Phone:

(+65)8319-0742

When working with freestanding scaffolding on construction sites, safety should always be the top priority. Adhering to scaffold safety regulations and guidelines is crucial to prevent accidents and create a secure working environment. In this article, we will discuss important safety tips to keep in mind when using freestanding scaffolding.

Key Takeaways:

- Adhering to scaffold safety regulations is essential for preventing accidents.

- Proper training and regular inspections minimize risks in scaffolding work.

- Understanding the different types of scaffolds and their associated hazards is crucial.

- Implementing best practices like thorough inspections and using appropriate PPE enhances safety.

- Training and tagging are essential components of a comprehensive scaffolding safety program.

Importance of Scaffolding Safety

Scaffolding safety is a critical aspect of the construction industry. With construction scaffolding being extensively used by industrial workers, it is essential to address the potential hazards and risks associated with this type of work. Adhering to scaffold safety regulations, providing adequate training, and conducting regular inspections are key measures that can significantly minimize accidents and foster a culture of safety on construction sites.

The use of construction scaffolding is prevalent in various industrial settings, including commercial construction, infrastructure development, and maintenance projects. Contractors and workers must prioritize safety to protect the well-being of those involved in construction activities. By implementing scaffold safety measures, potential accidents and injuries can be mitigated, ensuring a secure working environment for all.

Compliance with scaffold safety regulations plays a vital role in promoting best practices and preventing accidents. These regulations are designed to establish guidelines for the proper erection, maintenance, and dismantling of scaffolding structures. They outline specific requirements related to scaffold design, load capacity, and fall protection measures, among others. By adhering to these regulations, construction companies can proactively eliminate or minimize safety risks associated with scaffolding work.

Safeguarding Workers Through Proper Training

One of the crucial elements in ensuring scaffold safety is providing comprehensive training to workers. Proper training equips workers with the necessary skills and knowledge to safely assemble, use, and disassemble scaffolding structures. It enables them to understand and adhere to safety protocols, identify potential hazards, and employ effective preventive measures.

Industrial scaffolding training programs should cover various aspects, including scaffold components, erection and dismantling procedures, fall protection systems, and emergency response protocols. Workers should be educated on how to properly inspect scaffolds before each use and identify any signs of damage or instability. Training should also encompass recognizing common hazards, such as uneven ground, electrical lines, and inclement weather, and teach workers how to mitigate these risks.

Furthermore, regular refresher courses and toolbox talks can reinforce safe scaffolding practices and keep workers updated on the latest safety regulations and best practices. By investing in proper training, construction companies can instill a safety mindset among workers and significantly reduce the likelihood of accidents and injuries.

Regular Inspections for Scaffolding Safety

Regular inspections are critical to maintaining scaffold safety. Before deploying scaffolding, a thorough inspection should be conducted by a qualified person to ensure its stability and adherence to safety standards. This includes examining the structural integrity, securing systems, and ensuring adequate access points and guardrails are in place.

During the ongoing use of scaffolding, daily inspections must be undertaken by competent individuals to identify any potential issues or hazards. These inspections should encompass inspecting the scaffold platform, protective systems, anchor points, and connections to adjacent structures. Any deficiencies or damage should be promptly addressed to prevent accidents or scaffold failure.

An effective way to communicate the safety status of scaffolds is through tagging systems. This involves using colored tags to indicate the safety condition of each scaffold. Green tags signify that the scaffold is safe for use, while red tags indicate that the scaffold is not safe and should not be accessed until repairs or modifications are completed. Implementing tagging systems helps to minimize confusion and ensure that workers are aware of the safety status of the scaffolds they are working on.

| Importance of Scaffolding Safety | |

|---|---|

|

Types of Scaffolds and Common Hazards

Scaffolding is an integral part of construction projects, providing a safe and stable platform for workers to perform their tasks at elevated heights. Understanding the different types of scaffolds and their associated hazards is essential to ensure the safety of everyone involved.

Supported Scaffolding

Supported scaffolding is the most common type of scaffolding system used in construction. It consists of vertical posts, horizontal ledgers, diagonal braces, and a platform. This system is typically made of durable materials such as steel or aluminum.

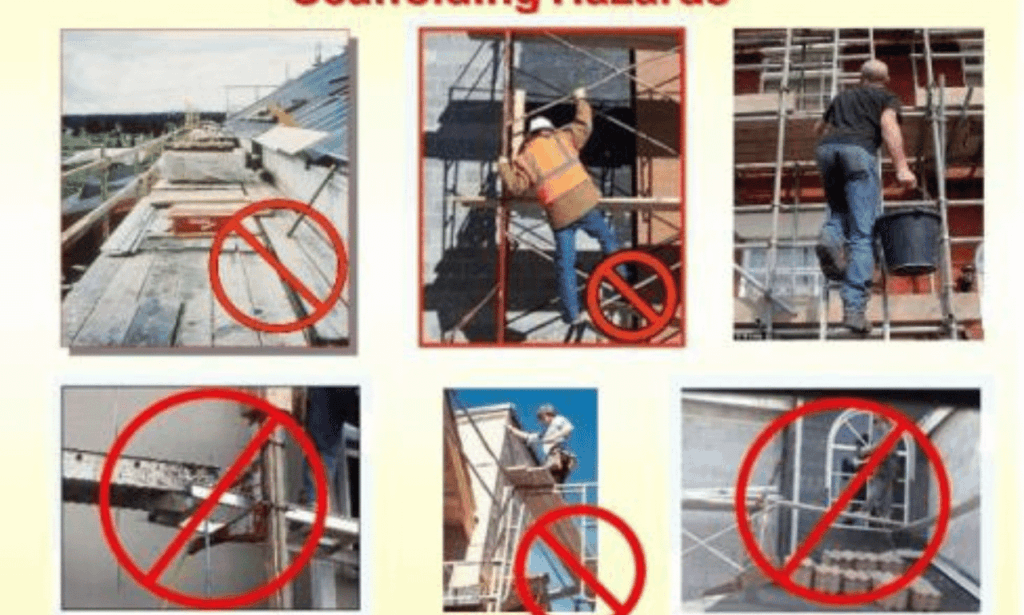

Common Hazards:

- Falls from heights due to improper installation or inadequate fall protection measures

- Debris falling from the platform, endangering workers below

- Scaffold collapse due to overloading or unstable footings

Suspended Scaffolding

Suspended scaffolding is commonly used for exterior building maintenance, painting, or window cleaning. It involves hanging platforms that are suspended by ropes or cables from an overhead structure.

Common Hazards:

- Falls from heights if workers are not properly secured or if cables/ropes malfunction

- Swinging of the platform due to wind or improper installation

- Inadequate inspection and maintenance of suspension equipment

Mobile Scaffolding

Mobile scaffolding, also known as rolling scaffolding, is designed with built-in wheels for easy mobility. It is commonly used in construction sites where frequent movement is required.

Common Hazards:

- Tip-overs or falls caused by uneven ground or improper locking of wheels

- Instability due to excessive height or overloading

- Lack of proper training on the safe use and setup of mobile scaffolds

It is crucial to address these hazards and take appropriate preventive measures to ensure the safety of workers on scaffolds. Regular inspections, proper training, and strict adherence to safety regulations are vital to minimize the risks associated with different types of scaffolding systems and create a secure working environment.

Scaffolding Safety Tips and Best Practices

Implementing specific safety tips and best practices can greatly enhance the safety of scaffolding operations. By prioritizing safety, construction companies can protect their workers and create a secure working environment. Below are some essential tips and practices to follow when working with scaffolding:

Thorough Inspections

Before each use, it is crucial to conduct thorough inspections of the scaffolding. Check for any damages, loose connections, or missing components. Ensure that all guardrails, toe boards, and safety nets are properly installed and secure. Regular inspections help identify potential hazards and minimize risks.

Proper Training

All workers involved in scaffolding operations should receive proper training. This includes training on scaffold assembly, use, dismantling, and safety procedures. Adequate training ensures that workers are familiar with scaffold safety regulations and aware of potential risks and hazards.

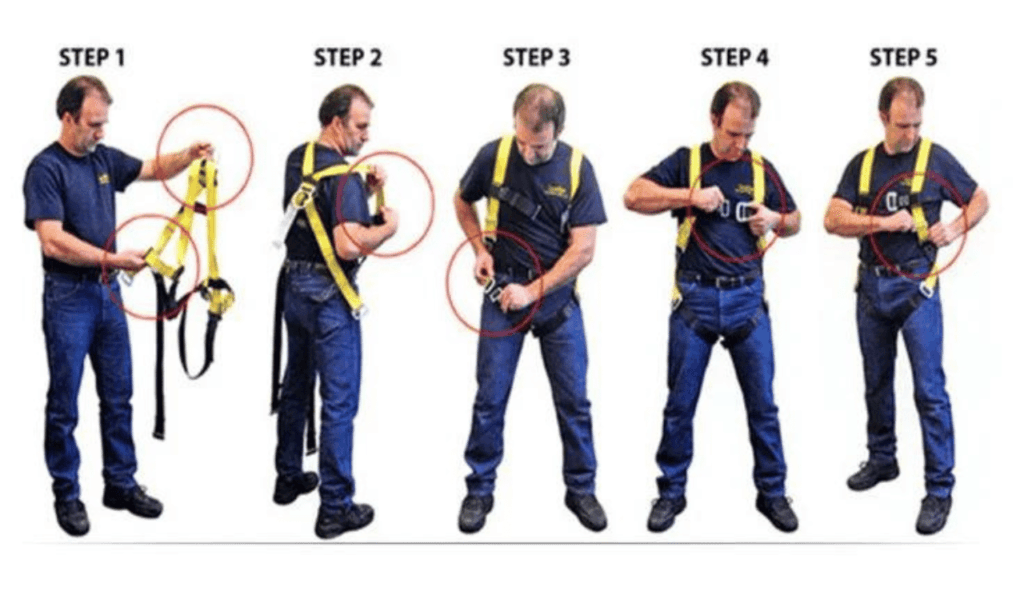

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment (PPE) is essential when working on scaffolds. This includes hard hats, high-visibility vests, safety harnesses, and non-slip footwear. PPE provides an additional layer of protection and minimizes the risk of accidents and injuries.

Understanding Load Capacity Limits

It is crucial to understand the load capacity limits of the scaffolding system. Avoid overloading the platform with excessive weight, materials, or equipment. Exceeding the load capacity can compromise the stability and integrity of the scaffold, leading to accidents or collapse.

Securing the Scaffold Platform

Ensure that the scaffold platform, including planks and guardrails, is properly secured. Secure the planks to prevent displacement or movement. Guardrails should be in place at all times to provide fall protection. Additionally, secure the scaffold to a stable structure or use appropriate bracing and tiebacks to prevent tipping or swaying.

Regular Maintenance and Inspections

Maintain a regular maintenance schedule for the scaffolding system. Inspect all components, including locking mechanisms, pins, and connections, for wear and tear. Any damaged or faulty parts should be repaired or replaced immediately. Regular maintenance and inspections help ensure the ongoing safety and integrity of the scaffold.

By following these safety tips and best practices, construction companies can reduce the risk of accidents and create a safe working environment for their employees. Strict adherence to scaffold safety regulations, proper training, thorough inspections, and regular maintenance are key to ensuring the safety of scaffolding operations.

Scaffolding Safety Training and Tagging

Proper training and tagging are critical aspects of ensuring scaffolding safety on construction sites. Workers must receive comprehensive training on scaffold assembly, use, and safety protocols to minimize the risk of accidents. This training equips them with essential knowledge and skills to navigate potential dangers effectively.

Additionally, scaffolds should undergo thorough inspections by a qualified person before each use. These inspections ensure that the scaffolding is structurally sound and meets the necessary safety standards. Inspectors assess various elements, including the stability of the structure, the integrity of guardrails, and the proper positioning of access points.

Once the inspection is complete, scaffolds are tagged to indicate their safety status. The tagging system employs different colors to convey specific messages. For example:

- Green tags: Scaffolds with green tags are safe for use and meet all the required safety regulations and standards.

- Yellow tags: Scaffolds with yellow tags require caution. These tags indicate that some safety precautions or modifications are necessary before use.

- Red tags: Scaffolds with red tags are unsafe for use and must not be accessed until the necessary repairs or adjustments are made.

This tagging system ensures clear communication among workers and serves as a visual reminder of the scaffold’s safety status. It helps prevent workers from unknowingly using scaffolds that pose risks to their well-being.

A comprehensive scaffolding safety program should include regular training sessions, inspections, and tagging procedures. By prioritizing training and tagging, construction companies can create a safety-conscious culture that enhances the overall well-being of workers and minimizes workplace accidents.

| Tag Color | Meaning |

|---|---|

| Green | Safe for use |

| Yellow | Caution – Modifications or precautions required |

| Red | Unsafe – Requires repairs or adjustments |

Conclusion

Promoting and ensuring safety on construction sites when using freestanding scaffolding is crucial for the well-being of workers and the success of the project. By following essential safety tips, adhering to scaffold safety regulations, providing proper training, conducting regular inspections, and maintaining a culture of safety, construction companies can minimize accidents and create a secure working environment for everyone involved.

Freestanding scaffolding offers convenience and flexibility in various construction projects, but it is important to understand and comply with scaffold safety regulations. Ensuring scaffold platform dimensions are appropriate for the task at hand is vital to prevent accidents and maintain stability.

Investing in proper training for workers and regular inspections for scaffolds helps identify and address potential hazards before they become dangerous. By prioritizing scaffold safety, construction companies can not only protect their workers but also avoid costly delays and legal complications.

Remember, safety is everyone’s responsibility. By establishing a strong safety culture and maintaining vigilance in adhering to scaffolding safety guidelines, construction companies can ensure that every worker goes home safely at the end of the day.

FAQ

What are some important safety tips when working with freestanding scaffolding?

Some important safety tips when working with freestanding scaffolding include adhering to safety guidelines and regulations, conducting thorough inspections before each use, providing proper training for all workers involved, using appropriate personal protective equipment (PPE), understanding load capacity limits, securing the scaffold platform, and conducting regular maintenance and inspections.

Why is scaffold safety important in the construction industry?

Scaffold safety is important in the construction industry because a significant percentage of construction workers use scaffolds. By complying with scaffold safety regulations, providing proper training, and conducting regular inspections, accidents can be minimized, and a culture of safety can be created on construction sites.

What are the common hazards associated with different types of scaffolding?

Common hazards associated with different types of scaffolding include falls, debris, and scaffold collapse. Supported scaffolding, suspended scaffolding, and mobile scaffolding each have their own set of safety considerations and potential hazards.

How can I enhance the safety of scaffolding operations?

To enhance the safety of scaffolding operations, you can implement specific safety tips and best practices. These include conducting thorough inspections before each use, providing proper training for all workers involved, using appropriate personal protective equipment (PPE), understanding load capacity limits, securing the scaffold platform, and conducting regular maintenance and inspections.

How important is training for scaffold safety?

Training plays a crucial role in ensuring scaffold safety. Workers must receive proper training on scaffold assembly, use, and safety protocols. Additionally, scaffolds should be inspected by a competent person before each use and tagged to indicate their safety status. Training and tagging are essential components of a comprehensive scaffolding safety program.

Why is prioritizing scaffold safety essential for construction projects?

Prioritizing scaffold safety is essential for the well-being of workers and the success of the project. By following essential safety tips, adhering to scaffold safety regulations, providing proper training, conducting regular inspections, and maintaining a culture of safety, construction companies can minimize accidents and create a secure working environment for everyone involved.