with elevated work

- Versatile design suits various trades and project types

- Compliance with OSHA regulations is crucial for jobsite safety

- Proper training on mobile scaffolding use is essential

Introduction to Hydro Mobile Scaffold Systems

Hydro Mobile scaffolds change the game in construction with their cutting-edge mast climbing work platforms. They bring unmatched efficiency and safety to facade work in new builds and renovations.

What are Hydro Mobile Scaffolds?

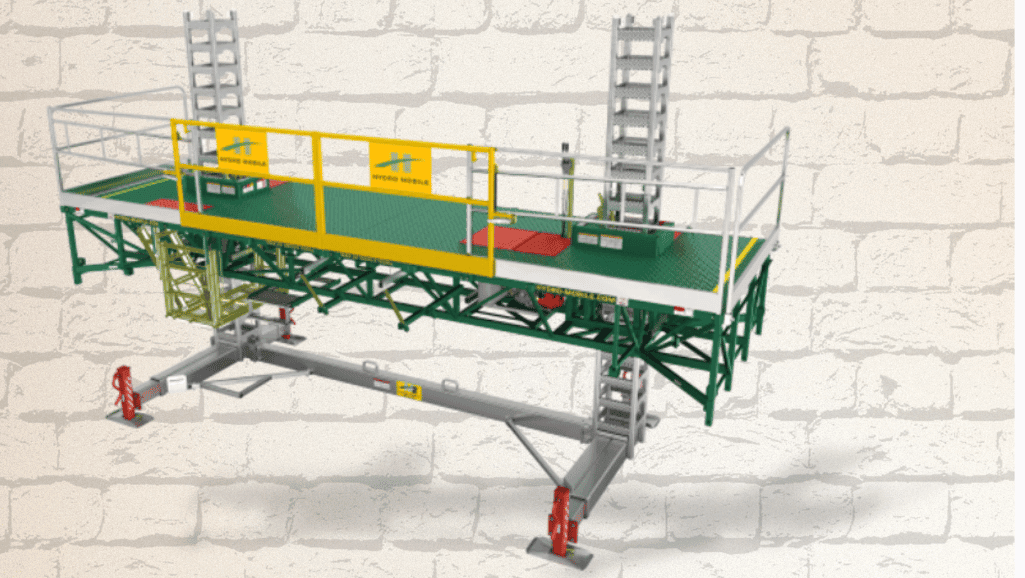

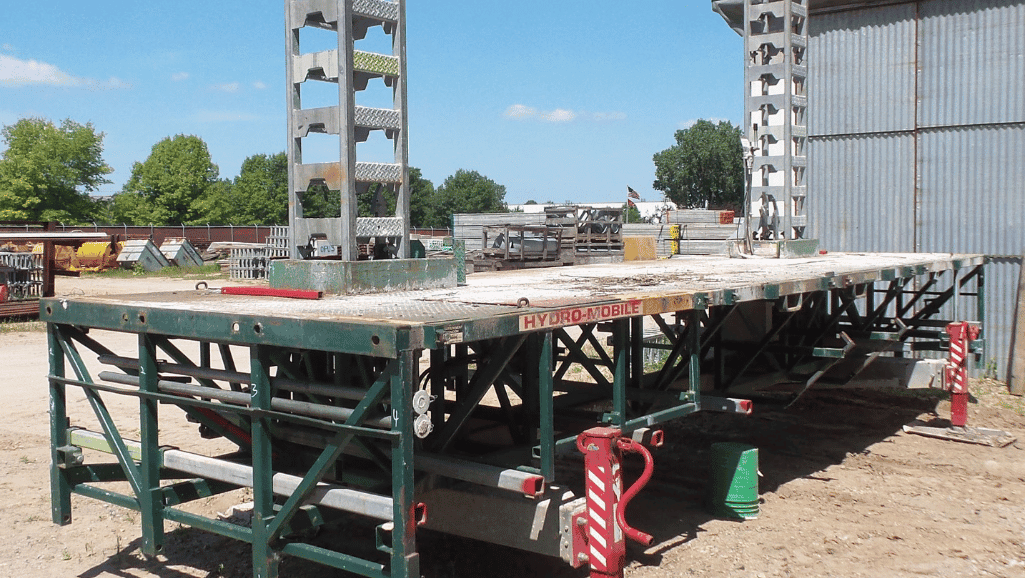

Hydro Mobile scaffolds are top-notch modular access systems for big facade projects. The M-Series platform is a leader in construction gear, known for its great features:

- Load capacity: 20,000 lb at 24′ (9,070 kg at 7.3 m)

- Climbing rate: 3′ per minute

- Maximum height: 250′ (76.2 m)

- Platform width: 7′ (2.1 m)

Key Features and Benefits

Hydro Mobile scaffolds beat traditional mast climbing scaffolding in many ways:

- Angled set-ups for architectural flexibility

- 30% estimated increase in productivity

- Minimum life expectancy of 15 years

- Quick installation with minimal parts

Applications in Construction and Renovation

These versatile mast climbing work platforms are great for many construction and renovation tasks:

- Masonry work

- Stone installation

- Marble facade construction

- Restoration projects

With their ability to fit different architectural needs and work site challenges, Hydro Mobile scaffolds are changing the game in temporary access solutions for construction.

The Evolution of Mast Climbing Work Platforms

Mast climbing work platforms changed the construction world when they arrived in North America in 1982. These hydraulic scaffolds are now key for masonry work. They boost productivity, safety, and efficiency like never before.

These platforms are now a big part of construction work. Hydro Mobile leads the market with over 5,000 platforms in North America and Europe. Their M-series can lift 20,000 pounds. The P-series and F-series can lift 10,000 and 15,500 pounds each.

Now, adjustable scaffolds are used on more than just tall buildings. They’re now common on two-story buildings too. This shows how versatile and easy they are to set up.

“Mast climbers have become the preferred method of access in the masonry industry, providing increased productivity, efficiency, reliability, and safety.”

A survey of 42 masonry contractors showed some interesting facts:

| Advantage | Percentage of Contractors |

|---|---|

| Increased Productivity | 70% |

| Time Savings | 60% |

| Enhanced Safety | 50% |

Even though 70% of contractors worried about the cost at first, the long-term gains of hydraulic scaffolding keep making them popular in construction.

Hydro Mobile Scaffold: Elevating Efficiency and Safety

Hydro Mobile scaffolds are changing the game in construction site mobility. They use hydraulic work platforms that are both efficient and safe. This makes them a big deal in the construction world.

Load Capacity and Platform Dimensions

The M-Series platform is a top choice among portable scaffold systems. It can hold up to 20,000 pounds at 24 feet and 14,800 pounds at 60 feet. It’s built for heavy-duty tasks.

Climbing Speed and Maximum Height

This platform is super fast, climbing 3 feet per minute. It can go as high as 250 feet. This makes it perfect for tall buildings.

Safety Features and Certifications

Hydro Mobile focuses on safety. The platform has a gravity-activated safety device and an overspeed break. It runs on a reliable 9 HP gasoline engine with an electric starter.

| Feature | Specification |

|---|---|

| Load Capacity | 20,000 lbs at 24′, 14,800 lbs at 60′ |

| Maximum Height | 250′ nominal |

| Climbing Speed | 3′ per minute |

| Drive System | Hydraulic ratchet |

| Engine | 9 HP gasoline with electric starter |

“Hydro Mobile scaffolds have transformed our approach to construction, boosting productivity by an estimated 30% while prioritizing worker safety.”

Hydro Mobile scaffolds are leading the way in making construction sites safer and more efficient. They’re proving their value in projects all over the world.

Boosting Productivity with Hydro Mobile Scaffolds

Hydro Mobile scaffolds change the game in construction, boosting productivity by up to 30%. They make work faster and cut down on setup time.

The M2 Mast Climbers stand out in modular scaffolding with their key features:

- 22,000 lbs capacity, perfect for heavy masonry tasks

- 7′ wide deck for lots of space to work

- 4,000 lb hoist system that lifts at 65′ per minute

- Solid deck to reduce trip risks

- Monorail system to cut down on lifting injuries

This adjustable height platform moves with the wall for the best working conditions. It can hold up to 8 walk-boards and extends 14′ beyond the platform. This means it can adapt to different building designs without needing more setup.

Setting up is quick and efficient. A skilled team can put up 148′ linear x 35′ vertical of M2 mast climbers in just 3-4 hours. The system comes with safety features like guardrails, toeboards, and anchor points, making it safe for workers.

“Hydro Mobile scaffolds have transformed our workflow. We’ve seen a significant boost in productivity and a noticeable improvement in worker safety.”

These scaffolds aren’t just for masonry. They’re great for many trades. They help save on labor costs and increase production. This makes them a smart choice for any project looking to improve efficiency and safety.

Safety Considerations and Best Practices

When using hydraulic mobile scaffolding, safety comes first. It’s important to have the right training and to check things regularly. Let’s look at important safety tips for working on overhead maintenance platforms.

Proper Training and Certification

Knowing how to use worker safety equipment is key. Good training helps workers know how to scaffolds safely. Hydro Mobile has a special program where clients learn about the equipment before they get it.

Fall Protection and Guardrail Systems

Preventing falls is a must on scaffolds. Guardrails should be at least 1 meter high. Safety harnesses are a must for heights over 1.8 meters. Toe boards keep tools from falling off.

Regular Maintenance and Inspections

Checking things every week keeps everyone safe. Make sure ladders are in good shape before using them and set them up right. Sole plates spread the weight out, and ledgers keep standards together for a solid platform. Bracing stops the platform from falling over, and clamps make sure everything stays tight.

“Safety isn’t expensive, it’s priceless.”

Being careful with hydraulic mobile scaffolding is crucial. Keep the work area clean, manage loads well, and follow wind speed rules (stop work at 65kmph). By focusing on these things, we make our work areas safer and more efficient.

Versatility in Design: Adapting to Project Needs

Hydro Mobile scaffolds are top choices for jobsites because they adapt to many construction projects. They fit a wide range of building types and work site needs. This makes them key in modern building.

Modular Components and Customization Options

The M-Series shows how portable elevated workstations can change to fit project needs. They come with many modular parts:

- Multipurpose inserts for specialized tasks

- Bridges in various lengths (6′, 10′, 14′, 18′, and 20′)

- Monorail system for effortless load sliding

These features let workers set up scaffolds in three dimensions. This boosts efficiency. The P-Series mast climbing platforms increase productivity by about 30%. This shows how good design can make a big difference.

Adapting to Different Building Facades

Hydro Mobile’s telescopic mast systems are great for tricky architectural designs. The M-Series can go from 20 to 250 feet high and hold up to 20,000 pounds. This shows they’re versatile for many building types.

“Mast climbers can increase productivity by 45% in the construction industry.”

This flexibility also makes work safer. It helps tackle the growing issue of injuries due to the weather. By offering stable, adjustable platforms, these scaffolds ensure safer work areas. They also meet the needs of complex building designs.

Cost-Effectiveness and Return on Investment

Hydro Mobile scaffolds are changing the game for construction projects. They offer great cost savings and a strong return on investment. Prices range from $35,000 to $100,000, making them pay for themselves in a few years.

These scaffolds are incredibly efficient. They can increase productivity by up to 35%. This is thanks to better safety and ergonomic work conditions. Here are some key points:

| Aspect | Traditional Scaffolding | Hydro Mobile Scaffolds |

|---|---|---|

| Erection Time | 100% | 30% |

| Productivity Increase | Baseline | Up to 35% |

| Labor Requirements | Higher | Reduced |

| Workers’ Compensation Claims | Higher | Reduced |

The scaffolding rental market is moving towards these new platforms. In the Midwest, 70% of commercial masonry jobs now use mast climbing work platforms. The Northeast is close behind at 50-60%. This shows how valuable they are becoming.

Buying Hydro Mobile scaffolds means investing in safety, efficiency, and long-term savings. They last for at least 15 years, giving construction companies lasting value. The future of construction access is here, changing job sites across America.

Environmental Impact and Sustainability

Hydro Mobile scaffolds are leading the way in sustainable construction. They are designed with green building in mind. These scaffolding systems help reduce the environmental impact of construction sites.

Energy Efficiency in Operation

Hydro Mobile scaffolds use a 9 HP gasoline engine for power. This setup cuts down on fuel use, making them great for sustainable projects. They produce fewer emissions and have a smaller carbon footprint.

Reduced Material Waste

Hydro Mobile scaffolds help cut down on material waste. They can be customized for different projects without using extra parts. This means less waste and supports sustainable building.

Longevity and Durability

Hydro Mobile scaffolds last at least 15 years. This means they don’t need to be replaced often. It also means less waste and saving resources over time. These scaffolds are a wise choice for companies focused on sustainability.

- Minimum 15-year lifespan

- Reduced need for replacements

- Lower resource consumption over time

Using Hydro Mobile scaffolds helps companies move towards more sustainable building. They offer efficiency, durability, and eco-friendliness. This meets the growing need for green construction solutions.

Conclusion

Hydro mobile scaffolds have changed the construction world. They mix efficient building solutions with the latest technology. This has greatly increased work speed and kept workers safe, making them key for today’s buildings.

At big projects like Site C in British Columbia, hydro mobile scaffolds show their power. They can hold heavy loads and change to fit different project needs. Their self-leveling and customizable features have made work better and earned praise in the industry.

Even with their many benefits, safety is key when using hydro mobile scaffolds. Past events show how important it is to follow safety rules, check things often, and train workers well. By using new technology and strict safety steps, hydro mobile scaffolds are making construction safer and more efficient.