Phone:

(+65)8319-0742

The scaffold screw jack is a key part of any stable construction scaffold. It’s often overlooked but is a marvel of engineering. This scaffold screw jack, or leveling jack, keeps the work area level and safe. It helps balance out uneven ground, protecting workers and the structure.

But how does a scaffold screw jack work? Let’s dive into its mechanics and importance. It’s a crucial tool in scaffolding, making work sites safer and more efficient. Similar to a machine screw jack, it converts rotary motion into linear motion, ensuring precise height adjustments and stability.

Understanding scaffold screw jacks is essential for construction experts and fans. Each turn of the screw jack adjusts the height, ensuring the scaffolding is perfectly aligned. This is vital for a stable building.

Key Takeaways

Scaffold screw jacks ensure a stable and level base for scaffolding frameworks.

Understanding how they operate is critical for onsite safety and structural integrity.

Height adjustment capabilities offer versatility across uneven grounds.

Industry standards, like EN 12810, test scaffold screw jacks for optimal load capacity.

Innovations from brands like Wellmade and Badger Ladder highlight customizable and durable scaffold solutions.

Lightweight materials such as aluminum enhance ease of handling without compromising durability.

The screw jack system is crucial in construction for achieving precise movement and stability.

An Overview of Scaffold Screw Jacks

Scaffold screw jacks are key in modern construction. They show big steps in scaffold screw jack technology for safety and stability. These tools adjust to keep scaffolding level on uneven ground. They can hold a lot of weight and stand up to harsh weather.

Looking into scaffold screw jack operation, we see they’re crucial for worker safety and job site efficiency. Their strong design lets them adjust up to 18 inches. This is vital in places where precision and flexibility are needed.

Construction pros have a good choice with scaffold screw jacks. Prices range from $44.80 to $62.40, showing their importance. They meet high safety standards like OSHA, CSA, and ANSI, proving they’re reliable and necessary.

Other important parts like scaffold decks, mason frames, and guard rail systems also have good prices. They range from $12.80 to $376.00. This ensures quality and safety without breaking the bank.

The way scaffold screw jacks work shows a focus on safety and efficiency. They’re tested to handle loads up to 39,770 lbs. This meets ANSI/SSFI SC100-5/05 standards.

Companies like APAC keep improving scaffold screw jack technology. They offer products with thread diameters from 34mm to 60mm. These fit different scaffolding systems, showing their wide use in construction worldwide.

In short, scaffold screw jacks are more than tools. They’re essential for safe and efficient building. They show the ongoing growth in design and function in the construction world.

What is a Screw Jack?

A screw jack is a type of mechanical device that converts rotary motion into linear motion, allowing for the lifting, positioning, and holding of heavy loads. These versatile tools are essential in various industries, including construction, manufacturing, and aerospace, where precise movement control and high load capacity are required. Screw jacks, also known as mechanical actuators, are integral components in automated machinery due to their high reliability and synchronization capabilities. By transforming rotational input into linear output, screw jacks provide a robust solution for tasks that demand precision and strength.

Understanding Scaffold Screw Jack Basics

Scaffold screw jacks are key in construction and maintenance. They add stability and adjustability to scaffolding. These tools have detailed designs that boost safety and efficiency on site. This section covers the basics of scaffold screw jacks, including their function, parts, assembly, and types. The lifting screw in scaffold screw jacks converts rotational motion to linear motion, which is crucial for adjusting the height and ensuring proper installation.

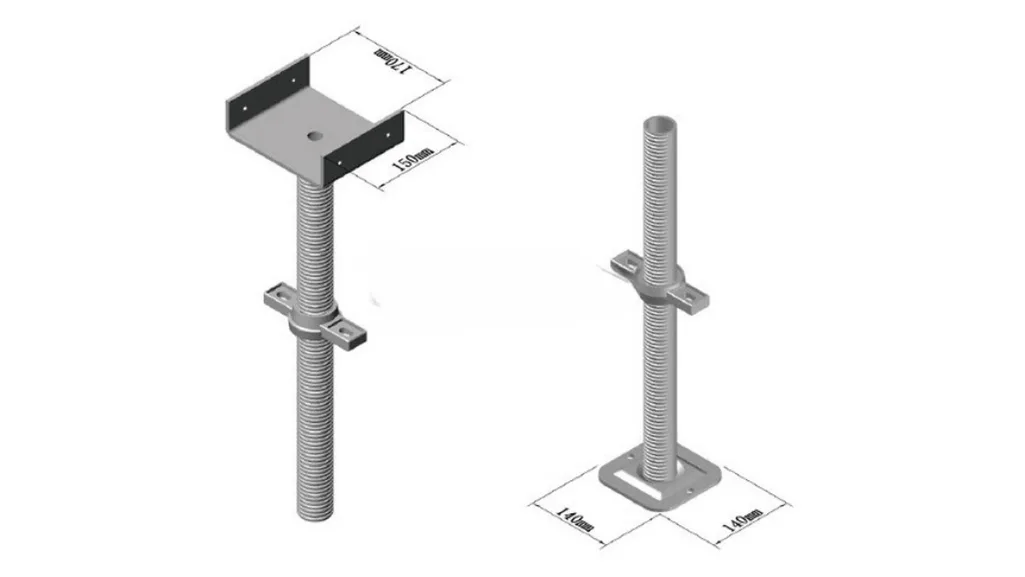

Components of a Scaffold Screw Jack: Assembly and Function

The scaffold screw jack function is to adjust scaffolding for even surfaces. Screw threads are essential in this function as they determine the efficiency and load-carrying capacity of the screw jack. This ensures a stable work area. The main scaffold screw jack parts are a base plate and an adjustable height rod. These parts are crucial for the system’s safety and function.

For more on how these parts work together, check out this resource on scaffolding components.

Different Types of Scaffold Screw Jacks

There are many scaffold screw jack types for different construction needs. Adjustable swivel jacks work on sloped grounds, while U-head jacks secure wooden beams. Each design aims to improve stability and safety, crucial for accident prevention and following industry standards. Additionally, a translating screw jack is often used in construction to convert rotational motion into linear movement, enhancing the precision and control of scaffold adjustments.

Screw Jack Type | Size (ODmm) | Material | Load Capacity | Surface Finish |

|---|---|---|---|---|

Solid Screw Jack | 26, 28, 30, 32, 34, 36, 38, 48 | Cast Iron, Cast Steel | Medium to Heavy | Zinc-plated, Hot-dip Galvanized |

Hollow Screw Jack | 34, 38, 48 | Drop Forged | Light to Heavy | Painted |

Knowing about scaffold screw jack assembly and scaffold screw jack function helps pick the right type. This ensures safety and efficiency in building scaffolds.

How Does a Scaffold Screw Jack Work: Lead Screw Operation and Mechanism

Learning about scaffold screw jacks is key for safer and more efficient work sites. These tools are vital for adjusting and stabilizing scaffolding. They help construction teams work safely on different terrains.

A rotating screw jack operates by the rotation of the worm wheel, which leads to the rotation of the lead screw, enabling the sliding of the nut along the lead screw.

Working Principle of a Screw Jack

The working principle of a screw jack revolves around the conversion of rotary motion into linear motion through the use of a lead screw and a worm gear. The lead screw, a threaded rod, is connected to a worm gear, which is rotated by either a motor or a manual handle. As the worm gear turns, it drives the lead screw to move linearly, thereby lifting or lowering the load. This mechanism leverages the mechanical advantage provided by the gearbox, which amplifies the force applied to the lead screw. This amplification allows screw jacks to lift heavy loads with minimal effort, making them indispensable in applications requiring precise and controlled linear motion.

The Role of Base Plate in Scaffold Screw Jack Work

The base plate is the foundation of scaffold screw jacks. It spreads the load evenly and keeps things stable. This part is crucial for keeping the scaffold upright, even under heavy loads. A keyed screw jack is important in preventing the lead screw from rotating, especially in applications requiring multiple screw jacks that share a common load.

The base plates’ wide, flat surface helps them stay balanced. This improves the safety and stability of the scaffolding.

Adjusting for Stability: Screw Jack Mechanism

The screw jack’s mechanism allows for easy adjustments, even when it’s loaded. This is especially important on uneven surfaces. It ensures the scaffold stays balanced and safe.

The mechanism uses worm or bevel gears. This means small turns in the adjustment rod lead to big changes in height. It keeps the structure strong and stable. Single-start screws in these jacks are often self-locking, providing additional stability by preventing unintended movement.

This combination of mechanics and operation makes the scaffold secure and adjustable. It fits well with different construction needs and worker requirements. The design is efficient, using energy only when needed.

Regular inspections and the ability to adapt to various conditions are also key. This shows how important reliable mechanisms like the screw jack are for safety.

Discover the detailed mechanics of scaffold screw jacks in real-world settings. See how they play a crucial role in modern construction and maintenance.

Examining Scaffold Screw Jack Design and Innovative Features

The evolution of scaffold screw jack design is changing the construction and building industry. It makes projects safer and more efficient. The use of scaffold screw jack features and scaffold adjustable leveling jacks brings flexibility and durability.

The design for Cuplock scaffolding is a big step forward. It’s popular in the Middle East’s construction sector. It allows for quick assembly and strong structures.

The design also supports hot-dip galvanizing for better protection against corrosion. This is key for systems to last long in tough environments. The Cuplock Universal Jack can hold up to 74 kN, showing its strong load-bearing ability.

Ease of assembly: Quick setup and dismantling thanks to new connection nodes and design.

High adaptability: Works well with many scaffolds, including mobile ones, making it useful in various settings.

Improved Safety: It’s more stable and reliable thanks to careful design and testing.

Scaffolding systems, like collapsible bar systems, are tested for how they handle loads. These tests show the scaffolding can stay stable even under heavy loads. The use of strain gauges and National Instruments equipment shows the high standards followed in testing.

The design of scaffold screw jacks is not just about holding weight. It’s also about adding features that make scaffolding more mobile, versatile, and safe. The aim is to make construction more efficient and safer for workers.

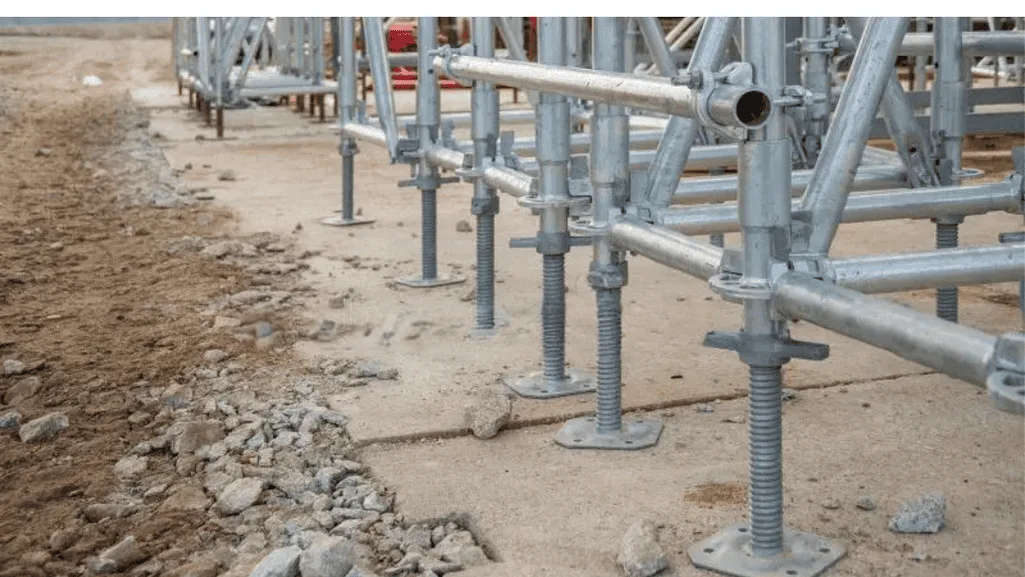

Practical Applications and Usage of Scaffold Screw Jacks

In construction and maintenance, scaffold screw jack usage is key for safe and level work. They are vital for both light and heavy tasks. These tools make work sustainable and adaptable.

A worm screw jack, also known as a screw jack, is widely used in various industries such as Steel Works Equipment, Pharmaceutical, and Aerospace for its reliability and ability to convert rotary motion into linear motion.

Levels and Terrain Adjustment with Scaffold Screw Jacks

Scaffold leveling with screw jacks is a big plus. They work well on both flat and uneven ground. This is because construction sites are rarely perfectly flat.

Screw jacks keep scaffolding horizontal, making work safer and more stable. They help with uneven ground at construction sites. This makes scaffolds stable, no matter the terrain. It also keeps workers safe and work efficient.

Maximizing Safety and Efficiency in Construction: Self Locking Mechanisms

The scaffold screw jack benefits go beyond just leveling. They are crucial for safety in construction. Using screw jacks well reduces accident risks. They also make work setups quicker and more secure. Ball screw jacks, with their low-friction design and efficiency in moving loads, further enhance safety and efficiency by offering a longer lifespan and reduced power requirements.

Using screw jacks improves safety in construction. The Scaffold Safety Program at Virginia Tech shows their importance. They are key to safe scaffolding, needing regular training for workers.

Capacity Type | Load (pounds per square foot) |

|---|---|

Light-Duty | 25 |

Medium-Duty | 50 |

Heavy-Duty | 75 |

Using scaffold screw jacks on construction sites is smart. They help with different terrains and loads efficiently. These tools meet safety standards and make work better by reducing setup times and hazards.

Construction and Material: Ensuring Scaffold Screw Jack Durability

In the construction world, safety and efficiency are key. Scaffold systems are crucial, and the scaffold screw jack is a vital part. Its strong build and material make it reliable and durable. Worm gears play a crucial role in translating the rotational motion of the worm screw into linear motion, which is essential for determining the lifting speed of the screw jack.

Materials Used in Scaffold Screw Jacks: Strength and Resistance

Structural steel, like Q235, is the main material for scaffold screw jacks. It’s strong and can handle heavy loads. This makes the scaffold screw jack reliable in tough construction settings. The material is also crucial in a translating keyed screw jack to prevent rotation, ensuring precise and consistent movement of the lead screw.

Steel’s strength means scaffold screw jacks can support thousands of pounds. This is important for worker safety and scaffold stability.

Galvanized Finishes for Longevity

A galvanized finish is added to steel components for extra protection. It fights off corrosion, which can harm metal structures. This finish makes scaffold screw jacks last longer and need less maintenance. Additionally, finishes are crucial in enhancing the durability of ball screws, which are significant in the motion industry.

Knowing about these features helps construction teams choose the right scaffolding. Durable scaffolds with strong screw jacks improve safety and work efficiency. For more on scaffolding, check out this scaffold overview.

Mechanical Advantage of Screw Jacks

Screw jacks offer a significant mechanical advantage over hydraulic systems, making them a cost-effective solution for high-load applications. The mechanical advantage of a screw jack is determined by the ratio of the lead screw’s thread pitch to the worm gear’s pitch. This ratio enables the amplification of the force applied to the lead screw, resulting in a higher load capacity. Additionally, screw jacks are energy-efficient, as they only require energy to lift or lower the load. In contrast, hydraulic systems waste energy by maintaining constant fluid pressure, regardless of the work being performed. This efficiency, combined with their ability to provide precise control and synchronization, makes screw jacks an ideal choice for various industrial applications.

Maintenance, Troubleshooting, and Scaffold Screw Jack Safety

Keeping scaffold structures safe and lasting requires regular maintenance and careful troubleshooting. It’s also key to follow strict safety rules for scaffold screw jacks. Scaffolding is complex, so it needs special care to work well and last long.

Proper maintenance is equally crucial for a machine screw jack to ensure its reliability in lifting, positioning, and aligning loads.

Importance of Regular Maintenance for Long-term Use

Keeping scaffold screw jacks in good shape is not just about the equipment. It’s also about keeping workers safe. Regular checks help find and fix problems before they cause harm. A good maintenance plan can make scaffolding last longer, up to 30% more with proper care.

Common Issues and Troubleshooting Techniques

Knowing how to fix common problems with scaffold screw jacks is crucial. Look for corrosion, make sure everything moves smoothly, and check the load capacity. This helps avoid failures and accidents. In fact, 78% of construction accidents are caused by equipment problems, showing how important checks are. Troubleshooting is essential to maintain the function of the lifting screw, ensuring the screw jack system operates efficiently.

Always clean scaffold equipment well after use, especially if it’s been exposed to paint or cement. These substances can damage metal and parts. Also, using WD-40 can help prevent rust and keep things working right.

Store the scaffold in a place that protects it from bad weather. Keep wooden parts dry to avoid warping and cover metal to stop rust and corrosion.

Maintenance Statistic | Impact on Safety and Projects |

|---|---|

Regular maintenance and proper inspection can prevent 92% of scaffolding accidents. | Decreased accident rates lead to fewer delays and lower costs in construction projects. |

65% of construction project delays are associated with scaffolding accidents. | Enhanced safety measures and diligent maintenance help in keeping project timelines on track. |

Compliance with safety regulations could lead to a 20% increase in worker productivity. | Greater efficiency and effectiveness in project execution. |

Choosing top-quality materials from trusted suppliers like AAIT Technocraft is important. It helps keep scaffold structures strong and offers expert advice on maintenance and safety.

Compliance with Standards: Scaffold Screw Jack Importance

Following scaffold screw jack standards is key to a safe construction site. The scaffold leveling tool and scaffold levelling equipment are crucial. They help prevent accidents and keep structures stable.

OSHA and other regulatory bodies set strict rules. These include using certified scaffold screw jacks. Not following these rules can lead to serious accidents.

Many accidents in construction are due to scaffolding issues.

Standards for scaffolding vary greatly between countries.

Ignoring these standards can cost construction firms a lot of money.

Only a few companies regularly check their scaffolds.

More training on using scaffolds safely is needed.

Standards ensure the quality of screw threads, which are essential for the performance and safety of screw jacks.

It’s clear that following scaffold screw jack standards is vital. It’s not just about following the law. It’s about keeping everyone safe and preventing accidents.

Using the right scaffold leveling tools helps reduce risks. It makes construction safer and more efficient. Regular checks and updates are essential for safety.

Using the best scaffold levelling equipment is crucial. Keeping up with standards and training staff is also important. It helps navigate the challenges of modern construction safely.

Conclusion

In construction, scaffold levelling jacks and tools are key. They are the backbone of scaffolding, providing stability and flexibility. These tools are essential for creating a solid base and adjusting scaffolding heights to fit any project. The screw jack system is also crucial in construction for achieving precise movement and stability in various applications.

There are different types of scaffold jacks, like Fixed Base Jacks for even surfaces and Adjustable Base Jacks for uneven ones. Swivel Base Jacks handle sloped areas. Choosing the right one is vital. Regular checks and following guidelines ensure they work safely and efficiently.

Scaffold jacks are crucial in every construction project. They support both the structure and the dreams behind it. By being mindful of weight limits and using high-quality jacks, we avoid risks. This ensures that the structures we build are safe and reliable.

FAQ

How does a scaffold screw jack work?

A scaffold screw jack gives scaffolding a stable base. It has a rod and nut for adjusting height. This makes the scaffold level on uneven ground, keeping workers and materials safe.

What are the components of a scaffold screw jack?

A scaffold screw jack has a base plate for even weight distribution. It also has a height-adjustable rod and a mechanism for locking the height. These parts make the scaffolding stable and level.

What are the different types of scaffold screw jacks?

There are solid-base jacks for stable ground, adjustable swivel jacks for sloped surfaces, and U-head jacks for wooden beams. Each type fits different scaffolding needs and ground conditions.

What role does the base plate serve in scaffold screw jack operation?

The base plate spreads the scaffolding’s weight evenly on the ground. This reduces pressure points and makes the scaffold stable. It prevents sinking or tilting on uneven surfaces.

How does adjusting for stability work with screw jack mechanisms?

Adjusting for stability involves turning the nut on the rod to change the height. This ensures the scaffold is perfectly horizontal. This adjustability is key for a safe working environment, even on uneven terrain.

What innovative features do scaffold screw jacks have?

Scaffold screw jacks have easy-adjust mechanisms for quick height changes. They work with various scaffolding systems and may have wheels for moving. Their sturdy build is for safety and long-term use on construction sites.

How do scaffold screw jacks maximize safety and efficiency in construction?

Scaffold screw jacks provide a level base for scaffolding, which is crucial for worker safety. They allow for fine adjustments to ensure the scaffolding is stable and horizontal. This secure platform boosts efficiency, as workers can move and work confidently.

What materials are used in scaffold screw jacks?

Scaffold screw jacks are made from structural steel. This material is strong and resistant to the heavy loads and dynamic forces of scaffolding. It ensures the jacks are durable and reliable for scaffold construction.

Why are galvanized finishes important for scaffold screw jacks?

Galvanized finishes protect the steel from corrosion and environmental damage. This keeps the jacks strong and safe over time, even in harsh environments.

What maintenance is required for scaffold screw jacks?

Maintenance includes regular inspections for damage, wear, or corrosion. Clean and lubricate the threads, and check that all parts work well. This maintenance ensures safe use and extends the jacks’ life.

What are some common issues and troubleshooting techniques for scaffold screw jacks?

Common problems include jammed or stiff mechanisms, bent rods, or damaged base plates. Troubleshooting involves cleaning the threads, fixing or replacing damaged parts, and checking the load capacity. Always follow manufacturer guidelines for safe use.

How do scaffold screw jacks comply with construction safety standards?

Scaffold screw jacks meet construction safety standards, like OSHA guidelines. They provide a level and stable base for scaffolding. This is key to preventing accidents and ensuring a safe work environment on construction sites.