Phone:

(+65)8319-0742

When it comes to work safety gear, one item stands out as a crucial piece of protection: the hard hat. Also known as a safety helmet or construction hard hat, this headgear plays a vital role in safeguarding workers in hazardous environments. If you work in the construction industry, it’s important to understand the essential tips for using a hard hat correctly and keeping yourself safe on the job.

Key Takeaways:

- Always wear a hard hat on a construction site to protect your head from potential hazards.

- Choose the right size of hard hat to ensure a comfortable and secure fit.

- Keep your hard hat in good condition by regularly inspecting it for signs of wear or damage.

- Ensure your hard hat is ANSI compliant, meeting the necessary safety standards.

- Avoid modifying your hard hat or attaching items to it, as this can compromise its effectiveness.

By following these essential hard hat safety tips, you can minimize the risk of head injuries and work confidently knowing you have reliable protection. Let’s explore each tip in more detail to ensure you have a thorough understanding of how to use your hard hat effectively.

The Importance of Hard Hats in the Construction Industry.

Construction sites are well-known for their inherent dangers, making safety equipment an absolute necessity. Among the vital pieces of safety gear in the construction industry, hard hats play a crucial role in protecting workers from various hazards. They are not only a visible symbol of safety but also provide essential head protection, mitigating the severity of injuries in unforeseen accidents.

With the construction industry being one of the most hazardous sectors, it is imperative to prioritize worker safety. According to statistics, thousands of injuries and fatalities occur in this industry each year. Falling debris, equipment malfunctions, and other unforeseen circumstances pose significant risks to workers on construction sites. Hard hats act as the first line of defense, safeguarding workers from potential head injuries caused by falling objects, debris, or other hazards present in the work environment.

Aside from being a physical barrier, hard hats serve as a visible symbol of safety on construction sites. By wearing hard hats, workers demonstrate their commitment to workplace safety and their roles as responsible professionals. Additionally, the sight of workers donning hard hats acts as a reminder to others in the vicinity to prioritize safety measures, creating a culture of compliance with safety protocols.

Head injuries are among the most severe and debilitating accidents that can occur on construction sites. By wearing hard hats, workers significantly reduce the risk of sustaining such injuries. Hard hats are designed to absorb and distribute the impact of a blow, protecting the skull and brain from damage. Even a minor incident, such as a small tool falling from a height, can have dire consequences without the appropriate protective gear.

To emphasize the significance of hard hats, consider the facts: numerous injuries and fatalities that occur in the construction industry could potentially have been prevented with the proper use of safety equipment. By ensuring that every worker wears a hard hat on the job site, employers demonstrate their commitment to worker safety.

The importance of hard hats cannot be overstated when it comes to the well-being of construction workers. They serve as a visible reminder of the hazards present in the construction industry and act as a proven protective measure against injuries and fatalities. By investing in hard hats and promoting their correct usage, the construction industry can provide a safe working environment that protects its most valuable assetâits workforce.

Choosing the Right Hard Hat for Maximum Protection.

When it comes to hard hat safety, selecting the correct size is paramount. A hard hat that fits snugly ensures optimal protection and comfort, minimizing the risk of head injuries. It’s vital to measure your head size accurately and choose a hard hat that offers a snug fit.

Hard hats are available in various sizes, and adjusting the suspension system is crucial to achieving the right fit. This suspension system helps customize the fit according to your head size and shape, providing a secure and comfortable experience throughout the workday.

Adequate protection is the primary goal of wearing a hard hat. If the hard hat is too large, it may slide around during movement, compromising its ability to protect you properly. On the other hand, a hard hat that is too small can cause discomfort, distracting you from your tasks and compromising overall safety.

The fit of your hard hat is critical in providing protection against impact, penetration, and electrical hazards. A properly adjusted hard hat ensures that the force from any impact is distributed evenly, reducing the risk of head injuries. It should sit securely on your head without wobbling or feeling too tight.

Additionally, a comfortable hard hat will encourage workers to wear it consistently, ensuring ongoing protection. Discomfort or constant readjustment creates potential distractions, making it more likely for workers to remove their hard hats, increasing the risk of head injuries.

Key Considerations for Choosing the Right Hard Hat:

- Measure your head size accurately to determine the right hard hat size.

- Adjust the suspension system to achieve a snug and comfortable fit.

- Ensure the hard hat provides adequate protection against impact, penetration, and electrical hazards.

- Choose a hard hat that offers both protection and comfort for extended periods of wear.

Choosing the right hard hat size is crucial for ensuring maximum protection, comfortable wear, and minimizing the risk of head injuries. A well-fitted hard hat with an appropriate suspension system provides the necessary level of protection while allowing for a comfortable and secure fit throughout your workday.

Maintaining Your Hard Hat for Optimal Safety.

Ensuring the optimal safety of your hard hat requires regular maintenance and inspection. By keeping your hard hat in good condition, you can trust that it will provide adequate protection in hazardous environments. Here are some essential practices to maintain your hard hat:

Inspect for Signs of Wear or Damage

Regularly examine your hard hat for any signs of wear or damage. Look for cracks, dents, or deformations that may compromise its protective capabilities. Any hard hat showing signs of damage should be replaced immediately to maintain optimal safety standards.

Choose Durable Materials

Hard hats are constructed using durable materials that can withstand various conditions. However, they are not invincible and can be damaged over time. Exposure to sunlight, heat, chemicals, and impact can all contribute to the deterioration of your hard hat. It is important to be mindful of these factors and ensure you take appropriate precautions to protect your hard hat from unnecessary damage.

Understand the Lifespan of Your Hard Hat

Hard hats have a lifespan ranging from 2 to 5 years, depending on the manufacturer. Regardless of their appearance, hard hats should be retired after this time to maintain optimal safety. Even if they appear to be in good condition, the materials may have degraded, reducing their effectiveness in protecting against potential hazards.

Proper Storage

Storing your hard hat correctly is crucial for maintaining its longevity and effectiveness. When not in use, keep your hard hat in a clean, dry place away from direct sunlight or excessive heat. This helps to prevent unnecessary degradation of the materials and ensures the hard hat remains in prime condition when you need it.

Replace When Necessary

It cannot be stressed enough â if you notice any signs of wear or damage on your hard hat, replace it immediately. Do not compromise your safety by attempting to extend the lifespan of a damaged hard hat. Investing in a new one will provide you with the assurance that you are adequately protected on the job.

By following these maintenance practices, you can ensure that your hard hat remains in optimal condition, providing you with the highest level of safety and protection.

ANSI Compliance for Hard Hat Safety.

When it comes to ensuring the necessary level of protection, hard hats should meet ANSI standards. The American National Standards Institute (ANSI) plays a crucial role in setting manufacturing standards for hard hats. These standards include requirements for impact resistance, penetration resistance, electrical insulation, and various performance criteria. Hard hats that are ANSI compliant have undergone rigorous testing and certification by independent laboratories to ensure they meet the minimum safety requirements.

By adhering to ANSI compliance, workers can have peace of mind knowing that their hard hats have been tested and certified to provide optimum protection against potential head injuries. ANSI standards are designed to address the specific hazards workers may face in their respective industries, ensuring that hard hats can withstand impact, resist penetration, and offer reliable electrical insulation.

To identify an ANSI-compliant hard hat, look for the ANSI label on the product. This label signifies that the hard hat has met the stringent requirements set forth by ANSI, making the hard hat a reliable choice for workers in hazardous environments.

ANSI Compliance Performance Criteria

The ANSI compliance performance criteria for hard hats prioritize protection and safety in various work situations. Here are some key performance criteria:

- Impact Resistance: Hard hats must be able to withstand significant impacts, preventing or minimizing head injuries in the event of falling objects or accidental collisions.

- Penetration Resistance: Hard hats must protect against sharp objects, such as nails or tools, from penetrating through the shell and impacting the head.

- Electrical Insulation: Hard hats should provide sufficient insulation against electrical hazards, safeguarding the wearer from electric shock and potential electrocution.

By adhering to these performance criteria, ANSI-compliant hard hats offer comprehensive protection on the job site. It is important for workers and employers to understand the significance of ANSI compliance and prioritize the use of properly certified hard hats in order to mitigate potential risks and enhance overall safety.

The image above highlights the importance of ANSI-compliant hard hats in the construction industry, where workers are exposed to various hazards on a daily basis.

| ANSI Compliance Benefits | Non-ANSI Compliant Risks |

|---|---|

| – Optimal protection against impact, penetration, and electrical hazards. | – Inadequate protection that may result in severe head injuries. |

| – Confidence in the hard hat’s reliability and adherence to safety standards. | – Lack of assurance about the hard hat’s performance in critical situations. |

| – Compliance with industry regulations and safety guidelines. | – Potential violation of safety regulations and increased liability. |

| – Enhanced workplace safety culture and employee well-being. | – Compromised workplace safety and increased risk of accidents. |

Best Practices for Hard Hat Safety.

When it comes to hard hat safety, following best practices is crucial to ensure optimal protection and minimize the risk of accidents. By implementing these guidelines, you can enhance your safety on the job.

Never Modify Your Hard Hat

Modifying your hard hat by drilling holes or attaching items to it is not recommended. These alterations can compromise the hat’s performance and create new hazards. It is essential to use a hard hat that is in its original condition and has not been modified in any way to ensure maximum safety.

Choose the Appropriate Type of Hard Hat

Consider the specific hazards you may encounter on the job when selecting a hard hat. For instance, if there is a risk of electrical shock, use an electrically insulated hard hat. Likewise, if you are working in an area with bright sunlight, opt for a hat with a wide brim or a built-in sun shield. The right type of hard hat will provide the necessary protection for your specific work environment.

Proper Storage is Key

When not in use, store your hard hat in a clean, dry place away from direct sunlight and heat sources. Exposure to extreme temperatures or sunlight can deteriorate the hat’s materials and compromise its effectiveness. Find a dedicated storage area where your hard hat can be kept safely, ensuring it remains in good condition for maximum safety.

Wear Your Hard Hat in the Correct Position

One of the most basic yet crucial aspects of hard hat safety is wearing it in the correct position. Ensure that the brim of the hard hat is facing forward, offering optimal protection to your head, face, and neck. Wearing the hat in any other position may reduce its effectiveness and leave you vulnerable to potential hazards.

By adhering to these best practices, you can promote a culture of safety and protect yourself from common risks associated with construction sites and other hazardous work environments.

| Best Practices for Hard Hat Safety | Benefits |

|---|---|

| Never modify your hard hat | Preserves hat’s performance |

| Choose the appropriate type of hard hat | Ensures maximum protection |

| Properly store your hard hat | Preserves hat’s materials and lifespan |

| Wear your hard hat in the correct position | Optimal protection for head, face, and neck |

Conclusion.

Hard hats are an indispensable element of worker safety in the construction industry. By adhering to best practices and following essential guidelines, such as wearing a hard hat at all times on a construction site, workers can significantly reduce the risk of head injuries and ensure compliance with OSHA standards. Choosing the right size and maintaining the hard hat in good condition are crucial factors in achieving maximum protection. Additionally, ensuring ANSI compliance and avoiding modifications to the hard hat further enhance its effectiveness.

Worker safety should always be a top priority in the construction industry. Hard hats provide vital protection against potential injuries and even fatalities from falling debris or other hazards. It is vital for employers and workers alike to prioritize the use of hard hats and implement proper safety protocols. Regular inspections, proper storage, and wearing the hard hat in the correct position are essential practices that contribute to a safe working environment.

Compliance with OSHA standards is not only a legal requirement but also a crucial step towards protecting worker well-being. By following best practices for hard hat safety and ensuring adherence to OSHA standards, construction companies and workers can work together to create a safer working environment. By incorporating these practices into their daily routines, workers can continue to perform their jobs confidently, knowing that they are taking the necessary precautions to protect their heads and prevent injuries.

FAQ

Should I always wear a hard hat on a construction site?

Yes, wearing a hard hat is essential on a construction site to protect your head from falling debris and other hazards.

How do I choose the right size hard hat?

To choose the right size hard hat, measure your head size and adjust the suspension system accordingly to ensure a snug and comfortable fit.

How do I keep my hard hat in good condition?

Regularly inspect your hard hat for signs of wear or damage, such as cracks, dents, or deformation. If any signs of damage are present, the hard hat should be replaced immediately.

What does ANSI compliance mean for hard hats?

ANSI compliance means that a hard hat meets the safety standards set by the American National Standards Institute, ensuring it provides the necessary level of protection.

Can I modify my hard hat?

No, it is not recommended to modify your hard hat by drilling holes or attaching items to it, as this can compromise its performance and create new hazards.

How do I store my hard hat?

Store your hard hat in a clean, dry place away from heat or direct sunlight when not in use to maintain its condition and effectiveness.

What is the correct position to wear a hard hat?

Always wear your hard hat with the brim facing forward for optimal protection.

Best Safety Glasses for Ultimate Eye Protection

When it comes to protecting your eyes, having the best safety glasses is crucial. Whether you work in…

Safety Essentials: High-Visibility Vest Guide

A high-visibility vest, also known as a neon vest or ANSI Class 2 vest, is a crucial component of safety…

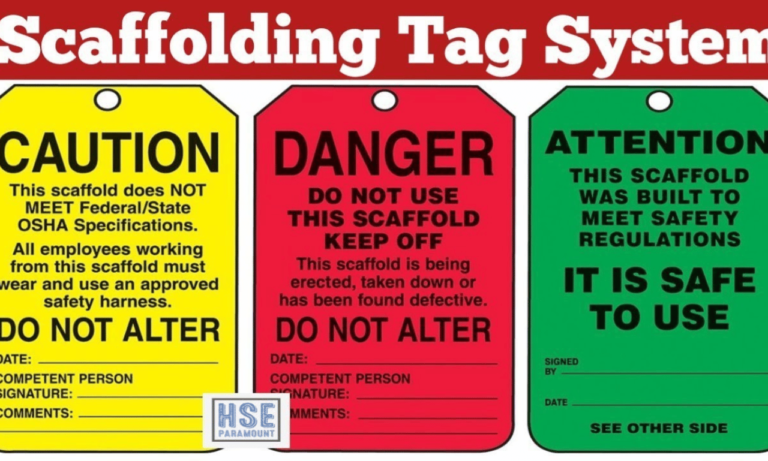

Scaffold Tagging System: Ensure Site Safety

In the construction industry, safety is paramount. With scaffolding being a common feature at job sites,…

Scaffold Tie Tool – Enhance Job Site Safety

Safety is of utmost importance when working at heights, especially in construction sites where scaffolding…

Best Chalk Line Tools for Straight, Precise Lines

Chalk lines are indispensable tools for achieving straight and precise lines in construction projects….

No posts found