Phone:

(+65)8319-0742

A high-visibility vest, also known as a neon vest or ANSI Class 2 vest, is a crucial component of safety gear for workers in hazardous environments. These vests are designed with bright, reflective materials that make them easily visible, especially in low-light conditions. They play a vital role in preventing accidents and ensuring worker safety. In this comprehensive guide, we will explore everything you need to know about high-visibility vests, including their types, classifications, standards, and factors to consider when selecting the right vest for your workers.

Key Takeaways:

- High-visibility vests are essential safety gear for workers in hazardous environments.

- They are designed with bright, reflective materials that enhance visibility.

- High-visibility vests reduce the risk of accidents and injuries in low-light conditions.

- When selecting a vest, consider factors such as color, classification, and fabric.

- Compliance with ANSI standards is crucial for ensuring worker safety.

What Is a High-Vis Safety Vest?

A high-visibility safety vest, also known as a high-vis vest, is a type of bright, reflective clothing that is worn by workers in hazardous areas. These vests are designed to make workers easily visible and enhance their safety. They typically cover the torso, chest, and shoulders, leaving the arms uncovered. The reflective material on the vest allows workers to be seen by drivers or other individuals in low-light situations, such as during the night or in low visibility conditions.

Visibility is paramount in potentially dangerous work environments. High-visibility vests, with their bright colors and reflective materials, provide a crucial layer of safety for workers. These vests are specially designed to stand out in various lighting conditions, ensuring that workers can be seen by others around them. By wearing high-vis vests, workers can minimize the risk of accidents and collisions, as they are easily identifiable.

High-visibility vests are made from durable materials that can withstand the rigors of the work environment. They are often constructed with fluorescent fabrics in bright colors, such as yellow or orange, that are highly visible even in dim light. These vests also feature reflective strips or panels that reflect light back to its source, increasing visibility from all angles.

Besides enhancing visibility, high-vis vests are also designed with practicality in mind. They typically feature convenient pockets for storing small tools or personal items, adjustable straps for a secure fit, and breathable materials for comfort during prolonged wear. Some vests may also include additional features like radio loops, badge holders, or ID panels for easy identification.

High-visibility vests are commonly worn by construction workers, road workers, emergency responders, warehouse staff, and utility workers. In these high-risk environments, the use of high-vis vests is not only a matter of compliance with safety regulations, but also a proactive step in preventing accidents and protecting workers.

Why Is a High-Vis Safety Vest Necessary?

A high-visibility safety vest, also referred to as an ANSI safety vest, is a necessary and mandated piece of protective equipment for workers in various industries. These vests serve a critical role in ensuring worker visibility in low-visibility situations, thereby helping to prevent accidents and injuries on the job. They are particularly vital for workers who need to divert their attention from traffic or work in areas with limited visibility.

By wearing high-visibility vests, workers can easily be identified and accounted for, reducing the risk of accidents and improving overall safety. The bright colors and reflective materials of these vests make workers easily visible, even in challenging lighting conditions or environments with poor visibility. This enhanced visibility plays a fundamental role in accident prevention and maintaining worker well-being.

Benefits of High-Visibility Vests:

- Increased worker visibility, especially in low-light or low-visibility situations

- Enhanced safety by reducing the risk of accidents and injuries

- Easy identification and accountability of workers

- Compliance with safety regulations and standards

- Improved worker confidence and peace of mind

Industries That Require High-Visibility Vests:

High-visibility vests are essential in various industries where worker safety is a top priority. Some of the industries that require the use of high-vis safety vests include:

- Construction and roadwork

- Transportation and logistics

- Emergency services and law enforcement

- Airport and airline operations

- Railway and public transport

- Warehousing and manufacturing

These industries often involve working in environments where the risk of accidents or collisions is higher. By wearing high-visibility vests, workers become more visible to their colleagues, equipment operators, and any individuals who may be in their vicinity. This increased visibility allows for better communication, coordination, and accident prevention.

| Industry | Percentage of workers at risk |

|---|---|

| Construction | 65% |

| Transportation | 43% |

| Emergency services | 82% |

| Warehouse | 58% |

| Manufacturing | 37% |

Considerations When Choosing a High-Visibility Vest

When selecting a high-visibility vest for your workers, it’s essential to take several important factors into consideration to ensure optimal safety and visibility. By paying attention to these considerations, you can choose a vest that meets the specific requirements of your work environment and provides maximum protection for your workers.

Color

The color of the high-visibility vest is an important consideration as it can impact visibility in different work environments. Bright colors such as neon yellow, orange, and lime green are often preferred as they are highly visible, especially in low-light conditions. Consider the color that contrasts well with the surroundings to ensure maximum visibility and safety.

Classification

High-visibility vests are classified based on their visibility and reflective properties. Ensure that the vest you choose meets the appropriate classification standards, such as ANSI Class 2 or ANSI Class 3, which provide different levels of visibility and reflectivity. The classification will depend on the specific work environment and the level of risk involved.

Fabric

The fabric of the high-visibility vest can affect comfort and durability. Look for vests made from lightweight and breathable materials that allow for ease of movement and ventilation. Additionally, consider the durability of the fabric to ensure that the vest can withstand the demands of the work environment and provide long-lasting performance.

Season

Consider the season in which the high-visibility vest will be worn. Different weather conditions and temperature extremes may require vests with specific features or materials. For example, vests with moisture-wicking properties may be suitable for hot weather, while vests with additional insulation may be necessary for cold weather conditions.

Features and Design

Think about any specific features or design preferences that are important for your workers. This could include features like pockets for storing tools or equipment, adjustable straps for a custom fit, or additional reflective tape for increased visibility. Consider the specific needs of your workers and select a vest that offers the desired features and design elements.

Fit

Ensuring that the high-visibility vest fits properly is crucial for both comfort and visibility. Look for vests with adjustable straps or closures that allow for a secure and customized fit. Proper fit ensures that the vest does not obstruct movement and provides maximum visibility to other workers and individuals in the vicinity.

By considering these factors when choosing a high-visibility vest, you can provide your workers with the best possible protection and visibility in hazardous work environments. Keep in mind the color, classification, fabric, season, features, design, and fit to select a vest that meets the specific needs and requirements of your workforce.

Standards and Classifications of High-Visibility Vests

High-visibility vests are essential safety garments that adhere to the standards set by the ANSI/ISEA 107-2015 Standard. This standard provides guidelines for the design and performance of high-visibility vests, ensuring maximum visibility and safety for workers in hazardous environments.

High-visibility vests are classified into three performance classes: Class 1, Class 2, and Class 3. Each class offers varying levels of visibility and reflective materials, catering to different work environments and activities.

Performance Classes

Class 1 vests provide the lowest level of visibility and are suitable for workers who operate in low-risk environments. These vests typically have a minimum of 155 square inches of background material and 6.46 linear feet of reflective material, ensuring a basic level of visibility.

Class 2 vests offer intermediate visibility and are ideal for workers in high-risk environments, such as construction sites and roadways. These vests have a minimum of 775 square inches of background material and 201 square inches of reflective material, ensuring enhanced visibility.

Class 3 vests provide the highest level of visibility and are recommended for workers who require maximum visibility, such as emergency responders and highway construction workers. These vests have a minimum of 1240 square inches of background material and 310 square inches of reflective material, offering superior visibility in all conditions.

Type O, Type R, Type P

In addition to performance classes, high-visibility vests are further categorized into different types based on the specific work environment and activities.

- Type O (Off-Road) vests are designed for workers who primarily operate off-road, such as parking lot attendants. These vests provide basic visibility and are not suitable for use in roadway environments.

- Type R (Roadway) vests are intended for workers who are exposed to traffic on roadways. These vests offer enhanced visibility and meet the standards for both daytime and nighttime use.

- Type P (Public Safety) vests are specifically designed for public safety personnel, such as police officers and firefighters. These vests provide maximum visibility and meet the highest standards for safety.

While high-visibility vests meeting ANSI/ISEA standards are highly recommended, there are also non-ANSI safety vests available in the market. Although these vests do not meet the ANSI standards, they still offer a basic level of visibility and can be suitable for workers in low-risk environments.

By understanding the standards and classifications of high-visibility vests, employers can select the appropriate vest for their workers, ensuring maximum visibility and safety in hazardous work environments.

Conclusion

High-visibility vests play a vital role in ensuring worker safety and preventing accidents in hazardous environments. These vests feature bright colors and reflective materials that make workers easily visible, reducing the risk of injuries and incidents. When selecting the right high-visibility vest for your workers, it is important to consider various factors such as color, classification, fabric, season, features, design, fit, and compliance with ANSI/ISEA standards.

By carefully considering these factors and providing workers with the appropriate high-visibility vests, you can prioritize their safety and create a safer work environment. The right vest not only enhances visibility but also ensures comfort and durability, allowing workers to perform their tasks effectively and confidently. Remember, accident prevention starts with selecting the right high-visibility vest that suits the specific needs of your work environment.

Investing in worker safety through the selection of high-quality high-visibility vests demonstrates a commitment to accident prevention and creating a culture of safety. By prioritizing worker safety and providing the necessary safety gear, you can foster a positive work environment that values the well-being of your employees. Protect your workers and minimize the risk of accidents by selecting the right high-visibility vest for their needs.

FAQ

What is a high-visibility vest?

A high-visibility vest, also known as a neon vest or ANSI Class 2 vest, is a type of reflective safety gear designed to make workers easily visible in hazardous environments, especially in low-light conditions.

Why is a high-visibility vest necessary?

High-visibility vests are necessary to enhance worker visibility and prevent accidents in low-visibility situations. They are particularly important for workers who need to divert their attention from traffic to perform their work, ensuring their safety.

What should I consider when choosing a high-visibility vest?

When selecting a high-visibility vest, consider factors such as the color, classification, fabric, season, features, design, fit, and compliance with ANSI/ISEA standards. These factors can impact the suitability, comfort, and durability of the vest for your workers.

How are high-visibility vests classified?

High-visibility vests are classified based on the ANSI/ISEA 107-2015 Standard. They are rated and approved according to different performance classes (Class 1, Class 2, and Class 3) and are also categorized into different types (Type O, Type R, Type P) based on the intended work environment.

Are non-ANSI safety vests still effective?

Non-ANSI safety vests, although not meeting the ANSI standards, still offer a basic level of visibility for workers in low-risk environments. However, it is recommended to use ANSI-approved vests for enhanced visibility and worker protection in hazardous environments.

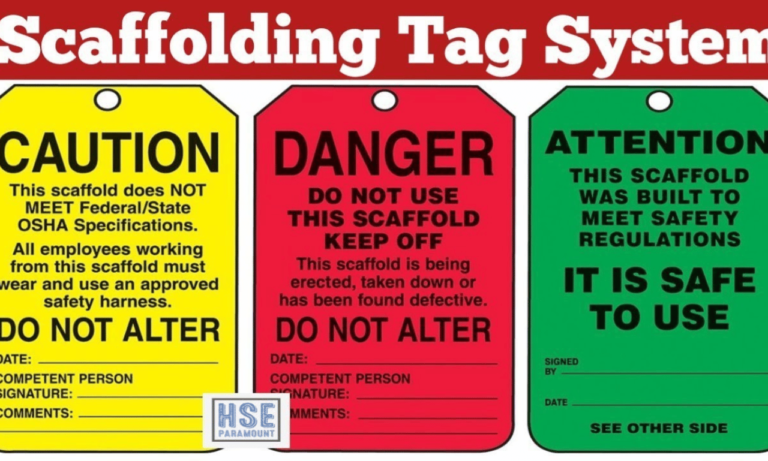

Scaffold Tagging System: Ensure Site Safety

In the construction industry, safety is paramount. With scaffolding being a common feature at job sites,…

Scaffold Tie Tool – Enhance Job Site Safety

Safety is of utmost importance when working at heights, especially in construction sites where scaffolding…

Best Chalk Line Tools for Straight, Precise Lines

Chalk lines are indispensable tools for achieving straight and precise lines in construction projects….

Best Tube Cutter for Scaffolding | Top Picks

When working with scaffolding, having a reliable and efficient tube cutter is essential. We have compiled…

Precise Plumb Bob Guide for Accurate Leveling

A plumb bob is an essential tool for accurate vertical alignment. It is used to determine if a surface…

No posts found