Phone:

(+65)8319-0742

In this comprehensive safety guide, we will explore the importance of edge protection and guard rail systems on construction sites and industrial settings. We will discuss the various components of these systems, their benefits in preventing falls, and the role of perimeter guardrails in ensuring workplace safety.

Understanding Edge Protection Solutions

In this section, we will delve into the different edge protection solutions available in the market. Ensuring construction site safety is of paramount importance, and edge protection and guard rail systems play a critical role in preventing accidents and falls. Let’s explore the various options and their applications in creating secure work environments.

Edge Protection Solutions for Construction Sites

Construction sites are inherently risky environments, with workers often operating at heights and near exposed edges. To mitigate these risks, construction companies employ edge protection systems that act as a protective barrier, preventing accidental falls. These systems not only safeguard workers but also contribute to compliance with safety regulations.

One fundamental element of edge protection on construction sites is the installation of rooftop guardrails. Rooftop guardrails provide a secure perimeter that allows workers to operate at heights without the fear of falling. They are designed to withstand significant force and impact, ensuring optimal protection for construction workers.

| Edge Protection Solutions | Applications |

|---|---|

| Scaffolding | – Construction of tall structures – Renovation and maintenance work |

| Temporary Guardrails | – Construction sites – Demolition projects |

| Toe Boards | – Building construction – Working on elevated platforms |

Alongside rooftop guardrails, other edge protection solutions are widely used in the construction industry. Scaffolding provides a stable working platform at various heights, ensuring workers can carry out tasks safely. Temporary guardrails offer quick and easy installation, making them ideal for construction sites and demolition projects. Toe boards, on the other hand, are essential for preventing objects from falling off elevated platforms and protecting workers below.

By adopting a comprehensive edge protection approach and utilizing appropriate solutions, construction companies can significantly enhance construction site safety and reduce the risk of falls and accidents.

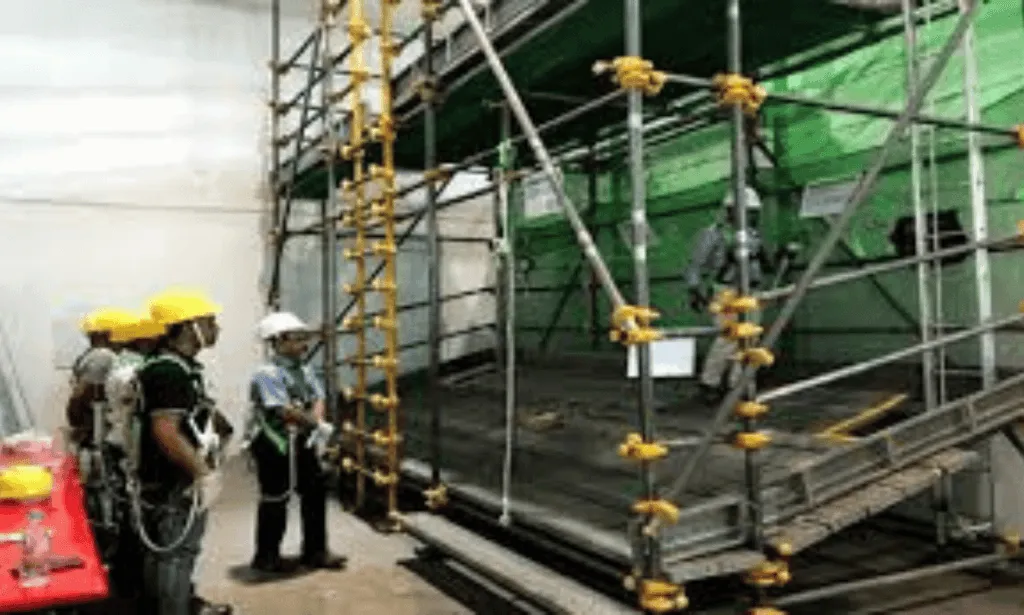

Image: Rooftop guardrails provide secure protection and prevent falls from heights.

The Role of Guard Rail Systems

Guard rail systems play a vital role in ensuring workplace safety, particularly in environments where there is a risk of falls. These systems are designed to provide edge protection and prevent accidents, prioritizing the well-being of workers and minimizing the occurrence of injuries.

Fall protection systems encompass a range of measures aimed at mitigating the hazards associated with working at heights. Guard rail systems are an essential component of such measures, offering a physical barrier that prevents individuals from inadvertently stepping or falling off edges and elevated areas.

Safety railing systems are carefully engineered and constructed to meet industry safety standards. They are typically made of durable materials, such as steel or aluminum, ensuring strength and stability. Safety railings provide a reliable and secure means of protection, allowing workers to focus on their tasks without fear of accidental falls.

When it comes to safeguarding workers, guard rail systems provide several key benefits:

- Prevention of Falls: Safety railings act as a protective barrier, creating a physical boundary that prevents workers from accidentally falling off edges or into hazardous areas.

- Promotion of Safe Working Practices: By clearly defining safe work zones and restricted areas, guard rail systems encourage employees to adopt responsible behavior and adhere to established safety protocols.

- Enhanced Visibility and Awareness: Safety railings are often highly visible, serving as a visual reminder of potential hazards. This increased visibility helps workers stay cognizant of their surroundings and take necessary precautions.

- Quick and Easy Installation: Many safety railing systems are designed for easy installation and reconfiguration. This flexibility allows for efficient adaptation to changing work environments and requirements.

The Various Types of Fall Protection Systems

There are different types of fall protection systems that can be incorporated into guard rail systems, each with its own unique features and applications:

| Type of Fall Protection System | Description |

|---|---|

| Anchorage Points | Fixed points of attachment to secure personal protective equipment (PPE) like harnesses and lanyards. |

| Safety Nets | Mesh nets that are installed below work areas to catch falling debris and protect workers from falls. |

| Lifelines and Lanyards | Retractable or fixed horizontal or vertical lines that workers can connect to using lanyards and harnesses, allowing for safe movement while working at heights. |

| Guard Rails | Rigid barriers that provide edge protection, preventing falls from elevated areas, rooftops, or balconies. |

By incorporating the appropriate fall protection systems, including safety railings, into guard rail designs, employers can create a comprehensive safety infrastructure that promotes a secure work environment and reduces the risk of accidents.

Components of Edge Protection and Guard Rail Systems

Edge protection and guard rail systems are comprised of various components that work together to ensure workplace safety. Understanding these components is crucial for creating a secure environment that minimizes the risk of accidents and falls. In this section, we will explore the key elements that make up these systems and discuss the role of industrial guard rail designs in enhancing safety.

Components of Edge Protection Systems:

1. Guard Railings: Guard railings are horizontal barriers that help prevent falls by providing a physical barrier between workers and potentially hazardous areas. They are typically made of durable materials such as metal or high-strength thermoplastic and are designed to withstand impact and weather conditions.

2. Toe Boards: Toe boards are installed at the base of guard railings to prevent objects from falling off raised surfaces, such as platforms or scaffolds. They create an additional barrier, ensuring a secure work environment.

3. Handrails: Handrails are vertical structures attached to guard railings that provide workers with something to hold onto for added stability and support. They are especially important on staircases, ramps, and elevated walkways.

4. Safety Chains: Safety chains are used in combination with guard railings to prevent unauthorized access to restricted areas. They act as a secondary barrier, ensuring that only authorized personnel can enter specific zones.

Industrial Guard Rail Designs:

Industrial guard rail systems are specifically designed to cater to the unique requirements of industrial settings, such as warehouses, manufacturing facilities, and construction sites. These designs prioritize durability, strength, and ease of installation.

An example of an industrial guard rail design is the modular guard rail system. This system consists of standard components that can be easily assembled and adjusted to fit different layouts. The modular design allows for flexibility and customization, making it suitable for various industrial applications.

Industrial guard rail systems typically feature heavy-duty materials, such as steel, that can withstand heavy impacts and extreme weather conditions. They are designed to provide robust protection and minimize the risk of accidents in high-risk areas, such as loading docks, machinery zones, and elevated platforms.

The image above showcases an industrial guard rail system in action, highlighting its effectiveness in creating a safe working environment. The robust construction and strategic placement of the guard railings provide a reliable barrier that prevents falls and protects workers from potential hazards.

By understanding the components that make up edge protection and guard rail systems, as well as the importance of industrial guard rail designs, businesses can establish a comprehensive safety infrastructure that prioritizes the well-being of their employees.

Installation and Maintenance Best Practices

Proper installation and regular maintenance are essential for ensuring the effectiveness and longevity of edge protection and guard rail systems. By following industry best practices, you can enhance safety on construction sites and industrial settings. This section outlines guidelines for the installation and maintenance of these systems, with a particular emphasis on roof safety systems.

Installation Guidelines

When installing edge protection and guard rail systems, it is crucial to adhere to manufacturer instructions and industry standards. Here are some key guidelines to consider:

- Inspect the site: Before installation, thoroughly examine the area to identify potential hazards and determine the most suitable system for the site.

- Choose the right system: Select edge protection and guard rail systems that are specifically designed for the intended application. Consider factors such as height, load capacity, and compatibility with existing structures.

- Secure the system: Ensure that the systems are properly anchored or fixed to provide stability and resistance against horizontal or vertical forces.

- Proper positioning: Install the systems at the appropriate distance from the edge to provide sufficient protection while allowing smooth workflow.

- Regular inspections: Conduct inspections during and after installation to verify that the systems are securely in place and meet safety standards.

Maintenance Guidelines

Maintaining edge protection and guard rail systems is crucial for their ongoing effectiveness. Regular inspections and maintenance activities can identify and address any issues promptly. Consider the following guidelines:

- Periodic inspections: Schedule routine inspections to assess the condition of the systems. Look for signs of wear, damage, or corrosion.

- Repair or replace damaged components: If any defects or damages are identified during inspections, promptly repair or replace affected components to maintain the integrity of the systems.

- Clean and remove debris: Regularly clean the systems, ensuring that there is no accumulation of debris or other materials that could hinder their function.

- Monitor for proper alignment: Check the alignment of the systems regularly to ensure they are providing consistent protection along the edge.

- Employee training: Provide training to workers on the importance of maintenance and the proper procedures for inspecting and maintaining the systems.

By following these installation and maintenance best practices, you can optimize the performance of edge protection and guard rail systems, reducing the risk of falls and ensuring a safer working environment.

| Installation Best Practices | Maintenance Best Practices |

|---|---|

| Inspect the site | Periodic inspections |

| Choose the right system | Repair or replace damaged components |

| Secure the system | Clean and remove debris |

| Proper positioning | Monitor for proper alignment |

| Regular inspections | Employee training |

Compliance and Safety Standards

Compliance with safety standards is of paramount importance on any construction site or industrial setting. In order to ensure the well-being of workers and prevent accidents, it is crucial to adhere to specific safety standards that apply to edge protection and guard rail systems.

By complying with these standards, companies and organizations can maintain a safe working environment and mitigate potential risks. Adhering to safety regulations not only protects workers from falls and accidents but also promotes a culture of safety and professionalism.

Some of the key safety standards that construction sites and industrial facilities should follow in relation to edge protection and guard rail systems include:

- Occupational Safety and Health Administration (OSHA) regulations: OSHA sets guidelines and standards to ensure workplace safety. Specifically, OSHA’s fall protection regulations play a critical role in preventing falls from heights and require employers to provide edge protection and guard rail systems where necessary.

- International Organization for Standardization (ISO) standards: ISO provides globally recognized standards that focus on quality, safety, and best practices. Standards such as ISO 14122-3 outline requirements for guard rail systems on machinery and equipment, contributing to overall workplace safety.

- National and local building codes: Building codes vary by jurisdiction and encompass regulations related to construction and safety. These codes often include specific provisions for edge protection and guard rail systems on worksites to safeguard workers.

By understanding and implementing these compliance measures, companies can significantly reduce the risk of accidents, injuries, and fatalities on their construction sites or in industrial settings. It is important to consult the relevant safety authorities and experts to ensure full compliance with all applicable regulations.

Safety Standards Comparison

| Safety Standard | Focus | Applicability |

|---|---|---|

| OSHA Regulations | Fall protection | United States |

| ISO Standards | Quality and safety | Global |

| National and Local Building Codes | Construction and safety | Varies by jurisdiction |

Training and Education for Workers

Proper training and education are paramount to promoting construction site safety. Workers involved in working with edge protection and guard rail systems must undergo specific training programs to ensure they possess the necessary skills and knowledge to handle these systems effectively. Additionally, providing comprehensive education and resources can further enhance their understanding of construction site safety protocols.

The Benefits of Comprehensive Training

Comprehensive training equips workers with the expertise needed to navigate edge protection and guard rail systems with confidence. By understanding the proper installation, maintenance, and usage of these systems, workers can minimize the risk of accidents and promote a safe working environment. Training programs cover essential aspects such as identifying potential hazards, following safety guidelines, and implementing best practices.

Moreover, comprehensive training empowers workers to recognize the signs of system failure or potential risks and take appropriate action. This proactive approach is essential in preventing accidents and ensuring the overall safety of the construction site.

Educational Resources

In addition to training programs, educational resources play a vital role in equipping workers with the necessary knowledge about edge protection and guard rail systems. These resources can take the form of instructional materials, safety manuals, online courses, and regular safety briefings. By providing easily accessible and up-to-date information, workers can stay informed about the latest safety standards and industry practices.

Furthermore, educational resources can help workers develop a safety mindset and instill a culture of vigilance on construction sites. By promoting continuous learning and awareness, workers can actively contribute to creating a safer work environment for themselves and their colleagues.

Measuring Training Effectiveness

It is essential for employers to assess the effectiveness of training programs to ensure that workers are equipped with the necessary skills and knowledge. Feedback mechanisms such as quizzes, assessments, or practical evaluations can gauge the understanding and retention of training material. Regular refresher courses and updates can also reinforce knowledge and address any gaps or changes in safety regulations.

Continuous evaluation and improvement of training programs are crucial to adapt to evolving safety standards and industry best practices. By regularly assessing training effectiveness, employers can maintain a high level of construction site safety and protect workers from potential risks.

Investing in comprehensive training and education for workers involved in edge protection and guard rail systems is a proactive approach to construction site safety. By equipping workers with the necessary knowledge and skills, employers can create a culture of safety and reduce the likelihood of accidents or injuries.

Conclusion

In conclusion, this safety guide has provided a comprehensive overview of edge protection and guard rail systems. We have examined the various components that make up these systems and highlighted their crucial role in fall prevention. By implementing edge protection and guard rail systems, workplaces can significantly reduce the risk of accidents and ensure the safety of their workers.

Throughout this guide, we have emphasized the importance of complying with safety standards and following installation and maintenance best practices. Adhering to these guidelines is essential to maximize the effectiveness of edge protection and guard rail systems in preventing falls.

Furthermore, we have discussed the significance of proper training and education for workers involved in working with these systems. Equipping employees with the necessary knowledge and skills not only enhances their safety but also promotes a culture of workplace safety.

By embracing edge protection and guard rail systems, following safety standards, and providing adequate training, businesses can create a safer work environment and safeguard the well-being of their employees. Prioritizing safety is not just a legal requirement but a moral obligation, and investing in these systems is a proactive approach to prevent accidents and protect lives.

FAQ

What are edge protection and guard rail systems?

Edge protection and guard rail systems are safety measures used in construction sites and industrial settings to protect workers from falls and prevent accidents. These systems typically include guardrails, handrails, and other protective barriers installed along edges, openings, and elevated surfaces.

Why are edge protection and guard rail systems important?

Edge protection and guard rail systems are crucial for ensuring workplace safety. They provide a physical barrier that prevents workers from accidentally falling from heights or entering hazardous areas. These systems play a vital role in reducing the risk of accidents and injuries on construction sites and industrial settings.

What is the role of perimeter guardrails in edge protection?

Perimeter guardrails are a type of edge protection system that forms a protective barrier around the perimeter of a construction site or elevated structure. These guardrails serve as a primary line of defense against falls, preventing unauthorized access to hazardous areas and ensuring the safety of workers.

What types of edge protection solutions are available?

There are various edge protection solutions available in the market, including guardrail systems, safety netting, temporary edge protection, and mobile edge protection. Each solution is designed to cater to different workplace conditions and requirements, providing effective fall prevention measures.

How do rooftop guardrails contribute to construction site safety?

Rooftop guardrails are specifically designed to provide edge protection on rooftops and other elevated platforms. They create a secure barrier that prevents falls from heights, ensuring the safety of workers who perform tasks on rooftops, such as maintenance, repairs, and installations.

What are safety railing systems, and why are they important?

Safety railing systems are a key component of edge protection and guard rail systems. They consist of sturdy railings and handrails that are installed along edges, staircases, and platforms to prevent falls and provide support for workers. Safety railing systems are vital in minimizing the risk of accidents and maintaining a safe working environment.