Phone:

(+65)8319-0742

In the world of construction, safety is of paramount importance. When it comes to working at heights, scaffolds play a crucial role in providing a secure platform for workers to perform their tasks. However, scaffold safety goes beyond just the construction and design; it also involves ensuring stability throughout the entire structure.

One of the key elements that contribute to scaffold stability is cross bracing. Cross bracing involves the installation of diagonal supports that connect the vertical and horizontal members of the scaffold, forming an X-shape pattern. This bracing technique significantly improves the scaffold’s overall strength and stability, making it a critical component of scaffold design and construction.

Compliance with scaffold regulations is essential for maintaining a safe working environment. Regulatory bodies, such as OSHA, have specific guidelines in place to ensure scaffold safety and stability. These regulations often require the use of cross bracing to meet the minimum standards for scaffold construction.

- Cross bracing is vital for ensuring scaffold stability and safety.

- Proper scaffold design and construction involve the correct installation of cross bracing.

- Compliance with scaffold regulations, such as those set by OSHA, is crucial for maintaining safety standards.

- The use of diagonal supports in scaffold construction helps distribute the load evenly and prevent swaying.

- Cross bracing plays a significant role in creating a secure working environment for scaffold users.

Understanding Scaffold Bracing Design

When it comes to scaffold design, the bracing plays a crucial role in ensuring the overall stability and strength of the structure. Scaffold bracing refers to the strategic placement of horizontal and diagonal components that provide support and rigidity to the scaffold system.

There are several types of scaffold bracing commonly used in construction projects, including cross bracing, which is particularly renowned for its effectiveness in enhancing scaffold stability. Cross bracing consists of diagonal components that form an X-shape between vertical posts, creating a rigid framework that prevents lateral movements and sway.

To better understand scaffold bracing design, let’s take a closer look at the key components involved:

1. Vertical Posts:

The vertical posts, also known as standards or uprights, are the vertical members that provide the main structural support for the scaffold. These posts are typically made from steel or aluminum and are strategically spaced to distribute the weight of the scaffold system.

2. Horizontal Ledgers:

The horizontal ledgers are the horizontal beams that connect the vertical posts, forming the base framework of the scaffold. These ledgers provide stability and serve as a platform for workers and materials. They are typically positioned at regular intervals along the scaffold structure.

3. Diagonal Braces:

The diagonal braces are the key elements in scaffold bracing design. These diagonal components, such as cross braces, are installed between vertical posts to create a geometrically stable structure. They help distribute the load evenly and reduce the risk of swaying or collapsing.

4. Couplers:

Couplers are the connectors that join the scaffold components together. They ensure a secure and rigid connection between the vertical posts, horizontal ledgers, and diagonal braces. Couplers are usually made of strong materials such as steel and are designed to withstand the forces exerted on the scaffold.

By carefully considering scaffold bracing design and implementing the appropriate components, construction professionals can create scaffolds that meet the necessary safety standards and provide a secure working environment for workers.

| Scaffold Bracing Design Components | Function |

|---|---|

| Vertical Posts | Provide main structural support |

| Horizontal Ledgers | Create the base framework |

| Diagonal Braces | Enhance stability and prevent sway |

| Couplers | Securely connect scaffold components |

Understanding scaffold bracing design is essential for ensuring the safety and stability of scaffolds. By incorporating the right components and following industry best practices, scaffold designers and construction professionals can create robust scaffold structures that comply with regulations and provide a secure working environment for all.

Meeting OSHA Scaffold Standards

When it comes to scaffold construction, meeting OSHA scaffold standards is of paramount importance. OSHA (Occupational Safety and Health Administration) has established specific regulations to ensure the safety of workers and the compliance of scaffold structures. Understanding and adhering to these standards is crucial for the well-being of workers and to avoid potential penalties and liabilities.

OSHA scaffold standards encompass various aspects of scaffold construction, including scaffold bracing. Bracing plays a vital role in the overall stability and strength of scaffold structures, preventing collapse or failure. Compliance with scaffold bracing requirements is key to maintaining a safe work environment.

Regular scaffold inspections are essential to ensure ongoing safety and compliance. Inspections help identify potential hazards, structural weaknesses, and any deviations from OSHA scaffold standards. By conducting regular inspections, construction companies can proactively address any issues and make necessary adjustments to ensure the safety and integrity of scaffolds.

During scaffold inspections, focus is placed on assessing the condition of scaffold bracing and its compliance with OSHA standards. Inspectors check for proper installation, including adequate spacing, alignment, and connections of bracing components. They also ensure that bracing is properly secured and that there are no signs of damage or wear and tear.

By meeting OSHA scaffold standards and conducting thorough scaffold inspections, construction companies can minimize the risk of accidents and create a safer work environment. Adhering to these standards not only protects workers but also helps build a reputation for prioritizing safety and compliance within the industry.

The Role of Cross Bracing in Scaffold Stability

When it comes to scaffold stability, cross bracing in scaffolds plays a critical role. Cross bracing refers to the diagonal supports that connect the vertical and horizontal members of a scaffold structure. These braces are essential for ensuring the overall stability and safety of the scaffold.

The primary function of cross bracing is to distribute the load evenly across the scaffold framework. This distribution prevents swaying and helps to maintain the stability of the entire scaffold. By connecting the vertical and horizontal members, cross bracing acts as a reinforcement, preventing the scaffold from collapsing or becoming unstable.

Proper installation of cross bracing is crucial to maximize its effectiveness. When constructing a scaffold, it is important to ensure that cross braces are installed at the correct angles and securely fastened. This will ensure that the braces are able to withstand the forces exerted on the scaffold, providing optimal stability.

Additionally, regular inspections should be conducted to ensure that the cross bracing remains in good condition. Over time, wear and tear can occur, compromising the effectiveness of the braces. Inspections allow for early detection of any issues and prompt repairs or replacements, maintaining the scaffold’s stability and safety.

In conclusion, cross bracing plays a vital role in scaffold stability. Its ability to distribute load and reinforce the scaffold structure ensures that the scaffold remains stable and safe for workers. By following best practices for installation and conducting regular inspections, the effectiveness of cross bracing can be maximized, offering optimal stability for scaffold construction.

Factors Affecting Scaffold Stability

When it comes to scaffold construction, ensuring stability is paramount to creating a safe working environment. Several factors can have a significant impact on scaffold stability, and understanding these factors is crucial for scaffold design and construction.

Scaffold Design: The design of the scaffold structure plays a vital role in its stability. Factors such as the type of scaffold system, the arrangement of scaffold components, and the use of proper bracing techniques can all contribute to scaffold stability. It is essential to follow industry best practices and adhere to recognized design standards.

Scaffold Height: The height of the scaffold also affects its stability. As the height of a scaffold increases, the risk of instability rises. It is important to consider the intended use of the scaffold and the necessary safety measures to prevent any potential issues related to height.

Base Support: The support provided at the base of the scaffold is critical for maintaining stability. A solid foundation, such as a level and properly secured footing, ensures that the scaffold remains stable and reduces the risk of collapse or tipping. Proper base support must be evaluated and implemented during scaffold construction.

Environmental Conditions: Environmental factors, such as wind, weather conditions, and ground stability, can significantly impact scaffold stability. It is important to assess and monitor the environmental conditions at the work site to determine the appropriate measures needed to enhance scaffold stability.

Factors Affecting Scaffold Stability:

| Factors | Description |

|---|---|

| Scaffold Design | Includes the type of scaffold system, arrangement of components, and bracing techniques implemented |

| Scaffold Height | Higher scaffolds pose higher risks of instability, necessitating appropriate safety measures |

| Base Support | Ensuring a solid foundation and secure footing for the scaffold structure |

| Environmental Conditions | Factors like wind, weather, and ground stability that can affect the scaffold’s stability |

Considering these factors during scaffold construction and design is essential for maintaining scaffold stability and preventing accidents or collapses. By addressing these factors, construction professionals can create a secure scaffolding system that ensures the safety of workers and compliance with scaffold regulations.

Importance of Training and Safety Practices

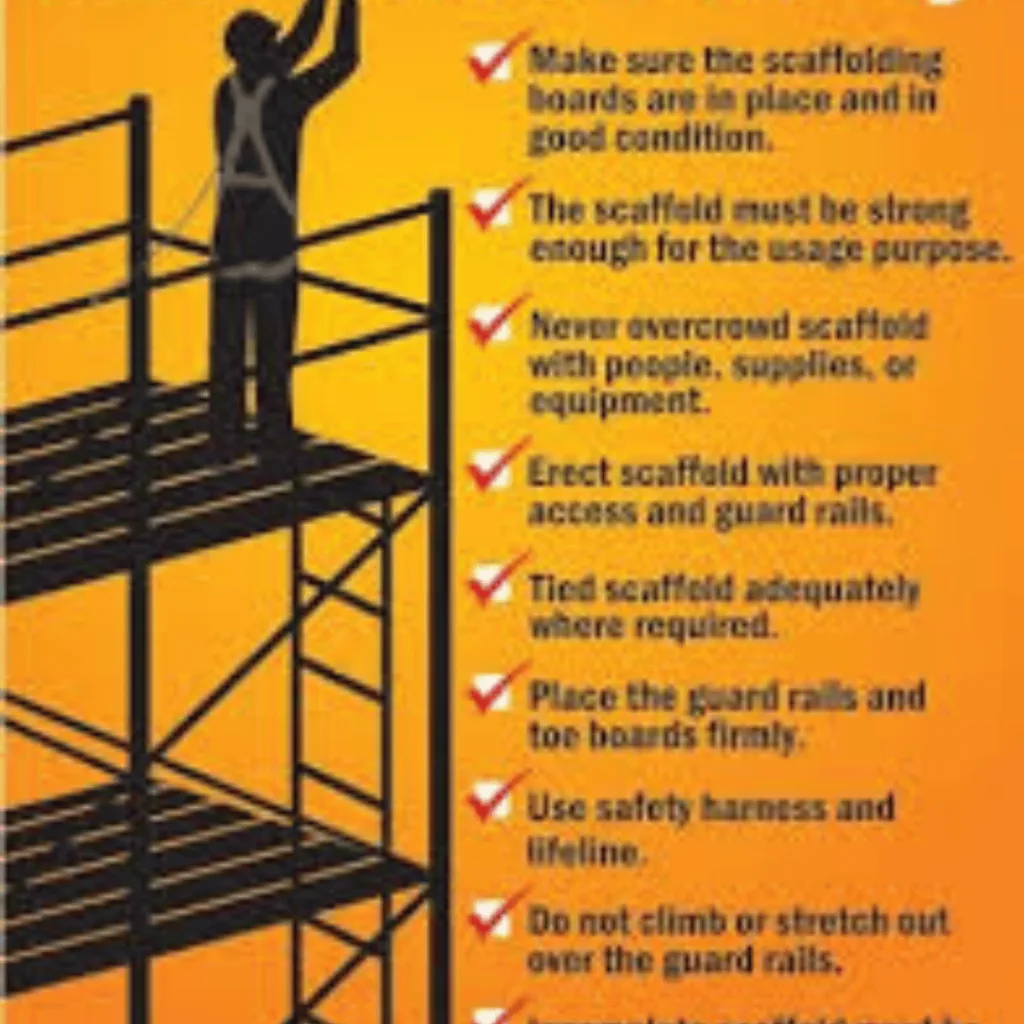

When it comes to scaffold construction, prioritizing training and safety practices is crucial. By properly training workers on scaffold assembly, bracing techniques, and safety protocols, you can ensure the safe and effective use of scaffolds, reducing the risks of accidents and injuries. Moreover, adhering to scaffold regulations is not just a legal requirement but also a way to promote a culture of safety and maintain a secure working environment.

By investing in thorough training programs for your workers, you equip them with the knowledge and skills necessary to construct scaffolds correctly and securely. This includes understanding the importance of scaffold stability, the proper installation of cross bracing, and the effective use of scaffold components. Additionally, workers should be trained on safety procedures, such as fall protection, inspection processes, and emergency response protocols.

Continuous education and awareness play a vital role in scaffold safety. Regularly informing workers about updated scaffold regulations and industry best practices ensures that they stay current with the latest safety guidelines. It also reinforces the importance of adhering to scaffold regulations and encourages a proactive approach to safety.

Benefits of Comprehensive Training and Safety Practices

A strong emphasis on training and safety practices in scaffold construction yields numerous benefits. Here are some key advantages:

- Reduces the risk of accidents and injuries

- Promotes a culture of safety and accountability

- Ensures compliance with scaffold regulations

- Increases worker confidence and productivity

- Enhances the overall quality and stability of scaffold structures

Remember, scaffold safety is not a one-time effort but an ongoing commitment. Regular refresher courses, safety reminders, and toolbox talks can help reinforce training and ensure that safe practices are consistently implemented on-site.

By prioritizing training and safety practices in scaffold construction, you are not only protecting the well-being of your workers but also safeguarding your project’s success and reputation.

| Training and Safety Practices Checklist | Benefits |

|---|---|

| Provide comprehensive scaffold construction training | Equips workers with the knowledge and skills to construct scaffolds correctly and securely |

| Emphasize proper installation of cross bracing | Achieves optimal scaffold stability and performance |

| Train workers on safety protocols and procedures | Reduces the risk of accidents and promotes a safe working environment |

| Maintain ongoing education on scaffold regulations and best practices | Ensures compliance with regulations and promotes a proactive safety culture |

| Regularly conduct refresher courses and safety reminders | Reinforces training and reinforces safe practices |

Conclusion

In conclusion, cross bracing in scaffolds plays a critical role in ensuring stability, safety, and compliance with scaffold regulations. Proper scaffold design, construction, and inspection are essential to create a secure scaffold environment.

By distributing the load evenly across the scaffold structure, cross bracing prevents swaying and enhances scaffold stability. This is especially crucial in challenging working conditions or when scaffolds are exposed to environmental factors.

To maintain scaffold safety, it is important for workers to receive proper training on scaffold assembly, bracing techniques, and safety practices. Ongoing education and awareness about scaffold regulations further promote a culture of safety and compliance.

In conclusion, prioritizing scaffold stability through cross bracing and adhering to safety measures ensures the safety and well-being of workers, reducing the risk of accidents and maintaining a productive work environment.

FAQ

What is the role of cross bracing in scaffolds?

Cross bracing plays a crucial role in ensuring stability and safety in scaffolds. It helps distribute the load evenly across the scaffold structure, preventing swaying and enhancing overall stability.

What are the different types of bracing used in scaffolds?

There are various types of bracing used in scaffolds, including cross bracing, diagonal bracing, and horizontal bracing. Each type contributes to the overall strength and stability of the scaffold structure.

How do scaffold bracing design and components contribute to scaffold stability?

Scaffold bracing design, including the use of cross bracing, is essential for maintaining scaffold stability. The components involved in bracing, such as tubes, clamps, and connectors, are designed to reinforce the structure, preventing collapse and ensuring worker safety.

What OSHA standards should scaffolds adhere to?

Scaffolds must comply with OSHA scaffold standards, including regulations related to bracing. These standards cover various aspects of scaffold construction, inspection, and safety measures to ensure a secure working environment.

How often should scaffold inspections be conducted?

Scaffold inspections should be conducted regularly to identify any potential hazards or issues that may compromise scaffold stability. The frequency of inspections will depend on factors such as scaffold usage, environmental conditions, and OSHA requirements.

How does scaffold design, height, and base support affect stability?

Scaffold design, including proper bracing, is crucial for stability. The height of the scaffold and the strength of the base support also play a significant role. A well-designed and correctly constructed scaffold, with adequate base support, ensures stability and reduces the risk of accidents.

Why is training important in scaffold construction?

Training is essential in scaffold construction to ensure that workers are proficient in proper assembly techniques, bracing methods, and safety protocols. Properly trained workers help minimize the chances of scaffold incidents and promote a culture of safety.